Abstract

Qualitative uncertainties are a key challenge for the further industrialization of additive manufacturing. To solve this challenge, methods for measuring the process states and properties of parts during additive manufacturing are essential. The subject of this review is in-situ process monitoring for material extrusion additive manufacturing. The objectives are, first, to quantify the research activity on this topic, second, to analyze the utilized technologies, and finally, to identify research gaps. Various databases were systematically searched for relevant publications and a total of 221 publications were analyzed in detail. The study demonstrated that the research activity in this field has been gaining importance. Numerous sensor technologies and analysis algorithms have been identified. Nonetheless, research gaps exist in topics such as optimized monitoring systems for industrial material extrusion facilities, inspection capabilities for additional quality characteristics, and standardization aspects. This literature review is the first to address process monitoring for material extrusion using a systematic and comprehensive approach.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Additive manufacturing is already an accepted technology for special applications and prototype production. However, it has considerable potential for further expansion in the future [1]. Examples of future applications are small-batch productions in the automotive [2] and aerospace [3] sectors as well as the production of customized medical devices [4]. Additive manufacturing can further be used in the jewelry [5] and construction industries [6]. Niche applications include mouthpieces for musical instruments [7] or textiles for clothing [8].

Solving the challenge of qualitative uncertainties in terms of materials, processes, and products, as well as process knowledge deficits, is vital to further incorporate additive manufacturing in the industry [9, 10]. Therefore, providing tools for comprehensive quality management is essential [11, 12]. Means of measuring process states and part properties during additive manufacturing are particularly relevant to achieving this aim [9, 13,14,15].

Process monitoring enables the assessment of whether a product satisfies certain requirements. In-situ inspection techniques fundamentally increase customer confidence in a product and reduce costs due to rejection, because process anomalies are detected immediately after they occur. Furthermore, information from process monitoring is the basis for implementing a closed-loop quality control [16]. A significant challenge for testing technologies in the field of additive manufacturing is the complex geometries of parts that contain infill structures and process-specific defects [17, 18]. This review aims to identify and analyze the existing literature on in-situ process monitoring for material extrusion (MEX), as it is one of the most widely used additive process categories [1, 19].

Former reviews, specifically on the additive manufacturing of metal parts, have already been published [17, 20, 21]. Their focus lies on monitoring techniques for powder bed [22] fusion and directed energy deposition [16, 23,24,25,26,27]. The results of these studies are not directly transferable to MEX because additive process categories are significantly different due to dissimilar processing principles being applied [9]. However, a number of reviews which comprise a wider range of additive process categories have been published: Vora and Sanyal [28] investigated the usability of different conventional inspection techniques for process monitoring in additive manufacturing. Their focus was the analysis of general functional principles. Process monitoring in MEX was merely minimally addressed. Charalampous et al. [29] discussed the research on sensor-based quality monitoring before, during, and after the additive manufacturing process. They presented nine different projects on MEX in-situ process monitoring. Controlling the additive processes using sensor technologies was the focus of a study [30] that listed commercially available solutions in addition to research work. It included eleven references regarding MEX. Lu and Wong [14] presented fundamental challenges and developed principles for monitoring with thermography, and acoustic emissions. However, MEX was only considered to a very limited extent. A review on ultrasonic testing by Honarvar and Varvani-Farahani [31] discussed two MEX projects. Furthermore, applications of machine learning have already been discussed in various publications [32,33,34]. One of their topics was process monitoring, but the presentation of MEX projects was marginal.

In summary, the studies on hand provide only a rather limited insight into the subject matter of MEX in-situ process monitoring. A comprehensive and systematic analysis of the state of knowledge has yet to be conducted. Therefore, the aim of this study is to compile and structure the current state of research using an approach that is as objective and comprehensive as possible. The following three central questions will be answered:

-

How much activity is involved in the field of process monitoring?

-

What methods and technologies are used for the process monitoring of which quality characteristics?

-

What are the research gaps?

After an overview of the fundamentals of MEX in Sect. 2, the methodology for the literature search and analysis is introduced in Sect. 3. Subsequently, in Sects. 4, 5, and 6 the results are presented and discussed, structured according to the abovementioned questions. Finally, Sect. 7 summarizes the main conclusions of the study.

2 Material extrusion

In MEX, a feedstock is extruded and deposited in beads by the relative movement between a nozzle and a substrate. During extrusion, the material is in a semi-solid state and solidifies when it reaches its final position and shape [19, 35]. Various sub-categories are grouped under the MEX process category. They differ in the type of extruder (plunger, gear, or screw), form of feedstock (filaments, rods, or pellets) [36], and kinematic design (Cartesian, polar, delta, or robot arm) [37].

The advantages of MEX are the simplicity of the process, relatively low costs [9] and a large variety of feedstock materials [38]. In addition to standard plastics, fiber-reinforced polymers can also be processed [39]. Furthermore, it is possible to produce parts from concrete [6], metals, ceramics, and multiple materials [36]. Because of the high material deposition rates that can be achieved [40], special MEX systems can be used for large-format additive manufacturing (build volumes of over 1 m3) [41]. MEX can compete with conventional manufacturing processes in terms of cost per unit for small and medium batch sizes [42]. An example of an application in this batch size range is polymer components for the aircraft industry [43].

Numerous influencing variables (e.g., process parameters and material properties) affect the mechanical and geometric properties as well as the surface characteristics of the parts produced by MEX [39, 44, 45]. Depending on the application, the requirements for the parts differ. Therefore, only certain quality characteristics related to the respective requirements are the target of process monitoring. Examples of quality characteristics are the geometric dimensions and density of parts [46]. Owing to the complex interactions among different influencing variables, various process faults that can negatively affect the quality of parts may occur. A selection of typical part defects is listed in Table 1.

3 Materials and methods

This study can be considered as a state-of-the-art review based on the classification of different review types by Grant and Booth [56]. The focus is on the presentation of the current status as well as the identification of research gaps. During the literature search step, as many thematically congruent publications as possible are identified using a systematic and reproducible search methodology. There is no evaluation and selection of publications based on the relevance of the study results and the quality of the study design. An aggregative approach is used to synthesize the identified sources by collecting and interpreting empirical data. In addition, a primary purpose is to provide an understanding of relevant research directions and topics [57].

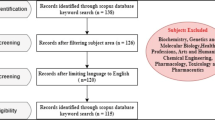

The process of literature search shown in Fig. 1 included, as a first step, a literature search of nine different popular databases in February 2020. Each database was searched multiple times. The searches corresponded to the keyword (“fused deposition modeling” OR “fused deposition modelling” OR “fused filament fabrication” OR “material extrusion” OR “fused layer modeling” OR “filament freeform fabrication”) AND (“process” OR “quality” OR “defect” OR “error” OR “fault” OR “condition”) AND (“assurance” OR “control” OR “detection” OR “inspection” OR “measurement” OR “metrology” OR “monitoring” OR “sensor”). Single search operations contained only one term for naming the additive manufacturing process (first operand for the Boolean AND operators). Therefore, six individual searches were performed to query the keyword completely. In each database, the entire record was searched, but the number of exported hits was limited to 500 per single search operation. If the database supported a limitation of the search to titles, abstracts, and keywords of the publications, an additional search in these categories was performed without limitation on the number of exported hits.

After removing the duplicates with the aid of the literature management software Citavi (Swiss Academic Software GmbH), the dataset contained 9176 entries. To analyze relevant sources only, inclusion and exclusion criteria were defined and applied to the dataset. The inclusion criteria were:

-

one of the sub-categories of MEX is treated;

-

central aim is in-situ process monitoring for quality assurance (assessing the status of 3D printer components or parts in production);

-

contribution is original research (peer-reviewed), dissertation or active patent.

The exclusion criteria were:

-

process monitoring is included but not for the purpose of quality assurance (e.g., sensor system to validate a simulation of the MEX process);

-

not in English or German;

-

older than 2013.

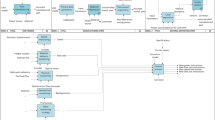

A total of 221 elements comprise the dataset for the review. The approach to analyze the identified publications, as well as the paper’s corresponding sections, is presented in Fig. 2.

4 How much activity is involved in the field of process monitoring?

The analysis of the publication dates of the contributions in Fig. 3 shows that publication activity is growing steadily, and the research activity in the field of process monitoring has been gaining importance. Growth rates since 2013 have at least been in the same range as those found by Vyavahare et al. [15] for the MEX research area in general. It should be noted that the value for the year 2020 cannot be interpreted directly because the process of searching the literature had been completed midyear.

The publication activity varies in the different sub-categories of MEX. The majority of the identified studies can be assigned to the field of monitoring techniques for fused deposition modeling [35]. The other sub-categories addressed are large-format MEX [58–63], bioprinting [64], and direct ink writing [65,66,67,68]. In addition to the processing of conventional filaments, some studies have examined manufacturing processes for continuous fibers [69, 70], pastes [71], and pellets [60, 62, 63, 72, 73]. Publications addressing MEX machines with delta [74,75,76,77,78,79,80,81,82,83,84,85,86,87,88] and robot arm [58, 72, 73, 89,90,91,92] kinematics are exceptions to the considered Cartesian systems.

