Abstract

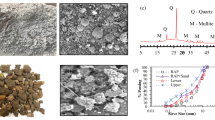

Geopolymer concrete is a new kind of environmentally friendly concrete. It gains early strength in room temperature without water curing, and by heating, strength continues to develop. This study investigates the possibility of using geopolymer concrete based on metakaolin (GPC) as a rigid pavement concrete slab material and as an efficient alternative to conventional Portland cement concrete (PCC). Different constitutes materials of GPC and PCC were tested to assure validity for use. Both GPC and PCC mixtures had 30 MPa compressive strength. GPC specimens were cured at room temperature, whereas PCC specimens were cured in water. GPC mixture was mixed at 2.5 alkaline solutions ratio, and the concentration of NaOH solution was 16 molar. The ratio of SiO2 to Na2O in Na2SiO3 solution was two. Compressive, flexural, and indirect tensile strength tests, as well as static modulus of elasticity, Poisson’s ratio tests and resistance to fuel tests, were performed on both GPC and PCC specimens. To study the behavior of rigid pavement slabs, 800 × 800 × 50 mm GPC and PCC slabs were subjected to mechanical loading tests in three positions (interior, edge and corner). The slabs were supported by a set of steel springs under a 20-mm layer of recycled rubber which had the same surface dimensions of the tested slabs to simulate a subgrade with a modulus of reaction of 36 MPa/m. GPC exhibited a comparable performance with PCC in all investigated parameters in this study with higher rigidity and resistance to surface abrasion in fuel resistance test.

Similar content being viewed by others

References

Eisa MS, Basiouny ME, Fahmy EA (2021) Effect of metakaolin-based geopolymer concrete on the length of rigid pavement slabs. Innov Infrastruct Solut, 6(2) article no. 91. https://doi.org/10.1007/s41062-021-00465-5

Ferdous MW, Kayali O, Khennane A (2013) A detailed procedure of mix design for fly ash based geopolymer concrete. In: Proceedings of the Fourth Asia-Pacific Conference on FRP in Structures (APFIS 2013), Melbourne, Australia, 11–13

Alanazi H, Yang M, Zhang D, Gao ZJ (2016) Bond strength of PCC pavement repairs using metakaolin-based geopolymer mortar. Cem Concr Compos 65:75–82. https://doi.org/10.1016/j.cemconcomp.2015.10.009

Shekhawat P, Sharma G, Singh RM (2020) Potential application of heat cured eggshell powder and flyash-based geopolymer in pavement construction. Int J Geosynth Ground Eng, 6(2) article no. 28. https://doi.org/10.1007/s40891-020-00213-2

Xincheng P, Changhui Y, Fan L (1999) Studies on resistance of alkali activated slag concrete to acid attack. In: Proceedings of the 2nd international conference on alkaline cements and concretes, 717–722. Kyiev, Ukraine

Ariffin MAM, Bhutta MAR, Hussin M, Tahir MM, Aziah N (2013) Sulfuric acid resistance of blended ash geopolymer concrete. Constr Build Mater 43:80–86. https://doi.org/10.1016/j.conbuildmat.2013.01.018

Bhutta MAR, Hussin WM, Azreen M, Tahir MM (2014) Sulphate resistance of geopolymer concrete prepared from blended waste fuel ash. J Mater Civ Eng 26(11):04014080. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001030

Olubenga A, Onwualu AP, Boakye E (2021) Characterization and mechanical performance of metakaolin- based geopolymer for sustainable building applications. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.121938

Rashad AM (2013) Metakaolin as cementitious material: History, scours, production and composition – A comprehensive overview. Constr Build Mater 41:303–318. https://doi.org/10.1016/J.CONBUILDMAT.2012.12.001

Davidovits J (1988) Geopolymer chemistry and properties. In: Proceedings of the 1st International Conference on Geopolymer, Compiègne, France, 1–3 June

Refaei DA, Abdelrahman MK, Ibrahim IA, Eldears F, Kandil AT (2017) Improvement the quality of Egyptian kaolin for industrial applications. Int J Adv Technol 8:174. https://doi.org/10.4172/0976-4860.1000174

Sinai Manganese Co. SMC website: https://www.smc-eg.com/MinKaolin.htm

Baioumy H, Albert Gilg H (2011) Pisolitic flint kaolin from Kalabsha, Egypt: a laterite-derived facies. Sediment Geol 236(1–2):141–152. https://doi.org/10.1016/j.sedgeo.2011.01.002

Castel A, Foster SJ, Ng T, Sanjayan JG, Gilbert RI (2016) Creep and drying shrinkage of a blended slag and low calcium fly ash geopolymer Concrete. Mater Struct 49(5):1619–1628. https://doi.org/10.1617/s11527-015-0599-1

Deb PS, Nath P, Sarker PK (2015) Drying shrinkage of slag blended fly ash geopolymer concrete cured at room temperature. In: Proceedings of the 5th International Conference of Euro Asia Civil Engineering Forum (EACEF-5), Surabaya, East Java, Indonesia, 15–18 September

Rangan BV (2008) Fly ash-based geopolymer concrete. Research report GC4, Faculty of Engineering, Curtin University of Technology, Perth, Australia. http://hdl.handle.net/20.500.11937/20680

Anuradha R, Sreevidya V, Venkatasubramani R, Rangan BV (2012) Modified guidelines for geopolymer concrete mix design using Indian standard. Asian J Civ Eng (Build Hous) 13(3):353–364. https://espace.curtin.edu.au/handle/20.500.11937/38772

