Abstract

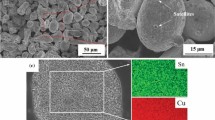

Semi-solid rheological squeeze forming has distinct advantages over traditional casting and forming techniques. In this study, a high-performance thin-walled CuSn10P1 alloy was successfully produced by combining liquid-metal instantaneous undercooling-induced nucleation, semi-solid slurry homogenization treatment, and semi-solid rheological squeeze forming. The effects of the forming specific pressure (MPa) and filling speed (mm/s) on the microstructure and mechanical properties of these parts were explored in this study, and the influence of the intergranular brittle phase (α-Cu + δ-Cu41Sn11 + Cu3P) content on the mechanical characteristics was determined. CuSn10P1 alloy with a Cu13.7Sn phase exhibiting a large number of spherical or nearly spherical morphological features coexisting with the high-tin solid-solution layer morphology was discovered and prepared at a mold temperature of 485 °C, specific pressure of 165 MPa, and filling speed of 22 mm/s. Parts with this microstructure had excellent mechanical properties, including an ultimate tensile strength of 419.95 MPa, yield strength of 228.89 MPa, and an elongation of 13.71%. This study illustrates the viability of semi-solid rheological squeeze casting for manufacturing high-performance thin-walled high-tin copper alloys.

Similar content being viewed by others

References

J.S. Park, C.W. Park, K.J. Lee, Implication of peritectic composition in historical high-tin bronze metallurgy. Mater. Charact. 60, 1268–1275 (2009). https://doi.org/10.1016/j.matchar.2009.05.009

S. Jie, M. Ting-yun, Q. Hui-xuan, L. Qi-song, Electrochemical behaviors and electrodeposition of single-phase Cu–Sn alloy coating in [BMIM]Cl. Electrochim. Acta 297, 87–93 (2019). https://doi.org/10.1016/j.electacta.2018.11.189

Y. Liu, L. Wang, K. Jiang, S. Yang, Electro-deposition preparation of self-standing Cu–Sn alloy anode electrode for lithium ion battery. J. Alloys Compd. 775, 818–825 (2019). https://doi.org/10.1016/j.jallcom.2018.10.207

J.B. Singh, W. Cai, P. Bellon, Dry sliding of Cu–15 wt%Ni–8 wt%Sn bronze: wear behaviour and microstructures. Wear 263, 830–841 (2007). https://doi.org/10.1016/j.wear.2007.01.061

S.M. So, K.Y. Kim, S.J. Lee, Y.J. Yu, H.A. Lim, M.S. Oh, Effects of Sn content and hot deformation on microstructure and mechanical properties of binary high Sn content Cu–Sn alloys. Mater. Sci. Eng. A (2020). https://doi.org/10.1016/j.msea.2020.140054

M.C. Flemings, Behavior of metal alloys in the semisolid state. Metall. Trans. A 22, 957–981 (1991). https://doi.org/10.1007/BF02661090

A. Rassili, M. Robelet, R. Bigot, Thixoforming of steel: parameters and means for industrialization. Solid State Phenom. 141, 213–218 (2008). https://doi.org/10.4028/www.scientific.net/SSP.141-143.213

K.N. Campo, C.C. de Freitas, S.-C. Moon, R. Dippenaar, R. Caram, In-situ microstructural observation of Ti–Cu alloys for semi-solid processing. Mater. Charact. 145, 10–19 (2018). https://doi.org/10.1016/j.matchar.2018.08.016

M. Kiuchi, R. Kopp, Mushy/semi-solid metal forming technology—present and future. CIRP Ann. 51, 653–670 (2002). https://doi.org/10.1016/s0007-8506(07)61705-3

J. Mathew, A. Mandal, S.D. Kumar, S. Bajpai, M. Chakraborty, G.D. West, P. Srirangam, Effect of semi-solid forging on microstructure and mechanical properties of in-situ cast Al–Cu–TiB2 composites. J. Alloys Compd. 712, 460–467 (2017). https://doi.org/10.1016/j.jallcom.2017.04.113

M.R. Rokni, A. Zarei-Hanzaki, H.R. Abedi, N. Haghdadi, Microstructure evolution and mechanical properties of backward thixoextruded 7075 aluminum alloy. Mater. Des. 1980–2015(36), 557–563 (2012). https://doi.org/10.1016/j.matdes.2011.11.061

H.R. Abedi, A. Zarei-Hanzaki, S.M. Fatemi-Varzaneh, A.A. Roostaei, The semi-solid tensile deformation behavior of wrought AZ31 magnesium alloy. Mater. Des. 31, 4386–4391 (2010). https://doi.org/10.1016/j.matdes.2010.05.004

S. Lü, S. Wu, X. Yang, L. Hao, W. Guo, X. Fang, Microstructure and mechanical properties of Mg97Zn1Y2 alloy reinforced with LPSO structure produced by semisolid squeeze casting. Mater. Sci. Eng. A 732, 359–367 (2018). https://doi.org/10.1016/j.msea.2018.07.025

Q.Y. Pan, S. Wiesner, D. Apelian, Application of the continuous rheoconversion process (CRP) to low temperature HPDC-part I: microstructure. Solid State Phenom. 116, 402–405 (2006). https://doi.org/10.4028/www.scientific.net/SSP.116-117.402

Q. Pan, M. Findon, D. Apelian, The continuous rheoconversion process (CRP): a novel SSM approach. In: 8th International Conference on Semi-Solid Processing of Alloys and Composites (2004).

