Abstract

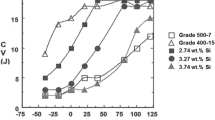

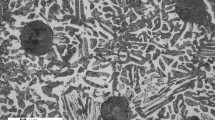

The use of ductile irons in thermo-mechanically loaded components is increasing, necessitating more knowledge of material properties at intermediate temperatures. A study of the mechanical properties of ductile irons at intermediate temperatures was conducted, investigating the effect of different pearlite fractions along with silicon content tests in fully ferritic microstructures. The effect of the pearlite fraction and silicon content on tensile and yield strength was measured at different temperatures, from room temperature to 450 °C. Models of tensile and yield strengths were developed based on those measurements. These resulting regression models were tested with data from the literature. Such models can be applied in various design tools, such as FEM calculations and in the optimisation of thermally and cyclic loaded ductile iron components.

Similar content being viewed by others

References

N. Fatahalla, Metallurgical parameters, mechanical properties and machinability of ductile cast iron. J. Mater. Sci. (UK) 31(21), 5765–5772 (1996)

M. Liam, V. Ray, O. Jason, W. Zhen, Census of world casting production: worldwide casting production growth slowed but still reported a 2.6% increase in 2018. Mod. Cast. 109(12), 26–28 (2019)

P. Ferro, Fatigue properties of ductile cast iron containing chunky graphite. Mater. Sci. Eng. A 554, 122–128 (2012). https://doi.org/10.1016/j.msea.2012.06.024

E. Foglio, Fatigue design of heavy section ductile irons: influence of chunky graphite. Mater. Des. 111, 353–361 (2016). https://doi.org/10.1016/j.matdes.2016.09.002

A. Mourujärvi, Influence of chunky graphite on mechanical and fatigue properties of heavy-section cast iron. Fatigue Fract. Eng. Mater. Struct. 32(5), 379–390 (2009). https://doi.org/10.1111/j.1460-2695.2009.01337.x

G. Ruff, Relationship between mechanical properties and graphite structure in cast irons. II—ductile iron. Mod. Cast. 70(7), 70–74 (1980)

H.K.D.H. Bhadeshia, Cementite. Int. Mater. Rev. (2019). https://doi.org/10.1080/09506608.2018.1560984

S. Ghodrat, Volume expansion of compacted graphite iron induced by pearlite decomposition and the effect of oxidation at elevated temperature. Oxid. Met. 80(1), 161–176 (2013)

ASM Handbook. 9th edition ed. Ohio, USA: American Society for Metals; 1978; Properties and Selection: Irons and Steels

A. Alhussein, Influence of silicon and addition elements on the mechanical behavior of ferritic ductile cast iron. Mater. Sci. Eng. A 605, 222–228 (2014). https://doi.org/10.1016/j.msea.2014.03.057

T. Burns, The Foseco Foundryman’s Handbook, 9th edition; 1986

R. Larker, Solution strengthened ferritic ductile iron ISO 1083/JS/500-10 provides superior consistent properties in hydraulic rotators—solution strengthened ferritic ductile iron ISO 1083/JS/500-10 provides superior consistent properties in hydraulic rotators. China Found. 6(4), 343–351 (2009)

R. González-Martínez, Effects of high silicon contents on graphite morphology and room temperature mechanical properties of as-cast ferritic ductile cast irons. Part I—microstructure. Mater. Sci. Eng. A. 712, 794–802 (2018). https://doi.org/10.1016/j.msea.2017.11.050

T. Ikeda, Influence of silicon content, strain rate and temperature on toughness and strength of solid solution strengthened ferritic ductile cast iron. Mater. Trans. 57(12), 2132–2138 (2016). https://doi.org/10.2320/matertrans.F-M2016832

F. Unkic, Vpliv silicija in bora na natezne lastnosti duktilne litine/the influence of silicon and boron on tensile properties of ductile iron. Livarski Vestnik. 59(2), 68–79 (2012)

Z. Wang, Effect of shrinkage porosity on mechanical properties of ferritic ductile iron. China Found. 10(3), 141–147 (2013)

P. Weiß, Mechanistic approach to new design concepts for high silicon ductile iron. Mater. Sci. Eng. A 713, 67–74 (2018). https://doi.org/10.1016/j.msea.2017.12.012