Some monitoring systems have been published several times and sometimes, several systems have been described in one publication. The grouping of sources according to project affiliation indicated that the dataset involved 145 different MEX monitoring systems. The criteria for grouping the sources according to project affiliation were research group membership and sensor technology.

For further characterization of the dataset, Fig. 4 illustrates which levels of functionalities of a process monitoring system have been addressed by the publications and in which development stage they are. The sensor system (F1) is a pure hardware setup. In the level that builds on it, data are processed and extracted (F2), e.g., for visualization. The third functionality level describes the automated data evaluation (F3) for the detection of anomalies. A closed-loop control (F4) represents the maximum possible functionality level of a monitoring system. Note that these categories progress in a typical order (F1→F2→F3→F4), where the latter categories necessitate accomplishment of the prior categories. Publications are placed in the highest category that their content represents. The stage of development is described with the following classifications: patent (P), preliminary studies (D1), and realized solution (D2).

Figure 4 shows that the current focus of research is in F3 since the maximum number of D1 and D2 occurs on this level of functionality. However, the conspicuously high number of patents in F4 indicates that an economic benefit is seen particularly for this level of functionality. In the long term, therefore, further research activity can be expected in this area.

5 What methods and technologies are used for the process monitoring of which quality characteristics?

5.1 Sensor technology groups and inspected elements

Various sensor technologies are used for process monitoring. Figure 5 displays the percentage shares of sensor technology groups in the total number of sensors used. The grouping is based on the measured physical quantities. The respective share of each sensor technology that is used simultaneously with another is represented by the “sensor fusion” section of the bar. Furthermore, all sensor technologies that have a share of less than 2% in the “one sensor technology” section and cannot be assigned to the other groups are collected under “other.”

Figure 6 depicts a statistical analysis of which elements of the additive manufacturing process are directly monitored by which sensor technology groups. On one hand, it is possible to monitor the components of the MEX machine that have an influence on the part quality. According to the main functional components of the MEX machine [19, 35, 45], the following are distinguished:

-

extrusion head (EH), including the extrusion nozzle and feedstock delivery mechanism;

-

feeding system (FS), for feedstock transport to the extrusion head;

-

build chamber (BC), including the housing and frame;

-

build platform (BP); and

-

axis system (AS), including the motors.

On the other hand, the part can be directly monitored. The following are distinguished depending on the area of monitoring:

-

entire part (P);

-

layers (L), equivalent to the build surfaces in the majority of cases; and

-

sidewalls of part (S).

Figure 6 shows that the measurement of vibration, acoustic and electrical signals, as well as force and pressure, is primarily used to monitor the components of the MEX machine. The part is inspected primarily using vision technologies. The focus is on monitoring the extrusion head and individual layers.

The following subsections describe the identified publications sorted by sensor technology groups and project affiliations. The general functional principles are introduced, and selected monitoring systems are explained precisely. For detailed descriptions of the treated sensor types and their general advantages and disadvantages, the reader can refer to Vora and Sanyal [28].

5.2 2D vision

In Table 2, the projects identified within the field of 2D vision are listed, along with their associated references. The projects were sorted based on the following priority: (1) used sensors (column “Sensors”), (2) inspected elements (column “Ele”), (3) project level of functionality (column “Fun”), and (4) stage of development (column “Dev”). The column “Data handling” provides a brief description of the methods used for sensor data processing. “Quality characteristics” are the features checked by the monitoring system. If the publications on a project do not contain certain information, this is indicated in the corresponding cell with the phrase “not applicable” (“n.a.”).

The generic term 2D vision is used in this paper to describe all sensor technologies that acquire two-dimensional images of an object in the visible wavelength range. Seven of the 23 patents identified in this work exclusively addressed 2D vision [111, 117, 136,137,138, 163]. Therefore, the potential of the sensor technology for MEX process monitoring is considered high by the industry.

The 2D vision technology is often used for the sequential inspection of layers. One technical variant includes mounting the sensor on the extrusion head [58, 65,66,67, 89, 104,105,106, 111, 112, 159,160,161,162]. For example, Liu et al. [160, 161] investigated overfill and underfill defects using two digital microscopes, which were attached to the extrusion head to continuously analyze the layer surface in a small area next to the nozzle (Fig. 7). For the extraction of features, a texture analysis method in which the layer surface was described with a gray-level co-occurrence matrix was used. Subsequently, the layer surface was divided into five classes using the k-nearest neighbors algorithm. The material flow rate and speed of the cooling fan on the extrusion head were adjusted using a proportional-integral-derivative (PID) controller according to the classification to increase the layer quality.

Investigation of layer surface quality using two digital microscopes. Adapted from [160],

In addition to projects that include mounting vision sensors on the extrusion head, another relevant approach is the stationary mounting of the camera with a view on the build platform. In this scenario, the entire layer is captured in one image acquisition [100, 101, 104,105,106,107,108,109,110, 129,130,131,132,133,134]. In one of the projects [131,132,133], statistical process control is used to evaluate the quality of the layer contours. Significant changes in the process caused by the exceedance of tolerance limits were displayed on quality control charts. In contrast, Delli et al. [134] compared images of a defect-free part with the actual manufactured part and used both a simple threshold method and a support vector machine to classify the part into one of two categories: good or bad.

Aside from process monitoring of individual layers, 2D vision sensors may also be used for the exclusive inspection of the sidewalls of parts. In this technical variant, the camera axis is often perpendicular to the normal vector of the build platform. Baumann et al. [113] used this approach to detect deformations on printed objects, detachments from the build platform, and lack of material flow. Because the 3D printer is a desktop device with an open housing, the camera can be placed in front of the 3D printer to capture images of one side of the part.

The use of a camera to inspect sidewalls in large-format additive manufacturing was investigated by MacDonald et al. [59]. Fourier analysis was used to determine the variation in layer heights from the image data. Due to the large size of the beads, they can be easily distinguished from one another with an algorithm. Especially in large-format MEX with pellet feedstock, the extrusion process is highly sensitive to parameter variations. The authors demonstrated that the resulting slumping of beads or small irregularities protruding from the sidewalls could be detected with the monitoring system.

In a series of publications, Straub [119,120,121,122,123,124,125,126] presented a sensor system consisting of five cameras arranged around the build platform. For data acquisition, the printing process is stopped, and the build platform is moved to a predefined position. Besides the use of multiple cameras, mobile solutions to move the camera around the object to be printed have been proposed in further studies [88, 90, 117]; thus, the sidewalls of the part can be fully captured. Figure 8 shows this as an example with a camera attached to the extrusion head of a robot MEX system using a special mount.

Camera attached to the extrusion head of a robotic MEX system for continuous multi-view inspection of sidewalls. Adapted from [90],

In addition to the inspection of manufactured parts, some systems also use 2D vision to monitor the mechanical components of a 3D printer. Greeff et al. [157, 158] utilized a digital microscope to inspect the filament delivery mechanism in an extrusion head. The speed and width of the filament were measured to calculate the volume flow. Moreover, the speed of the feeding gear was determined and compared with that of the filament to calculate slippage effects.

5.3 Temperature monitoring

Since materials are melted because of heat during MEX, the acquisition of temperature data is a practical method for evaluating the condition of the manufacturing process. Table 3 summarizes the corresponding publications. Temperature sensors for measuring and controlling the temperature of the build platform, extruder, and ambient air in the build chamber are conventionally installed in many MEX systems [178]. However, aside from sensors that are in contact with the measured surface, a large portion of the identified publications involve temperature determination via thermography. Thermography is an imaging technique used to display the surface temperature of objects. The intensity of the infrared radiation serves as a measure of the temperature.

Thermal cameras are often used to determine the temperature of the layers. Borish et al. [60] developed a method for calculating the average temperature of a layer in large-format MEX. They paused the printing process until the temperature decreases below a certain value. When this condition is attained, the next layer can be processed. The thermal camera is attached to a movable arm that is pneumatically driven. The study shows that temperature measurements are particularly relevant for large-format additive manufacturing since in rapid printing processes cooling times are sometimes insufficient and parts collapse under their own weight.

Monitoring the sidewall of a part with a thermal camera, Ferraris et al. [171] determined a correlation between the characteristic temperature curves and the size of the bonding surfaces between adjacent beads. Using a similar hardware setup, the tensile strength of samples was predicted in a work by Bartolai et al. [173, 174].

