Abstract

Railway transport has shown a steady growth in passenger numbers over the past 20 years across the UK. Passengers travel with luggage. It has been forecasted that there will be a reduction of “luggage racks-to-seats” ratio in the future passenger train fleet. There are currently no baggage transfer systems at any of the train stations as part of the urban rail transit system in the UK. Hence, the purpose of this study is to investigate the possibility of having a baggage transfer service at Newcastle Central Station, which can serve different travel destinations. A simulation modelling study of different parts of the baggage check-in shop within the railway station is offered. Check-in point, movement of luggage around Newcastle Central, baggage reclaims and storage areas have been contemplated and evaluated using SIMUL8 event-based simulation package. The results for the simulation model developed show that a baggage transfer service at Newcastle Central Station is possible with a mixture of walk-in and online check-in options.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Because of the absence of baggage transfer service in all of the UK’s train stations as part of the urban rail transit systems in the UK, the main aim of this study is to investigate the possibility of designing and launching a new baggage transfer system at Newcastle Central Station, which can serve passengers and their luggage travelling to various destinations in the region and across the country. This new service is intended to facilitate the passengers’ boarding and alighting process on trains for those carrying heavy luggage to give a smoother and thus more comfortable journey, whilst in transit.

According to the latest road traffic estimates in Great Britain issued by the Department of Transport, it has been revealed that over 324 billion vehicle miles have been travelled on the UK’s roads in the year ending March 2017, which is 1.7% higher than the previous year and has set a new record level since 2007. The rolling annual motor vehicle traffic has also been increasing for the past 4 years [1]. The increase in road traffic results has worsened the air pollution level by emitting toxic nitrogen oxides and other greenhouse gases such as carbon dioxide. Apart from the general pollution problem, with an increase in road traffic, there would be a greater chance of having traffic jams mainly in urban and suburban areas and the travel time of the journey will, therefore, be significantly increased. It’s harder to predict the journey time due to traffic congestions. Many travellers opt for driving their cars in city and intercity travel because it is difficult to transport baggage to and from desirable locations especially when their luggage becomes quite bulky.

Amongst different modes of public transport, rail transit is one of the most sustainable modes for city and intercity journeys. In terms of carbon emissions, the emission from a typical diesel car is 0.181 kg CO2/km when national rail is only around 0.0485 kg CO2/km [2]. Carbon dioxide emission from cars is thus around four times more than the emission from national rail.

In the UK, there is a reasonable network of rail tracks covering most parts of the country, which provides generally shorter journey times than other modes of transport. As the railway systems can provide travellers with a smoother and more comfortable journey, it is possible to attract more travellers to use rail for city and intercity travel. Dealing efficiently with heavy luggage, though plays an important role in improving the passenger’s journey. It was found that one quarter of the UK railway customers showed dissatisfied views towards the space for luggage on existing trains and metro cars [3]. The British trains are designed to have plenty of seats stuck together, but there is not enough room for luggage storage above and below each seat, as well as at the end of the train car in many cases.

A newly designed baggage transfer system is proposed, which can make it possible for travellers to drop off their bulky bags at a railway station just before their actual departure time and experience baggage-less journey. A new baggage transfer service is designed to use regular passenger trains and/or freight trains as a means for transporting baggage. This new system further utilises the capacity of the rail service that promotes sustainable transport and benefits from less environmental damage when compared with road couriers.

A proposed design of the baggage drop-off point is made considering location in the rail station, storage, security issues and movement mechanism solutions across different platforms of Newcastle Central. Difficulties in implementing the service are also identified. Solutions to these issues and alternative proposals are made. A simulation model of the baggage movement within the station is developed and implemented using SIMUL8 software. Different components of the system are analysed separately and in a network. The results are used to evaluate the whole system concept based on the performance data about how well the system can handle baggage in practice.

2 Market Uptake

2.1 Baggage Size, Passengers and Trains

According to the National Rail Conditions of Carriage, each passenger can take one piece of hand luggage, which can be held on the passenger's lap if required plus two extra items with size not more than 30 cm × 70 cm × 90 cm. Each passenger should be able to manage their luggage without any extra help from rail staff members. However, some items cannot be brought on board, including items that may cause injury, inconvenience or nuisance; items for which there is not enough space; items that cause a delay in loading or unloading of the train or that are not packed in a suitable manner. Any item that exceeds the limit may be required to be conveyed into a separate carriage and is subject to an extra charge, not exceeding half of the adult single fare for the journey [4].

In general, the largest suitcase size available in the market is around 32 inch across, which gives approximately 80 cm × 54 cm × 30 cm. For a hand luggage carry-on a flight, it varies among companies, but generally the dimensions are around 55 cm × 35 cm × 20 cm [5]. This should fit the criteria set by the National Rail. However, it may be very hard to get on board with two pieces of luggage this size as there is usually a large unlevelled gap between the train and the platform edge.

