Abstract

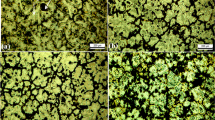

In this study, to improve the creep property of 6016 aluminum alloys, in-situ ZrB2 and Al2O3 nanoparticles were introduced by the direct melt reaction method. The microstructures and creep behaviors of the in-situ (ZrB2+Al2O3)/AA6016 composites were studied. A clean and tightly bound interface between the particles and matrix is observed. The relationships between Al2O3 and ZrB2 nanoparticles with α -Al are the coherent and semi-coherent relationships, respectively. In comparison with the matrix alloys, the composites exhibit lower steady creep rates, about 3–18 times lower, and higher threshold stress. For the matrix alloys and composites, the dislocation climb mechanism is indicated by the true stress exponent of 5. After the creep test at 200 °C/70 MPa, the grain size in the 3 vol. % composite is about 68 µm, which is smaller than that in matrix alloy (156 µm). After the creep test at 200 °C/70 MPa, the diameters of the θ′ and β phases in the matrix alloy are 26 nm and 201 nm, and the fabricated 3 vol. % composite shows smaller diameters (17 nm and 168 nm) and higher density.

Similar content being viewed by others

References

X. Kai, C. Chen, X. Sun, C. Wang, Y. Zhao, Mater. Des. 90, 1151–1158 (2016)

B. Li, Q. Pan, C. Chen, H. Wu, Z. Yin, J. Alloys Compd. 664, 553–564 (2016)

Y. Gao, P. Guan, R. Su, H.W. Chen, C. Yang, C. He, L. Cao, H. Song, J.Y. Zhang, X.F. Zhang, G. Liu, J. Nie, J. Sun, E. Ma, Mater. Res. Lett. 8, 446–453 (2020)

S. Tjong, Z. Ma, Compos. Sci. Technol. 59, 1117–1125 (1999)

X. Kai, S. Huang, L. W, R. Tao, Y. Peng, Z. Mao, F. Chen, G. Li, G. Chen, Y. Zhao, J. Mater. Sci. Tech. 35, 2107–2114 (2019).

Z. Liu, M. Rakita, W. Xu, X. Wang, Q. Han, Chem. Eng. J. 263, 317–324 (2015)

A. Gnanavelbabu , K.T.S. Surendran, S. Kumar, Inter. Metalcast. 16, 759–782 (2022). https://doi.org/10.1007/s40962-021-00634-3

Z. Xu, Y. Zhao, X. Kai, C. Miao, R. Cao, Mater. Lett. 316, 132021 (2022)

L. Zhang, D. Yang, F. Qiu, J. Wang, Q. Jiang, Mater. Sci. Eng. A. 624, 102–109 (2015)

C. Guan, Y. Zhao, G. Chen, X. Kai, W. Qian, R. Tao, L. Huang, X. Ga, L. Jin, Mater. Sci. Eng. A. 822, 141661 (2021)

W. Tian, Q. Zhao, R. Geng, F. Qiu, Q. Jiang, Mater. Sci. Eng. A. 713, 190–194 (2018)

J. David Raja Selvam, I. Dinaharan, S. Vibin Philip, P.M. Mashinini, J. Alloys Compd. 740, 529–535 (2018).

L. Huang, Y. Zhao, X. Kai, C. Guan, X. Gao, P. Zhao, T. Wang, Mater. Charac. 193, 112296 (2022)

C. Xia, Y. Zhao, F. Chen, X. Kai, R. Tao, Z. Fang, Y. Sun, Mater. Res. Express. 7, 066501 (2020)

S.M. Dar, Y. Zhao, X. Kai, C. Guan, Z. Xu, Inter. Metalcast. 16, 2162–2174 (2022). https://doi.org/10.1007/s40962-021-00736-y

Y. Birol, J. Alloys Compd. 458, 271–276 (2008)

M. Huang, X. Li, H. Yi, N. Ma, H. Wang, J. Alloy. Compd. 389, 275–280 (2005)

X. Zeng, W. Zhang, N. Wei, R. Liu, M. Ma, Mater. Sci. Eng. A. 443, 224–228 (2007)

Z. Ma, S. Tjong, Compos. Sci. Technol. 61, 771–786 (2001)

F. Mohamed, Mater. Sci. Eng. A. 245, 242–256 (1998)

R. Lagneborg, B. Bergman, Met. Sci. 10, 20–28 (1976)

L. Wang, F. Qiu, Q. Zhao, M. Zha, Q. Sci. Rep. 7, 4540 (2017)

K. McReynolds, K. Wu, P. Voorhees, Acta Mater. 120, 264–272 (2016)

H. Yoshida, K. Yokoyama, N. Shibata, Y. Ikuhara, T. Sakuma, Acta Mater. 52, 2349–2357 (2004)

T. Nakajima, M. Takeda, T. Endo, Mater. Sci. Eng. A. 387, 670–673 (2004)

W. Tian, Q. Zhao, Q. Zhang, F. Qiu, Q. Jiang, Mater. Sci. Eng. A. 700, 42–48 (2017)

Acknowledgements

The authors would like to acknowledge the financial support of the Natural Science Foundation of China (Nos. 52071158, U20A20274, 51701085, U1664254), the Six Talents Peak Project of Jiangsu Province (2018-XCL-202), the Open Funds of SKLMMC of SJTU (MMC-KF18-16), the Jiangsu Province Key Laboratory of High-end Structural Materials (HSM1803, 1902).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, P., Zhao, Y., Kai, X. et al. Research on Microstructure and High-Temperature Creep Behavior of In-Situ (ZrB2+Al2O3)/AA6016 Nanocomposite. Inter Metalcast 18, 1026–1036 (2024). https://doi.org/10.1007/s40962-023-01057-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01057-y