5.4 Vibration monitoring

Vibration can be measured at many of the mechanical components of the 3D printer (Table 4). A key issue is the monitoring of extrusion head vibrations. Tlegenov et al. [181, 182] attached an accelerometer to an extruder to determine the effective nozzle diameter, which was used as a measure for nozzle clogging conditions. They observed that the amplitude of the vibration increased nonlinearly with decreasing effective nozzle diameter. The results of an analytical model for the theoretical determination of the amplitude exhibited good agreement with those of the experiments using both Bowden and direct extruders. In another research work [185] sensors were attached to both the extrusion head and build platform. This enabled the detection of part deformations and defective extruder conditions. The detection of defects in mechanical components of the MEX machine was solely investigated by Yen and Chuang [87].

5.5 3D vision

The advantage of 3D vision compared to 2D vision is that height information can be captured. Table 5 indicates that nearly all of the publications address the monitoring of individual layers, in which comparison with different types of digital reference information was used for error detection.

If structured light or stereoscopic imaging systems are used, the sensors are rigidly aligned to the build platform [75, 76, 100, 186,187,188,189,190,191, 193]. Holzmond and Li [193] for example, used two five-megapixel cameras to create a stereoscopic imaging system. The viewing axes of the cameras were aligned perpendicular to the layers. To capture images of the layers, the extrusion head was moved out of the viewing axis by making it print a waste part parallel to the target part. After each layer, the extrusion head moved to the waste part, creating a time window for image acquisition. A reference point cloud was generated from the G-code, which could be compared with the captured point cloud to detect defects. The approach was limited in that the system could only inspect materials with naturally textured surfaces.

In contrast, laser triangulation sensors record single height profiles. Therefore, a relative movement between the inspection object and sensor should be attained to generate a 3D point cloud from a large number of height profiles. Hence, the laser triangulation system is attached to the extrusion head of the MEX machine and can be moved over the layer surface [62, 64, 72, 73, 195,196,197].

5.6 Acoustic emission monitoring

Acoustic emission monitoring can be used because various actuators and mechanical components of the 3D printer generate noise (Table 6). If anomalies occur, they will cause changes in the acoustic emissions. Many studies have used this sensor technology to monitor extrusion heads. For example, Wu et al. [203] attached an acoustic emission sensor to an extruder with vacuum grease. The mounting arrangement is depicted in Fig. 9. The state of the extruder was classified into the following using a hidden semi-Markov model: extruding without material, material loading/unloading, idle, and normal extruding. In validation experiments, a classification accuracy of more than 90% was achieved.

Installation of an acoustic emission sensor attached to the extrusion head. Adapted by permission from Springer Nature: Springer Int. J. Adv. Manuf. Technol. [203],

In another study [205, 206], a sensor mounted on the build platform next to the part could detect detachment of the part from the build platform and deformations. The defective part came into contact with the nozzle, which resulted in altered acoustic emissions. Moreover, recording devices can be placed next to the 3D printer [207,208,209,210]. Using this setup, Chhetri et al. [207] reconstructed the geometry of layers based on the acoustic emissions of the axes and motors. By comparing the reconstructed geometry with the original G-code, they were able to identify cyberattacks. Evaluation experiments demonstrated that a modified geometry of a quadcopter baseplate was detectable.

5.7 Electrical quantities monitoring

Table 7 lists all identified sources in the field of monitoring electrical quantities. The sensors used are often for monitoring motor currents. For example, the currents of the motors to push the filament through the extrusion head or to move the axes are measured. Nozzle blockages or incorrect axis movement cause changes in the motor current and can be evaluated. Kim et al. [211,212,213] observed that the motor current of an extruder is correlated with the level of extrusion pressure. The extrusion pressure depends on the size of the nozzle outlet and the distance between the nozzle and substrate. If the part is deformed and the distance to the nozzle outlet is reduced, or if a foreign object prevents the material from exiting, the pressure will increase and changes in the motor current will occur.

5.8 Force and pressure monitoring

Hitherto publications on force and pressure measurements focused on investigations of extrusion head elements (Table 8). Klar et al. [71] showed that the extrusion force in a piston-based extrusion device for processing ceramic, silicone, and acrylic pastes can be measured using a load cell. Force variations were directly related to the flow characteristics of the material. Other than the extrusion forces, forces acting at the nozzle tip owing to the external effects of substrate defects can also be measured [219]. Furthermore, in the MEX of continuous fibers, fibers that are not fed at a sufficient rate by the delivery mechanism result in analyzable changes in forces. Exceedingly high forces, in turn, cause fiber pull-out and shearing [69].

5.9 Other sensor technologies

In this section, different sensor technologies with small numerical shares of publication in the literature are summarized (Table 9). In some publications, fiber Bragg grating sensors are presented as possible means of measuring strains. In such a system, the printing process is interrupted at a certain point and optical fibers are placed on the unfinished part. Subsequently, these are overprinted with additional material (Fig. 10). If deformations of the part and consequently of the optical fiber occur, they can be detected and analyzed [221,222,223,224,225,226,227]. Since the placement of the optical fibers as well as the properties of the surrounding material have an impact on the accuracy of the measurements, Falcetelli et al. [246] discussed and investigated different fiber embedding strategies.

copyright 2013, with permission from Elsevier. Right figures redrawn and adapted from [221], copyright 2016, with permission from Elsevier (Creative Commons license. https://creativecommons.org/licenses/by-nc-nd/4.0)

Process monitoring with embedded optical fiber and schematic view of the cross-section. Left figure adapted from [224],

Some research groups used ultrasonic sensors to analyze the part structures. Reflections of high-frequency pulses exerted onto the part were analyzed based on the duration until detection [229,230,231,232,233]. Another relevant approach is the use of encoders to determine the axis positions and to implement closed-loop control of the axis movement. This approach is considered state of the art within the NC machine industry [237]. It is also present in some MEX machines available for purchase [30].

The heterogeneity of monitoring systems prevented the further formation of clusters with similar functional principles. Therefore, the authors refer to individual publications for additional information.

5.10 Sensor fusion technologies

The fusion of data from multiple sensor technologies is a powerful method for monitoring a large number of features. Table 10 and Fig. 5 show that 2D vision and 3D vision are rarely used in combination with other sensor technologies. This is presumably due to the large information volume of the measurement data of the optical inspection systems. Additionally, optical measurement techniques are commonly used to inspect the quality characteristics of a part. In contrast, measurements that describe the condition of the 3D printer must be obtained via various routes to characterize the heterogeneous components of the machine.

An effective grouping of the identified monitoring systems is not possible. As an example, a monitoring system consisting of six thermocouples for temperature measurements at the extruder, at the build platform, and in ambient air is presented here. Furthermore, two sensors were used to measure the vibrations of the build platform and extrusion head. An infrared sensor measured the temperature of the build surface near the nozzle at the location at which the material was deposited. The authors explained that no additional benefit could be expected from using the thermocouples; therefore, only vibration and infrared sensors were used for process monitoring. The dimensional accuracy, surface roughness, and underfills could be determined [276,277,278]. The underfills were classified as “normal operation,” “stringy extrusion,” and “nozzle clogged.” When producing a standard test artifact, the system achieved an accuracy of 97% for classifying into these three categories [276].

6 What are the research gaps?

6.1 Key topics for sensor technology and data processing

In a workshop of the National Institute of Standards and Technology, USA, the measurement science roadmap for polymer-based additive manufacturing was elaborated. Said roadmap specifies developments concerning measurement science required for the industrialization of additive manufacturing. For process monitoring, four prioritized roadmap topics (RT) were identified [13]:

-

RT1: new in-situ imaging modalities

-

RT2: real-time process measurement at required spatial and temporal resolution

-

RT3: in-situ control and model integration

-

RT4: big data analytics

A comparison of RT1 with the identified literary sources shows that the current research activity likewise focuses on the development of imaging modalities. From an industrial perspective, approaches that address the inspection of layers are particularly promising. Here, a single sensor module can be utilized to inspect both the outer walls and inner structures of parts. Geometries and surface characteristics can be effectively inspected using 2D vision and 3D vision. Optical temperature measurements can be used to verify the thermal material properties. In addition to imaging techniques, monitoring of extrusion head conditions should be prioritized in future research because it is a key element of MEX systems. Measurements of current, vibrations, and acoustic signals are advantageous because the sensors can be installed with minimal effort. In contrast, force and pressure measurements require modifying the mechanical extrusion head components. However, this enables precise determination of the polymer melt conditions.

Regardless of the sensor technology, there is a fundamental necessity for research on integrating sensors into industrial MEX systems. New and improved sensor concepts that are designed for high ambient temperatures and large build volumes are required. Furthermore, efficient sensor modules, which can be realized in MEX machines despite restrictions due to moving machine parts and frame structures, must be developed.

