Abstract

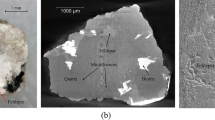

The rockfill exhibits a substantial amount of particle breakage when subjected to higher range of stresses. The deformations of rockfill under such excessive stresses often lead to failure and cannot be ignored. The degree of particle breakage is related to the type of the material as well as the particle shape. Based on this, artificially simulated rockfill materials with three different aggregate shapes (prism, cube, and cylinder) were prepared by cement paste-casting method. Through a series of medium-sized triaxial shear tests, the effects of confining pressure and particle shape on the fracture characteristics of the artificial rockfill and its secant modulus were investigated. The useful relationships between particle sphericity and roundness with deformation modulus and particle breakage rate were proposed.

Similar content being viewed by others

References

Miura N, O-Hara S (1979) Particle-crushing of a decomposed granite soil under shear stresses. Soils Found 19(3):1–14

Gupta AK (2009) Effect of particle size and confining pressure on breakage and strength parameters of rockfill materials. Electron J Geotech Eng 14(H):1–12

Xiao Y, Liu H, Zhang WG, Liu HL, Yin F (2016) Testing and modeling of rockfill materials: a review. J Rock Mech Geotech Eng 8(3):415–422

Ovalle C, Frossard E, Dano C, Hu W, Maiolino S, Hicher PY (2014) The effect of size on the strength of coarse rock aggregates and large rockfill samples through experimental data. Acta Mech 225(8):2199–2216

Zhang BY, Zhang JH, Sun GL (2015) Deformation and shear strength of rockfill materials composed of soft siltstones subjected to stress, cyclical drying/wetting and temperature variations. Eng Geol 190:87–97

Gupta AK (2016) Effects of particle size and confining pressure on breakage factor of rockfill materials using medium triaxial test. J Rock Mech Geotech Eng 8(3):378–388

Frossard E, Hu W, Dano C, Hicher PY (2012) Rockfill shear strength evaluation: a rational method based on size effects. Géotechnique 62(5):415–427

Won MS, Kim YS (2008) A case study on the post-construction deformation of concrete face rockfill dams. Can Geotech J 45(6):845–852

Chen SS, Huo JP (2009) Impact of the ‘5.12’ Wenchuan earthquake on Zipingpu concrete face rock-fill dam and its analysis. Geomech Geoeng 4(4):299–306

Marsal RJ (1967) Large scale testing of rockfill materials. Soil Mech Found Div 93(2):27–43

Lee KL, Farhoomand I (1967) Compressibility and crushing of granular soil. Can Geotech J 4(1):68–86

Charles JA, Watts KS (1980) The influence of confining pressure on the shear strength of compacted rockfill. Géotechnique 30(4):353–367

Cho GC, Dodds J, Santamarina JC (2006) Particle shape effects on packing density, stiffness, and strength: natural and crushe sands. J Geotech Geoenviron Eng 132(5):591–602

Shin H, Santamarina JC (2013) Role of particle angularity on the mechanical behavior of granular mixtures. J Geotech Geoenviron Eng 139(2):353–355

Santamarina JC, Cho GC (2004) Soil behaviour: the role of particle shape”. advances in geotechnical engineering. Proc Skempton Conf 1:1–14

Soroush A, Jannatiaghdam R (2012) Behavior of rockfill materials in triaxial compression testing. Int J Civ Eng 10(2):153–161

Shinohara K, Oida M, Golman B (2000) Effect of particle shape on angle of internal friction by triaxial compression test. Powder Technol 107(1–2):131–136

Cheng ZL, Ding HS, Wu LP (2007) Experimental study on mechanical behaviour of granular material. Chin J Geotech Eng 29(8):1151–1158

Kong DZ, Zhang QG, Zhang BY, Sun X (2009) Particle breakage ratio of artificial rockfill materials. Chin J Tsinghua Univ (Sci & Tech) 49(6):811–815

Takei M, Kusakabe O, Hayashi T (2001) Time-dependent behavior of crushable materials in one-dimensional compression tests. Soils Found 41(1):97–121

