Abstract

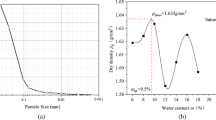

Using low-cost polymeric geosynthetics has proven to be a sustainable solution for a wide range of geotechnical problems, including liquefaction and associated disasters. The grain shape of sand governs the sand-geosynthetic interactions and its macro-level mechanical behavior and is the key to understanding and obtaining performance-based designs for reinforced soil structures. This paper investigates the micromechanics behind the effects of grain shape on the liquefaction response of unreinforced and reinforced sand through strain-controlled consolidated, truly undrained cyclic simple shear tests on granular materials with the same grain size and different grain shapes varying from completely rounded to angular. A layer of nonwoven geotextile was used in tests on reinforced sand. Grain shape is characterized through microscopic image analysis carried out in MATLAB. A series of densification tests and interface shear tests are performed to complement the cyclic simple shear tests in understanding the mechanism of liquefaction. With the increase in particle angularity by 77 and 123 times, the liquefaction resistance of the reinforced sand in terms of the number of cycles increased by about 200% and 270%, respectively. Results showed that the rate of densification is significantly affected by the particle shape and inclusion of geotextile, with maximum retardation of 24% for angular particles. An increase in the angularity of the particles has two advantages for providing liquefaction resistance to the particles: first, by increasing interlocking to achieve a stable configuration, and second, by improving interface friction to prevent particle movement and mobilization of pore water pressure.

Similar content being viewed by others

Data Availability

Data is available in the form of excel spreadsheets and are available from the corresponding author upon reasonable request.

References

Finn WDL, Pickering DJ, Bransby PL (1971) Sand liquefaction in triaxial and simple shear tests. J Soil Mech Found Div 97(4):639–659. https://doi.org/10.1061/JSFEAQ.0001579

Castro G (1975) Liquefaction and cyclic mobility of saturated sands. J Geotech Eng Div 101(6):551–569. https://doi.org/10.1061/AJGEB6.0000173

Ishihara K, Tatsuoka F, Yasuda S (1975) Undrained deformation and liquefaction of sand under cyclic stresses. Soils Found 15(1):29–44. https://doi.org/10.3208/sandf1972.15.29

Kramer SL (1996) Geotechnical earthquake engineering. Pearson Education India

Yoshimine M, Ishihara K (1998) Flow potential of sand during liquefaction. Soils Found 38(3):189–198. https://doi.org/10.3208/sandf.38.3_189

De Alba PA, Chan CK, Seed HB (1976) Sand liquefaction in large-scale simple shear tests. J Geotech Eng Div 102(9):909–927. https://doi.org/10.1061/AJGEB6.0000322

Ansell P, Brown SF (1978) A cyclic simple shear apparatus for dry granular materials. Geotech Test J 1(2):82–92. https://doi.org/10.1520/GTJ10375J

Shaw P, Brown SF (1986) Cyclic simple shear testing of granular materials. Geotech Test J 9(4):213–220. https://doi.org/10.1520/GTJ10632J

Amer MI, Kovacs WD, Aggour MS (1987) Cyclic simple shear size effects. J Geotech Eng 113(7):693–707. https://doi.org/10.1061/(ASCE)0733-9410(1987)113:7(693)

Dyvik R, Berre T, Lacasse S, Raadim B (1987) Comparison of truly undrained and constant volume direct simple shear tests. Geotechnique 37(1):3–10. https://doi.org/10.1680/geot.1987.37.1.3

Vaid YP, Sivathayalan S (1996) Static and cyclic liquefaction potential of Fraser Delta sand in simple shear and triaxial tests. Can Geotech J 33(2):281–289. https://doi.org/10.1139/t96-007

Thirugnanasampanther S (2016) Cyclic behaviour and dynamic properties of soils under simple shear loading. Doctoral dissertation, Carleton University

Naik SP, Choudhury B, Garg A (2021) Laboratory investigations of liquefaction mitigation of ganga sand using stable carbon material: a case study. Int J Geosynth Gr Eng 7(4):1–14. https://doi.org/10.1007/s40891-021-00333-3

Altun S, Göktepe AB, Lav MA (2008) Liquefaction resistance of sand reinforced with geosynthetics. Geosynth Int 15(5):322–332. https://doi.org/10.1680/gein.2008.15.5.322

Huang Y, Wen Z (2015) Recent developments of soil improvement methods for seismic liquefaction mitigation. Nat Hazards 76(3):1927–1938. https://doi.org/10.1007/s11069-014-1558-9

Bao X, Jin Z, Cui H et al (2020) Static liquefaction behavior of short discrete carbon fiber reinforced silty sand. Geosynth Int 27(6):606–619. https://doi.org/10.1680/jgein.20.00021

