Abstract

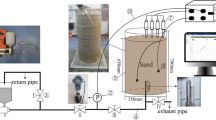

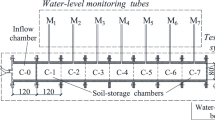

Seepage prevention and reinforcement of sandy soft soil layer are the important subjects in geotechnical engineering. A set of constant pressure permeable grouting device has been developed to study the diffusion rule of new permeable polymer in sandy soil layer. Based on the orthogonal experimental design, the effects of grouting pressure, grouting time, sand moisture content and sand porosity on the diffusion of new permeable polymer in sand are studied. Through the establishment of spatial coordinate system, the diffusion range of permeable polymer slurry is studied. The experimental results show that: the main and secondary order affecting the diffusion range of permeable polymer in the X-axis and Y-axis are sand porosity, grouting pressure, grouting time, and sand moisture content. The primary and secondary orders of influencing factors on the Z-axis diffusion range of permeable polymer are sand porosity, grouting time, grouting pressure, and sand moisture content. The effects of grouting pressure, grouting time, sand layer porosity on permeable polymer diffusion and the effect of permeable polymer on soil displacement during diffusion are studied by COMSOL numerical analysis software. The results of numerical analysis show that the grouting pressure, grouting time, and porosity of sand layer promote the diffusion of permeable polymer. The slight deformation of soil mass and small disturbance to soil layer can be caused by slurry during diffusion process. A function model between slurry diffusion range and grouting parameters are established, and verified by numerical simulation for comparison. The results show that the numerical simulation values of permeable polymer grouting results in the three comparison scenarios A1, A2 and A3 are greater than the theoretical calculation values, and the difference between them is not significant. The difference between the calculated value and the theoretical value of the three comparison schemes are 6.3%, 11.7% and 7.39%, respectively.

Similar content being viewed by others

Data Availability

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

References

Ou C, Teng F, Wang I (2008) Analysis and design of partial ground improvement in deep excavations. Comput Geotech 35(4):576–584. https://doi.org/10.1016/j.compgeo.2007.09.005

Zhang Z, Xu J (2013) A multi-mode resource-constrained project scheduling model with bi-random coefficients for drilling grouting construction project. Int J Civil Eng 11(1):1–13

Pei J et al (2016) Design and performance validation of high-performance cement paste as a grouting material for semi-flexible pavement. Constr Build Mater 126:206–217. https://doi.org/10.1016/j.conbuildmat.2016.09.036

Zhang J et al (2017) Bonding characteristics of grouting layer in prefabricated cement concrete pavement. Constr Build Mater 145:528–537. https://doi.org/10.1016/j.conbuildmat.2017.04.041

Su H et al (2017) Experiment study on the grouting material for the fabricated metro station’s joint with tenon and mortise. Sci Adv Mater 9(9):1644–1652. https://doi.org/10.1166/sam.2017.3132

Rostislav D, Magdalena K (2017) Options for the remediation of embankment dams using suitable types of alternative raw materials. Constr Build Mater 143:649–658. https://doi.org/10.1016/j.conbuildmat.2017.02.089

Heidarzadeh M, Mirghasemi AA, Niroomand H (2015) Construction of relief wells under artesian flow conditions at dam toes: engineering experiences from Karkheh earth dam, Iran. Int J Civil Eng 13(1B):73–80. https://doi.org/10.22068/IJCE.13.1.73

Wang S et al (2019) Study on the long-term performance of cement-sodium silicate grout and its impact on segment lining structure in synchronous backfill grouting of shield tunnels. Tunn Undergr Space Technol. https://doi.org/10.1016/j.tust.2019.103015

Di H et al (2021) In situ grouting tests for differential settlement treatment of a cut-and-cover metro tunnel in soft soils. Bull Eng Geol Environ 80(8):6415–6427. https://doi.org/10.1007/s10064-021-02276-5

Wang R et al (2019) Full-scale experimental study of the dynamic performance of buried drainage pipes under polymer grouting trenchless rehabilitation. Ocean Eng 181:121–133. https://doi.org/10.1016/j.oceaneng.2019.04.009

