Abstract

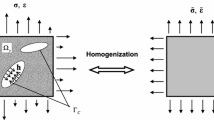

This study presents an enhanced integrative constitutive model for brittle materials subjected to dynamic loading by combining a micromechanics-based damage model and a breakage mechanics model. The damage model was used to describe microcracking, which captures the initial fragmentation of brittle solids due to growth of cracks until the material transforms into a granulated material. The dynamic behavior of the granulated material was described with a breakage mechanics model, which is activated when the damage level reaches a predefined critical threshold. The response of reference material boron carbide was simulated under confined/unconfined compression and ballistic impact loading conditions. The predictive capability of the integrative model was investigated by comparing the unconfined and confined simulation results with experimental data quantitatively and qualitatively. The simulations were also performed with an integrative model adopting a Drucker–Prager based two surface model to investigate the role of the granular material model on the macroscopic dynamic response. The two integrative models, which provided similar failure strength values under unconfined compression, predicted considerable different damage pattern in sphere impact simulations. A series of sensitivity simulations revealed that some critical granular model parameters strongly control the extent and spatial distribution of damage, and penetration resistance. The sphere impact simulations conducted with different impact velocities were able to reproduce various deformation features observed in previous experimental studies. The capability of the integrative model in capturing many aspects of the dynamic response of brittle materials under different loading conditions suggests that it can provide useful guidance for the design and development of next generation materials.

Similar content being viewed by others

References

Vogler TJ, Reinhart WD, Chhabildas LC (2004) Dynamic behavior of boron carbide. J Appl Phys 95(8):4173–4183. https://doi.org/10.1063/1.1686902

Klopp RW, Shockey DA (1991) The strength behavior of granulated silicon carbide at high strain rates and confining pressure. J Appl Phys 70(12):7318–7326. https://doi.org/10.1063/1.349750

LaSalvia JC, Normandia MJ, Miller HT, MacKenzie DE (2005) Sphere impact induced damage in ceramics: II. Armor-Grade B4C and WC. In: Advances in ceramic armor: a collection of papers presented at the 29th international conference on advanced ceramics and composites, 23–28 January 2005, Cocoa Beach, Florida, ceramic engineering and science proceedings. pp 183–192. https://doi.org/10.1002/9780470291276.ch21

Shockey DA, Marchand AH, Skaggs SR, Cort GE, Burkett MW, Parker R (1990) Failure phenomenology of confined ceramic targets and impacting rods. Int J Impact Eng 9(3):263–275. https://doi.org/10.1016/0734-743X(90)90002-D

Normandia MJ (2004) Impact response and analysis of several silicon carbides. Int J Appl Ceram Technol 1(3):226–234. https://doi.org/10.1111/j.1744-7402.2004.tb00174.x

Chen W, Ravichandran G (1997) Dynamic compressive failure of a glass ceramic under lateral confinement. J Mech Phys Solids 45(8):1303–1328. https://doi.org/10.1016/S0022-5096(97)00006-9

Luo H, Chen W (2004) Dynamic compressive response of intact and damaged AD995 alumina. Int J Appl Ceram Technol 1(3):254–260. https://doi.org/10.1111/j.1744-7402.2004.tb00177.x

Paliwal B, Ramesh KT, McCauley JW, Chen M (2008) Dynamic compressive failure of AlON under controlled planar confinement. J Am Ceram Soc 91(11):3619–3629. https://doi.org/10.1111/j.1551-2916.2008.02712.x

Chocron S, Dannemann KA, Walker JD, Nicholls AE, Anderson CE (2009) Static and dynamic confined compression of borosilicate glass. In: DYMAT—international conference on the mechanical and physical behaviour of materials under dynamic loading, vol 1, pp 67–72

Johnson GR, Holmquist TJ (1994) An improved computational constitutive model for brittle materials. AIP Conf Proc 309(1):981–984. https://doi.org/10.1063/1.46199

