Abstract

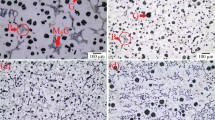

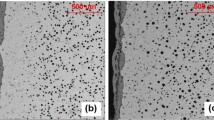

In this study, novel SiNb-xAl (x:0–4 wt.%) ductile cast irons were developed to be used as exhaust manifold material. Initial oxidation stages of these alloys were studied at 800 °C in air and in a gas atmosphere (9 % CO2, 4 % O2 and 87 % N2) and compared with a commercial SiMo ductile iron. It was found that the newly developed ductile cast irons had higher oxidation resistance compared to the SiMo ductile iron under the studied test conditions, and this resistance increased further, as aluminum content of the ductile cast iron increased. Both surfaces and cross sections of the oxidized cast irons were characterized by 3D profilometer, scanning electron microscope equipped with energy-dispersive spectrometer and X-ray diffraction technique. Dense Fe-rich nodules and an extremely thick bilayer scale were detected on the surface of the SiMo ductile iron in both test environments. However, the number of nodules on the surface and their distribution frequency were decreased in SiNb cast iron. Aluminum addition to SiNb cast iron caused a further reduction in the number of nodules and also a finer scale formation due to the presence of an Al-rich protective layer on the surface. All these findings are encouraging that new cast irons can be used as alternative materials to SiMo ductile iron.

Similar content being viewed by others

References

A.A. Partoaa, M. Abdolzadeh, M. Rezaeizadeh, Effect of fin attachment on thermal stress reduction of exhaust manifold of an off road diesel engine. J. Cent. South. Univ. 24, 546–559 (2017). https://doi.org/10.1007/s11771-017-3457-1

T. Johnson, A., Joshi, review of vehicle engine efficiency and emissions. SAE Int. J. Eng. 11(6), 1307–1330 (2018)

M. Ekström, S. Jonsson, High-temperature mechanical-and fatigue properties of cast alloys intended for use in exhaust manifolds. Mater. Sci. Eng. A 616, 78–87 (2014). https://doi.org/10.1016/j.msea.2014.08.014

L.M. Åberg, C. Hartung, Solidification of SiMo nodular cast iron for high temperature applications. Trans. of Indian Inst. Met. 65, 633–636 (2012). https://doi.org/10.1007/s12666-012-0216-8

J.P. Shingledecker, P.J. Maziasz, N.D. Evans, M.J. Pollard, Creep behavior of a new cast austenitic alloy. Int. J. Press. Vessels Pip. 84, 21–28 (2007). https://doi.org/10.1016/j.ijpvp.2006.09.014

H. Kazdal Zeytin, C. Kubilay, H. Aydın, A.A. Ebrinc, B. Aydemir, Effect of microstructur on exhaust manifold cracks produced from SiMo ductile iron. J. Iron. Steel Res. Int. 16, 32–36 (2009). https://doi.org/10.1016/S1006-706X(09)60040-6

P.J. Maziasz, Development of creep-resistant and oxidation-resistant austenitic stainless steels for high temperature applications. JOM 70, 66–75 (2018). https://doi.org/10.1007/s11837-017-2642-x

F. Tholence, M. Norell, High temperature corrosion of cast alloys in exhaust environments. II - cast stainless steels. Oxid. Met. 69, 37–62 (2008). https://doi.org/10.1007/s11085-007-9082-x

M.P. Brady, G. Muralidharan, D.N. Leonard, J.A. Haynes, R.G. Weldon, R.D. England, Long-term oxidation of candidate cast iron and stainless steel exhaust system alloys from 650 to 800 °C in air with water vapor. Oxid. Met. 82, 359–381 (2014). https://doi.org/10.1007/s11085-014-9496-1

Y.H. Zhang, M. Li, L.A. Godlewski, J.W. Zindel, Q. Feng, Effective design of new austenitic cast steels for ultra-high temperature automotive exhaust components through combined CALPHAD and experimental approaches. Metall. and Mater. Trans. A 47, 3289–3294 (2016). https://doi.org/10.1016/j.msea.2016.12.023