Bahadori H, Motamedi H, Hasheminezhad A, Motamed R (2020) Shaking table tests on shallow foundations over geocomposite and geogrid-reinforced liquefiable soils. Soil Dyn Earthq Eng 128:105896. https://doi.org/10.1016/j.soildyn.2019.105896

Hazarika H, Pasha SMK, Ishibashi I et al (2020) Tire-chip reinforced foundation as liquefaction countermeasure for residential buildings. Soils Found 60(2):315–326. https://doi.org/10.1016/j.sandf.2019.12.013

Dutta S, Nanda RP (2022) Waste rubber–soil mat for protection of structures from earthquake-induced liquefaction. Int J Geosynth Gr Eng 8(5):1–8. https://doi.org/10.1007/s40891-022-00397-9

Zhang X, Russell AR (2021) Liquefaction potential and effective stress of fiber-reinforced sand during undrained cyclic loading. J Geotech Geoenvironmental Eng 147(7):04021042. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002530

Rasouli H, Fatahi B (2022) Liquefaction and post-liquefaction resistance of sand reinforced with recycled geofibre. Geotext Geomembranes 50(1):69–81. https://doi.org/10.1016/j.geotexmem.2021.09.002

Jain A, Mittal S, Shukla SK (2023) Use of polyethylene terephthalate fibres for mitigating the liquefaction-induced failures. Geotext Geomembranes 51(1):245–258. https://doi.org/10.1016/j.geotexmem.2022.11.002

Krishnaswamy NR, Thomas Isaac N (1994) Liquefaction potential of reinforced sand. Geotext Geomembranes 13(1):23–41. https://doi.org/10.1016/0266-1144(94)90055-8

Nong ZZ, Park SS, Lee DE (2021) Comparison of sand liquefaction in cyclic triaxial and simple shear tests. Soils Found 61(4):1071–1085. https://doi.org/10.1016/j.sandf.2021.05.002

Mao X, Fahey M (2003) Behaviour of calcareous soils in undrained cyclic simple shear. Géotechnique 53(8):715–727. https://doi.org/10.1680/geot.2003.53.8.715

Cho G-C, Dodds J, Santamarina JC (2007) Closure to “Particle shape effects on packing density, stiffness, and strength: natural and crushed sands” by Gye-Chun Cho, Jake Dodds, and J. Carlos Santamarina. J Geotech Geoenviron Eng 133(11):1474. https://doi.org/10.1061/(ASCE)1090-0241(2007)133:11(1474)

Yang J, Wei LM (2012) Collapse of loose sand with the addition of fines: the role of particle shape. Géotechnique 62(12):1111–1125. https://doi.org/10.1680/geot.11.P.062

Vangla P, Gali ML (2016) Effect of particle size of sand and surface asperities of reinforcement on their interface shear behaviour. Geotext Geomembranes 44(3):254–268. https://doi.org/10.1016/j.geotexmem.2015.11.002

Yang G, Yan X, Nimbalkar S, Xu J (2019) Effect of particle shape and confining pressure on breakage and deformation of artificial rockfill. Int J Geosynth Gr Eng 5(2):1–10. https://doi.org/10.1007/s40891-019-0164-z

Latha GM, Lakkimsetti B (2022) Morphological perspectives to quantify and mitigate liquefaction in sands. Indian Geotech J 52:1244–1252. https://doi.org/10.1007/s40098-022-00649-5

Hyslip JP, Vallejo LE (1997) Fractal analysis of the roughness and size distribution of granular materials. Eng Geol 48(3–4):231–244. https://doi.org/10.1016/S0013-7952(97)00046-X

Bowman ET, Soga K, Drummond W (2001) Particle shape characterisation using Fourier descriptor analysis. Geotechnique 51(6):545–554. https://doi.org/10.1680/geot.2001.51.6.545

Sozer ZB (2005) Two dimensional characterization of topographies of geomaterial particles and surfaces. Doctoral dissertation, Georgia Institute of Technology

Roussillon T, Piégay H, Sivignon I et al (2009) Automatic computation of pebble roundness using digital imagery and discrete geometry. Comput Geosci 35(10):1992–2000. https://doi.org/10.1016/j.cageo.2009.01.013

Altuhafi F, O’sullivan C, Cavarretta I (2013) Analysis of an image-based method to quantify the size and shape of sand particles. J Geotech Geoenvironmental Eng 139(8):1290–1307. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000855

Zheng J, Hryciw RD (2015) Traditional soil particle sphericity, roundness and surface roughness by computational geometry. Géotechnique 65(6):494–506. https://doi.org/10.1680/geot.14.P.192

