Abstract

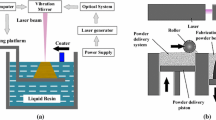

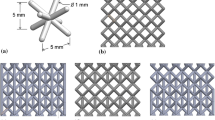

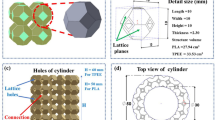

Since the development of additive manufacturing (3D printing), there has been a growing interest in the use of 3D printed lattice structures for a range of mechanical and biomedical applications. This study investigates the elastic properties of different types of strut-based lattice structures obtained through a series of compression tests and compares them against numerically calculated properties of intended designs. Two different 3D printing processes are employed for the fabrication of lattice structures, including selective laser sintering (SLS) and digital light processing (DLP). Gibson-Ashby power-law for cellular structures has been initially utilised as a framework for the comparison of numerical and experimental results. The results are normalised, allowing the comparison of elastic properties of lattices made in different polymer materials independent of the bulk material properties. This study suggests that although the mechanical properties of the fabricated parts are heavily dependent on the design of lattice unit-cell, the mechanical properties can be significantly different to those of intended designs depending on the 3D printing process used for the fabrication of lattice structures.

Similar content being viewed by others

Abbreviations

- AM:

-

Additive manufacture

- μ-CT:

-

Micro-computed tomography

- BCC:

-

Body-centred cubic

- FCC:

-

Face-centered cubic

- FEM:

-

Finite element method

- SLM:

-

Selective laser melting

- SLS:

-

Selective laser sintering

- FDM:

-

Fused deposition modelling

- DLP:

-

Digital light processing

- TPMS:

-

Triply periodic minimal surface

- UV:

-

Ultraviolet

- RSMD:

-

Root mean square deviation

- E l :

-

Lattice specimen modulus [MPa]

- E s :

-

Solid material modulus [MPa]

- n :

-

Power-law coefficient

- ρl :

-

Lattice specimen density [kg/m3]

- ρs :

-

Solid material density [kg/m3]

- P :

-

Laser power [W]

- E r :

-

Relative elastic modulus

- ρr :

-

Relative density (g/mm3)

- R :

-

Strut radius (mm)

- a :

-

Unit cell length (mm)

References

Brackett D, Ashcroft I, Hague R (2011) Topology optimization for additive manufacturing. In: Proceedings of the solid freeform fabrication symposium, austin, TX, pp 348–362

Thompson MK, Moroni G, Vaneker T, Fadel G, Campbell RI, Gibson I, Bernard A, Schulz J, Graf P, Ahuja B (2016) Design for additive manufacturing: trends, opportunities, considerations, and constraints. CIRP Ann 65(2):737–760

Abdi M, Ashcroft I, Wildman R (2014) High resolution topology design with iso-XFEM. In: Proceedings of the solid freeform fabrication symposium, pp 1288–1303

Liu J, Gaynor AT, Chen S, Kang Z, Suresh K, Takezawa A, Li L, Kato J, Tang J, Wang CC (2018) Current and future trends in topology optimization for additive manufacturing. Struct Multidiscip Optim 57(6):2457–2483

Aremu AO, Brennan-Craddock J, Panesar A, Ashcroft IA, Hague RJ, Wildman RD, Tuck C (2017) A voxel-based method of constructing and skinning conformal and functionally graded lattice structures suitable for additive manufacturing. Addit Manuf 13:1–13

Panesar A, Abdi M, Hickman D, Ashcroft I (2018) Strategies for functionally graded lattice structures derived using topology optimisation for additive manufacturing. Addit Manuf 19:81–94

Fleck NA, Deshpande VS, Ashby MF (2010) Micro-architectured materials: Past, present and future. Proc R Soc A: Math Phys Eng Sci 466(2121):2495–2516

Syam WP, Jianwei W, Zhao B, Maskery I, Elmadih W, Leach R (2018) Design and analysis of strut-based lattice structures for vibration isolation. Precis Eng 52:494–506

Catchpole-Smith S, Sélo R, Davis AW, Ashcroft IA, Tuck CJ, Clare A (2019) Thermal conductivity of TPMS lattice structures manufactured via laser powder bed fusion. Addit Manuf 30:100846

Ryan G, Pandit A, Apatsidis DP (2006) Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials 27(13):2651–2670

Echeta I, Feng X, Dutton B, Leach R, Piano S (2020) Review of defects in lattice structures manufactured by powder bed fusion. Int J Adv Manuf Technol 106(5):2649–2668

Abdi M, Ashcroft I, Wildman RD (2018) Design optimisation for an additively manufactured automotive component. Int J Powertrains 7(1–3):142–161

Maconachie T, Leary M, Lozanovski B, Zhang X, Qian M, Faruque O, Brandt M (2019) SLM lattice structures: properties, performance, applications and challenges. Mater Des 183:108137

Bici M, Brischetto S, Campana F, Ferro CG, Seclì C, Varetti S, Maggiore P, Mazza A (2018) Development of a multifunctional panel for aerospace use through SLM additive manufacturing. Procedia CIRP 67:215–220

Weeger O, Boddeti N, Yeung S, Kaijima S, Dunn ML (2019) Digital design and nonlinear simulation for additive manufacturing of soft lattice structures. Addit Manuf 25:39–49

Mahmoud D, Elbestawi MA (2017) Lattice structures and functionally graded materials applications in additive manufacturing of orthopedic implants: a review. J Manuf Mater Process 1(2):13

Fina F, Goyanes A, Madla CM, Awad A, Trenfield SJ, Kuek JM, Patel P, Gaisford S, Basit AW (2018) 3D printing of drug-loaded gyroid lattices using selective laser sintering. Int J Pharm 547(1–2):44–52