It has been studied in Holloway et al.’s paper [6] that there is a general increase in boarding time if there are steps between the train and the platform. Also, the heavier the luggage that the passenger carry, the longer the time it would take for them to get on board. This effect is especially significant to elderly than adolescents. As a result, this affects the overall dwell time of a train at the station and potentially causes delays to the service.

People used more railway transport in the last 20 years across the UK [7]. In the age group 21–29 years, 8% of English people used the National Rail at least once a week. [8].

Visiting friends or relatives was the purpose of a long distance train journey for most people (54%) followed by holidays (28%) and business trips (19%). When opting to use the train instead of a car, most people suggested that “it was easier and quicker by train” (40%) followed by “not willing to drive” (20%) [9].

It was also found that the use of railway in the UK increases with income. People with the highest income households travelled almost six times more than the lowest income households by rail in 2015. Similarly, managers and professional people travel far more by rail than those who are unemployed or doing routine and manual jobs [10].

In terms of train punctuality, around 90% of passenger trains had less than 5 min variation from the originally planned timetable for a short-distance journey and 10 min for a long-distance journey [11]. The punctuality of freight rail in Europe was around 70% in 2003 [12]. This information was useful in adding the extra factor onto the simulation model to improve the reliability of the result. Further infromation is available at [13,14,15,16].

2.2 Case Studies on Similar Services

There are some baggage transfer services across the world with some using courier services and a few using railway. Some of these are studied to find what is required to keep the service running and popular. However, some of the services that were less successful and withdrawn from practice are also studied to understand what went wrong, so that a concept can be built to prevent the new service from repeating similar errors.

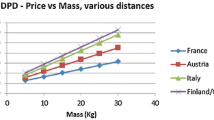

2.2.1 Current Services in the UK

There is no luggage transfer service provided by any railway operators in the UK. The only way to get baggage shipped is through courier service using road transport such as HGVs or vans. Some of the services provide drop-off in shops, for example Parcelforce and DPD. Services such as InPost allows users to drop off and pick up their baggage at self-managing lockers at their destination. However, there is a size limit of 64 cm × 38 cm × 38 cm with maximum weight of 15 kg [17]. Some of the other couriers provide door-to-door courier service, for example CitySprint, DHL and UPS. However, all these services are intended for shipment of parcels and express services internationally and thus charge the user a premium fare. Apart from this, many of these services require pre-book for pick-up 1 day earlier and do not offer same-day delivery. Furthermore, a majority of these services do not pick up or deliver on weekends or charge an additional cost to the final bill. As a result, these services are not very attractive to railway users who only want to send their baggage to the train station right before their travel and then pick it up upon their arrival at the destination.

2.2.2 Current Services in Other Countries

Because there is currently no baggage transfer service in the UK, some examples in other countries were studied to understand how their systems work and survive competition with other courier companies.

2.2.2.1 Hong Kong Airport Express Line

Hong Kong Airport Express Line is one of the services in the MTR system. It connects the Hong Kong International Airport in Chap Lap Kok with city centre in Kowloon and Hong Kong Island. The main usage of this airport express service is a shuttle between airport and city centre as when the train leaves the airport, all the stations in the rest of the line is only for set-down only. Similarly for inbound service, the stations towards the airport are only for pick-up only. There are on board luggage racks but there is still free in-town check-in service for major airlines provided in Hong Kong Station and Kowloon Station to allow passengers to travel baggage-free. The baggage can be checked-in between 90 min and 1 day prior to the scheduled departure time of the flight. There is, however, a baggage size limit of 145 cm × 100 cm × 85 cm and a maximum weight limit of 90 kg when using this service. This exceeds most of the airline luggage limits. All bags ought to be checked-in. Once a baggage is checked-in, the traveller will only meet their bags upon arrival in the airport of their destination. There is no separate freight train transporting the baggage, but they are sent to one of the carriages at either end of the airport express train, which is used for loading of baggage only [18].

2.2.2.2 Hong Kong MTR Intercity Through Train

There are cross-border trains connecting Hong Kong and four cities in China including Guangzhou, Foshan, Shanghai and Beijing. The free luggage allowance for each passenger is 20 kg. Any luggage that is in excess of the limit is required to get consigned. The check-in point and the pick-up point are located at the train terminus stations. The baggage service is not free and has a base fare plus extra cost for each 5 kg of luggage. For a 20-kg luggage to be consigned on the Hong Kong-to-Shanghai service (20 h travel time), it would only cost HKD $77, which is approximately equal to £8. The maximum weight of each checked luggage allowed is 50 kg, but there is no mention of size limit. After the baggage check-in, all of the luggage is transferred onto the same train as the passenger, but separated into a different carriage. As such, the baggage can be picked up at the train station upon arrival at the destination [19].