R. Osei, S. Lekakh, R. O’Malley, Effect of Al Additions on scale structure and oxidation kinetics of 430-ferritic stainless steel reheated in a combustion atmosphere. Metall. and Mater. Trans. B 52, 3423–3438 (2021). https://doi.org/10.1007/s11663-021-02272-w

P. Matteis, G. Scavino, A. Castello, D. Firrao, High temperature fatigue properties of a Si-Mo ductile cast iron. Procedia Mater. Sci. 3, 2154–2159 (2014). https://doi.org/10.1016/j.mspro.2014.06.349

P. Matteis, G. Scavino, A. Castello, D. Firrao, High-cycle fatigue resistance of Si-Mo ductile cast iron as affected by temperature and strain rate. Metall. and Mater. Trans. A 46, 4086–4094 (2015). https://doi.org/10.1007/s11661-015-3029-7

G.A. Çelik, M.I.T. Tzini, Ş Polat, J.S. Aristeidakis, ŞH. Atapek, P.I. Sarafolou, G.N. Haidemenopoulos, Simulation and analysis of the solidification characteristics of a Si-Mo ductile iron. J. Min. Metall. Sect. B. 57, 53–62 (2021). https://doi.org/10.2298/JMMB200717003C

Y. Li, J. Liu, W. Huang et al., Failure analysis of a diesel engine exhaust manifold. Inter Metalcast (2022). https://doi.org/10.1007/s40962-022-00796-8

Ekström M. Oxidation and corrosion fatigue aspects of cast exhaust manifolds Ph.D. thesis KTH Royal Institute of Technology; 2015.

D. Pierce, A. Haynes, J. Hughes, R. Graves, P. Maziasz, G. Muralidharan et al., High temperature materials for heavy duty diesel engines: historical and future trends. Prog Mater Sci 103, 109–179 (2019). https://doi.org/10.1016/j.pmatsci.2018.10.004

F. Tholence, M. Norell, Nitride precipitation during high temperature corrosion of ductile cast irons in synthetic exhaust gases. J. Phys. Chem. Solids 66, 530–534 (2005). https://doi.org/10.1016/j.jpcs.2004.05.010

F. Tholence, M. Norell, High temperature corrosion of cast alloys in exhaust environments. I – ductile cast irons. Oxid. Met. 69, 13–36 (2008). https://doi.org/10.1007/s11085-007-9081-y

M.M. Ibrahim, A. Nofal, M.M. Mourad, Microstructure and hot oxidation resistance of SiMo ductile cast irons containing Si-Mo-Al. Metall. and Mater. Trans. B 48, 1149–1157 (2017). https://doi.org/10.1007/s11663-016-0871-y

M. Stawarz, P.M. Nuckowski, Effect of Mo addition on the chemical corrosion process of SiMo cast iron. Materials 13, 1745 (2020). https://doi.org/10.3390/ma13071745

M. Stawarz, SiMo ductile iron crystallization process. Arch. Foundry Eng. 17, 147–152 (2017). https://doi.org/10.1515/afe-2017-0027

M. Ekström, P. Szakalos, S. Jonsson, Influence of Cr and Ni on high-temperature corrosion behavior of ferritic ductile cast iron in air and exhaust gases. Oxid. Met. 80, 455–466 (2013). https://doi.org/10.1007/s11085-013-9389-8

S.N. Lekakh, A. Bofah, W.-T. Chen, L. Godlewski, M. Li, Prevention of high-temperature surface degradation in SiMo Cast Irons by Cr and Al alloying. Metall Mater Trans B 51, 2542–2554 (2020). https://doi.org/10.1007/s11663-020-01975-w

C. Delprete, R. Sesana, Experimental characterization of a Si–Mo–Cr ductile cast iron. Mater. Des. 57, 528–537 (2014). https://doi.org/10.1016/j.matdes.2014.01.002

M.M. Ibrahim, M.M. Mourad, A.A. Nofal, A.I.Z. Farahat, Microstructure, hot oxidation resistance and damping capacity of Al- alloyed cast iron. Int. J. Cast Met. Res. 30, 61–69 (2017). https://doi.org/10.1080/13640461.2016.1239895