The large number of patents on closed-loop control in Fig. 4 indicates that this topic is considered to be fundamentally important in the industry. High-performance measurement technology (RT2) is a prerequisite for these control loops (RT3). For the resolution of acquired data and speed of data processing, satisfactory results have already been achieved for some specific measurement tasks. This is demonstrated by the first controlled systems that adjust process parameters in sufficiently short periods and with adequate accuracy [63, 160, 180]. However, these systems require much improvement. For example, sensor technologies for detecting small voids or part contours in large-area, high-resolution layer images at high speeds are not yet available. Furthermore, classifying monitoring systems use only a few classes; therefore, they have low resolutions. Moreover, the current closed-loop control is based on simple causal relationships. Mathematical models that describe complex relationships between several process parameters, control variables, and part properties have not yet been sufficiently researched.

Large and complex datasets generated by different sensor technologies and assignable to the field of big data analytics (RT4) were not used in the identified publications. Therefore, datasets with heterogeneous sensor data from several varying print jobs must be generated in the future to train robust inspection algorithms. The analysis of the literature has confirmed the significance of this subject by demonstrating that, owing to the complexity of the inspection task, only multi-sensor approaches enable comprehensive monitoring of the MEX process.

6.2 Rarely examined quality characteristics

Aside from the specific wear-prone components of the 3D printer, all properties of the parts are, in principle, relevant to MEX monitoring. The requirements for a part can be divided into mechanical and geometrical requirements, surface requirements, and requirements for feedstock materials [280].

The focus of the current research is on part geometries and surface properties in terms of overfill and underfill. However, measurements of surface roughness were addressed by only two research projects [267, 276,277,278]. The measurement of mechanical properties is another important aspect that was investigated by merely two works as well: Bartolai et al. [173, 174] and Zhang et al. [271, 272] addressed the prediction of tensile strengths. Means of inspecting material characteristics were not considered in any publication. The monitoring of these quality characteristics, which the current research only addresses to a limited extent, represents a gap for future research.

6.3 Variety and complexity of monitored parts

A challenge with MEX monitoring is the required flexibility [14]. Varying and often complex part geometries are manufactured in very small batches. Furthermore, many different materials can be processed. Therefore, the extent to which the flexibility of the MEX is reflected in the reviewed monitoring systems was investigated. The properties of parts manufactured in projects with the aim of process monitoring for quality assessment were analyzed considering the aspects listed below:

-

complexity of geometries (simple or complex),

-

number of different geometries,

-

materials used, and

-

number of different materials used.

The analysis showed that 19.3% of the projects contained an investigation of complex part geometries, 55.9% monitored simple geometries, and 24.8% did not specify the geometry. Simple geometries include, among others, cuboids, cylinders, or single material beads. In contrast, the complex geometries describe a prosthesis or valve housing, for example. For the number of different geometries per project, the authors observed that 47.6% of the projects investigated one geometry, 12.4% two geometries, and 7.6% three geometries. More than three geometries were analyzed in only 8.3% of the projects, while 24.1% did not specify the geometry.

40.7% of works did not specify the material. Polylactide (PLA) and acrylonitrile butadiene styrene (ABS) were used in 34.5% and 26.9% of the projects, respectively. Composite materials were used in 6.2%, polycarbonate in 2.1%, and ceramic materials in 1.4% of the projects. Other materials had a proportion of < 1% each. In 74.4% of the projects that specify the material, only one type of material was investigated, while 19.8% of the projects used two, 4.7% three, and 1.2% four different materials. Projects that employed more than one material consistently produced different parts separately from just one material each. Only one publication [252] stated that the part was made from PLA and one additional support material.

The results show that projects with high complexity and variation in part geometries and materials are strongly underrepresented in the dataset. The analyzed monitoring systems tend to monitor manufacturing processes for simple geometries and small numbers of varying parts. Regarding the materials used, ABS and PLA dominate the research projects, the number of different materials per project is oftentimes low and multiple material parts are only considered to a minor extent. However, complex geometries and cost-intensive materials (e.g., metal-filled or fiber-reinforced plastics) are particularly suitable for process monitoring, because this is where the economic efficiency of the inspection system is most easily achieved. Therefore, there is considerable potential for further research regarding the monitoring of various complex parts.

6.4 Standardization

Owing to the novelty of the technology and the diversity of the topic, standardization in the field of additive manufacturing is still in its early stages. There are only a limited number of standards for the specification of part properties and non-destructive testing methods [14, 28]. Analysis of the identified publications has also shown that no consistent definitions are used for quality characteristic names, feature specifications, and tolerance limits.

As a first step towards standardization, ISO/ASTM 52901 [281] basically describes how part characteristics, tolerances, and test methods are to be defined between the customer and the supplier. With regard to process monitoring, the decision of whether a process variation represents a defect or not is particularly crucial [282]. Future projects can use the draft standard ISO/ASTM DIS 52924 [46] to specify these tolerance limits, as the document defines the quality levels of MEX plastic parts in terms of relative part density, dimensional accuracy, and mechanical properties for an entire part. However, to analyze small defects with high spatial resolution, MEX-specific characteristics must be considered. For example, unsupported bridging results in changes in geometric tolerances.

For the description of part characteristics, general standards such as the geometrical product specification matrix model [283] are applicable. Here, surface imperfections in the layer structure can be characterized according to the ISO 8785 standard, which specifies the nomenclature and characteristics of these irregularities [284]. Furthermore, standards for conventional non-destructive testing methods can be adapted to the process monitoring of MEX [14].

7 Conclusion

Monitoring of MEX during the manufacturing process is crucial for the industrial use of this technology. The publication activity in this field is increasing. This clearly indicates that the subject is significant. The wide range of sensor technologies used and quality characteristics monitored demonstrate that the existing monitoring systems have been researched at many functional levels. However, for the widespread utilization of monitoring systems, further optimization is required.

The strength of this review is in its systematic approach to the literature search and the large dataset used. The state of knowledge is presented comprehensively, and research gaps are identified. Limitations exist because of the possibility that the literature evaluation and identification of future priorities are affected by the individual perspectives of the authors. For a highly differentiated analysis of the publications, future reviews may also include more systematic and detailed assessments of the results and quality of studies.

References

Wohlers T, Campbell I, Diegel O et al (2018) Wohlers Report 2018. 3D printing and additive manufacturing state of the industry: Annual Worldwide Progress Report. Wohlers Associates Inc, Fort Collins

Yi L, Gläßner C, Aurich JC (2019) How to integrate additive manufacturing technologies into manufacturing systems successfully: a perspective from the commercial vehicle industry. J Manuf Syst 53:195–211. https://doi.org/10.1016/j.jmsy.2019.09.007

Najmon JC, Raeisi S, Tovar A (2019) Review of additive manufacturing technologies and applications in the aerospace industry. In: Froes F, Boyer R (eds) Additive Manufacturing for the Aerospace Industry. Elsevier, Amsterdam , pp 7–31

Javaid M, Haleem A (2018) Additive manufacturing applications in medical cases. A literature based review. Alexandria J Med 54:411–422. https://doi.org/10.1016/j.ajme.2017.09.003

Klotz UE, Tiberto D, Held F (2017) Optimization of 18-karat yellow gold alloys for the additive manufacturing of jewelry and watch parts. Gold Bull 50:111–121. https://doi.org/10.1007/s13404-017-0201-4

Bos F, Wolfs R, Ahmed Z et al (2016) Additive manufacturing of concrete in construction: potentials and challenges of 3D concrete printing. Virtual Phys Prototyp 11:209–225. https://doi.org/10.1080/17452759.2016.1209867

Bacciaglia A, Ceruti A, Liverani A (2019) Evaluation of 3D printed mouthpieces for musical instruments. Rapid Prototyp J 26:577–584. https://doi.org/10.1108/RPJ-07-2019-0187

Bloomfield M, Borstrock S (2018) Modeclix. The additively manufactured adaptable textile. Mater Today Commun 16:212–216. https://doi.org/10.1016/j.mtcomm.2018.04.002

Ngo TD, Kashani A, Imbalzano G et al (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos Part B Eng 143:172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

Energetics Incorporated, National Institute of Standards and Technology (2013) Measurement Science Roadmap for Metal-Based Additive Manufacturing. National Institute of Standards and Technology (NIST), Columbia MD

Kim H, Lin Y, Tseng T-LB (2018) A review on quality control in additive manufacturing. Rapid Prototyp J 24:645–669. https://doi.org/10.1108/RPJ-03-2017-0048

Huang T, Wang S, He K (2015) Quality control for fused deposition modeling based additive manufacturing: Current research and future trends. 2015 First Int Conf Reliab Syst Eng (ICRSE). https://doi.org/10.1109/ICRSE.2015.7366500

Pellegrino J, Makila T, McQueen S et al (2016) Measurement Science Roadmap for Polymer-Based Additive Manufacturing. National Institute of Standards and Technology (NIST), Columbia

Lu QY, Wong CH (2018) Additive manufacturing process monitoring and control by non-destructive testing techniques: challenges and in-process monitoring. Virtual Phys Prototyp 13:39–48. https://doi.org/10.1080/17452759.2017.1351201