Vangla P, Roy N, Gali ML (2018) Image based shape characterization of granular materials and its effect on kinematics of particle motion. Granul Matter 20(1):1–19. https://doi.org/10.1007/s10035-017-0776-8

Pillai AG, Gali ML (2022) New perspectives on bentonite hydration and shear strength of GCL-sand interfaces based on particle shape characterizations. Int J Geosynth Gr Eng 8(2):1–17. https://doi.org/10.1007/s40891-022-00366-2

DeGregorio VB, Ahmadi G (1990) A model for dilatation, densification, and static liquefaction of loose sands. Math Geol 22(1):1–13. https://doi.org/10.1007/BF00890294

Abichou T, Benson CH, Edil TB (2002) Micro-structure and hydraulic conductivity of simulated sand-bentonite mixtures. Clays Clay Miner 50(5):537–545. https://doi.org/10.1346/000986002320679422

Cui D, Wu W, Xiang W et al (2017) Stick-slip behaviours of dry glass beads in triaxial compression. Granul Matter 19(1):1–18. https://doi.org/10.1007/s10035-016-0682-5

ASTM Standard D4253 (2016) Standard test methods for maximum index density and unit weight of soils using a vibratory table. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D4253-16E01

ASTM Standard D4254 (2016) Standard test methods for minimum index density and unit weight of soils and calculation of relative density. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D4254-16

ASTM Standard D854 (2014) Standard test methods for specific gravity of soil solids by water pycnometer. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D0854-14

Moayed RZ, Alibolandi M (2018) Effect of geotextile reinforcement on cyclic undrained behavior of sand. Soil Dyn Earthq Eng 104:395–402. https://doi.org/10.1016/j.soildyn.2017.11.013

Su L, Zhou L, Zhang X, Ling X (2022) Experimental and numerical modeling on liquefaction resistance of geotextile reinforced sand. Soil Dyn Earthq Eng 159:107345. https://doi.org/10.1016/j.soildyn.2022.107345

ASTM Standard D8296 (2019) Standard test method for consolidated undrained cyclic direct simple shear test under constant volume with load control or displacement control. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D8296-19

Varghese RM, Gali ML (2014) Shaking table tests to investigate the influence of various factors on the liquefaction resistance of sands. Nat Hazards 73:1337–1351. https://doi.org/10.1007/s11069-014-1142-3

Rouholamin M, Bhattacharya S, Orense RP (2017) Effect of initial relative density on the post-liquefaction behaviour of sand. Soil Dyn Earthq Eng 97:25–36. https://doi.org/10.1016/j.soildyn.2017.02.007

Wei X, Yang J (2019) Characterizing the effects of fines on the liquefaction resistance of silty sands. Soils Found 59(6):1800–1812. https://doi.org/10.1016/j.sandf.2019.08.010

Ni X, Ye B, Zhang F, Feng X (2020) Influence of specimen preparation on the liquefaction behaviors of sand and its mesoscopic explanation. J Geotech Geoenviron Eng 147(2):04020161. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002456

Fardad Amini P, Noorzad R (2018) Energy-based evaluation of liquefaction of fiber-reinforced sand using cyclic triaxial testing. Soil Dyn Earthq Eng 104:45–53. https://doi.org/10.1016/j.soildyn.2017.09.026

Haeri SM, Noorzad R, Oskoorouchi AM (2000) Effect of geotextile reinforcement on the mechanical behavior of sand. Geotext Geomembranes 18(6):385–402. https://doi.org/10.1016/S0266-1144(00)00005-4

Vaid YP, Fisher JM, Kuerbis RH, Negussey D (1990) Particle gradation and liquefaction. J Geotech Eng 116(4):698–703. https://doi.org/10.1061/(ASCE)0733-9410(1990)116:4(698)

Yang J, Luo XD (2018) The critical state friction angle of granular materials: does it depend on grading? Acta Geotech 13(3):535–547. https://doi.org/10.1007/s11440-017-0581-x

Moreira DDC, dos Santos CAS, Mesquita ALA, Moreira DC (2020) Influence of particle size distribution of iron ore fines on liquefaction during marine transportation. Powder Technol 373:301–309. https://doi.org/10.1016/j.powtec.2020.06.052

ElGhoraiby MA, Park H, Manzari MT (2020) Stress-strain behavior and liquefaction strength characteristics of Ottawa F65 sand. Soil Dyn Earthq Eng 138:106292. https://doi.org/10.1016/j.soildyn.2020.106292

Khashila M, Hussien MN, Karray M, Chekired M (2021) Liquefaction resistance from cyclic simple and triaxial shearing: a comparative study. Acta Geotech 16:1735–1753. https://doi.org/10.1007/s11440-020-01104-6

