Abstract

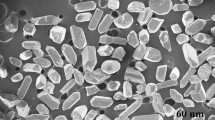

In this study, effect of external pressure on the microstructure and mechanical properties of in situ (ZrB2+Al2O3/Al3Zr)/6016 composites, synthesized under electromagnetic field, is investigated using scanning electron microscopy, X-ray diffraction and tensile testing. It is found that the application of 0.5MPa external pressure can promote uniformity in shape and slight decrease in α-Al grain size due to pressure-assisted faster solidification rate, and thus results in strengthening of both the 6016 alloy and in situ (ZrB2+Al2O3/Al3Zr)/6016 nanocomposite. It is also found that the external pressure can inhibit the growth of in situ reinforcement particles present in (ZrB2+Al2O3/Al3Zr)/6016 nanocomposite, restricting their size to lower aspect ratios. The improved strengthening of the composite matrix contributes to the simultaneously higher yield strength (YS), ultimate tensile strength (UTS), %elongation and hardness. The work hardening rate and improvement in mechanical properties are discussed in terms of reinforcement particles’ size and morphology of tensile fracture.

Similar content being viewed by others

References

P.A. Kumar, P. Rohatgi, D. Weiss, Int. J. Metalcast. 14, 291–317 (2020). https://doi.org/10.1007/s40962-019-00375-4

A.M. Samuel, H. Liu, F.H. Samuel, J. Mater. Sci. 28, 6785–6798 (1993). https://doi.org/10.1007/BF00356432

S. Gowri, F.H. Samuel, Metall. Trans. A 23, 3369–3376 (1992). https://doi.org/10.1007/BF02663446

F.M. Yarandi, P.K. Rohatgi, S. Ray, J. Mater. Eng. Perf. 2, 359–364 (1993). https://doi.org/10.1007/BF02648823

M. Zolfaghari, M. Azadi, M. Azadi, Int. J. Metalcast. 15, 152–168 (2021). https://doi.org/10.1007/s40962-020-00437-y

R. Gecu, A. Karaaslan, Int. J. Metalcast. 13, 311–319 (2019). https://doi.org/10.1007/s40962-018-0253-0

P. Garg, A. Jamwal, D. Kumar, K.K. Sadasivunic, C.M. Hussain, P. Gupta, J. Mater. Res. Tech. 8, 4924–4939 (2019). https://doi.org/10.1016/j.jmrt.2019.06.028

H.M. Enginsoy, E. Bayraktar, D. Katundi, F. Gatamorta, I. Miskioglu, Compos. Part B. 194, 108040 (2020). https://doi.org/10.1016/j.compositesb.2020.108040

S. Zhao, H. Zhang, Z. Cui, D. Chen, Z. Chen, Mater. Charac. 178, 111243 (2021). https://doi.org/10.1016/j.matchar.2021.111243

S. Baazamat, M. Tajally, E. Borhani, J. Alloys Compd. 653, 39–46 (2015). https://doi.org/10.1016/j.jallcom.2015.08.267

M.M. Jalilvand, Y. Mazaheri, A. Heidarpour, M. Roknian, Surf. Coat. Tech. 360, 121–132 (2019). https://doi.org/10.1016/j.surfcoat.2018.12.126

K. Ozturk, R. Gecu, A. Karaaslan, Cer. Inter. 47, 18274–18285 (2021). https://doi.org/10.1016/j.ceramint.2021.03.147

M. Wang, Y. Li, B. Chen, D. Shi, J. Umeda, K. Kondoh, J. Shen, Mater. Sci. Eng. A 808, 140893 (2021). https://doi.org/10.1016/j.msea.2021.140893

T. Han, F. Wang, J. Li, N. Zhao, C. He, Compos. Part B. 212, 108700 (2021). https://doi.org/10.1016/j.compositesb.2021.108700

S.R. Bakshi, D. Lahiri, A. Agarwal, Int. Mater. Rev. 55, 41–64 (2010). https://doi.org/10.1179/095066009X12572530170543

