Abstract

Lost cores used to manufacture complex aluminium components through high-pressure die casting (HPDC) processes need to withstand very high injection velocities and pressures. The conventional sand cores used in other casting processes, such as sand casting or low-pressure die casting, do not support the aggressive process parameters of the HPDC, so advanced ceramic cores must be used. These cores must be strong enough not to get broken during the casting process, but, at the same time, they must have a minimum porosity to be easily removed from the casting to obtain the finished part. Due to this porosity, the aluminium penetrates the core surface during the casting process. So, the criterion here is to find the necessary compromise between strength and porosity and to protect the core surface from the aluminium penetration. In this work, two research lines have been followed to address these challenges. On the one hand, different refractory coatings have been applied to the ceramic core surface with the aim of sealing it. Amongst the coatings analysed, boron nitride-based one has been found to be the most suitable and cost-effective solution to avoid aluminium penetration. On the other hand, silica has been proved to be a suitable infiltration agent to increase the strength of the core.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

HPDC is the most widely used casting process to manufacture aluminium components,1 thanks to its versatility, high production rate and the possibility of producing thin-walled and, consequently, lighter components.2 The weight reduction in components is mandatory in an industry such as automotive which is continuously searching for a reduction in the vehicles’ fuel consumption and emissions. This is one of the ways to comply with the EU standards that are continuously tightening the emission limits of cars.3

For the last 25 years, aluminium has been substituted for many iron-based automotive components thanks to its good strength-to-weight ratio. However, some of the parts cannot be produced in aluminium by HPDC process due to their complexity. Those components with complex geometries or undercuts require removable cores to create internal cavities. This is the case of the closed-deck engine block. Due to the configuration of this type of block, it is not possible to use permanent cores in the die. Removable or collapsible cores (also known as lost cores) must be used to create the water jacket, i.e. the water-filled cavity surrounding the cylinders in an engine.

The cores used in the high-pressure die casting-lost core (HPDC-LC) process need to withstand high flow velocities (more than 30 m/s at the gates) and high hydrostatic pressures (over 600 bars) of the molten aluminium.4 Thus, they need to be strong enough not to get broken during the injection process. Sand cores used in sand casting and low-pressure die casting processes are not suitable since they cannot cope with these requirements. Some researchers 5,6,–7 have worked in the development of salt cores based on water-soluble inorganic salts that are easily removed from the casting. Bending strength values over 20 Mpa have been reached in some formulations.6,7 However, the high corrosivity of these salts and the penetration of aluminium during the casting process represent a problem.

In this project, advanced ceramic cores have been used to produce aluminium castings by HPDC-LC process. The cores must be strong enough not to get broken during the casting process, but, at the same time, they must have a minimum porosity to be easily removed from the casting to obtain the finished part. The technology proposed and developed in this project to remove the core from the casting has been ultra-high-pressure water jet technology.

Due to this porosity, aluminium penetrates the core surface during the injection process, creating an interface between the aluminium part and the core and making the de-coring of the part nearly impossible. The solution to this problem has been addressed by coating the cores with a refractory coating.

The other challenge to be approached was the fact that the cores manufactured for the casting of engine blocks through HPDC did not withstand the pressure of the casting process and it was not possible to change the parameters of the manufacturing process of the cores. To solve this issue, infiltrating trials were performed with colloidal silica, based on some research results where the strength increase in ceramic cores when infiltrated with colloidal silica and/or alumina has been demonstrated.8,9

Experimental

To start with the coating trials, five commercial refractory coatings from different suppliers with different compositions and price levels were selected and traded off (Table 1). Preliminary trials were performed first, using aluminosilicate ceramic bars of 44 × 11 × 11 mm manufactured by Rauschert Italia using a dry pressing + sintering process. One of the faces of the bars was coated using a brush, then dried for 24 h and finally inserted in a sand mould with the coated face exposed. Aluminium was melted in an induction furnace and poured over the different coated samples at 700 °C, the temperature at which it is usually injected. Once solidified, the aluminium part was separated from the ceramic bar and the coated surface was visually inspected to determine whether there was any sign of reaction between the coating and the aluminium.

Three coatings, with no evidence of reaction, were selected to continue with the study in the HPDC trials. A part with similar geometry to the core designed for the engine block but with a smaller size (monocylinder core) was designed for these trials. These cores were manufactured by Rauschert Italia using the dry pressing + sintering process. They had the same composition of the bars and were coated with two of the most popular coating application methods for foundry cores: brushing and spraying.10 In the brushing method, a brush was used to apply the coating on the cores’ surface. Two coating layers were applied leaving 10 min to dry the first before applying the second one. Then, the cores were air-dried for 24 h. In the spraying method, a spray gun was used. The coating was diluted in some water (50:50), and it was sprayed over the cores’ surface from a distance of 30 cm. After letting the cores dry for 15 min, a second layer was sprayed and finally the cores were air-dried for 24 h.