S. Chandra-ambhorn, T. Tummaporn, P. Jiradech, High temperature oxidation of Al-alloyed SiMo cast iron in CO2-containing atmospheres. Adv. Mater. Res. 813, 132–135 (2013). https://doi.org/10.4028/www.scientific.net/amr.813.132

S. Xiang, B. Zhu, S. Jonsson, High-temperature corrosion-fatigue behavior of ductile cast irons for exhaust manifolds applications. Mater. Sci. Forum 925, 369–376 (2018). https://doi.org/10.4028/www.scientific.net/MSF.925.369

N. Scheidhauer, C. Doööaschk, G. Wolf, Oxidation resistant cast iron for high temperature application. Mater. Sci. Forum 925, 393–399 (2018). https://doi.org/10.4028/www.scientific.net/MSF.925.393

H.K.D.H. Bhadeshia, R.W.K. Honeycombe, Steels Microstructure and Properties, 3rd edn. (Elsevier Ltd., Oxford, UK, 2006)

S.N. Lekakh, C. Johnson, L. Godlewski et al., Control of high-temperature static and transient thermomechanical behavior of SiMo Ductile Iron by Al alloying. Inter Metalcast (2022). https://doi.org/10.1007/s40962-022-00768-y

G. Aktaş Çelik, M-I. T. Tzini, Ş. H. Atapek, Ş. Polat, G. N. Haidemenopoulos, Computation of the effect of alloying elements on the physical properties of SiMo ductile cast iron. in Proc. IMMC19, (2018) 1086-1089.

G. Aktaş Çelik, Egzoz manifoldu olarak kullanılan sünek dökme demirlerin alaşımlama ile geliştirilmesi, PhD Thesis, 2020, Kocaeli, Turkey.

G. Aktaş Çelik, M.-I.T. Tzini, ŞH. Atapek, Ş Polat, G.N. Haidemenopoulos, Matrix design of a novel ductile cast iron modified by W and Al: a comparison between thermodynamic modeling and experimental data. Metall. Mater. Eng. 26, 15–29 (2020). https://doi.org/10.30544/449

G. Aktaş Çelik, M.-I.T. Tzini, ŞH. Atapek, Ş Polat, G.N. Haidemenopoulos, Thermal and microstructural characterization of a novel ductile cast iron modified by aluminum addition. Int. J. Miner. Metall. Mater. 27, 190–199 (2020). https://doi.org/10.1007/s12613-019-1876-8

G. Aktaş Çelik, Ş.H. Atapek, Ş. Polat, M-I.T. Tzini, G. N. Haidemenopoulos, Hot oxidation resistance of a novel cast iron modified by Nb and Al addition for exhaust manifold applications. Metall. and Mater. Trans. A, (2022), in press.

A. Ebel, O. Marsan, J. Lacaze, B. Malard, Cyclic oxidation of high- silicon spheroidal graphiteiron. Corros. Sci. 192, 109854 (2021). https://doi.org/10.1016/j.corsci.2021.109854

A. Ebel, S.Y. Brou, B. Malard, J. Lacaze, D. Monceau, L. Vaissière, High-temperature oxidation of a high silicon SiMo spheroidal cast iron in air with in situ change in H2O content. Mater. Sci. Forum 925, 353–360 (2018). https://doi.org/10.4028/www.scientific.net/msf.925.353

S.N. Lekakh, C. Johnson, A. Bofah et al., Improving high-temperature performance of high Si-alloyed ductile iron by altering additions. Inter Metalcast 15, 874–888 (2021). https://doi.org/10.1007/s40962-020-00524-0

K. Dawi, J. Favergeon, G. Moulin, High temperature corrosion of the Si-Mo cast iron in exhaust atmosphere. Mater. Sci. Forum 595–598, 743–751 (2008). https://doi.org/10.4028/www.scientific.net/MSF.595-598.743

ASM Handbook, Vol. 1, Properties and Selection: Irons, Steels, and High Performance Alloys, 4th ed., ASM International, Ohio, pp. 17-210, (1995).

