Abstract

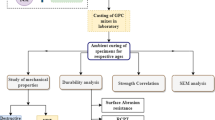

Concern exists regarding the performance of concrete containing a higher percentage of recycled aggregates. There is an ongoing effort to improve the strength and durability characteristics of such concrete in various ways. As part of that effort, this study investigated the laboratory performance of geopolymer concrete containing a higher dosage of reclaimed asphalt pavement (RAP) as a pavement construction material. A series of laboratory investigations were performed to evaluate the mechanical, durability, and morphological characteristics of RAP-geopolymer concrete (GPC). The mechanical properties of RAP-geopolymer concrete were also compared with RAP-Portland cement concrete (PCC) produced using ordinary Portland cement (OPC). Results indicated that RAP-geopolymer concrete exhibited higher compressive, flexural, split tensile strength as compared to RAP-cement concrete. Further, RAP-geopolymer concrete revealed satisfactory results in terms of durability regarding wet–dry cycles and water absorption (sorptivity). Morphological and microstructural investigation using scanning electron microscopy (SEM), X-Ray diffraction (XRD), and Fourier-transform infrared spectroscopy (FTIR) also discovered the formation of geopolymer compounds in RAP-geopolymer concrete which explains the better mechanical and durability properties of such concrete mixtures.

Similar content being viewed by others

References

Engineering Overview, National Asphalt Pavement Association, Lanham, MD, USA. https://www.asphaltpavement.org/index.php?option=com_content&view=article&id=14&Itemid=33. Accessed June 30, 2019.

Pavement Types, Pavement Interactive. https://www.pavementinteractive.org/reference-desk/pavement-types-and-history/pavement-types/. Accessed June 30, 2019.

Reclaimed Asphalt Pavement in Asphalt Mixtures: State of The Practice. https://www.fhwa.dot.gov/publications/research/infrastructure/pavements/11021/002.cfm. Accessed December 21, 2020.

Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice, Federal Highway Administration 2011, (Publication no. FHWA-HRT-11-021)

User Guidelines for Waste and Byproduct Materials in Pavement Construction, Federal Highway Administration Research and Technology, Washington, DC, USA. https://www.fhwa.dot.gov/publications/research/infrastructure/structures/97148/rap131.cfm/. Accessed June 30, 2019.

Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage 2014, National Asphalt Pavement Association (NAPA), 5th Annual Survey, 2014. Report No: Information Series 138 (5th edition)

Noferini, L., Simone, A., Sangiorgi, C., & Mazzotta, F. (2017). Investigation on performances of asphalt mixtures made with Reclaimed Asphalt Pavement: Effects of interaction between virgin and RAP bitumen. International Journal of Pavement Research and Technology, 10(4), 322–332.

Singh, D., & Girimath, S. (2018). Toward Utilization of ground tire rubber and reclaimed pavement materials with asphalt Binder: Performance evaluation using essential work of fracture. International Journal of Pavement Research and Technology, 11(6), 594–602.

Hoyos, L., Puppala, A., & Ordonez, C. (2011). Characterization of cement-fiber-treated reclaimed asphalt pavement aggregates: Preliminary investigation. Journal of Materials in Civil Engineering, 23, 977–989.

Arulrajah, A., Piratheepan, J., & Disfani, M. M. (2013). Reclaimed asphalt pavement and recycled concrete aggregate blends in pavement subbases: Laboratory and field evaluation. Journal of Materials in Civil Engineering, 26, 349–357.

Puppala, A. J., Saride, S., & Williammee, R. (2011). Sustainable reuse of limestone quarry fines and RAP in pavement base/subbase layers. Journal of Materials in Civil Engineering, 24, 418–429.

Hajj, E., Sebaaly, P., & Kandiah, P. (2010). Evaluation of the use of reclaimed asphalt pavement in airfield HMA pavements. Journal of Transportation Engineering, 136, 181–189.