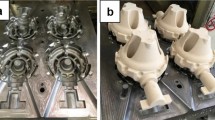

For the HPDC trials, a 950-ton industrial high-pressure die casting machine was used. First, the core was inserted in the die cavity and the die was closed (Figure 1a). Then, the aluminium alloy was injected at 700 °C and, when solidified, the aluminium part was extracted (Figure 1b). From each part, a section was cut and the ceramic core was removed from the aluminium casting using a chisel and hammer. Then, a small sample was cut and a metallographic specimen was prepared in those cases in which penetration of aluminium was observed. An optical microscope was used to analyse whether the aluminium had penetrated the core or not. This same microscope was also used to measure the thickness and the uniformity of the coating layers applied by either brushing or spraying method.

The cast aluminium monocylinders were machined and sent to FerroČrtalič, the company responsible for the development of a specific machine to remove the cores from the aluminium part. This process, named as de-coring, was based on the ultra-high-pressure water jet technology.

For the infiltration trials, ceramic bars of two different density levels were used. Bars of 130 × 11 × 11 mm were again prepared by Rauschert using different pressing levels during the dry pressing step to obtain bars with two different densification levels: low density of 1.7 g/cm3 (corresponding to 63% of the bulk density) and high density of 1.9 g/cm3 (corresponding to 71% of the bulk density). Twenty-four bars from each density level were used by Tecnalia for the infiltration trials. A colloidal dispersion of silicon (IV) oxide in water (30%) from Alfa Aesar was employed as infiltration agent. Previously pre-sintered bars were infiltrated in air or vacuum during infiltration periods of 1, 2 and 4 h. The effect of the infiltration media and the infiltration time in the porosity reduction and in the bending strength increase was studied. The total porosity of the bars was calculated by measuring the bulk density and the apparent density of the bars and using the following formula that relates them with the porosity:

being ρbulk the bulk density of the bars (without porosity) and ρap the density measured in each bar.

Three-point bending tests were performed following the UNE EN 60672-2 standard to measure the bending strength of the bars. Three bars were tested for each studied condition.

A scanning electron microscope JEOL JEM5910LV was used to analyse the microstructure of the ceramic bars before and after the infiltration process. This equipment is equipped with an energy-dispersive spectroscopy (EDS) system, and it was used in a semiquantitative mode to determine the chemical composition of the samples studied.

Results and Discussion

Coating Trials

Visual inspection performed on the samples coated with different refractory paints after pouring molten aluminium over them did not reveal any sign of penetration of the aluminium in the ceramic, which was attributed to the absence of applied pressure. However, the surface of the uncoated bar in contact with aluminium was darker, revealing a possible reaction between the ceramic and the aluminium. Similar signs of reaction were observed in two of the coated bars (RC1 and RC2). With the other three paints, the coating layer was unchanged. For the next step (the HPDC trials), only the three paints with better results (RC3, RC4 and RC5) were selected.

Table 2 lists the main features of the two coating methods employed to apply the coatings on the cores’ surface. The metallographic characterization revealed that with the spraying method the layer of the applied coating was thinner and slightly more uniform. Coating layers between 60 µm and 100 µm thickness could be seen in the sprayed samples with a good interface between the ceramic substrate and the applied coating, as it is shown in Figure 2b. However, with the brushing method quite irregular coating layers were formed with higher thicknesses ranging from 125 to 200 µm (Figure 2a). Moreover, it takes a relatively long time to complete the coating when using brushes, prolonging this stage of the casting process. Consequently, the spraying method seems to be the most appropriate method, and it was the method selected to coat the monocylinder cores for the HPDC trials.

Five monocylinder cores were coated with each of the three refractory paints selected after the preliminary trials. And five more cores were left uncoated. The microstructural analysis of the castings revealed that in the uncoated ceramic core a cermet layer of around 200 µm thickness was formed as a result of the penetration of aluminium during the casting (Figure 3a). In the core coated with RC3, some penetration of aluminium in the core could also be observed, although the cermet layer created had lower thickness (around 50 µm) (Figure 3b). In the cores coated with RC4 and RC5, no penetration was observed, and the ceramic could be completely removed from the casting (Figure 4) giving, as a result, a smooth aluminium surface completely free of ceramic penetration.

In order to confirm the good behaviour of these two refractory coatings, some of the castings with cores coated with RC4 and RC5 were used in the de-coring trials to confirm that the ultra-high-pressure water jetting machine developed by FerroČrtalič was able to completely remove the cores from inside the aluminium part. The de-coring trials concluded that in the castings with uncoated cores, it was not possible to completely remove the ceramic as a layer remained attached to the aluminium surface due to the previously mentioned penetration. However, in the coated cores the ceramic was completely removed from the cast part and, using an endoscope, it was seen that the aluminium had a smooth surface.

Boron nitride-based coating (RC4) confirmed its good non-wetting behaviour in contact with aluminium, and it showed to have an excellent thermal and chemical stability in the temperature range of molten aluminium.11 Moreover, it did not react with the ceramic core and sealed the surface to avoid aluminium penetration during the casting. As it was the cheapest coating of the two candidates that showed to have better behaviour, it was the one selected for the HPDC trials of the engine blocks.