Patankar SV, Ghugal YM, Jamkar SS (2015) Mix design of fly ash based geopolymer concrete. Adv Struct Eng New Delhi. https://doi.org/10.1007/978-81-322-2187-6_123

Wallah SE (2009) Drying shrinkage of heat-cured fly ash-based geopolymer concrete. Mod Appl Sci 3:14–21. https://doi.org/10.5539/mas.v3n12p14

Seneviratne C, Gunasekara C, Law DW et al (2020) Creep, shrinkage and permeation characteristics of geopolymer aggregate concrete: long-term performance. Archiv Civ Mech Eng. https://doi.org/10.1007/s43452-020-00119-w

Murmu AL, Patel A (2020) Studies on the properties of fly ash–rice husk ash-based geopolymer for use in black cotton soils. Int J Geosynth Ground Engineering, 6(3) article no. 38. https://doi.org/10.1007/s40891-020-00224-z

Lu D, Luo J, Xu Z (2015) Effect of metakaolin on the drying shrinkage behaviour of portland cement pastes. In: Scrivener K, Favier A (eds) Calcined clays for sustainable concrete, vol 10. RILEM Bookseries, Springer, Dordrecht

Güneyisi E, Gesoğlu M, Mermerdaş K (2008) Improving strength, drying shrinkage, and pore structure of concrete using metakaolin. Mater Struct 41:937–949. https://doi.org/10.1617/s11527-007-9296-z

Westergaard HM (1926) Analysis of stresses in concrete pavements due to variations of temperature. In: Proceedings of the Sixth Annual Meeting of the Highway Research Board Held, 6, 201–215, Washington D.C., 2–3 December

Portland Cement Association (1984) The design for concrete highway and street pavements. PCA, Skokie, Illinois

AASHTO (1993) Guide for design of pavement structures. American Association of State Highway and Transportation Officials; Washington DC, USA

Yoder EJ, Witczak MW (1975) Principles of pavement design, 2nd edn. Wiley, New York

FDOT (2009) Florida Department of Transportation. Rigid pavement design manual. Pavement Management Office, Document No. 625–010–006-e, Tallahassee, Florida

Suryawanshi NT, Thakare SB (2018) Self-curing assessment of Meta Kaolin based high strength concrete using super absorbent polymer. Int J Civ Eng Technol (IJCIET) 9(13):1082–1087

ASTM C618/C618M (2018) Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International, West Conshohocken, PA

British Standards Institution BS EN 197–1 (2011) Cement: Composition, specifications and conformity criteria for common cements. London, UK

Egyptian Standard Specification (ESS) 4756-1 (2009) Composition, specifications and conformity criteria for common cements, Egyptian organization for standards and quality (EOS), Cairo, Egypt

Egyptian Code of Practice for Design and Construction of Reinforced Concrete Structures (ECP 203–2020). Ministry of Housing, Utilities and Urban Communities. Cairo, Egypt. 2020

ASTM C494/C494M (2019) Standard specification for chemical admixtures for concrete. ASTM International, West Conshohocken, PA

Rajamane NP, Jeyalakshmi R (2014) Quantities of sodium hydroxide solids and water to prepare sodium hydroxide solution of given molarity for Geopolymer Concrete mixes. Indian concrete institute journal, ICI update Aug.- Sep. 2014, 4:9

British Standards Institution BS EN 12390–3 (2014). Testing hardened concrete - Part 3: Compressive strength of test specimens. BSI, London, UK

ASTM C293/C293M (2016) Standard test method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading). ASTM International, West Conshohocken, PA

Marathe S, Mithanthaya IR, Mithun BM, Shetty S, Akarsh PK (2020) Performance of slag-fly ash based alkali activated concrete for paver applications utilizing powdered waste glass as a binding ingredient. Int J Pavement Res Technol 14:196–203. https://doi.org/10.1007/s42947-020-0173-2

ASTM C496/C496M (2017) Standard test method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International, West Conshohocken, PA

ASTM C469/C469M (2017) Standard test method for Static Modulus of Elasticity and Poisson's Ratio of Concrete in Compression. ASTM International, West Conshohocken, PA

British Standards Institution BS EN 12697–43 (2014). Bituminous mixtures: Test methods for hot mix asphalt. Resistance to fuel. BSI, London, UK

Hammons MI (1998) Advanced pavement design: Finite element modeling for rigid pavement joints, report II: Model development. DOT/FAA/AR-97/7; U.S. Army Engineer Waterways Experiment Station 3909 Halls Ferry Road, Vicksburg, MS 39180–6199; Office of Aviation Research, U.S. Department of Transportation, Federal Aviation Administration.

Al-Hedad ASA, Hadi MNS (2018) Effect of geogrid reinforcement on the flexural behaviour of concrete pavements”. Road Mater Pavement Des 20(5):1005–1025. https://doi.org/10.1080/14680629.2018.1428217

Acknowledgements

The authors are thankful to the team work of Housing and Building National Research Center, Egypt.

Funding

None.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Eisa, M.S., Fahmy, E.A. & Basiouny, M.E. Using metakaolin-based geopolymer concrete in concrete pavement slabs. Innov. Infrastruct. Solut. 7, 1 (2022). https://doi.org/10.1007/s41062-021-00601-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-021-00601-1