Vyavahare S, Teraiya S, Panghal D et al (2020) Fused deposition modelling: a review. Rapid Prototyp J 26:176–201. https://doi.org/10.1108/RPJ-04-2019-0106

Leach RK, Bourell D, Carmignato S et al (2019) Geometrical metrology for metal additive manufacturing. CIRP Ann Manuf Technol 68:677–700. https://doi.org/10.1016/j.cirp.2019.05.004

Chauveau D (2018) Review of NDT and process monitoring techniques usable to produce parts by welding or additive manufacturing. Weld World 62:1097–1118. https://doi.org/10.1007/s40194-018-0609-3

Albakri MI, Sturm LD, Williams CB et al (2017) Impedance-based non-destructive evaluation of additively manufactured parts. Rapid Prototyp J 23:589–601. https://doi.org/10.1108/RPJ-03-2016-0046

ISO/ASTM DIS 52900 (2018) Additive manufacturing – General principles – Terminology

Liu W-W, Tang Z-J, Liu X-Y et al (2017) A review on in-situ monitoring and adaptive control technology for laser cladding remanufacturing. Procedia CIRP 61:235–240. https://doi.org/10.1016/j.procir.2016.11.217

Xia C, Pan Z, Polden J et al (2020) A review on wire arc additive manufacturing: Monitoring, control and a framework of automated system. J Manuf Syst 57:31–45. https://doi.org/10.1016/j.jmsy.2020.08.008

Mani M, Lane BM, Donmez MA et al (2017) A review on measurement science needs for real-time control of additive manufacturing metal powder bed fusion processes. Int J Prod Res 55:1400–1418. https://doi.org/10.1080/00207543.2016.1223378

Yan Z, Liu W, Tang Z et al (2018) Review on thermal analysis in laser-based additive manufacturing. Opt Laser Technol 106:427–441. https://doi.org/10.1016/j.optlastec.2018.04.034

Chua ZY, Ahn IH, Moon SK (2017) Process monitoring and inspection systems in metal additive manufacturing: status and applications. Int J Precis Eng Manuf Green Technol 4:235–245. https://doi.org/10.1007/s40684-017-0029-7

Everton SK, Hirsch M, Stravroulakis P et al (2016) Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater Des 95:431–445. https://doi.org/10.1016/j.matdes.2016.01.099

Tapia G, Elwany A (2014) A review on process monitoring and control in metal-based additive manufacturing. J Manuf Sci Eng . https://doi.org/10.1115/1.4028540

Grasso M, Colosimo BM (2017) Process defects and in situ monitoring methods in metal powder bed fusion: a review. Meas Sci Technol. https://doi.org/10.1088/1361-6501/aa5c4f

Vora HD, Sanyal S (2020) A comprehensive review: metrology in additive manufacturing and 3D printing technology. Prog Addit Manuf. https://doi.org/10.1007/s40964-020-00142-6

Charalampous P, Kostavelis I, Tzovaras D (2020) Non-destructive quality control methods in additive manufacturing: a survey. Rapid Prototyp J 26:777–790. https://doi.org/10.1108/RPJ-08-2019-0224

Mercado Rivera FJ, Rojas Arciniegas AJ (2020) Additive manufacturing methods: techniques, materials, and closed-loop control applications. Int J Adv Manuf Technol 109:17–31. https://doi.org/10.1007/s00170-020-05663-6

Honarvar F, Varvani-Farahani A (2020) A review of ultrasonic testing applications in additive manufacturing: Defect evaluation, material characterization, and process control. Ultrasonics 108:106227. https://doi.org/10.1016/j.ultras.2020.106227

Goh GD, Sing SL, Yeong WY (2020) A review on machine learning in 3D printing: applications, potential, and challenges. Artif Intell Rev. https://doi.org/10.1007/s10462-020-09876-9

Meng L, McWilliams B, Jarosinski W et al (2020) Machine learning in additive manufacturing: a review. JOM 72:2363–2377. https://doi.org/10.1007/s11837-020-04155-y

Razvi SS, Feng S, Narayanan A et al (2019) A review of machine learning applications in additive manufacturing. Proc ASME 2019 Int Des Eng Tech Conf Comput Inf Eng Conf. https://doi.org/10.1115/DETC2019-98415

Gibson I, Rosen D, Stucker B et al (2021) Chapter 6 - Material Extrusion. In: Gibson I, Rosen D, Stucker B et al (eds) Additive Manufacturing Technologies, 3rd edn. Springer, Cham, pp 171–202

Gonzalez-Gutierrez J, Cano S, Schuschnigg S et al (2018) Additive manufacturing of metallic and ceramic components by the material extrusion of highly-filled polymers: a review and future perspectives. Materials. https://doi.org/10.3390/ma11050840

Kampker A, Triebs J, Kawollek S et al (2019) Review on machine designs of material extrusion based additive manufacturing (AM) systems - status-Quo and potential analysis for future AM systems. Procedia CIRP 81:815–819. https://doi.org/10.1016/j.procir.2019.03.205

Anandkumar R, Babu SR (2019) FDM filaments with unique segmentation since evolution: a critical review. Prog Addit Manuf 4:185–193. https://doi.org/10.1007/s40964-018-0069-8

Mohan N, Senthil P, Vinodh S et al (2017) A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys Prototyp 12:47–59. https://doi.org/10.1080/17452759.2016.1274490

Leary M (2020) Chapter 4 - Detail DFAM. In: Leary M (ed) Additive manufacturing materials and technologies: design for additive manufacturing. Elsevier, Amsterdam , pp 91–122

Nieto DM, Molina SI (2019) Large-format fused deposition additive manufacturing: a review. Rapid Prototyp J 26:793–799. https://doi.org/10.1108/RPJ-05-2018-0126

Franchetti M, Kress C (2017) An economic analysis comparing the cost feasibility of replacing injection molding processes with emerging additive manufacturing techniques. Int J Adv Manuf Technol 88:2573–2579. https://doi.org/10.1007/s00170-016-8968-7

Davies S (2021) Stratasys to supply 3D printed parts to several additional aircraft families as Airbus renews contract. TCT Magazine. https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/stratasys-3d-printed-parts-several-airbus-aircraft-families. Accessed 18 Apr 2021

Mohamed OA, Masood SH, Bhowmik JL (2015) Optimization of fused deposition modeling process parameters. A review of current research and future prospects. Adv Manuf 3:42–53. https://doi.org/10.1007/s40436-014-0097-7

Rahim TNAT, Abdullah AM, Md Akil H (2019) Recent developments in fused deposition modeling-based 3D printing of polymers and their composites. Polym Rev 59:589–624. https://doi.org/10.1080/15583724.2019.1597883

ISO/ASTM DIS 52924 (2020) Additive manufacturing – Qualification principles – Classification of part properties for additive manufacturing of polymer parts

Chen RK, Lo TT, Chen L et al (2015) Nano-CT characterization of structural voids and air bubbles in fused deposition modeling for additive manufacturing. Proc ASME Int Manuf Sci Eng Conf. https://doi.org/10.1115/MSEC2015-9462

Turner BN, Strong R, A. Gold S, (2014) A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp J 20:192–204. https://doi.org/10.1108/RPJ-01-2013-0012

Bochmann L, Bayley C, Helu M et al (2015) Understanding error generation in fused deposition modeling. Surf Topogr Metrol Prop. https://doi.org/10.1088/2051-672X/3/1/014002

Hsiang Loh G, Pei E, Gonzalez-Gutierrez J et al (2020) An overview of material extrusion troubleshooting. Appl Sci 10:4776. https://doi.org/10.3390/app10144776

Turner BN, Gold SA (2015) A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp J 21:250–261. https://doi.org/10.1108/RPJ-02-2013-0017

Jafari MA, Han W, Mohammadi F et al (2000) A novel system for fused deposition of advanced multiple ceramics. Rapid Prototyp J 6:161–175. https://doi.org/10.1108/13552540010337047

Sood AK, Ohdar RK, Mahapatra SS (2012) Experimental investigation and empirical modelling of FDM process for compressive strength improvement. J Adv Res 3:81–90. https://doi.org/10.1016/j.jare.2011.05.001

Jagenteufel R, Hofstätter T, Kamleitner F et al (2017) Rheology of high melt strength polypropylene for additive manufacturing. Adv Mater Lett 8:712–716. https://doi.org/10.5185/amlett.2017.1450

Beran T, Mulholland T, Henning F et al (2018) Nozzle clogging factors during fused filament fabrication of spherical particle filled polymers. Addit Manuf 23:206–214. https://doi.org/10.1016/j.addma.2018.08.009

Grant MJ, Booth A (2009) A typology of reviews: an analysis of 14 review types and associated methodologies. Health Info Libr J 26:91–108. https://doi.org/10.1111/j.1471-1842.2009.00848.x

Booth A, Sutton A, Papaioannou D (2016) Systematic approaches to a successful literature review, 1st edn. Sage Publications, London