2.2.2.3 Swiss SBB Luggage and Flight Luggage Service

The Swiss national railway company, SBB, provides different types of courier services, which serves both internationally and within the country. Formerly, they used rail for transportation of baggage, but have switched to use AKS courier services now. The general rule for luggage transfer is that any piece of the luggage cannot exceed 25 kg. Items that can be shipped include bags, suitcases, skis, snowboards, sledges and bicycles. In order to use the luggage transfer service, one must possess a valid train ticket for the whole journey to the destination or hold an annual travel card. The entire luggage transferred includes insurance to cover a value of CHF 2000 or more depending on each service [20].

For domestic services, it includes luggage drop-off at 32 selected train stations across the country. However, it takes 2 days to get the baggage to be shipped to the destination station with a charge of CHF 12 per item. A faster option is available which requires a drop off of the baggage in the morning, with varying cut off time from 9 am to 11 am, and able to be picked up on the same day after 6 pm. However, this service requires an extra CHF 30 for flat rate for shipping. Apart from baggage drop-off at station, SBB also offers door-to-door service as well as an express version of this at a further extra cost of flat rate of CHF 40 and CHF 70, respectively. However, for door-to-door service, they require a registration of pick up date 2 days prior to that and 1 day for express service [20].

For international service, it is currently available to send the luggage to Germany only. It takes 4–6 days for the shipment of the baggage to a Germany mainland address [21]. It is also available for door-to-door service from Swiss to Germany, but not return. This works principally very similar to the domestic service [20].

Other than normal luggage service, SBB also provides flight luggage service. If one is travelling to or from Geneva or Zurich airport with Swiss or Edelweiss Airline, they can check in their flight baggage at any of the selected train station the evening before their flight. They can get back their baggage upon arrival at the airport abroad. This service is similar to Hong Kong Airport Express Line as discussed above. However, there is an extra charge of CHF 22 per item. Similar to normal luggage services provided by SBB, there are express and or door-to-door services at a further extra cost to the customers [22].

2.2.2.4 Austrian Haus–Haus-Gepäck Service

Similar to SBB door-to-door service, the Austrian railway company, ÖBB, also provides luggage transfer service by courier. It is required to book this service when purchasing a train ticket and it is required to allow at least two working days before actual pick-up date. However, the pick-up and delivery days are only in Monday to Friday 8 am to 5 pm and there is no weekend service. Pick-up and delivery is also available abroad from Germany, South Tyrol and Switzerland with extra cost and time. For domestic normal luggage, including suitcases, bags, rucksacks and ski boot bags, the price is 19.4 Euro. For special luggage such as skis, snowboards, wheelchairs, prams and pushchairs, the price is 29.4 Euro [23].

2.2.3 Ceased Services

There are some services that were found environmentally unfavourable and thus were discontinued including Virgin Bag Magic in the UK and Bangkok city centre check-in for flights.

Virgin Trains launched a luggage delivery service in November 2014 called Virgin Bag Magic. This service allows a courier company, Parcels 4 Delivery (P4D), to pick up the baggage on the day before the actual travel date from any address including home, office or hotel. The baggage is delivered using courier vans on the following day or a pre-selected date to any address in the UK. The price of this service started at £9.99 per piece and was available every day throughout the year except Christmas and New Year's Day [24]. The baggage allowed to be delivered included bags, cases, presents or bicycles, but the service came to an end on 12 August 2016 without giving a reason from Virgin Trains or P4D [25, 26].

Similar research work has been done by Reece and Marinov [27], where two airlines offered baggage check-in in Bangkok city centre with Bangkok Airport Rail Link. The bag check-in time was 3–12 h prior to the flight departure. This service is very similar to the case in Hong Kong Airport Express Line, but this one only lasted for around 3 years and was closed in 2014 due to high cost and low popularity as the station accessibility is poor, trains were not punctual, carriage design was poor, and it had a similar price as taxi service, which was not appealing to customers [28].

2.3 Studies of Rolling Stocks Layouts

There are different train operators using different types of rolling stocks with different layouts serving Newcastle Central Station. It is important to study the fleet in order to ensure suitable resources on each service. It is also of interest to study the future changes of a train fleet as this affects the potential market of the baggage transfer system.