S. Mondal, Metals Mater. Inter. 27, 2188–2204 (2021). https://doi.org/10.1007/s12540-020-00750-5

M. Khoshghadam-Pireyousefan, R. Rahmanifard, L. Orovcik, P. Svec, V. Klemm, Mater. Sci. Eng. A 772, 138820 (2020). https://doi.org/10.1016/j.msea.2019.138820

X. Kai, S. Huang, L. Wu, R. Tao, Y. Peng, Z. Mao, F. Chen, G. Li, G. Chen, Y. Zhao, J. Mater. Sci. Tech. 35, 2107–2114 (2019). https://doi.org/10.1016/j.jmst.2019.04.020

X. Kai, K. Tian, C. Wang, L. Jiao, G. Chen, Y. Zhao, J. Alloys Compd. 668, 121–127 (2016). https://doi.org/10.1016/j.jallcom.2016.01.152

L.Y. Chen, J.Y. Peng, J.Q. Xu, H. Choi, X.C. Li, Scripta Mater. 69, 634–637 (2013). https://doi.org/10.1016/j.scriptamat.2013.07.016

Y. Tsunekawa, H. Suzuki, Y. Genma, Mater. Des. 22, 467–472 (2001). https://doi.org/10.1016/S0261-3069(00)00079-0

Y. Ren, W. Ma, K. Wei, W. Yu, Y. Dai, K. Morita, Vaccum 109, 82–85 (2014). https://doi.org/10.1016/j.vacuum.2014.06.026

H. Xu, X. Jian, T.T. Meek, Q. Han, Mater. Lett. 58, 3669–3673 (2004). https://doi.org/10.1016/j.matlet.2004.02.055

D.G. Eskin, Mater. Sci. Tech. 33, 636–645 (2016). https://doi.org/10.1080/02670836.2016.1162415

I. Kaldre, A. Bojarevics, JOM 72, 2892–2897 (2020). https://doi.org/10.1007/s11837-020-04160-1

L. Luo, L. Luo, Y. Su, L. Su, L. Wang, R. Chen, J. Guo, H. Fu, J. Mater. Sci. Tech. 79, 1–14 (2021). https://doi.org/10.1016/j.jmst.2020.11.035

J. Barbosa, H. Puga, J. Mater. Process. Tech. 244, 150–156 (2017). https://doi.org/10.1016/j.jmatprotec.2017.01.031

N.A. Mufti, P.D. Webster, T.A. Dean, Mater. Sci. Tech. 11, 803–809 (2013). https://doi.org/10.1179/mst.1995.11.8.803

A. Maleki, B. Niroumand, A. Shafyei, Mater. Sci. Eng. A 428, 135–140 (2006). https://doi.org/10.1016/j.msea.2006.04.099

P. Fu, A.A. Luo, H. Jiang, L. Peng, Y. Yu, C. Zhai, A.K. Sachdev, J. Mater. Process. Tech. 205, 224–234 (2008). https://doi.org/10.1016/j.jmatprotec.2007.11.111

S.N. Chen, W. Yang, H. Yu, Y.L. Zhang, J. Alloys Compd. 611, 1–6 (2014). https://doi.org/10.1016/j.jallcom.2014.05.033

X. Wu, H. Zhang, Z. Ma, L. Jia, H. Zhang, J. Mater. Eng. Perf. 27, 483–491 (2018). https://doi.org/10.1007/s11665-017-2920-3

Z. Fang, Y. Zhao, X. Kai, R. Tao, C. Xia, Z. Zhang, Y. Sun, Mater. Res. Exp. 7, 026508 (2020). https://doi.org/10.1088/2053-1591/ab6e34

X. Kai, Y. Zhao, A. Wang, C. Wang, Z. Mao, Compos. Sci. Tech. 116, 1–8 (2015). https://doi.org/10.1016/j.compscitech.2015.05.006

B. Zhang, S.L. Cockcroft, D.M. Maijer, J.D. Zhu, A.B. Phillion, JOM 57, 36–43 (2005). https://doi.org/10.1007/s11837-005-0025-1

L. Yao, S. Cockcroft, J. Zhu, C. Reilly, Metall. Mater. Trans. A 42, 4137–4148 (2011). https://doi.org/10.1007/s11661-011-0811-z