Maher, M.H., Gucunski, N., Papp, W. (1997). Recycled asphalt pavement as a base and sub-base material, vol. 1275, ASTM Special Technical Publication, pp. 42–53.

Taha, R., Ali, G., Basma, A., & Al-Turk, O. (1999). Evaluation of reclaimed asphalt pavement aggregate in road bases and subbases. Transportation Research Record: Journal of the Transportation Research Board, 1652, 264–269.

Muñoz-Cáceres, O., Raposeiras, A. C., Movilla-Quesada, D., Castro-Fresno, D., Lagos-Varas, M., Andrés-Valeri, V. C., & Valdés-Vidal, G. (2021). Mechanical performance of sustainable asphalt mixtures manufactured with copper slag and high percentages of reclaimed asphalt pavement. Construction and Building Materials, 340, 124653. https://doi.org/10.1016/j.conbuildmat.2021.124653 ISSN 0950-0618.

Chen, S.-H., Linb, D.-F., Luob, H.-L., & Lin, Z.-Y. (2017). Application of reclaimed basic oxygen furnace slag asphalt pavement in road base aggregate. Construction and Building Materials, 157, 647–653.

Faramarzia, M., Wayne Leeb, K., Kimc, Y., & Kwond, S. (2018). Case study on a cement treated RAP containing asphalt emulsion and acryl polymer. Case Studies in Construction Materials, 9, e00211

Sultan, S. A., & Guo, Z. (2016). Evaluating the performance of sustainable perpetual pavements using recycled asphalt pavement in China. International Journal of Transportation Science and Technology, 5(3), 200–209.

Modarres, A., & Hosseini, Z. (2014). Mechanical properties of roller compacted concrete containing rice husk ash with original and recycled asphalt pavement material. Materials and Design, 64, 227–236.

Delwar, M., Fahmy, M., Taha, R. (1997). Use of reclaimed asphalt pavement as an aggregate in portland cement concrete. ACI Materials, 94(3).

Hossiney, N., Wang, G., Tia, M., and Bergin, M.J. (2008). Evaluation of concrete containing rap for use in concrete pavement. International Journal of Pavement Research and Technology, 3(5).

Huang, B., Shu, X., & Li, G. (2005). Laboratory investigation of Portland cement concrete containing recycled asphalt pavements. Cement and Concrete Research., 35(10), 2008–2013.

Huang, B., Shu, X., and G, E. (2006). Burdette, mechanical properties of concrete containing recycled asphalt pavements. Magazine of Concrete Research, 58(5).

Malhotra, V. M. (2004). Global warming, and role of supplementary cementing materials and superplasticisers in reducing greenhouse gas emissions from the manufacturing of portland cement. International Journal of Structural Engineering, 1(2), 116–130.

Naik, T.R. (2005). Sustainability of cement and concrete industries. Achieving Sustainability in Construction, 2015

Salloum, T. (2007). Effect of fly ash replacement on Alkali and Sulphate resistance of mortars, MS Thesis, Department of Building, Civil and Environmental Engineering, Concordia University Montreal, Quebec, Canada.

Rangan, B. V. (2008). Fly ash-based geopolymer concrete, research report GC-4. Curtin University of Technology.

Davidovits, J. (2008). Geopolymer chemistry and applications (2nd ed.). Institute Geopolymer.

Hoy, M., Horpibulsuk, S., & Arulrajah, A. (2016). Strength development of recycled asphalt pavement—Fly ash geopolymer as a road construction material. Construction and Building Materials, 117, 209–219.

Avirneni, D., Peddinti, P. R. T., & Saride, S. (2016). Durability and long term performance of geopolymer stabilized reclaimed asphalt pavement base courses. Construction and Building Materials, 121, 198–209.

Movilla-Quesada, D., Muñoz, O., Raposeiras, A. C., & Castro-Fresno, D. (2018). Thermal suspectability analysis of the reuse of fly ash from cellulose industry as contribution filler in bituminous mixtures. Construction and Building Materials, 160, 268–277. https://doi.org/10.1016/j.conbuildmat.2017.11.046 ISSN 0950-0618.