Infiltration Trials

Figure 5 shows the bending strength increase in the bars infiltrated with silica in air and in vacuum conditions at different infiltrating periods. The bending strength values of the non-infiltrated bars were taken as baseline to measure this strength increase. As shown in the left graph, strength increases up to 135% were obtained in the low-density bars as a result of the infiltration in air. The longer the infiltrating time, the higher the strength increase, but two hours seem to be enough to reach the maximum infiltration in both air and vacuum. No significative influence of the infiltrating medium can be deduced from these results. The maximum infiltration level was correlated with a porosity reduction of 6%, reducing the total porosity in the bars from 37 to 31%.

In the case of the high-density bars, it could be seen that the longer the infiltrating time the higher the strength increase. The maximum strength levels were measured in the samples infiltrated for 4 h, in both mediums (Figure 5, right graph). However, and contrarily to what could be expected, higher values were measured in the bars infiltrated in air than in vacuum. The total porosity in the bars before the infiltration process was calculated to be 29.5%, and this lower porosity in the bars with higher density can be the explanation for the higher time needed by the silica to be introduced within the pores of the bars. The maximum strength increase was achieved in the bars infiltrated in air for 4 h. An average strength increase of 46% was measured in these bars, and this was obtained with a porosity reduction of nearly 3% (from 29.5 to 26.7%). The lower strength increase achieved in the high-density bars is attributed to the lower open porosity available for the silica to get infiltrated. The lower porosity reduction was also attributed to this fact, even if the infiltration time was higher in these bars.

Metallographic analysis of the ceramic bars was performed. Looking at the micrographs, no apparent differences were observed between the bars before and after the infiltration process (Figure 6). However, when looking at the results of the EDS analysis of the low-density bars (Figure 7) and focusing the attention on the intensity of the peaks corresponding to silicon (Si) and aluminium (Al), it can be seen that before the infiltration both peaks have the same height, while after the infiltration the peak corresponding to silicon is higher. This shows that more Si is inside the sample after the infiltration, confirming the introduction of some silica within the ceramic bar. In the EDS analysis of the high-density bars (Figure 8), it can also be observed an increase in the peak corresponding to Si in the infiltrated sample. However, the height increase of this peak is lower than the one observed in the low-density infiltrated bar, thus confirming the introduction of a lower amount of SiO2 inside the ceramic bar.

Conclusions

Two different approaches have been followed to solve technical challenges of using ceramic cores in the HPDC-LC process.

On the one hand, different refractory coatings have been studied aiming to find a coating non-wetted by molten aluminium, which could seal the surface of the core and avoid aluminium penetration even with the HPDC process. Boron nitride-based solution has been selected based on a cost criterion amongst the two potential suitable alternatives.

On the other hand, the lack of strength of ceramic cores to withstand the high injection velocities and pressures of the casting process was solved by infiltrating with silica. Higher strength increases were measured in the low-density bars due to the higher porosity reduction as a consequence of the infiltration of a higher amount of silica. Two hours of air infiltration were enough to reach the maximum strength increase in the low-density bars, while 4 h were needed in the high-density bars to reach the peak of strength.

As a result of this research, closed-deck engine blocks have been produced at Edertek using ceramic cores infiltrated in air with SiO2 and coated with a boron nitride-based coating using the spraying method.

References

European Aluminium Association, The Aluminium Automotive Manual (2002). https://www.european-aluminium.eu/media/1526/aam-manufacturing-1-casting-methods.pdf. Accessed May 2018

J. Collot, Mater. Manuf. Process. 16(5), 595–617 (2007)

European Commission. https://ec.europa.eu/clima/policies/strategies/2020_en. Accessed May 2018

F. Czerwinski, M. Mir, W. Kasprzak. Int. J. Cast Met. Res. 1–12 (2014)

P. Jelínek, E. Adámková, Arch. Found. Eng. 14(2), 101–104 (2014)

J. Yaokawa, D. Miura, K. Anzai, Y. Yamada, H. Yoshii, Mater. Trans. 48(5), 1034–1041 (2007)

J. Yamada. Yamaha patent US 2011/062624(A1) (2011)

Y.-H. Kim, J.-G. Yeo, S.-C. Choi, Ceram. Int. 42, 8878–8883 (2016)

J.B. Yu, Z.M. Ren, B.Q. Wang, Y.W. Zhang, Adv. Mat. Res. 177, 418–420 (2011)

U.C. Nwaogu, N.S. Tiedje, Mat. Sci. Appl. 2, 1143–1160 (2011)

F. Reusch, S. Rudolph, Giesserei 80(8), 256–259 (1993)

Acknowledgements

This work has been carried out under the framework of the CORE 4.0 project funded by the European Union’s Horizon 2020 research and innovation programme under grant agreement no 701197. The authors wish to show their gratitude to Rauschert Italia for manufacturing the ceramic cores and the bars, Edertek for helping with the die casting trials and machining of the samples and FerroČrtalič for making the de-coring tests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Merchán, M., de Cortázar, M.G., Galarraga, H. et al. Research on Coatings and Infiltration to Strengthen Ceramic Lost Cores Used in High-Pressure Die Casting Processes. Inter Metalcast 13, 597–603 (2019). https://doi.org/10.1007/s40962-018-00301-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-018-00301-0