Abstract

Particle size and shape are major factors in determining the mechanical behavior of granular media. This paper discusses experiments conducted at particle and assembly scales on two materials (i.e., glass beads and quartz sand) and it interprets them in light of fracture mechanics theories. First, diametral compression tests on particles of varying size have been conducted to measure the energy stored in individual grains at the onset of fracture. Then, oedometric compression tests on samples made of the same particles have been performed to measure the yielding pressure, as well as to track the evolution of breakage. These experiments have been used to test the performance of recently proposed scaling laws bridging the energy released by a single particle with the work input required to comminute an assembly. The results show that the variables associated with macroscopic comminution scale with the grain size according to the same power law functions that control the size-dependence of the corresponding particle-scale quantities. Major differences between the scaling laws of glass beads and quartz sands have been found, with the former approaching the size effect law associated with fracture by central splitting and the latter being closer to the trends predicted by fracture at the contacts. These findings emphasize the key role of the particle shape on the energetics of breakage, thus motivating further studies focusing on different shapes, for which even wider ranges of fracture modes and scaling laws may exist.

Similar content being viewed by others

References

McDowell, G.R., Bolton, M.D.: On the micromechanics of crushable aggregates. Geotechnique 48(5), 667–679 (1998)

Nakata, Y., Hyodo, M., Hyde, A.F.L., Kato, Y., Murata, H.: Microscopic particle crushing of sand subjected to high pressure one-dimensional compression. Soils Found. 41(1), 69–82 (2001)

Zhang, Y.D., Buscarnera, G., Einav, I.: Grain size dependence of yielding in granular soils interpreted using fracture mechanics, breakage mechanics and Weibull statistics. Geotechnique 66(2), 149–160 (2016). doi:10.1680/jgeot.15.P.119

Oldecop, L.A., Alonso, E.E.: A model for rockfill compressibility. Geotechnique 51(2), 127–139 (2001). doi:10.1680/geot.2001.51.2.127

Yang, Z.X., Jardine, R.J., Zhu, B.T., Foray, P., Tsuha, C.H.C.: Sand grain crushing and interface shearing during displacement pile installation in sand. Geotechnique 60(6), 469–482 (2010). doi:10.1680/geot.2010.60.6.469

Kuwajima, K., Hyodo, M., Hyde, A.F.: Pile bearing capacity factors and soil crushabiity. J. Geotech. Geoenviron. 135(7), 901–913 (2009). doi:10.1061/(ASCE)GT.1943-5606.0000057

McDowell, G.R.: On the yielding and plastic compression of sand. Soils Found. 42(1), 139–145 (2002)

Wang, F.W., Sassa, K., Wang, G.H.: Mechanism of a long-runout landslide triggered by the August 1998 heavy rainfall in Fukushima Prefecture, Japan. Eng. Geol. 63(1–2), 169–185 (2002). doi:10.1016/S0013-7952(01)00080-1

Nakata, Y., Kato, Y., Hyodo, M., Hyde, A.F.L., Murata, H.: One-dimensional compression behaviour of uniformly graded sand related to single particle crushing strength. Soils Found. 41(2), 39–51 (2001)

Billam J (1972) Some aspects of the behavior of granular materials at high pressures. In: Parry RHG, Foulis GT (eds) Roscoe memorial symposium: stress–strain behavior of soils, Cambridge, March 29–31, 1971

Sadrekarimi, A., Olson, S.M.: Particle damage observed in ring shear tests on sands. Can. Geotech. J. 47(5), 497–515 (2010). doi:10.1139/T09-117

Lade, P.V., Yamamuro, J.A., Bopp, P.A.: Significance of particle crushing in granular materials. J. Geotech. Eng.-ASCE 122(4), 309–316 (1996). doi:10.1061/(Asce)0733-9410

Ovalle, C., Dano, C., Hicher, P.Y.: Experimental data highlighting the role of surface fracture energy in quasi-static confined comminution. Int. J. Fract. 182(1), 123–130 (2013). doi:10.1007/s10704-013-9833-4

Shahnazari, H., Rezvani, R.: Effective parameters for the particle breakage of calcareous sands: an experimental study. Eng. Geol. 159, 98–105 (2013). doi:10.1016/j.enggeo.2013.03.005