G. Xiao, J. Jiang, Y. Wang, Y. Liu, Y. Zhang, Microstructure and mechanical properties of nickel-based superalloy GH4037 parts formed by thixoforming. Mater. Sci. Eng. A (2020). https://doi.org/10.1016/j.msea.2020.139196

Y. Meng, S. Sugiyama, J. Yanagimoto, Microstructural evolution during RAP process and deformation behavior of semi-solid SKD61 tool steel. J. Mater. Process. Technol. 212, 1731–1741 (2012). https://doi.org/10.1016/j.jmatprotec.2012.04.003

Y. Meng, S. Sugiyama, M. Soltanpour, J. Yanagimoto, Effects of predeformation and semi-solid processing on microstructure and mechanical properties of Cr–V–Mo steel. J. Mater. Process. Technol. 213, 426–433 (2013). https://doi.org/10.1016/j.jmatprotec.2012.09.021

J. Jiang, G. Xiao, Y. Wang, Y. Qi, Microstructure evolution of wrought nickel based superalloy GH4037 in the semi-solid state. Mater. Charact. 141, 229–237 (2018). https://doi.org/10.1016/j.matchar.2018.04.057

M. Cao, Z. Wang, Q. Zhang, Microstructure-dependent mechanical properties of semi-solid copper alloys. J. Alloys Compd. 715, 413–420 (2017). https://doi.org/10.1016/j.jallcom.2017.03.360

L. Jia, X. Lin, H. Xie, Z.-L. Lu, X. Wang, Abnormal improvement on electrical conductivity of Cu–Ni–Si alloys resulting from semi-solid isothermal treatment. Mater. Lett. 77, 107–109 (2012). https://doi.org/10.1016/j.matlet.2012.03.010

G. Xiao, J. Jiang, Y. Wang, Y. Liu, Y. Zhang, Effects of forming temperature, soaking time and dwell time on the microstructure and mechanical properties of thixoformed nickel-based superalloy parts. J. Mater. Res. Technol. JMRT 10, 1250–1261 (2021). https://doi.org/10.1016/j.jmrt.2020.12.111

Z.F. Huang, J.D. Xing, C. Guo, Microstructure and properties of semisolid hypereutectic high chromium cast iron prepared by slope cooling body method. Ironmak. Steelmak. 37, 607–611 (2013). https://doi.org/10.1179/030192309x12549935902266

S. Scudino, C. Unterdörfer, K.G. Prashanth, H. Attar, N. Ellendt, V. Uhlenwinkel, J. Eckert, Additive manufacturing of Cu–10Sn bronze. Mater. Lett. 156, 202–204 (2015). https://doi.org/10.1016/j.matlet.2015.05.076

P. Han, F. Xiao, W. Zou, B. Liao, Influence of hot pressing temperature on the microstructure and mechanical properties of 75% Cu–25% Sn alloy. Mater. Des. 53, 38–42 (2014). https://doi.org/10.1016/j.matdes.2013.06.024

Z. Mao, D.Z. Zhang, J. Jiang, G. Fu, P. Zhang, Processing optimisation, mechanical properties and microstructural evolution during selective laser melting of Cu–15Sn high-tin bronze. Mater. Sci. Eng. A 721, 125–134 (2018). https://doi.org/10.1016/j.msea.2018.02.051

E. Erzi, M. Tiryakioğlu, Feeding distance of tin bronze castings: intrinsic and extrinsic estimates. Mater. Sci. Technol. 35, 2211–2216 (2019). https://doi.org/10.1080/02670836.2019.1666226

X. Liu, J. Luo, X. Wang, L. Wang, J. Xie, Columnar grains-covered small grains Cu–Sn alloy prepared by two-phase zone continuous casting. Prog. Nat. Sci. Mater. Int. 23, 94–101 (2013). https://doi.org/10.1016/j.pnsc.2013.01.014

A.P. Ventura, C.A. Wade, G. Pawlikowski, M. Bayes, M. Watanabe, W.Z. Misiolek, Mechanical properties and microstructural characterization of Cu-4.3 Pct Sn fabricated by selective laser melting. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 48, 178–187 (2016). https://doi.org/10.1007/s11661-016-3779-x

J.Y. Yang, G.H. Kim, W.J. Kim, High-strain-rate solute drag creep in a Cu-22%Sn alloy (Cu17Sn3) with near peritectic composition. Mater. Charact. (2020). https://doi.org/10.1016/j.matchar.2020.110325

B.B. Straumal, A.R. Kilmametov, B. Baretzky, O.A. Kogtenkova, P.B. Straumal, L. Lityńska-Dobrzyńska, R. Chulist, A. Korneva, P. Zięba, High pressure torsion of Cu–Ag and Cu–Sn alloys: limits for solubility and dissolution. Acta Mater. 195, 184–198 (2020). https://doi.org/10.1016/j.actamat.2020.05.055