G. Alonso, D.M. Stefanescu, J. Sanchez et al., Effect of the type of inoculant on the shrinkage porosity of high-silicon SG Iron. Inter Metalcast 16, 106–118 (2022). https://doi.org/10.1007/s40962-021-00605-8

J. Lacaze, Trace elements and graphite shape degeneracy in nodular graphite cast irons. Inter Metalcast 11, 44–51 (2017). https://doi.org/10.1007/s40962-016-0115-6

G. Alonso, P. Larrañaga, D.M. Stefanescu et al., Kinetics of nucleation and growth of graphite at different stages of solidification for spheroidal graphite iron. Inter Metalcast 11, 14–26 (2017). https://doi.org/10.1007/s40962-016-0094-7

J.M. Tartaglia, R.B. Gundlach, G.M. Goodrich, Optimizing structure-property relationships in ductile iron. Inter Metalcast 8, 7–38 (2014). https://doi.org/10.1007/BF03355592

K. Jalava, K. Soivio, J. Laine et al., Effect of silicon and microstructure on spheroidal graphite cast iron thermal conductivity at elevated temperatures. Inter Metalcast 12, 480–486 (2018). https://doi.org/10.1007/s40962-017-0184-1

S.N. Lekakh, Communication: characterization of spatial distribution of graphite nodules in cast iron. Inter Metalcast 11, 743–748 (2017). https://doi.org/10.1007/s40962-016-0128-1

D. Franzen, B. Pustal, A. Bührig-Polaczek, Influence of Graphite-Phase Parameters on the Mechanical Properties of High-Silicon Ductile Iron. Inter Metalcast (2022). https://doi.org/10.1007/s40962-022-00761-5

J. Laine, K. Jalava, J. Vaara et al., The mechanical properties of ductile iron at intermediate temperatures: the effect of silicon content and pearlite fraction. Inter Metalcast 15, 538–547 (2021). https://doi.org/10.1007/s40962-020-00473-8

J. Laine, A. Leppänen, K. Jalava et al., Ductile iron optimization approach for mechanically and thermally loaded components. Inter Metalcast 15, 962–968 (2021). https://doi.org/10.1007/s40962-020-00529-9

C. Hartung, R. Logan, A. Plowman et al., Research on solution strengthened ferritic ductile Iron (SSFDI) structure and properties using different treatment and inoculation materials. Inter Metalcast 14, 1195–1209 (2020). https://doi.org/10.1007/s40962-020-00469-4

I. Pereira, G. Alonso, V. Anjos et al., The influence of alloying elements on damping capacity of nodular cast irons for braking system components. Inter Metalcast 14, 802–808 (2020). https://doi.org/10.1007/s40962-020-00426-1

D. Franzen, B. Pustal, A. Bührig-Polaczek, Mechanical properties and impact toughness of molybdenum alloyed ductile iron. Inter Metalcast 15, 983–994 (2021). https://doi.org/10.1007/s40962-020-00533-z

Y.S. Jang, M. Phaniraj, D.I. Kim et al., Effect of aluminum content on the microstructure and mechanical properties of hypereutectoid steels. Metall Mater Trans A 41, 2078–2084 (2010). https://doi.org/10.1007/s11661-010-0233-3

A. Shayesteh-Zeraati, H. Naser-Zoshki, A.R. Kiani-Rashid, Microstructural and mechanical properties (hardness) investigations of Al-alloyed ductile cast iron. J. Alloys Compd. 500, 129–133 (2010). https://doi.org/10.1016/j.jallcom.2010.04.003

A.R. Kiani-Rashid, Influence of austenitising conditions and aluminium content on microstructure and properties of ductile irons. J. Alloys Compd. 470, 323–327 (2009). https://doi.org/10.1016/j.jallcom.2008.02.070

N. Haghdadi, B. Bazaz, H.R. Erfanian-Naziftoosi, A.R. Kiani-Rashid, Microstructural and mechanical characteristics of Al-alloyed ductile iron upon casting and annealing. Int. J. Miner. Metall. Mater. 19, 812–820 (2012). https://doi.org/10.1007/s12613-012-0633-z

M.M. Khalvan, M. Divandari, Microstructure of spheroidal graphite aluminum-alloyed cast irons (SGAACI) containing up to 7.5 wt% produced via in-mold process. Inter Metalcast 15, 271–280 (2021)