Einav, I.: Breakage mechanics—part II: modelling granular materials. J. Mech. Phys. Solids 55(6), 1298–1320 (2007). doi:10.1016/j.jmps.2006.11.004

Einav, I.: Breakage mechanics–part I: theory. J. Mech. Phys. Solids 55(6), 1274–1297 (2007). doi:10.1016/j.jmps.2006.11.003

Einav, I.: Fracture propagation in brittle granular matter. In: Proceedings of the Royal Society A: Mathematical, Physical and Engineering Science, vol. 463 no. 2087, pp. 3021–3035 (2007). doi:10.1098/rspa.2007.1898

Jaeger, J.C.: Failure of rocks under tensile conditions. In: International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts, vol. 4, no. 2, pp. 219–227 (1967). doi:10.1016/0148-9062(67)90046-0

Tavares, L., King, R.: Single-particle fracture under impact loading. Int. J. Miner. Process. 54(1), 1–28 (1998)

Hiramatsu, Y., Oka, Y.: Determination of the tensile strength of rock by a compression test of an irregular test piece. In: International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts, vol. 3, no. 2, pp. 89–90 (1966). doi:10.1016/0148-9062(66)90002-7

Shipway, P.H., Hutchings, I.M.: Fracture of brittle spheres under compression and impact loading. 1. Elastic stress distributions. Philos. Mag. A 67(6), 1389–1404 (1993)

Griffith, A.A.: The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. Lond. Ser. A Contain. Pap. Math. Phys. Character 221(582–593), 163–198 (1921). doi:10.1098/rsta.1921.0006

Nguyen, G.D., Einav, I.: The energetics of cataclasis based on breakage mechanics. Pure Appl. Geophys. 166(10–11), 1693–1724 (2009). doi:10.1007/s00024-009-0518-x

Zhang, Y.D., Buscarnera, G.: Grainsize dependence of clastic yielding in unsaturated granular soils. Granul. Matter 16(4), 469–483 (2014). doi:10.1007/s10035-014-0491-7

Jaky, J.: The coefficient of earth pressure at rest. J. Soc. Hung. Archit. Eng. 78(22), 355–358 (1944)

Buscarnera, G., Einav, I.: The yielding of brittle unsaturated granular soils. Geotechnique 62(2), 147–160 (2012). doi:10.1680/geot.10.P.118

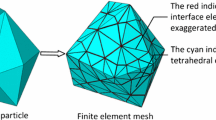

Cil, M.B., Buscarnera, G.: DEM assessment of scaling laws capturing the grain size dependence of yielding in granular soils. Granul. Matter 18(3), 36 (2016). doi:10.1007/s10035-016-0638-9

Ham, A., Wang, J., Stammer, J.G.: Relationships between particle shape characteristics and macroscopic damping in dry sands. J. Geotech. Geoenviron. Eng. 138(8), 1002–1011 (2011)

Zhang, J., Wong, T.-F., Davis, D.M.: Micromechanics of pressure-induced grain crushing in porous rocks. J. Geophys. Res.: Solid Earth 95(B1), 341–352 (1990). doi:10.1029/JB095iB01p00341

Agnolin, I., Roux, J.-N., Massaad, P., Jia, X., Mills, P.: Sound wave velocities in dry and lubricated granular packings packings: numerical simulations and experiments. arXiv preprint arXiv:0901.2995 (2009)

Cho, G.-C., Dodds, J., Santamarina, J.C.: Particle shape effects on packing density, stiffness, and strength: natural and crushed sands. J. Geotech. Geoenviron. Eng. 132(5), 591–602 (2006)

Acknowledgements

Acknowledgment is made to the donors of the American Chemical Society-Petroleum Research Fund for partial support of this research. The Army Research Office (Grant W911NF1610439) is also gratefully acknowledged. Part of this work has been conducted at the testing facilities of the Northwestern University Materials Research Science and Engineering Center (MRSEC), supported by the National Science Foundation (DMR-0520513).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Appendix

Appendix

1.1 Fracture models

1.1.1 (a) Surface crack model

The failure load due to the surface crack can be expressed as follows [3]:

where \(b^{\prime }=\frac{1}{1.12}\left( {\frac{\pi \alpha }{2}} \right) ^{-1/2}\) is a coefficient associated with the crack geometry, while \(\alpha \) is a dimensionless crack size (i.e., the crack length normalized for the particle diameter). \(G_{{\textit{IC}}}\) is the critical energy release rate (here assumed to be \(0.95 \hbox { J/m}^{2}\)).

