Abstract

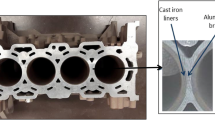

The cylinder head is one of the most complex and concentrated load components of the engine, playing an important role in the safety and reliability of the engine. In this paper, the finite element method is used to simulate the casting and heat treatment process of cylinder head. The distribution characteristics of microstructure, shrinkage porosity defects as well as mechanical properties are analyzed, and the mechanical properties simulation results were verified by experimental data. The results show that the microstructure varies significantly at different regions and is related to local cooling rate. The shrinkage porosity defects are mainly distributed in the thick walls and thin–thick wall junctions, but the porosity value is small and the effect on the mechanical properties could be ignored. The mechanical properties of different cylinders are similar, but there are obvious differences at the top plate, force wall and bottom plate in each cylinder, with a maximum difference of 12%. The large discrepancies of microstructure, shrinkage porosity defects as well as mechanical properties in cylinder head are caused by the different local filling and cooling conditions in the casting process.

Similar content being viewed by others

Availability of data and material

Not applicable for that section.

References

Z. Shi, Q. Wang, G. Zhao et al., Effects of erbium modification on the microstructure and mechanical properties of A356 aluminum alloys. Mater. Sci. Eng. A 626, 102–107 (2015)

J. Hirsch, T. Al-Samman, Superior light metals by texture engineering: optimized aluminum and magnesium alloys for automotive applications. Acta Mater. 61, 818–843 (2013)

H. Wang, G. Li, Y. Zhao et al., In situ fabrication and microstructure of Al2O3 particles reinforced aluminum matrix composites. Mater. Sci. Eng. A 527(12), 2881–2885 (2010)

W. Jiang, X. Chen, B. Wang, Effects of vibration frequency on microstructure, mechanical properties, and fracture behavior of A356 aluminum alloy obtained by expendable pattern shell casting. Int. J. Adv. Manuf. Technol. 83(1–4), 167–175 (2016)

B. Whitley, Novel three-dimensional modeling technology for advanced simulation, printing, and casting of A356 impeller. Int. J. Metalcast. 7, 57–59 (2013). https://doi.org/10.1007/BF03355546

D. Roy, S. Ghosh, A. Basumallick et al., Preparation of Fe-aluminide reinforced in situ metal matrix composites by reactive hot pressing. Mater. Sci. Eng. A 415(1–2), 202–206 (2006)

M. Hu, J. Cai, W. Sun et al., Die casting simulation and process optimization of an A356 aluminum alloy polishing plate. Int. J. Metalcast. 10(3), 315–321 (2016). https://doi.org/10.1007/s40962-016-0045-3

M. Marzouk, M. Jain, S. Shankar, Effect of Sr-modification on the bendability of cast aluminum alloy A356 using digital image correlation method. Mater. Sci. Eng. A 598, 277–287 (2014)

M. Javidani, D. Larouche, Application of cast Al–Si alloys in internal combustion engine components. Int. Mater. Rev. 59(3), 132–158 (1989)

S. Zhang, Z. Wang, Y. Han et al., Experimental and theoretical studies on thermo-mechanical fatigue test for aluminium cast alloy. Fatigue Fract. Eng. Mater. Struct. 43(1), 110–118 (2020a)

R. Fuoco, M. Moreira, Fatigue cracks in aluminum cylinder heads for diesel engines. Int. J. Metalcast. 4(4), 19–32 (2010). https://doi.org/10.1007/BF03355500

L. Pavlak, J.C. Sturm, Reduction of oxide inclusions in aluminum cylinder heads through autonomous designs of experiments. Int. J. Metalcast. 11, 174–188 (2017). https://doi.org/10.1007/s40962-016-0096-5

E. Kilinc, S. Akbalik, Y. Birol, Optimization of the strontium modification process in gravity permanent mould tilt cast AlSi6Cu4 cylinder heads. Int. J. Metalcast. (2017). https://doi.org/10.1007/s40962-017-0158-3

J. Yi, Y. Gao, P. Lee et al., Scatter in fatigue life due to effects of porosity in cast A356-T6 aluminum–silicon alloys. Metall. Mater. Trans. A 34, 1879–1890 (2003)

M. Zhang, J. Pang, Y. Qiu et al., Influence of microstructure on the thermo-mechanical fatigue behavior and life of vermicular graphite cast irons. Mater. Sci. Eng. A 771, 138617 (2020)

M. Garat, Optimization of an aluminum cylinder head alloy of the AlSi7Cu3MnMg type reinforced by additions of peritectic elements. Int. J. Metalcast. 5, 17–24 (2011). https://doi.org/10.1007/BF03355515

E. Kilinc, Y. Birol, Optimising the T6 heat treatment for gravity cast AlSi7MgCu0.5 alloy V8 cylinder heads. Int. J. Cast Metal Res. 30, 244–250 (2017)

D. Zhou, Z. Kang, C. Yang et al., A novel approach to model and optimize qualities of castings produced by differential pressure casting process. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00596-6

H. Mayer, M. Papakyriacou, B. Zettl et al., Influence of porosity on the fatigue limit of die cast magnesium and aluminium alloys. Int. J. Fatigue 25, 245–256 (2003)