Maskery I, Sturm L, Aremu AO, Panesar A, Williams CB, Tuck CJ, Wildman RD, Ashcroft IA, Hague RJ (2018) Insights into the mechanical properties of several triply periodic minimal surface lattice structures made by polymer additive manufacturing. Polymer 152:62–71

Ravari MK, Kadkhodaei M, Badrossamay M, Rezaei R (2014) Numerical investigation on mechanical properties of cellular lattice structures fabricated by fused deposition modeling. Int J Mech Sci 88:154–161

Keshavarzan M, Kadkhodaei M, Forooghi F (2020) An investigation into compressive responses of shape memory polymeric cellular lattice structures fabricated by vat polymerization additive manufacturing. Polym Testing 91:106832

Dar UA, Mian HH, Abid M, Topa A, Sheikh MZ, Bilal M (2020) Experimental and numerical investigation of compressive behavior of lattice structures manufactured through projection micro stereolithography. Mater Today Commun 25:101563

Peto M, Ramirez-Cedillo E, Uddin MJ, Rodriguez CA, Siller HR (2019) Mechanical behavior of lattice structures fabricated by direct light processing with compression testing and size optimization of unit cells. In: ASME international mechanical engineering congress and exposition, pp V003T04A031

Al-Saedi DSJ, Masood SH, Faizan-Ur-Rab M, Alomarah A, Ponnusamy P (2018) Mechanical properties and energy absorption capability of functionally graded F2BCC lattice fabricated by SLM. Mater Des 144:32–44

Marco M, Belda R, Miguélez MH, Giner E (2020) Numerical analysis of mechanical behaviour of lattice and porous structures. Composite Struct 261:113292

Lozanovski B, Leary M, Tran P, Shidid D, Qian M, Choong P, Brandt M (2019) Computational modelling of strut defects in SLM manufactured lattice structures. Mater Des 171:107671

Gümrük R, Mines R (2013) Compressive behaviour of stainless steel micro-lattice structures. Int J Mech Sci 68:125–139

Jin N, Wang F, Wang Y, Zhang B, Cheng H, Zhang H (2019) Failure and energy absorption characteristics of four lattice structures under dynamic loading. Mater Des 169:107655

Alaña M, Lopez-Arancibia A, Pradera-Mallabiabarrena A, Ruiz de Galarreta S (2019) Analytical model of the elastic behavior of a modified face-centered cubic lattice structure. J Mech Behav Biomed Mater 98:357–368

Bonatti C, Mohr D (2019) Mechanical performance of additively-manufactured anisotropic and isotropic smooth shell-lattice materials: Simulations & experiments. J Mech Phys Solids 122:1–26

Dong L, Deshpande V, Wadley H (2015) Mechanical response of Ti–6Al–4V octet-truss lattice structures. Int J Solids Struct 60–61:107–124

Flodberg G, Pettersson H, Yang L (2018) Pore analysis and mechanical performance of selective laser sintered objects. Addit Manuf 24:307–315

Lei H, Li C, Meng J, Zhou H, Liu Y, Zhang X, Wang P, Fang D (2019) Evaluation of compressive properties of SLM-fabricated multi-layer lattice structures by experimental test and μ-CT-based finite element analysis. Mater Des 169:107685

Leary M, Mazur M, Elambasseril J, McMillan M, Chirent T, Sun Y, Qian M, Easton M, Brandt M (2016) Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater Des 98:344–357

Gibson LJ, Ashby MF (1988) The structure and properties of cellular solids. Cambridge University Press

Gibson LJ, Ashby MF (1999) Cellular solids: Structure and properties. Cambridge University Press

Al-Ketan O, Rowshan R, Al-Rub RKA (2018) Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit Manuf 19:167–183

Maskery I, Aboulkhair NT, Aremu AO, Tuck CJ, Ashcroft IA, Wildman RD, Hague RJ (2016) A mechanical property evaluation of graded density al-Si10-mg lattice structures manufactured by selective laser melting. Mater Sci Eng, A 670:264–274

Sinterit, "PA12 smooth," Technical datasheet pp.1, Aug. 2019

kudo3d, "3DSR-UHR-resin," Technical datasheet pp.1, Aug. 2019

ASTM D1621–16, Standard Test Method for Compressive Properties of Rigid Cellular Plastics, ASTM International, West Conshohocken, PA, 2016

ASTM D695–15, Standard Test Method for Compressive Properties of Rigid Plastics, ASTM International, West Conshohocken, PA, 2015

Maconachie T, Tino R, Lozanovski B, Watson M, Jones A, Pandelidi C, Alghamdi A, Almalki A, Downing D, Brandt M (2020) The compressive behaviour of ABS gyroid lattice structures manufactured by fused deposition modelling. Int J Adv Manuf Technol 107(11):4449–4467

Leary M, Mazur M, Williams H, Yang E, Alghamdi A, Lozanovski B, Zhang X, Shidid D, Farahbod-Sternahl L, Witt G (2018) Inconel 625 lattice structures manufactured by selective laser melting (SLM): Mechanical properties, deformation and failure modes. Mater Des 157:179–199

Shaw B, Dirven S (2016) Investigation of porosity and mechanical properties of nylon SLS structures. In: 2016 23rd international conference on mechatronics and machine vision in practice (M2VIP), pp 1–6

Funding

This study was funded by the Faculty of Computing, Engineering and Media at De Montfort University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ali, H.M.A., Abdi, M. & Sun, Y. Insight into the mechanical properties of 3D printed strut-based lattice structures. Prog Addit Manuf 8, 919–931 (2023). https://doi.org/10.1007/s40964-022-00365-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-022-00365-9