1.1.2 (b) Central crack model

The failure load for central split of a particle can be expressed through the following equation [3]:

where \(a^{\prime }=\frac{\sqrt{\pi }}{\sqrt{2\alpha }}\) is a coefficient associated with the crack geometry, \(G_{IC}\) is the critical energy release rate (here assumed to be \(0.95\hbox { J/m}^{2})\) and the coefficients \(a^{\prime }\) and \(b^{\prime }\) are associated with the dimensionless crack size.

1.2 Contact model

1.2.1 (a) Linear contact model

A linear contact involves a constant contact area (i.e., not altered by the applied force). This type of contact is here modeled through the following force-displacement law:

where \(a_{c}\) is the contact radius; R is the particle radius; and \(\delta \) is the contact deformation ( \(\delta = {\Delta }/2\)).

By substituting Eq. 13 into Eq. 2, the relation between characteristic particle strength and energy stored at the onset of fracture can be expressed as follows:

1.2.2 (b) Hertzian contact model

In case of the contact between an elastic particle and a rigid loading plate, the force-displacement response for a Hertzian contact can be expressed through the following relations:

By substituting Eq. 15 into Eq. 2, the relation between characteristic particle strength and the energy stored at the onset of fracture can be expressed as follows:

1.2.3 (c) Conical contact model

The load-displacement relation for a conical contact model derived by Zhang et al. [3] can be expressed as follows:

By substituting Eq. 17 into Eq. 2, the relation between characteristic particle strength and the energy stored at the onset of fracture is:

where \(A_s\) is the tangent of the contact angle between the particle and a horizontal surface [3].

1.3 Combination of failure model and contact model

It is possible to express the characteristic particle strength, \(\sigma _{{\textit{pc}}}\), in Eqs. 14, 16, and 18 in terms of grain size by combining Eqs. 11 and 12 with Eq. 1. While the failure model based on central splitting can be combined with any of three contact models, the failure criterion based on surface fracture can only be used in combination with a Hertzian contact law. Therefore, four expressions of \(E_{{\textit{pc}}}\) are obtained as a function of the grain size, d.

1.3.1 (a) Surface crack

-

(i)

Hertzian contact model

Equation 11 can be expressed as a function of \(\sigma _{{\textit{pc}}}\) by using Eq. 1. By substituting the resulting expression into Eq. 16 gives:

1.3.2 (b) Central crack

Equation 12 can be expressed as a function of \(\sigma _{{\textit{pc}}}\) by using Eq. 1. Then, by substituting the resulting expression into Eqs. 14, 16 and 18 the following relations are obtained:

-

(i)

Linear contact model

$$\begin{aligned} E_{{\textit{pc}}} =1.531a^{\prime }\left( {\frac{ a_{c}}{{\textit{R}}}} \right) ^{-2}\left( {\frac{G_{{\textit{IC}}} }{1-v^{2}}} \right) d_{p}^{-1} \end{aligned}$$(20) -

(ii)

Hertzian contact model

$$\begin{aligned} E_{{\textit{pc}}}=0.897\pi ^{2/3} a^{{\prime }^{{5/3}}}\left( {\frac{1-v^{2}}{{\textit{E}}}} \right) ^{-1/6}G_{{\textit{IC}}}^{5/6} d_{p}^{-5/6} \end{aligned}$$(21) -

(iii)

Conical contact model

$$\begin{aligned} E_{{\textit{pc}}}=0.717A_{s}^{1/4} \pi ^{3/4} a^{{\prime }^{{3/2}}}\left( {\frac{1-v^{2}}{{\textit{E}}}} \right) ^{-1/4}G_{{\textit{IC}}}^{3/4} d_{p}^{-3/4}\nonumber \\ \end{aligned}$$(22)

Rights and permissions

About this article

Cite this article

Sohn, C., Zhang, Y.D., Cil, M. et al. Experimental assessment of continuum breakage models accounting for mechanical interactions at particle contacts. Granular Matter 19, 67 (2017). https://doi.org/10.1007/s10035-017-0750-5

Received:

Published:

DOI: https://doi.org/10.1007/s10035-017-0750-5