Sutjipto S, Tish D, Paul G et al (2019) Towards visual feedback loops for robot-controlled additive manufacturing. In: Willmann J, Block P, Hutter M et al (eds) Robotic Fabrication in Architecture, Art and Design 2018, vol 21. Springer, Cham, pp 85–97

MacDonald E, Burden E, Walker J et al (2017) Spatial frequency analysis for improved quality in big area additive manufacturing (BAAM). Proc ASME 2017 Int Mech Eng Congr Expo. https://doi.org/10.1115/IMECE2017-70630

Borish M, Post BK, Roschli A et al (2019) In-situ thermal imaging for single layer build time alteration in large-scale polymer additive manufacturing. Procedia Manuf 34:482–488. https://doi.org/10.1016/j.promfg.2019.06.202

Choo K, Friedrich B, Daugherty T et al (2019) Heat retention modeling of large area additive manufacturing. Addit Manuf 28:325–332. https://doi.org/10.1016/j.addma.2019.04.014

Borish M, Post BK, Roschli A et al (2019) Defect Identification and Mitigation Via Visual Inspection in Large-Scale Additive Manufacturing. JOM 71:893–899. https://doi.org/10.1007/s11837-018-3220-6

Borish M, Post BK, Roschli A et al (2020) Real-Time Defect Correction in Large-Scale Polymer Additive Manufacturing via Thermal Imaging and Laser Profilometer. Procedia Manuf 48:625–633. https://doi.org/10.1016/j.promfg.2020.05.091

Armstrong AA, Norato J, Alleyne AG et al (2020) Direct process feedback in extrusion-based 3D bioprinting. Biofabrication. https://doi.org/10.1088/1758-5090/ab4d97

Wasserfall F, Ahlers D, Hendrich N (2019) Optical in-situ verification of 3D-printed electronic circuits. IEEE 15th Int Conf Autom Sci and Eng (CASE). https://doi.org/10.1109/COASE.2019.8842835

Friedrich L, Begley M (2018) In situ characterization of low-viscosity direct ink writing: Stability, wetting, and rotational flows. J Colloid Interface Sci 529:599–609. https://doi.org/10.1016/j.jcis.2018.05.110

Friedrich L, Begley M (2019) In situ digital image analysis in direct ink writing. In: Seppala JE, Kotula AP, Snyder CR (eds) Polymer-Based Additive Manufacturing: Recent Developments, vol 1315. American Chemical Society, Washington, pp 131–149

Hardin JO, Grabowski CA, Lucas M et al (2019) All-printed multilayer high voltage capacitors with integrated processing feedback. Addit Manuf 27:327–333. https://doi.org/10.1016/j.addma.2019.02.011

DeBacker W, Sinkez P, Chhabra I et al (2020) In-process monitoring of continuous fiber additive manufacturing through force/torque sensing on the nozzle. AIAA SciTech Forum. https://doi.org/10.2514/6.2020-1632

Stockett RC, Tyler KL, Alfson BL et al (2018) Systems and methods for controlling additive manufacturing. US Patent 2018/0065307A1

Klar V, Pearce JM, Kärki P et al (2019) Ystruder: Open source multifunction extruder with sensing and monitoring capabilities. HardwareX. https://doi.org/10.1016/j.ohx.2019.e00080

Magnoni P, Rebaioli L, Fassi I et al (2017) Robotic AM System for Plastic Materials: Tuning and On-line Adjustment of Process Parameters. Procedia Manuf 11:346–354. https://doi.org/10.1016/j.promfg.2017.07.117

Rebaioli L, Magnoni P, Fassi I et al (2019) Process parameters tuning and online re-slicing for robotized additive manufacturing of big plastic objects. Robot Comput Integr Manuf 55:55–64. https://doi.org/10.1016/j.rcim.2018.07.012

Li F, Yu Z, Shen X et al (2019) Status recognition for fused deposition modeling manufactured parts based on acoustic emission. E3S Web Conf 95. https://doi.org/10.1051/e3sconf/20199501005

Nuchitprasitchai S, Roggemann M, Pearce JM (2017) Factors effecting real-time optical monitoring of fused filament 3D printing. Prog Addit Manuf 2:133–149. https://doi.org/10.1007/s40964-017-0027-x

Nuchitprasitchai S, Roggemann M, Pearce J (2017) Three hundred and sixty degree real-time monitoring of 3-D printing using computer analysis of two camera views. F Manuf Mater Process 1:2. https://doi.org/10.3390/jmmp1010002

He K, Yang Z, Bai Y et al (2018) Intelligent fault diagnosis of delta 3D printers using attitude sensors based on support vector machines. Sensors. https://doi.org/10.3390/s18041298

Zhang S, Sun Z, Long J et al (2019) Dynamic condition monitoring for 3D printers by using error fusion of multiple sparse auto-encoders. Comput Ind 105:164–176. https://doi.org/10.1016/j.compind.2018.12.004

Guo J, Wu J, Sun Z et al (2019) Fault diagnosis of delta 3D Printers Using Transfer Support Vector Machine With Attitude Signals. IEEE Access 7:40359–40368. https://doi.org/10.1109/ACCESS.2019.2905264

He K, Zeng L, Shui Q et al (2019) Low-cost and Small-sample Fault Diagnosis for 3D Printers Based on Echo State Networks. Progn Syst Health Manag Conf (PHM-Qingdao). https://doi.org/10.1109/PHM-Qingdao46334.2019.8942894

Zhang S, He K, Cabrera D et al (2019) Transmission condition monitoring of 3D printers based on the echo state network. Appl Sci 9:3058. https://doi.org/10.3390/app9153058

Li C, Cabrera D, Sancho F et al (2021) Fusing convolutional generative adversarial encoders for 3D printer fault detection with only normal condition signals. Mech Syst Signal Process. https://doi.org/10.1016/j.ymssp.2020.107108

Long J, Sun Z, Li C et al (2020) A novel sparse echo autoencoder network for data-driven fault diagnosis of delta 3-D printers. IEEE Trans Instrum Meas 69:683–692. https://doi.org/10.1109/TIM.2019.2905752

Long J, Zhang S, Li C (2020) Evolving Deep Echo State Networks for Intelligent Fault Diagnosis. IEEE Trans Ind Inform 16:4928–4937. https://doi.org/10.1109/tii.2019.2938884

Zhang S, Sun Z, Li C et al (2020) Deep hybrid state network with feature reinforcement for intelligent fault diagnosis of delta 3-D printers. IEEE Trans Ind Inform 16:779–789. https://doi.org/10.1109/TII.2019.2920661

Zhang S, Duan X, Li C et al (2021) Pre-classified reservoir computing for the fault diagnosis of 3D printers. Mech Syst Signal Process. https://doi.org/10.1016/j.ymssp.2020.106961

Yen C-T, Chuang P-C (2019) Application of a neural network integrated with the internet of things sensing technology for 3D printer fault diagnosis. Microsyst Technol. https://doi.org/10.1007/s00542-019-04323-4

Wang Y, Huang J, Wang Y et al (2020) A CNN-based Adaptive Surface Monitoring System for Fused Deposition Modeling. IEEE ASME Trans Mechatron. https://doi.org/10.1109/TMECH.2020.2996223

Kutzer MD, DeVries LD, Blas CD (2018) Part monitoring and quality assessment of conformal additive manufacturing using image reconstruction. Proc ASME 2018 Int Des Eng Tech Conf Comput Inf Eng Conf 5B. https://doi.org/10.1115/DETC2018-85370

Shen H, Sun W, Fu J (2019) Multi-view online vision detection based on robot fused deposit modeling 3D printing technology. Rapid Prototyp J 25:343–355. https://doi.org/10.1108/RPJ-03-2018-0052

Shen H, Du W, Sun W et al (2020) Visual detection of surface defects based on self-feature comparison in robot 3-D printing. Appl Sci. https://doi.org/10.3390/app10010235

Chen Z, Horowitz R (2019) Vision-assisted arm motion planning for freeform 3D Printing. 2019 Am Control Conf (ACC):4204–4209. https://doi.org/10.23919/ACC.2019.8814699

Jin Z, Zhang Z, Gu GX (2020) Automated real-time detection and prediction of interlayer imperfections in additive manufacturing processes using artificial intelligence. Adv Intell Syst. https://doi.org/10.1002/aisy.201900130

Jeong H, Kim M, Park B et al (2017) Vision-Based Real-Time Layer Error Quantification for Additive Manufacturing. Proc ASME 2017 12th Int Manuf Sci Eng Conf. https://doi.org/10.1115/MSEC2017-2991

Prakash SKA, Mahan T, Williams G et al (2020) Detection of System Compromise in Additive Manufacturing Using Video Motion Magnification. J Mech Des. https://doi.org/10.1115/1.4045547

Makagonov NG, Blinova EM, Bezukladnikov II (2017) Development of visual inspection systems for 3D printing. 2017 IEEE Conf Russ Young Res Electr Electron Eng (EIConRus):1463–1465. https://doi.org/10.1109/EIConRus.2017.7910849