S.N. Lekakh, V.L. Richards, N. Medvedeva, Effect of Si segregation on low temperature toughness of ductile iron. AFS Trans. 120, 319–327 (2012)

A. Alhussein, M. Risbet, A. Bastien, J.P. Chobaut, D. Balloy, J. Favergeon, Influence of silicon and addition elements on the mechanical behavior of ferritic ductile cast iron. Mater. Sci. Eng. A 605, 222–228 (2014). https://doi.org/10.1016/j.msea.2014.03.057

Q. Cai, Z. Chen, C. Xu et al., Effect of elemental segregation on the microstructure and mechanical properties of heavy section compacted graphite iron. Inter Metalcast (2022). https://doi.org/10.1007/s40962-022-00758-0

A. Bedolla-Jacuinde, E. Solis, B. Hernandez, Effect of niobium in medium alloyed ductile cast irons. Int. J. Cast Met. Res. 16, 481–486 (2003). https://doi.org/10.1080/13640461.2003.11819625

J. Lacaze, B. Sundman, An assessment of Fe-C-Si system. Metall. Mater. Trans. A 22, 2211–2223 (1991). https://doi.org/10.1007/BF02664987

L.L. Liu, Q.Q. Guo, Y. Niu, Transition between different oxidation modes of binary Fe–Si alloys at 600–800 °C in Pure O2. Oxid Met 79, 201–224 (2013). https://doi.org/10.1007/s11085-012-9318-2

L.L. Liu, Q.Q.Y. guoNiu, Transition between different oxidation modes of binary Fe–Si Alloys at 600–800 °C in pure O2. Oxid. Met. 79, 201–224 (2013). https://doi.org/10.1007/s11085-012-9318-2

P. Tomaszewicz, G.R. Wallwork, Observations of nodule growth during the oxidation of pure binary iron-aluminum alloys. Oxid. Met. 19, 165–185 (1983). https://doi.org/10.1007/BF00666643

R. Prescott, M.J. Graham, The oxidation of iron-aluminum alloys. Oxid. Met. 38, 73–87 (1992). https://doi.org/10.1007/BF00665045

A.R. Kiani Rashid, D.V. Edmonds, Oxidation behaviour of Al-alloyed ductile cast irons at elevated temperature. Surf. Interface Anal. 36, 1011–1013 (2004). https://doi.org/10.1002/sia.1825

M.A. Mendez, A. Arenas, R. Niklas, A. González, J.S. Conde, J.J.D. Damborenea, Effect of silicon and graphite degeneration on high-temperature oxidation of ductile cast irons in open air. Oxid. Met. 91, 225–242 (2019). https://doi.org/10.1007/s11085-018-9875-0

M.M. Ibrahim, A. Nofal, M.M. Mourad, Microstructure and hot oxidation resistance of SiMo ductile cast irons containing Si-Mo-Al. Metall. and Mater. Trans. B. 48, 1149–1157 (2017). https://doi.org/10.1007/s11663-016-0871-y

S.N. Lekakh, A. Bofah, L.A. Godlewski, M. Li, Effect of micro-structural dispersity of SiMo ductile iron on high temperature performance during static oxidation. Metals 12, 661 (2022). https://doi.org/10.3390/met12040661

S. Chandra-Ambhorn, T. Tummaporn, P. Jiradech, High temperature oxidation of Al-alloyed SiMo cast iron in CO2-containing atmospheres. AMR 813, 132–135 (2013). https://doi.org/10.4028/www.scientific.net/amr.813.132

Acknowledgement

The authors, G. Aktaş Çelik, Ş. Polat and Ş. H. Atapek, wish to acknowledge the financial support given by Scientific Research Projects Coordination Unit of Kocaeli University under the project numbers 2017/118 and 2019/118.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aktaş Çelik, G., Atapek, Ş.H. & Polat, Ş. Initial Oxidation Stage of SiMo and SiNb-xAl Ductile Cast Irons in Air and CO2-Containing Atmospheres. Inter Metalcast 17, 1763–1777 (2023). https://doi.org/10.1007/s40962-022-00883-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-022-00883-w