S. Biswas, Use of published experimental results to validate approaches to gray and ductile iron mechanical properties prediction. Int. J. Metalcast. 11(4), 656–674 (2017). https://doi.org/10.1007/s40962-016-0126-3

M. Riebisch, Impact of carbide-promoting elements on the mechanical properties of solid-solution-strengthened ductile iron. Int. J. Metalcast. (2019). https://doi.org/10.1007/s40962-019-00358-5

J. Roučka, Properties of type SiMo ductile irons at high temperatures. Arch. Metall. Mater. 63(2), 601–607 (2018). https://doi.org/10.24425/122383

M. Ekström, High-temperature mechanical- and fatigue properties of cast alloys intended for use in exhaust manifolds. Mat. Sci. Eng. A 616, 78–87 (2014). https://doi.org/10.1016/j.msea.2014.08.014

K. Jalava, Effect of silicon and microstructure on spheroidal graphite cast iron thermal conductivity at elevated temperatures. Int. J. Metalcasting 12(3), 480–486 (2018). https://doi.org/10.1007/s40962-017-0184-1

F. Szmytka, Thermo-mechanical fatigue resistance characterization and materials ranking from heat-flux-controlled tests. Application to cast-irons for automotive exhaust part. Int. J. Fatigue. 55, 136–146 (2013). https://doi.org/10.1016/j.ijfatigue.2013.06.012

H. Mouri, Effect of dynamic strain aging on isothermal (473 K) low cycle fatigue of ferritic ductile cast iron. Mater. Trans. 50(8), 1935 (2009)

D. Caillard, An in situ study of hardening and softening of iron by carbon interstitials. Acta Mater. 59(12), 4974–4989 (2011). https://doi.org/10.1016/j.actamat.2011.04.048

K. Jalava, J. Laine, J. Vaara, T. Frondelius, J. Orkas, Investigation on dynamic strain aging behavior of ferritic–pearlitic ductile irons. Mater. Sci. Technol. (2019). https://doi.org/10.1080/02670836.2019.1685760

B. Jost, Temperature dependent cyclic deformation and fatigue life of EN-GJS-600 (ASTM 80-55-06) ductile cast iron. Int. J. Fatigue. 96, 102–113 (2017). https://doi.org/10.1016/j.ijfatigue.2016.11.010

C. Thomser, Optimized durability prediction of cast iron based on local microstructure. Int. J. Metalcast. 11(2), 207–215 (2017). https://doi.org/10.1007/s40962-016-0091-x

I. Svensson, T. Sjögren, On modeling and simulation of mechanical properties of cast irons with different morphologies of graphite. Int. J. Metalcast. 3, 67–77 (2009). https://doi.org/10.1007/BF03355460

M. Hafiz, Mechanical properties of SG-iron with different matrix structure. J. Mater. Sci. 36(5), 1293–1300 (2001)

P. Canzar, Microstructure influence on fatigue behaviour of nodular cast iron. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 556(1), 88–99 (2012). https://doi.org/10.1016/j.msea.2012.06.062

S. Kubota, Effect of microstructure on mechanical properties and machinability of spheroidal graphite cast iron. Chuzo Kogaku (J. Jpn Found. Eng.) 85(8), 489–496 (2013). https://doi.org/10.11279/jfes.85.489

J. Toribio, Influence of microstructure on strength and ductility in fully pearlitic steels. Metals 6(12), 318 (2016). https://doi.org/10.3390/met6120318

L. Dix, Static mechanical properties of ferritic and pearlitic lightweight ductile iron castings. Trans. Am. Found. Soc. 111, 895–910 (2003)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

40962_2020_473_MOESM1_ESM.xlsx

Appendix 1: Mechanical values of different pearlite fractions and calculated values. Appendix 2: Mechanical values of different silicon contents (0% pearlite) and calculated values (XLSX 18 kb)

Rights and permissions

About this article

Cite this article

Laine, J., Jalava, K., Vaara, J. et al. The Mechanical Properties of Ductile Iron at Intermediate Temperatures: The Effect of Silicon Content and Pearlite Fraction. Inter Metalcast 15, 538–547 (2021). https://doi.org/10.1007/s40962-020-00473-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00473-8