Narayanan BN, Beigh K, Loughnane G et al (2019) Support vector machine and convolutional neural network based approaches for defect detection in fused filament fabrication. Proc SPIE: Appl Mach Learn. https://doi.org/10.1117/12.2524915

Zhang Z, Fidan I (2019) Failure detection of fused filament fabrication via deep learning. Proc 30th Annu Int Solid Free Fabr Symp:2156–2164

Kim C, Hillstrom A, Coronel J et al (2018) Design of air cooling housing for image sensors using additive manufacturing technology. 2018 Int Conf Inf Commun Technol Robot (ICT-ROBOT):1–4. https://doi.org/10.1109/ICT-ROBOT.2018.8549891

Preissler M, Zhang C, Rosenberger M et al (2017) Platform for 3D inline process control in additive manufacturing. Proc SPIE Opt Meas Syst Ind Insp X. https://doi.org/10.1117/12.2270493

Malik A, Lhachemi H, Ploennigs J et al (2019) An application of 3D model reconstruction and augmented reality for real-time monitoring of additive manufacturing. Procedia CIRP 81:346–351. https://doi.org/10.1016/j.procir.2019.03.060

Straub J (2017) 3D printing cybersecurity: Detecting and preventing attacks that seek to weaken a printed object by changing fill level. Proc SPIE Dimens Opt Metrol Insp Pract Appl VI. https://doi.org/10.1117/12.2264575

Straub J (2017) Identifying positioning-based attacks against 3D printed objects and the 3D printing process. Proc SPIE Pattern Recognit Track XXVIII. https://doi.org/10.1117/12.2264671

Wu M, Phoha VV, Moon YB et al (2016) Detecting malicious defects in 3D printing process using machine learning and image classification. Proc ASME 2016 Int Mech Eng Congre Expo. https://doi.org/10.1115/IMECE2016-67641

Wu M, Song Z, Moon YB (2019) Detecting cyber-physical attacks in CyberManufacturing systems with machine learning methods. J Intell Manuf 30:1111–1123. https://doi.org/10.1007/s10845-017-1315-5

Wu M, Moon YB (2020) Alert correlation for detecting cyber-manufacturing attacks and intrusions. J Comput Inf Sci Eng. https://doi.org/10.1115/1.4044208

Hurd S, Camp C, White J (2015) Quality assurance in additive manufacturing through mobile computing. Int Conf Mob Comput Appl Serv:203–220. https://doi.org/10.1007/978-3-319-29003-4_12

Wu M, Song J, Lucas Lin LW et al (2018) Establishment of intrusion detection testbed for CyberManufacturing systems. Procedia Manuf 26:1053–1064. https://doi.org/10.1016/j.promfg.2018.07.142

Wang S, Huang T, Hou T (2017) Statistical Process Control in Fused Deposition Modeling based on Tanimoto similarity of uniform surface images of product. 2017 2nd Int Conf Reliab Syst Eng (ICRSE). https://doi.org/10.1109/ICRSE.2017.8030806

Huang T, Wang S, Yang S et al (2020) Statistical process monitoring in a specified period for the image data of fused deposition modeling parts with consistent layers. J Intell Manuf. https://doi.org/10.1007/s10845-020-01628-4

Cho G, Asano H, Kon M (2019) Object-forming machine, cross-section measurement apparatus, and cross-section measurement method. US Patent 10618220B2

Jin Z, Zhang Z, Gu GX (2019) Autonomous in-situ correction of fused deposition modeling printers using computer vision and deep learning. Manuf Lett 22:11–15. https://doi.org/10.1016/j.mfglet.2019.09.005

Baumann F, Roller D (2016) Vision based error detection for 3D printing processes. MATEC Web Conf. https://doi.org/10.1051/matecconf/20165906003

Trinks S, Felden C (2019) Image mining for real time fault detection within the smart factory. 2019 IEEE 21st Conf Bus Inform (CBI):584–593. https://doi.org/10.1109/cbi.2019.00074

Trinks S, Felden C (2019) Image mining for real time quality assurance in rapid prototyping. 2019 IEEE Int Conf Big Data:3529–3534. https://doi.org/10.1109/BigData47090.2019.9005514

Wang Y, Lin Y, Zhong RY et al (2019) IoT-enabled cloud-based additive manufacturing platform to support rapid product development. Int J Prod Res 57:3975–3991. https://doi.org/10.1080/00207543.2018.1516905

Capri S, Asbury RC (2019) Image-based monitoring and feedback system for three-dimensional printing. US Patent 10265911B1

Chen P-Y, Lin W-T (2015) Three dimensional printing apparatus and method for detecting printing anomaly. US Patent 9632037B2

Straub J (2015) Initial work on the characterization of additive manufacturing (3D Printing) using software image Analysis. Machines 3:55–71. https://doi.org/10.3390/machines3020055

Straub J (2015) Characterization of 3D printing output using an optical sensing system. Proc SPIE Dimens Opt Metrol Insp Pract Appl IV. https://doi.org/10.1117/12.2177647

Straub J (2016) Alignment issues, correlation techniques and their assessment for a visible light imaging-based 3D printer quality control system. Proc SPIE Image Sens Technol Mater Devices Syst Appl III:9854. https://doi.org/10.1117/12.2228081

Straub J (2016) Automated testing and quality assurance of 3d printing / 3D printed hardware: assessment for quality assurance and cybersecurity purposes. 2016 IEEE AUTOTESTCON. https://doi.org/10.1109/AUTEST.2016.7589613

Straub J (2016) Characterization of internal geometry / covered surface defects with a visible light sensing system. Proc SPIE Image Sens Technol Mater Devices Syst Appl III:9854. https://doi.org/10.1117/12.2227802

Straub J (2017) An approach to detecting deliberately introduced defects and micro-defects in 3D printed objects. Proc SPIE: Dimens Opt Metrol Insp Pract Appl VI. https://doi.org/10.1117/12.2264588

Straub J (2017) A combined system for 3D printing cybersecurity. Proc SPIE Dimens Opt Metrol Insp Pract Appl VI. https://doi.org/10.1117/12.2264583

Straub J (2017) Physical security and cyber security issues and human error prevention for 3D printed objects: Detecting the use of an incorrect printing material. Proc SPIE Dimens Opt Metrol Insp Pract Appl VI. https://doi.org/10.1117/12.2264578

Ceruti A, Liverani A, Bombardi T (2017) Augmented vision and interactive monitoring in 3D printing process. Int J Interact Des Manuf 11:385–395. https://doi.org/10.1007/s12008-016-0347-y

Lyngby RA, Wilm J, Eiríksson ER et al (2017) In-line 3D print failure detection using computer vision. Joint Special Interest Group meeting between euspen and ASPE: Dimensional Accuracy and Surface Finish in Additive Manufacturing

Johnson A, Zarezadeh H, Han X et al (2016) Establishing in-process inspection requirements for material extrusion additive manufacturing. Fraunhofer Direct Digit Manuf Conf

Oleff A, Küster B, Stonis M et al (2020) Optische Qualitätsprüfung für die additive Materialextrusion. ZWF 115:52–56. https://doi.org/10.3139/104.112228

He K, Zhang Q, Hong Y (2019) Profile monitoring based quality control method for fused deposition modeling process. J Intell Manuf 30:947–958. https://doi.org/10.1007/s10845-018-1424-9

Wu Y, He K, Zhou X et al (2017) Machine Vision based Statistical Process Control in Fused Deposition Modeling. 2017 12th IEEE Conf Ind Electron Appl (ICIEA):936–941. https://doi.org/10.1109/ICIEA.2017.8282973

Wu Y, He K, Hu H et al (2019) Process Monitoring of Fused Deposition Modeling through Profile Control. 2018 IEEE Int Conf Cyborg Bionic Syst (CBS):936–941. https://doi.org/10.1109/CBS.2018.8612192

Delli U, Chang S (2018) Automated Process Monitoring in 3D Printing Using Supervised Machine Learning. Procedia Manuf 26:865–870. https://doi.org/10.1016/j.promfg.2018.07.111

Engle J, Nguyen R, Buah K et al (2019) Reducing computer visualization errors for in-process monitoring of additive manufacturing systems using smart lighting and colorization system. Proc 30th Annu Int Solid Free Fabr Symp:1482–1496

Peek GA (2016) Printer monitoring. US Patent 9514397B2

Perez AA, Haid CM, Doll MP et al (2018) Automatic process control of additive manufacturing device. US Patent 10427348B2

Cheverton MA, Allen Nafis C, Tait RW et al (2015) Operational performance assessment of additive manufacturing. US Patent 9724876B2

Fastowicz J, Bąk D, Mazurek P et al (2018) Estimation of geometrical deformations of 3D prints using local cross-correlation and Monte Carlo Sampling. In: Choraś M, Choraś RS (eds) Image Processing and Communications Challenges 9, vol 681. Springer, Cham, pp 67–74