Seed HB, Lee KL (1966) Liquefaction of saturated sands during cyclic loading. J Soil Mech Found Div 92(6):105–134. https://doi.org/10.1061/JSFEAQ.0000913

Altuhafi FN, Coop MR, Georgiannou VN (2016) Effect of particle shape on the mechanical behavior of natural sands. J Geotech Geoenviron Eng 142(12):04016071. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001569

Kazmi D, Serati M, Williams DJ et al (2021) The potential use of crushed waste glass as a sustainable alternative to natural and manufactured sand in geotechnical applications. J Clean Prod 284:124762. https://doi.org/10.1016/j.jclepro.2020.124762

Pillai AG, Gali ML (2022) Role of particle shape on the shear strength of sand-GCL interfaces under dry and wet conditions. Geotext Geomembranes 50(2):262–281. https://doi.org/10.1016/j.geotexmem.2021.11.004

Wadell H (1932) Volume, shape, and roundness of rock particles. J Geol 40(5):443–451

Krumbein WC, Sloss LL (1951) Stratigraphy and sedimentation. LWW 71(5):401

Lees G (1964) A new method for determining the angularity of particles. Sedimentology 3(1):2–21. https://doi.org/10.1111/j.1365-3091.1964.tb00271.x

Afzali-Nejad A, Lashkari A, Shourijeh PT (2017) Influence of particle shape on the shear strength and dilation of sand-woven geotextile interfaces. Geotext Geomembranes 45(1):54–66. https://doi.org/10.1016/j.geotexmem.2016.07.005

Peng Z, Chen C, Wu L (2021) Numerical investigation of particle shape effect on sand shear strength. Arab J Sci Eng 46(11):10585–10595. https://doi.org/10.1007/s13369-021-05430-z

Jones DRV, Dixon N (1998) Shear strength properties of geomembrane/geotextile interfaces. Geotext Geomembranes 16(1):45–71. https://doi.org/10.1016/S0266-1144(97)10022-X

Liu F, Ying M, Yuan G et al (2021) Particle shape effects on the cyclic shear behaviour of the soil–geogrid interface. Geotext Geomembranes 49(4):991–1003. https://doi.org/10.1016/j.geotexmem.2021.01.008

Vangla P, Latha GM (2015) Influence of particle size on the friction and interfacial shear strength of sands of similar morphology. Int J Geosynth Gr Eng 1(1):1–12. https://doi.org/10.1007/s40891-014-0008-9

Nemat-Nasser S, Takahashi K (1984) Liquefaction and fabric of sand. J Geotech Eng 110(9):1291–1306. https://doi.org/10.1061/(ASCE)0733-9410(1984)110:9(1291)

Nemat-Nasser S, Shokooh A (1979) A unified approach to densification and liquefaction of cohesionless sand in cyclic shearing. Can Geotech J 16(4):659–678. https://doi.org/10.1139/t79-076

Nemat-Nasser S, Tobita Y (1982) Influence of fabric on liquefaction and densification potential of cohesionless sand. Mech Mater 1(1):43–62. https://doi.org/10.1016/0167-6636(82)90023-0

Cuellar V, Bazant ZP, Krizek RJ, Silver ML (1977) Densification and hysteresis of sand under cyclic shear. J Geotech Eng Div 103(5):399–416. https://doi.org/10.1061/AJGEB6.0000420

Youd TL (1972) Compaction of sands by repeated shear straining. J Soil Mech Found Div 98(7):709–725. https://doi.org/10.1061/JSFEAQ.0001762

Whitman RV (1971) Resistance of soil to liquefaction and settlement. Soils Found 11(4):59–68. https://doi.org/10.3208/sandf1960.11.4_59

Acknowledgements

The work reported in this paper is funded by the SERB POWER fellowship (SPF/2021/000041) of the Department of Science and Technology (DST), India, and the Dam Rehabilitation and Improvement Project (DRIP) of the Ministry of Water Resources, Government of India. The cyclic simple shear equipment utilized for conducting the tests was procured with financial assistance from DST FIST Phase 3 funding. The authors gratefully appreciate the funding organization for the help.

Author information

Authors and Affiliations

Contributions

BL and MLG contributed to the conceptualization and design of experiments. BL conducted all the experiments. BL and MLG analyzed and interpreted all the test results. BL wrote the original draft, and MLG contributed to editing and supervising. All authors read and approved this manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lakkimsetti, B., Gali, M.L. Grain Shape Effects on the Liquefaction Response of Geotextile-Reinforced Sands. Int. J. of Geosynth. and Ground Eng. 9, 15 (2023). https://doi.org/10.1007/s40891-023-00434-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-023-00434-1