Yang MJ et al (2002) Prediction of grout penetration in fractured rocks by numerical simulation. Can Geotech J 39(6):1384–1394. https://doi.org/10.1139/T02-063

Zhou Z et al (2019) Micromechanism of the diffusion of cement-based grouts in porous media under two hydraulic operating conditions: constant flow rate and constant pressure. Acta Geotech 14(3):825–841. https://doi.org/10.1007/s11440-018-0704-z

Seo HJ et al (2014) Pillar-reinforcement technology beneath existing structures: small-scale model tests. KSCE J Civ Eng 18(3):819–826. https://doi.org/10.1007/s12205-014-1392-3

Ghafar AN et al (2016) An experimental approach to the development of dynamic pressure to improve grout spread. Rock Mech Rock Eng 49(9):3709–3721. https://doi.org/10.1007/s00603-016-1020-2

Mohammed MH, Pusch R, Knutsson S (2015) Study of cement-grout penetration into fractures under static and oscillatory conditions. Tunn Undergr Space Technol 45:10–19. https://doi.org/10.1016/j.tust.2014.08.003

Dou J et al (2020) Grouting experiment in a completely weathered granite dam abutment: case study on grouting technique and test analysis. Environ Earth Sci. https://doi.org/10.1007/s12665-020-09140-x

Chun BS, Lee YJ, Chung HI (2006) Effectiveness of control leakage after application of permeation grouting to earth fill dam. KSCE J Civ Eng 10(6):405–414

Zhao Z, Wang T, Jin X (2021) Study on permeation grouting rules for loess and method for predicting migration radius. KSCE J Civ Eng 25(8):2876–2883. https://doi.org/10.1007/s12205-021-1597-1

Fan J et al (2018) Evaluating permeability and efficiency of substrates by using permeation grouting sand column test. KSCE J Civ Eng 22(8):2843–2855. https://doi.org/10.1007/s12205-017-2535-0

Celik F (2019) The observation of permeation grouting method as soil improvement technique with different grout flow models. Geomech Eng 17(4):367–374. https://doi.org/10.12989/gae.2019.17.4.367

Mirza J et al (2013) Properties of microfine cement grouts at 4 degrees C, 10 degrees C and 20 degrees C. Constr Build Mater 47:1145–1153. https://doi.org/10.1016/j.conbuildmat.2013.05.026

Pantazopoulos IA et al (2012) Development of microfine cement grouts by pulverizing ordinary cements. Cement Concr Compos 34(5):593–603. https://doi.org/10.1016/j.cemconcomp.2012.01.009

Chen JJ, Kwan AKH (2012) Superfine cement for improving packing density, rheology and strength of cement paste. Cement Concr Compos 34(1):1–10. https://doi.org/10.1016/j.cemconcomp.2011.09.006

Golhashem MR, Uygar E (2020) Volume change and compressive strength of an alluvial soil stabilized with butyl acrylate and styrene. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.119352

Bhardwaj AK, McLaughlin RA, Levy GJ (2010) Depositional seals in polyacrylamide-amended soils of varying clay mineralogy and texture. J Soils Sediments 10(3):494–504. https://doi.org/10.1007/s11368-010-0198-2

Zhang Y et al (2019) Preparation and characterization of chemical grouting derived from lignin epoxy resin. Eur Polym J 118:290–305. https://doi.org/10.1016/j.eurpolymj.2019.05.003

Saada Z et al (2006) Evaluation of elementary filtration properties of a cement grout injected in a sand. Can Geotech J 43(12):1273–1289. https://doi.org/10.1139/T06-082

Axelsson M, Gustafson G, Fransson A (2009) Stop mechanism for cementitious grouts at different water-to-cement ratios. Tunn Undergr Space Technol 24(4):390–397. https://doi.org/10.1016/j.tust.2008.11.001

Maghous S et al (2007) A model for in situ grouting with account for particle filtration. Comput Geotech 34(3):164–174. https://doi.org/10.1016/j.compgeo.2006.11.003