Zhang BY, Jie YX, Kong DZ (2013) Computers and geotechnics particle size distribution and relative breakage for a cement ellipsoid aggregate. Comput Geotech 53:31–39

Rothenburg L, Bathurst RJ (1992) Micromechanical features of granular assemblies with planar elliptical particles. Géotechnique 42(1):79–95

Kock I, Huhn K (2007) Influence of particle shape on the frictional strength of sediments—a numerical case study. Sed Geol 196(1–4):217–233

Mirghasemi AA, Rothenburg L, Matyas EL (2002) Influence of particle shape on engineering properties of assemblies of two-dimensional polygon-shaped particles. Géotechnique 52(3):209–217

Gong J, Liu J (2017) Effect of aspect ratio on triaxial compression of multi-sphere ellipsoid assemblies simulated using a discrete element method. Particuology 32:49–62

Cho N, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min Sci 44(7):997–1010

Zhou W, Ma G, Chang XL, Zhou CB (2013) Influence of particle shape on behavior of rockfill using a three-dimensional deformable DEM. J Eng Mech 139:1868–1873

Shen JY, Jimenez R (2018) Predicting the shear strength parameters of sandstone using genetic programming. Bull Eng Geol Env 77(4):1647–1662

Wadell H (1932) Volume, shape, and roundness of rock particles. J Geol 40(5):443–451

Uthus L, Hoff I, Horvli I (2005) Evaluation of grain shape characterization methods for unbound aggregates. In: Seventh international conference on the bearing capacity of road, railways and airfields. Trondheim, Norway, 27–29 June 2005

Janoo VC (1998) Quantification of shape, angularity, and surface texture of base course materials. Special Report 98-1,US Army Corps of Engineers, Cold Regions Research & Engineering Laboratory

Sukumaran B, Ashmawy AK (2001) Quantitative characterisation of the geometry of discret particles. Géotechnique 51(7):619–627

Blott SJ, Pye K (2008) Particle shape: a review and new methods of characterization and classification. Sedimentology 55(1):31–63

Sneed ED, Folk RL (1958) Pebbles in the lower colorado river, texas a study in particle morphogenesis. J Geol 66(2):114–150

Barrett PJ (1980) The shape of rock particles, a critical review. Sedimentology 27:291–303

Xiao Y, Liu HL, Chen YM, Jiang JS (2014) Strength and deformation of rock fill material based on large-scale triaxial compression tests. I: influences of density and pressure. J Geotech Geoenviron Eng 140(12):1–16

Duncan JM, Chang CY (1970) Nonlinear analysis of stress and strain in soils. Soil Mech Found Div 5:1629–1653

Zhou B, Wang J, Wang H (2018) Three-dimensional sphericity, roundness and fractal dimension of sand particles. Géotechnique 68(1):18–30

Tapias M, Alonso EE, Gili J (2015) A particle model for rockfill behaviour. Géotechnique 65(12):975–994

Kong DZ, Zhang QG, Zhang BY, Sun X (2009) Particle breakage ratio of artificial rockfill materials. J Tsinghua Univ (Science and Technology) 49(6):811–815

Lade PV, Yamamuro JA, Bopp PA (1996) Significance of particle crushing in granular materials. J Geotech Eng 122(4):309–316

Hardin BO (1985) Crushing of soil particles. J Geotech Eng 111(10):1177–1192

Nakata Y, Hyde AFL, Hyodo M, Murata H (1999) A probabilistic approach to sand particle crushing in the triaxial test. Géotechnique 49(5):567–583

Acknowledgements

The financial support provided by the National Natural Science Foundation of China (No. 51479059) and Fundamental Research Funds for the Central Universities of China (No. 2017B12514) are greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, G., Yan, X., Nimbalkar, S. et al. Effect of Particle Shape and Confining Pressure on Breakage and Deformation of Artificial Rockfill. Int. J. of Geosynth. and Ground Eng. 5, 15 (2019). https://doi.org/10.1007/s40891-019-0164-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-019-0164-z