Fossum AF, Brannon RM (2006) On a viscoplastic model for rocks with mechanism-dependent characteristic times. Acta Geotech 1(2):89–106. https://doi.org/10.1007/s11440-006-0010-z

Holmquist TJ, Johnson GR (2005) Characterization and evaluation of silicon carbide for high-velocity impact. J Appl Phys 97(9):093502. https://doi.org/10.1063/1.1881798

Paliwal B, Ramesh KT (2008) An interacting micro-crack damage model for failure of brittle materials under compression. J Mech Phys Solids 56(3):896–923. https://doi.org/10.1016/j.jmps.2007.06.012

Tonge AL, Ramesh KT (2016) Multi-scale defect interactions in high-rate brittle material failure. Part I: model formulation and application to ALON. J Mech Phys Solids 86:117–149. https://doi.org/10.1016/j.jmps.2015.10.007

Zeng Q, Tonge AL, Ramesh KT (2019) A multi-mechanism constitutive model for the dynamic failure of quasi-brittle materials. Part II: integrative model. J Mech Phys Solids 131:20–42. https://doi.org/10.1016/j.jmps.2019.06.015

Le J (2018) Multiscale modeling of probabilistic failure of quasibrittle structures under impact. U.S. Army Research Office, Project No. W911NF1510197, Final Report

Huang C, Subhash G (2003) Influence of lateral confinement on dynamic damage evolution during uniaxial compressive response of brittle solids. J Mech Phys Solids 51(6):1089–1105. https://doi.org/10.1016/S0022-5096(03)00002-4

Basista M, Gross D (1998) The sliding crack model of brittle deformation: an internal variable approach. Int J Solids Struct 35(5):487–509. https://doi.org/10.1016/S0020-7683(97)00031-0

Deshpande VS, Gamble EAN, Compton BG, McMeeking RM, Evans AG, Zok FW (2011) A constitutive description of the inelastic response of ceramics. J Am Ceram Soc 94(s1):s204–s214. https://doi.org/10.1111/j.1551-2916.2011.04516.x

Grechka V, Kachanov M (2006) Effective elasticity of fractured rocks: a snapshot of the work in progress. Geophysics 71(6):W45–W58. https://doi.org/10.1190/1.2360212

Nemat-Nasser S, Deng H (1994) Strain-rate effect on brittle failure in compression. Acta Metall Mater 42(3):1013–1024. https://doi.org/10.1016/0956-7151(94)90295-X

Gailly BA, Espinosa HD (2002) Modelling of failure mode transition in ballistic penetration with a continuum model describing microcracking and flow of pulverized media. Int J Numer Methods Eng 54(3):365–398. https://doi.org/10.1002/nme.427

Cil MB, Hurley RC, Graham-Brady L (2019) A rate-dependent constitutive model for brittle granular materials based on breakage mechanics. J Am Ceram Soc 102(9):5524–5534. https://doi.org/10.1111/jace.16376

Simo JC, Ortiz M (1985) A unified approach to finite deformation elastoplastic analysis based on the use of hyperelastic constitutive equations. Comput Methods Appl Mech Eng 49(2):221–245. https://doi.org/10.1016/0045-7825(85)90061-1

Housen KR, Holsapple KA (1999) Scale effects in strength-dominated collisions of rocky asteroids. Icarus 142(1):21–33. https://doi.org/10.1006/icar.1999.6206

Duvant G, Lions JL (1976) Inequalities in mechanics and physics. Springer, Berlin

Einav I (2007) Breakage mechanics—Part I: theory. J Mech Phys Solids 55(6):1274–1297. https://doi.org/10.1016/j.jmps.2006.11.003

Nguyen GD, Einav I (2009) The energetics of cataclasis based on breakage mechanics. Pure Appl Geophys 166(10–11):1693–1724