Maghous S, Dormieux L, Barthelemy JF (2009) Micromechanical approach to the strength properties of frictional geomaterials. Eur J Mech A-Solids 28(1):179–188. https://doi.org/10.1016/j.euromechsol.2008.03.002

Liao K, Huang C (2011) Estimation of groutability of permeation grouting with microfine cement grouts using RBFNN. Adv Neural Netw – ISNN 2011. https://doi.org/10.1007/978-3-642-21111-9_54

Guo C, Hu D, Wang F (2021) Diffusion behavior of polymer grouting materials in sand and gravel. Soil Mech Found Eng 57(6):440–444. https://doi.org/10.1007/s11204-021-09690-7

Guo C et al (2019) A field experimental study on the diffusion behavior of expanding polymer grouting material in soil. Soil Mech Found Eng 56(3):171–177. https://doi.org/10.1007/s11204-019-09586-7

Hao M et al (2018) Numerical and experimental studies of diffusion law of grouting with expansible polymer. J Mater Civil Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002130

Li B et al (2021) Experimental and numerical study on polymer grouting pretreatment technology in void and corroded concrete pipes. Tunn Undergr Space Technol. https://doi.org/10.1016/j.tust.2021.103842

Vennapusa PKR, Zhang Y, White DJ (2016) Comparison of pavement slab stabilization using cementitious grout and injected polyurethane foam. J Perf Constr Facil. https://doi.org/10.1061/(ASCE)CF.1943-5509.0000916

Fang H et al (2019) Experimental and numerical investigation on repairing effect of polymer grouting for settlement of high-speed railway unballasted track. Appl Sci-Basel. https://doi.org/10.3390/app9214496

Wang F et al (2011) Experimental study on the anti-permeability properties of polymer grouting materials. Mater Design. https://doi.org/10.4028/www.scientific.net/AMR.284-286.1952

Wei Y et al (2017) Microstructure and fatigue performance of polyurethane grout materials under compression. J Mater Civil Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001954

Liu J et al (2019) Topsoil reinforcement of sandy slope for preventing erosion using water-based polyurethane soil stabilizer. Eng Geol 252:125–135. https://doi.org/10.1016/j.enggeo.2019.03.003

Wang C et al (2020) An experimental study on the reinforcement of silt with permeable polyurethane by penetration grouting. Adv Civil Eng. https://doi.org/10.1155/2020/8834331

Wang SY et al (2010) Numerical and experimental studies of pressure-controlled cavity expansion in completely decomposed granite soils of Hong Kong. Comput Geotech 37(7–8):977–990. https://doi.org/10.1016/j.compgeo.2010.08.006

Liu H et al (2017) High pressure jet-grouting column installation effect in soft soil: theoretical model and field application. Comput Geotech 88:74–94. https://doi.org/10.1016/j.compgeo.2017.03.005

Huang F, Jianguo L, Gao H et al (2018) Modified Maag’s spherical diffusion model of vacuum penetration grouting. Math Probl Eng 2018:1–7. https://doi.org/10.1155/2018/1758651

Krizek RJ, Perez T (1985) Chemical grouting in soils permeated by water. J Geotech Eng 111(7):898–915. https://doi.org/10.1061/(ASCE)0733-9410(1985)111:7(898)

Acknowledgements

The work present in this paper was supported by National Key Research and Development Program of China (2019YFC1510803-2); National Natural Science Foundation of China (Grant No. 52178369; 52109140); Key Projects of High Schools of Henan province (20A560021); Natural Science Foundation of Henan Province (202300410424); Youth Talent Promotion Project of Henan Province (2021HYTP016); Key Specialized Research and Development Breakthrough in Henan Province (212102310977); China Postdoctoral Science Foundation (2019M662533). These financial supports are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Yu, B., Wan, Y. et al. Experimental Investigation and Numerical Verification on Diffusion of Permeable Polymers in Sandy Soils with Considering Grouting Parameters. Int J Civ Eng 21, 617–632 (2023). https://doi.org/10.1007/s40999-022-00780-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-022-00780-7