Fastowicz J, Bąk D, Mazurek P et al (2018) Quality assessment of 3D Printed surfaces in Fourier Domain. In: Choraś M, Choraś RS (eds) Image Processing and Communications Challenges 9, vol 681. Springer, Cham, pp 75–81

Fastowicz J, Okarma K (2016) Texture based quality assessment of 3D prints for different lighting conditions. In: Chmielewski LJ, Datta A, Kozera R et al (eds) Computer Vision and Graphics, vol 9972. Springer, Cham, pp 17–28

Fastowicz J, Okarma K (2017) Entropy based surface quality assessment of 3D Prints. In: Silhavy R, Senkerik R, Kominkova Oplatkova Z et al (eds) Artificial Intelligence Trends in Intelligent Systems. Springer, Cham, pp 404–413

Fastowicz J, Okarma K (2018) Fast quality assessment of 3D printed surfaces based on structural similarity of image regions. 2018 Int Interdiscip PhD Workshop (IIPhDW):401–406. https://doi.org/10.1109/IIPHDW.2018.8388399

Fastowicz J, Okarma K (2019) Automatic colour independent quality evaluation of 3D printed flat surfaces based on CLAHE and Hough Transform. In: Choraś M, Choraś RS (eds) Image Processing and Communications Challenges 10, vol 892. Springer, Cham, pp 123–131

Lech P, Fastowicz J, Okarma K (2018) Quality evaluation of 3D printed surfaces based on HOG features. In: Chmielewski LJ, Kozera R, Orłowski A et al (eds) Computer Vision and Graphics. Springer, Cham, pp 199–208

Okarma K, Fastowicz J (2016) No-reference quality assessment of 3D prints based on the GLCM analysis. 2016 21st Int Conf Methods Model Autom Robot:788–793. https://doi.org/10.1109/MMAR.2016.7575237

Okarma K, Fastowicz J (2017) Quality assessment of 3D prints based on feature similarity metrics. In: Choraś RS (ed) Image Processing and Communications Challenges 8. Springer, Cham, pp 104–111

Fastowicz J, Okarma K (2019) Quality Assessment of Photographed 3D printed flat surfaces using Hough transform and histogram equalization. J Univers Comput Sci 25:707–717. https://doi.org/10.3217/jucs-025-06-0701

Okarma K, Fastowicz J (2018) Color Independent Quality Assessment of 3D Printed Surfaces Based on Image Entropy. Proc 2017 10th Int Conf Comput Recognit Syst (CORES):308–315. https://doi.org/10.1007/978-3-319-59162-9

Okarma K, Fastowicz J (2019) Adaptation of full-reference image quality assessment methods for automatic visual evaluation of the surface quality of 3D Prints. Elektron ir Elektrotechnika 25:57–62. https://doi.org/10.5755/j01.eie.25.5.24357

Okarma K, Fastowicz J (2020) Computer vision methods for non-destructive quality assessment in additive manufacturing. In: Burduk R, Kurzynski M, Wozniak M (eds) Progress in Computer Recognition Systems, vol 977. Springer, Cham, pp 11–20

Okarma K, Fastowicz J (2020) Improved quality assessment of colour surfaces for additive manufacturing based on image entropy. Pattern Anal Appl 23:1035–1047. https://doi.org/10.1007/s10044-020-00865-w

Okarma K, Fastowicz J, Tecław M (2016) Application of structural similarity based metrics for quality assessment of 3D prints. In: Chmielewski LJ, Datta A, Kozera R et al (eds) Computer Vision and Graphics. Springer, pp 244–252

Fastowicz J, Grudziński M, Tecław M et al (2019) Objective 3D printed surface quality assessment based on entropy of depth maps. Entropy. https://doi.org/10.3390/e21010097

Fastowicz J, Lech P, Okarma K (2020) Combined metrics for quality assessment of 3D printed surfaces for aesthetic purposes: Towards Higher Accordance with Subjective Evaluations. In: Krzhizhanovskaya VV, Závodszky G, Lees MH et al (eds) Computational Science – ICCS 2020: Lecture Notes in Computer Science, vol 12143. Springer, Cham, pp 326–339

Blanco D, Fernandez P, Noriega A et al (2020) Layer contour verification in additive manufacturing by means of commercial flatbed scanners. Sensors. https://doi.org/10.3390/s20010001

Greeff GP, Schilling M (2017) Closed loop control of slippage during filament transport in molten material extrusion. Addit Manuf 14:31–38. https://doi.org/10.1016/j.addma.2016.12.005

Greeff GP, Schilling M (2017) Comparing retraction methods with volumetric exit flow measurement in molten material extrusion. Joint Special Interest Group meeting between euspen and ASPE: Dimensional Accuracy and Surface Finish in Additive Manufacturing:70–74

Basile V, Modica F, Fontana G et al (2020) Improvements in accuracy of fused deposition modeling via integration of low-cost on-board vision systems. J Micro Nanomanuf. https://doi.org/10.1115/1.4046038

Liu C, Law ACC, Roberson D et al (2019) Image analysis-based closed loop quality control for additive manufacturing with fused filament fabrication. J Manuf Syst 51:75–86. https://doi.org/10.1016/j.jmsy.2019.04.002

Liu C, Roberson D, Kong Z (2017) Textural analysis-based online closed-loop quality control for additive manufacturing processes. Proc 2017 Ind Syst Eng Conf:1127–1132

Liu C (2019) Smart additive manufacturing using advanced data analytics and closed loop control. Dissertation, Virginia Polytechnic Institute and State University

Batchelder JS, Bosveld MS (2014) Encoded consumable materials and sensor assemblies for use in additive manufacturing systems. US Patent 9855679B2

Li N, Link G, Jelonnek J (2020) 3D microwave printing temperature control of continuous carbon fiber reinforced composites. Compos Sci Technol. https://doi.org/10.1016/j.compscitech.2019.107939

Malekipour E, Attoye S, El-Mounayri H (2018) Investigation of layer based thermal behavior in fused deposition modeling process by infrared thermography. Procedia Manuf 26:1014–1022. https://doi.org/10.1016/j.promfg.2018.07.133

Lu Y, Wang Y (2018) Monitoring temperature in additive manufacturing with physics-based compressive sensing. J Manuf Syst 48:60–70. https://doi.org/10.1016/j.jmsy.2018.05.010

Lu Y, Wang Y (2019) An improvement of physics based compressive sensing with domain decomposition to monitor temperature in fused filament fabrication process. Proc ASME 2019 14th Int Manuf Sci Eng Conf. https://doi.org/10.1115/MSEC2019-2899

Lu Y, Wang Y (2019) An efficient transient temperature monitoring of fused filament fabrication process with physics-based compressive sensing. IISE Trans 51:168–180. https://doi.org/10.1080/24725854.2018.1499054

He K, Wang H, Hu H (2018) Approach to online defect monitoring in fused deposition modeling based on the variation of the temperature field. Complexity. https://doi.org/10.1155/2018/3426928

Hu H, He K, Zhong T et al (2019) Fault diagnosis of FDM process based on support vector machine (SVM). Rapid Prototyp J 26:330–248. https://doi.org/10.1108/RPJ-05-2019-0121

Ferraris E, Zhang J, van Hooreweder B (2019) Thermography based in-process monitoring of Fused Filament Fabrication of polymeric parts. CIRP Ann Manuf Technol 68:213–216. https://doi.org/10.1016/j.cirp.2019.04.123

Pooladvand K, Salerni AD, Furlong C (2019) In-situ thermal monitoring of printed components during rapid prototyping by fused deposition modeling. Proc 2019 Annu Conf Exp Appl Mech 95:131–140. https://doi.org/10.1007/978-3-030-30098-2_20

Bartolai J, Simon TR, Xie R (2016) Predicting strength of thermoplastic polymer parts produced using additive manufacturing. Proc 27th Annu Int Solid Free Fabr Symp:951–963

Bartolai J, Simpson TW, Xie R (2018) Predicting strength of additively manufactured thermoplastic polymer parts produced using material extrusion. Rapid Prototyp J 24:321–332. https://doi.org/10.1108/RPJ-02-2017-0026

Hsu S-H, Chen W-Y (2018) System and method for detecting printing filament for three dimensional printing. US Patent 10042350B2

Pollard D, Ward C, Herrmann G et al (2017) Filament Temperature Dynamics in Fused Deposition Modelling and Outlook for Control. Procedia Manuf 11:536–544. https://doi.org/10.1016/j.promfg.2017.07.147

Pollard D (2019) Improved thermal control and mechanical property evaluation for multi-dimensional fused filament fabrication of sandwich cores. Dissertation, University of Bristol

Müller M, Wings E (2016) An architecture for hybrid manufacturing combining 3D printing and CNC machining. Int J Manuf Mater Mech Eng. https://doi.org/10.1155/2016/8609108