Y. Li, L. Li, B. Geng, Q. Wang, R. Zhou, X. Wu, H. Xiao, Microstructure characteristics and strengthening mechanism of semisolid CuSn10P1 alloys. Mater. Charact. (2021). https://doi.org/10.1016/j.matchar.2021.110898

Z. He, R. Zhou, Y. Li, T. Liu, W. Xiong, Z. Liu, C. Wang, H. Xiao, Effect of wall thickness on microstructure uniformity and properties of CuSn10P1 alloy in semi-solid rheological squeeze casting. Rare Metal Mat. Eng. 51, 4157–4165 (2022)

Z. Liu, R. Zhou, W. Xiong, Z. He, T. Liu, Y. Li, Compressive rheological behavior and microstructure evolution of a semi-solid CuSn10P1 alloy at medium temperature and low strain. Metals (2022). https://doi.org/10.3390/met12010143

W. Xiong, R. Zhou, Z. Liu, Y. Li, Research on neural network genetic algorithm optimization in the preparation of CuSn10P1 semi-solid slurry with the fully enclosed melt-constrained cooling inclined plate. J. Adv. Mech. Des. Syst. Manuf. (2021). https://doi.org/10.1299/jamdsm.2021jamdsm0026

Q. Wang, R. Zhou, Y. Li, B. Geng, Characteristics of dynamic recrystallization in semi-solid CuSn10P1 alloy during hot deformation. Mater. Charact. (2020). https://doi.org/10.1016/j.matchar.2019.109996

Y. Zhou, Y. Cui, Q. Zhang, Z. Yang, Y. Li, H. Xiao, Effect of solution temperature on microstructure and properties of thixotropic back-extruded tin-bronze shaft sleeve. Materials (Basel) (2022). https://doi.org/10.3390/ma15155254

P. Das, P. Dutta, Phase field modelling of microstructure evolution and ripening driven grain growth during cooling slope processing of A356 Al alloy. Comput. Mater. Sci. 125, 8–19 (2016). https://doi.org/10.1016/j.commatsci.2016.08.022

V. Chakkravarthy, M. Lakshmanan, P. Manojkumar, R. Prabhakaran, Crystallographic orientation and wear characteristics of TiN, SiC, Nb embedded Al7075 composite. Mater. Lett. (2022). https://doi.org/10.1016/j.matlet.2021.130936

C. Wang, Z. Dong, K. Li, M. Sun, J. Wu, K. Wang, G. Wu, W. Ding, A novel process for grain refinement of Mg–RE alloys by low frequency electro-magnetic stirring assisted near-liquidus squeeze casting. J. Mater. Process. Technol. (2022). https://doi.org/10.1016/j.jmatprotec.2022.117537

Y. Yang, P. Tan, Y. Sui, Y. Jiang, R. Zhou, Influence of Zr content on microstructure and mechanical properties of As-cast Al–Zn–Mg–Cu alloy. J. Alloys Compd. (2021). https://doi.org/10.1016/j.jallcom.2021.158920

D.V. Kudashov, H. Baum, U. Martin, M. Heilmaier, H. Oettel, Microstructure and room temperature hardening of ultra-fine-grained oxide-dispersion strengthened copper prepared by cryomilling. Mater. Sci. Eng. A 387–389, 768–771 (2004). https://doi.org/10.1016/j.msea.2004.05.049

H. Xiao, Z. Duan, N. Li, Y. Li, R. Zhou, D. Lu, Y. Jiang, Mechanical properties of thixo-extruded copper alloy. Rare Metal Mat. Eng. 48, 531–537 (2019)

A.E. Nassef, A.I. Alateyah, M.A. El-Hadek, W.H. El-Garaihy, Mechanical behavior and fracture surface characterization of liquid-phase sintered Cu–Sn powder alloys. Adv. Mater. Lett. 8, 717–722 (2017). https://doi.org/10.5185/amlett.2017.1485

H. Xiao, Y. Cui, C. Xiong, L. Chen, X. Zhang, Y. Li, R. Zhou, Effect of annealing temperature on microstructure and properties of thixo-extruded tin bronze bushing. Rare Metal Mat. Eng. 50, 4119–4127 (2021)

H. Xiao, Z. Duan, N. Li, C. Xiong, R. Zhou, D. Lu, Y. Jiang, Effect of heat treatment temperature on microstructure and mechanical properties of semi-solid extruded tin bronze. Rare Metal Mat. Eng. 48, 235–241 (2019)

Funding

This research was supported by the Natural Science Foundation of China (Grant No. 51765026) and Analysis and Testing Fund of Kunming University of Science and Technology (Grant No. 2021P20201130019)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xiong, W., Zhou, R., Liu, Z. et al. Effects of Forming Specific Pressure and Filling Speed on Microstructure and Mechanical Properties of Thin-Walled CuSn10P1 Alloy Parts by Rheological Squeeze Forming. Inter Metalcast 18, 1438–1454 (2024). https://doi.org/10.1007/s40962-023-01109-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01109-3