Likitlersuang, S., & Chompoorat, T. (2016). Laboratory investigation of the performances of cement and fly ash modified asphalt concrete mixtures. International Journal of Pavement Research and Technology, 9(5), 337–344.

Saride, S., Avirneni, D., & Challapalli, S. (2016). Micro-mechanical interaction of activated fly ash mortar and reclaimed asphalt pavement materials. Construction and Building Materials, 123, 424–435.

Hoy, M., Rachan, R., Horpibulsuk, S., Arulrajah, A., & Mirzababaei, M. (2017). Effect of wetting–drying cycles on compressive strength and microstructure of recycled asphalt pavement—Fly ash geopolymer. Construction and Building Materials, 144, 624–634.

Rahman S. S., Khattak M. J. (2020). Mechanical and durability characteristics of roller compacted geopolymer concrete using reclaimed asphalt pavement. International Conference on Civil Infrastructure and Construction (CIC 2020), Doha, Qatar, 2–5 February 2020, https://doi.org/10.29117/cic.2020.0053

Asayesh, S., Javid, A. A. S., Ziari, H., & Mehri, B. (2021). Evaluating fresh state, hardened State, thermal expansion and bond properties of geopolymers for the repairing of concrete pavements under restrained conditions. Construction and Building Materials, 292, 123398. https://doi.org/10.1016/j.conbuildmat.2021.123398 ISSN 0950–0618.

ASTM C39/C39M-20. (2020). Standard test method for compressive strength of cylindrical concrete specimens. ASTM International, West Conshohocken, PA. www.astm.org

ASTM C78/C78M-18 (2018). Standard test method for flexural strength of concrete (using simple beam with third-point loading). ASTM International, West Conshohocken. www.astm.org

ASTM C496/C496M-17 (2017). Standard test method for splitting tensile strength of cylindrical concrete specimens. ASTM International, West Conshohocken, PA. www.astm.org

ASTM D8044–16, Standard Test Method for Evaluation of Asphalt Mixture Cracking Resistance using the Semi-Circular Bend Test (SCB) at Intermediate Temperatures, ASTM International, West Conshohocken, PA, 2016, www.astm.org29. Lee, W., Van Deventer, J. (2002). The effects of inorganic salt contamination on the strength and durability of geopolymers, Colloids Surface A, 211(2), 115–126.

ASTM D559/D559M-15. (2015). Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixtures. ASTM International, West Conshohocken, PA, www.astm.org

ASTM C1585–20 (2020) Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International, West Conshohocken, PA, www.astm.org

Lee, W., & Van Deventer, J. (2002). The effects of inorganic salt contamination on the strength and durability of geopolymers. Colloids and Surfaces A, 211(2), 115–126.

Morsy, M., Saleh, A., Al-Salloum, Y., & Almusallam, T. (2014). Effect of sodium silicate to sodium hydroxide ratios on strength and microstructure of fly ash geopolymer binder. Arabian Journal for Science and Engineering, 39(6), 4333–4339.

Acknowledgements

The authors sincerely thank the University of Louisiana at Lafayette for sponsoring this study by providing the Infrastructure and Materials Testing Laboratory research facility and testing equipment. A special thank you is extended to Mark LeBlanc for assisting in testing and Boral Fly Ash to supply materials.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

The authors confirm contribution to the paper as follows: study conception and design: MJK and SSR; Experimentation: SSR; and analysis and interpretation of results, and draft manuscript preparation: SSR and MJK. All the authors reviewed the results and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Rahman, S.S., Khattak, M.J. Feasibility of Reclaimed Asphalt Pavement Geopolymer Concrete as a Pavement Construction Material. Int. J. Pavement Res. Technol. 16, 888–907 (2023). https://doi.org/10.1007/s42947-022-00169-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-022-00169-8