J. Campbell, Mater. Sci. Tech. 31, 565–572 (2014). https://doi.org/10.1179/1743284714Y.0000000581

W. Dai, S. Wu, S. Lü, C. Lin, Mater. Sci. Eng. A 538, 320–326 (2012). https://doi.org/10.1016/j.msea.2012.01.051

W. Jiang, Z. Fan, D. Liao, D. Liu, Z. Zhao, X. Dong, Mater. Des. 32, 926–934 (2011). https://doi.org/10.1016/j.matdes.2010.08.015

Q. Hu, W. Guo, H. Zhao, Mater. Sci. Eng. A 819, 141470 (2021). https://doi.org/10.1016/j.msea.2021.141470

J.J. Sobczak, L. Drenchev, R. Asthana, Int. J. Cast Met. Res. 25, 1–14 (2013). https://doi.org/10.1179/1743133611Y.0000000016

A.F. Ilkhchy, M. Jabbari, P. Davami, Int. Commun. Heat Mass Transf. 39, 705–712 (2012). https://doi.org/10.1016/j.icheatmasstransfer.2012.04.001

A. Jahangiri, S.P.H. Marashi, M. Mohammadaliha, V. Ashoftea, J. Mater. Process. Tech. 245, 1–6 (2017). https://doi.org/10.1016/j.jmatprotec.2017.02.005

M. Masoumi, H. Hu, Mater. Sci. Eng. A 528, 3589–3593 (2011). https://doi.org/10.1016/j.msea.2011.01.032

Y. Jiang, F. Liu, J. Alloys Comp. 809, 151829 (2019). https://doi.org/10.1016/j.jallcom.2019.151829

A. Azarniya, A. Abdollah-zadeh, H.R.M. Hosseini, S. Ramakrishna, Adv. Eng. Mater. 21, 1801269 (2019). https://doi.org/10.1002/adem.201801269

R. Tao, Y. Zhao, X. Kai, Z. Zhao, R. Ding, L. Liang, W. Xu, J. Alloys Compd. 754, 114–123 (2018). https://doi.org/10.1016/j.jallcom.2018.04.282

O. Engler, C. Schäfer, O.R. Myhr, Mater. Sci. Eng. A 639, 65–74 (2015). https://doi.org/10.1016/j.msea.2015.04.097

U. Aybarç, O. Ertuğrul, M.Ö. Seydibeyoğlu, Int. J. Metalcast. 15, 638–649 (2021). https://doi.org/10.1007/s40962-020-00490-7

X. Liu, S. Jia, L. Nastac, Int. J. Metalcast. 8, 51–58 (2014). https://doi.org/10.1007/BF03355591

M. Shayan, B. Eghbali, B. Niroumand, Inter. J. Metalcast. 15, 1427–1440 (2021). https://doi.org/10.1007/s40962-021-00574-y

V.S. Ayar, M.P. Sutaria, Int. J. Metalcast. 14(1), 59–68 (2020)

V.S. Ayar, M.P. Sutaria, Int. J. Metalcast. 15, 1047–1056 (2021). https://doi.org/10.1007/s40962-019-00328-x

F. Zhang, P. Sun, X. Li, G. Zhang, Mater. Sci. Eng. A 300, 12–21 (2001). https://doi.org/10.1016/S0921-5093(00)01811-6

M. Manoharan, M. Gupta, Compos. Part B 30, 107–112 (1999). https://doi.org/10.1016/S1359-8368(98)00041-9

Funding

The authors would like to acknowledge the financial support of the Natural Science Foundation of China (Nos. U20A20274, 52071158, 51701085, U1664254), the Six Talents Peak Project of Jiangsu Province (2018-XCL-202), the Open Funds of SKLMMC of SJTU (MMC-KF18-16), the Jiangsu Province Key Laboratory of High-end Structural Materials (HSM1803).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing financial or personal interests that could have appear to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dar, S.M., Zhao, Y., Kai, X. et al. Effect of External Pressure on the Microstructure and Mechanical Properties of In Situ (ZrB2+Al2O3/Al3Zr)/6016 Nanocomposites. Inter Metalcast 16, 2162–2174 (2022). https://doi.org/10.1007/s40962-021-00736-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00736-y