R.A. Harding, M. Wickins, H. Wang et al., Development of a turbulence-free casting technique for titanium aluminides. Intermetallics 19, 805–813 (2011)

A. Patel, L. Nastac, Mathematical modeling of microshrinkage formation during solidification of A356 castings. Int. J. Metalcast. 8(1), 21–27 (2014). https://doi.org/10.1007/BF03355568

Y. Zhang, N. Ma, Y. Le et al., Mechanical properties and damping capacity after grain refinement in A356 alloy. Mater. Lett. 59, 2174–2177 (2005)

Q. Wang, Microstructural effects on the tensile and fracture behavior of aluminum casting alloys A356/357. Metall. Mater. Trans. A 34A, 2887–2899 (2003)

Y. Wang, D. Li, Y. Peng, Numerical simulation of low pressure die casting of magnesium wheel. Int. J. Adv. Manuf. Technol. 32, 257–264 (2007)

A. Starobin, D. Goettsch, M. Walker et al., Gas pressure in aluminum block water jacket cores. Int. J. Metalcast. 5(3), 57–64 (2011)

L. Yang, L. Chai, Y. Liang, Numerical simulation and experimental verification of gravity and centrifugal investment casting low pressure turbine blades for high Nb-TiAl alloy. Intermetallics 66, 149–155 (2015)

W. Jiang, Z. Fan, Gating system optimization of low pressure casting A356 aluminum alloy intake manifold based on numerical simulation. China Foundry 11, 119–124 (2014)

D. Lados, D. Apelian, Fatigue crack growth characteristics in cast Al–Si–Mg alloys: Part I. Effect of processing conditions and microstructure. Mater. Sci. Eng. A 385(1–2), 200–211 (2004)

L. Zhang, Y. Jiang, Z. Ma et al., Effect of cooling rate on solidified microstructure and mechanical properties of aluminium-A356 alloy. J. Mater. Process. Technol. 207, 107–111 (2008)

J. Gan, J. Du, C. Wen et al., The effect of Fe content on the solidification pathway, microstructure and thermal conductivity of hypoeutectic Al–Si alloys. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00580-0

A. Bahmani, N. Hatami, N. Varahram et al., A mathematical model for prediction of microporosity in aluminum alloy A356. Int. J. Adv. Manuf. Technol. 64, 1313–1321 (2013)

M. Alizadeh, Correlation between the continuous casting parameters and secondary dendrite arm spacing in the mold region. Mater. Lett. 91, 146–149 (2013)

C. Barbosa, T. Silva, H. Azevedo et al., Correlation between unsteady-state solidification and electrochemical corrosion parameters of an AlSiMg alloy. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00571-1

A. Mazahery, M. Shabani, Experimental investigation on the aging response, hardness and total impact energy absorption of Sr-modified heat-treatable cast automotive aluminum alloys. Trans. Indian Inst. Met. 67, 753–759 (2014a)

S. Zhang, Z. Xu, Z. Wang, Numerical modeling and simulation of water cooling-controlled solidification for aluminum alloy investment casting. Int. J. Adv. Manuf. Technol. 91, 763–770 (2017)

M. Ibrahim, A. Samuel, H. Doty et al., Effect of aging conditions on precipitation hardening in Al–Si–Mg and Al–Si–Cu–Mg alloys. Int. J. Metalcast. 11, 274–286 (2017). https://doi.org/10.1007/s40962-016-0057-z

M. Zhu, Z. Jian, G. Yang, Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys. Mater. Des. 36, 243–249 (2012)

G. Garza-Elizondo, A. Samuel, F. Samuel et al., Effects of alloying elements additions on ambient temperature performance of Al–Si–Cu–Mg base alloys. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-020-00568-2

D.L. Zhang, L. Zheng, D. StJohn, Effect of a short solution treatment time on microstructure and mechanical properties of modified Al–7Si–0.3Mg alloy. J. Light Met. 2(1), 27–36 (2002)

A. Güneren, E. Dokumacı, Cooling behavior of A356 alloy in surfactant quenching medium. Int. J. Metalcast. 14, 580–588 (2020). https://doi.org/10.1007/s40962-019-00386-1

R. Mackay, A. Elsayed, G. Byczynski, Novel approach to thermal processing development for precision sand casting process (PSCP) of aluminum engine blocks. Int. J. Metalcast. (2020). https://doi.org/10.1007/s40962-020-00526-y

D. Lee, Choong, Effect of artificial ageing on the defect susceptibility of tensile properties to porosity variation in A356 aluminium alloys. Int. J. Metalcast. 12, 321–330 (2018). https://doi.org/10.1007/s40962-017-0168-1

B. Liao, Y. Park, H. Ding, Effects of rheocasting and heat treatment on microstructure and mechanical properties of A356 alloy. Mater. Sci. Eng. A 528, 986–995 (2011)

Q. Wang, C. Davidson, Solidification and precipitation behaviour of Al–Si–Mg casting alloys. J. Mater. Sci. 36, 739–750 (2001)