Tengattini A, Das A, Einav I (2016) A constitutive modelling framework predicting critical state in sand undergoing crushing and dilation. Géotechnique 66(9):695–710. https://doi.org/10.1680/jgeot.14.P.164

Rubin MB, Einav I (2011) A large deformation breakage model of granular materials including porosity and inelastic distortional deformation rate. Int J Eng Sci 49(10):1151–1169. https://doi.org/10.1016/j.ijengsci.2011.05.002

Tonge AL, Ramesh KT (2016) Multi-scale defect interactions in high-rate failure of brittle materials, Part II: application to design of protection materials. J Mech Phys Solids 86:237–258. https://doi.org/10.1016/j.jmps.2015.10.006

Hogan JD, Farbaniec L, Shaeffer M, Ramesh KT (2015) The effects of microstructure and confinement on the compressive fragmentation of an advanced ceramic. J Am Ceram Soc 98(3):902–912. https://doi.org/10.1111/jace.13353

LaSalvia JC, Normandia MJ, Miller HT, MacKenzie DE (2005) Sphere impact induced damage in ceramics: I. Armor-Grade SiC and TiB2. In: Advances in ceramic armor: a collection of papers presented at the 29th international conference on advanced ceramics and composites, 23–28 January 2005, Cocoa Beach, Florida, ceramic engineering and science proceedings. pp 170–181. https://doi.org/10.1002/9780470291276.ch20

Holmquist TJ, Johnson GR, Gooch W (2005) Modeling the 14.5 mm BS41 projectile for ballistic impact computations. Comput Ballist II WIT Trans Model Simul 40:61–75. https://doi.org/10.2495/CBAL050071

Ravichandran G, Subhash G (1994) Critical appraisal of limiting strain rates for compression testing of ceramics in a split Hopkinson pressure bar. J Am Ceram Soc 77(1):263–267. https://doi.org/10.1111/j.1151-2916.1994.tb06987.x

Wang H, Ramesh KT (2004) Dynamic strength and fragmentation of hot-pressed silicon carbide under uniaxial compression. Acta Mater 52(2):355–367. https://doi.org/10.1016/j.actamat.2003.09.036

Sammis C, King G, Biegel R (1987) The kinematics of gouge deformation. Pure Appl Geophys 125(5):777–812. https://doi.org/10.1007/BF00878033

Mescall J, Weiss V (1983) Material behavior under high stress and ultrahigh loading rates, vol 29. Plenum Publishing Corp., New York

Curran DR, Seaman L, Cooper T, Shockey DA (1993) Micromechanical model for comminution and granular flow of brittle material under high strain rate application to penetration of ceramic targets. Int J Impact Eng 13(1):53–83. https://doi.org/10.1016/0734-743X(93)90108-J

Alshibli KA, Cil MB (2018) Influence of particle morphology on the friction and dilatancy of sand. J Geotech Geoenviron Eng 144(3):04017118. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001841

Sarkar D, Goudarzy M, König D (2019) An interpretation of the influence of particle shape on the mechanical behavior of granular material. Granul Matter 21(3):53. https://doi.org/10.1007/s10035-019-0909-3

Sohn C, Zhang YD, Cil M, Buscarnera G (2017) Experimental assessment of continuum breakage models accounting for mechanical interactions at particle contacts. Granul Matter 19(4):67. https://doi.org/10.1007/s10035-017-0750-5

Acknowledgements

Research was sponsored by the Army Research Laboratory and was accomplished under Cooperative Agreement Number W911NF-12-2-0022. The views and conclusions contained in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of the Army Research Laboratory or the U.S. Government. The U.S. Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation herein.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cil, M.B., Zeng, Q., Hurley, R.C. et al. An Integrative Model for the Dynamic Behavior of Brittle Materials Based on Microcracking and Breakage Mechanics. J. dynamic behavior mater. 6, 472–488 (2020). https://doi.org/10.1007/s40870-020-00251-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-020-00251-x