A. Mazahery, M.O. Shabani, Modification mechanism and microstructural characteristics of eutectic Si in casting Al–Si alloys: a review on experimental and numerical studies. J. Met. 66, 726–738 (2014b)

S. Nallusamy, A review on the effects of casting quality, microstructure and mechanical properties of cast Al–Si–0.3Mg alloy. Int. J. Perform. Eng. 12(2), 143–154 (2016)

Y. Egorova, L. Davydenko, I. Mamonov, The study of the complex mechanical properties of rolled bars of VT6 alloy as a function of chemical composition and structure type. Mater. Sci. Forum 989, 283–289 (2020)

X. Wang, Y. Hui, Y. Hou et al., Direct investigation on high temperature tensile and creep behavior at different regions of directional solidified cast turbine blades. Mech. Mater. 136, 103068 (2019)

Q. Wang, L. Xiao, W. Liu et al., Effect of heat treatment on tensile properties, impact toughness and plane-strain fracture toughness of sand-cast Mg–6Gd–3Y–0.5 Zr magnesium alloy. Mater. Sci. Eng. A 705, 402–410 (2017)

E. Niyama, T. Uchida, M. Morikawa et al., A method of shrinkage prediction and its application to steel casting practice. AFS Int. Cast Met. J. 52(9), 52–63 (1982)

L. Liu, Q. Yang, Q. Li et al., Prediction of shrinkage cavity and porosity in centrifugal cast rollers by Niyama criterion. Foundry Technol. 30(12), 1580–1583 (2009)

ESI Group, ProCAST User Manual, Version 2018.0

E. Starke, Aluminum Alloys: Thermal Treatments, in: Encyclopedia of Materials: Science and Technology (Elsevier, Oxford, 2001), pp. 116–118. https://doi.org/10.1016/B0-08-043152-6/00025-5

M. Paradis, M. Abdelaziz, A. Samuel et al., Effect of mold type on the microstructure and tensile properties of A356 alloy. Int. J. Metalcast. 11, 523–535 (2017). https://doi.org/10.1007/s40962-016-0102-y

H. Yavuz, O. Ertugrul, Numerical analysis of the cooling system performance and effectiveness in aluminum low-pressure die casting. Int. J. Metalcast. 15(1), 216–228 (2020). https://doi.org/10.1007/s40962-020-00446-x

J. Cho, C. Kim, The relationship between dendrite arm spacing and cooling rate of Al-Si casting alloys in high pressure die casting. Int. J. Metalcast. 8(1), 49–55 (2014). https://doi.org/10.1007/BF03355571

Y. Li, J. Liu, Q. Zhang et al., Casting defects and microstructure distribution characteristics of aluminum alloy cylinder head with complex structure. Mater. Today Commun. 27, 102416 (2021). https://doi.org/10.1016/j.mtcomm.2021.102416

Y. Duan, F. Zhang, Y. Dan et al., Numerical prediction of fatigue life of an A356-T6 alloy wheel considering the influence of casting defect and mean stress. Eng. Fail. Anal. 118(4), 104903 (2020)

A. Wickberg, G. Gustafsson, L.-E. Larsson, Microstructural effects on the fatigue properties of a cast A17SiMg alloy. Isr. J. Plant Sci. 52(3), 195–204 (2004)

Q.G. Wang, D. Apelian, D. Lados, Fatigue behavior of A356–T6 aluminum cast alloys. Part I. Effect of casting defects. J. Light Met. 1(1), 73–84 (2001)

R. Chen, Y. Shi, Q. Xu, Effect of cooling rate on solidification parameters and microstructure of Al–7Si–0.3Mg–0.15Fe alloy. Trans. Nonferrous Met. Soc. China 24, 1645–1652 (2014)

J. Huang, H. Zhao, Z. Chen, Microstructure and properties of A356 alloy wheels fabricated by low-pressure die casting with local squeeze. J. Mater. Eng. Perform. 28(4), 2137–2146 (2019)

M. Okayasu, Y. Ohkura, S. Takeuchi et al., A study of the mechanical properties of an Al–Si–Cu alloy (ADC12) produced by various casting processes. Mater. Sci. Eng. A 543, 185–192 (2012)

Funding

This work was supported by Chinese National Program on Key Basic Research Project (Grant No.261 6141B012887).

Author information

Authors and Affiliations

Contributions

JL contributed to the conception of the study; YL performed the simulation and the data analyses as well as wrote the manuscript, contributing significantly to analysis and manuscript preparation; HZ and WH helped perform the analysis with constructive discussions.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Code availability

Not applicable for that section.

Ethics approval

This research work does not contain any studies with human participants or animals performed by any of the authors.

Consent for publication

The work described is original research that has not been published previously, and not under consideration for publication elsewhere, in whole or in part. That its publication has been approved by the responsible authorities at the institution where the work is carried out.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Liu, J., Zhou, H. et al. Study on the Distribution Characteristics of Microstructure and Mechanical Properties Within the Cylinder Head of Low-Pressure Sand Cast Aluminum Alloy. Inter Metalcast 16, 1252–1264 (2022). https://doi.org/10.1007/s40962-021-00678-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00678-5