2.3.1 Current Fleet

Arriva Cross Country, owning most extensive bus and train network in UK, uses mainly Class 220/221 Voyager trains, which are 4/5 car trains. But they can be coupled to form longer trains of 8/10 coaches. Some of their services are run by high-speed trains of seven coaches. For Virgin Trains East Coast, they use nine-coach high-speed trains or electric Mallard trains. For First Transpennine Express, they use three-car Class 185. Northern Rail runs usually with two-car diesel trains, but they are running very few long journey intercity routes, so it is out of the scope of this study as a very limited number of passengers would use the baggage transfer service, making it unstainable to run the service.

There are generally one or two luggage racks provided in each coach. However, they vary in size, and, for example, coach D on Cross-Country Voyager trains, there are two extra-large luggage racks at one end, which links to the bike storage area. Each rack is as large as two smaller racks in the other coaches. Also, apart from luggage racks at either end of the coach, there are usually overhead luggage racks provided for smaller hand carry baggage.

2.3.2 Future Fleet

Virgin Trains East Coast has announced that there will be brand new trains called “Virgin Azuma” Class 800/801 in service in 2018 for Intercity Express Programme. There will be 23 sets of new trains with formation of either five or nine coaches for each set [29, 30]. They are built with the intention of increasing the capacity of the train and the line. However, Bradbury and Dyall [31] have reviewed that some of the spaces originally for luggage space have been converted to seats. Also, there is a great reduction in table seats, which means that the space between the back of two seats becomes unavailable to passengers to put their luggage between.

2.3.3 Fleet Comparisons

Table 1 shows a summary of each train type in UK. Class 185 from First Transpennine Express has currently the lowest rack-to-seat ratio for standard class passengers. Both train types for cross-country trains has the highest number of racks per seat in standard class. But it is noted that due to the huge size of the luggage racks on Coach D of the Voyager trains, it has been treated as two racks on each side.

About the future change of the fleet, it can be found that the rack-to-seat ratio is further reduced to just 0.0259 on standard class Virgin Trains East Coast Class 800/801 trains. This is nearly half of the luggage space to be found on Voyager trains. The ratio of first class compartment is further reduced to only 0.022 for the new Class 800/801 trains, which is even less than half of that from the original HST train. Therefore, this may cause problems in luggage storage in the future, especially for trains going to and from London, which is usually very busy.

3 Newcastle Central Station

3.1 Technical Characteristics

3.1.1 General Operation

Newcastle Central Station is one of the largest stations in northeast England. This station lies on the East Coast Main Line (ECML) connecting London and northeast Scotland including Edinburgh and Aberdeen. Virgin Trains East Coast is currently managing the station and providing services running along the ECML. Apart from this, Arriva Cross Country provides services that connect Scotland and south or southwest England via Birmingham. First TransPennine Express also provides services connecting Newcastle to Manchester and Liverpool. Northern provides services connecting Newcastle to the northwest of England. Newcastle Central Station is a hub for services to various destinations across the whole country. It is the busiest station in the region with hundreds of services each day. Over 8.1 million passengers used this train in 2015–2016 with an increase of around 2% from the previous year [32]. There will be extra seats provided by the new trains on Virgin Trains East Coast in 2018 as well as up to a 22-min reduction of journey time [33]. Also, the Office of Rail and Road (ORR) has approved an introduction of new train operators by First Group running on the ECML between London and Edinburgh calling at Newcastle from 2021 [34]. With all these favourable factors, there should be a continuous growth of passenger numbers using the station in the future.

3.1.2 Station Layout

There is one main entrance to the station followed by some shops and facilities in front of the ticket gates. There are two car parks at each end of the station, one for long stay and one for short stay. The Tyne and Wear Metro service is one of the most important public transports across the station, so there is a metro station on the left hand side of the main entrance, which is fairly close to the ticket gates. For the platform layout, Platforms 1, 2, 9–12 are located on the concourse side of the station, whereas Platforms 3–8 are located across the bridge. The footbridge is equipped with ramps, and alternatively there is a lift connecting Platforms 3–4 to the concourse, but not Platforms 5–8 [35].

3.2 Location of Collection Point

The criteria to be used when selecting the location of the baggage collection point:

-

Avoid large modification of existing infrastructure of the station.

-

Reduce interference with other passengers.

-

Provide a large empty space nearby available for storage of received or un-transported baggage.

-

Allow public easy access to the baggage collection point.

-

Position as close as possible to the operable barriers to reduce transport time.

Based on these criteria, a baggage collection point is identified. It is close to the Metro exits and the main entrance, so passengers wishing to use the service do not need to walk a long way to get to the collection point. It is also closer to the barrier and the lift resulting in a shorter transportation time to or from the train. It is a better choice in terms of location. However, as the location is currently a car park, some spaces of the car park may need to be sacrificed in order to build a collection point with storage.

Apart from the location, there are a few more points to note when designing this service:

-

For safety, there should be a security check when dropping off the baggage.

-

The trolley should be covered with plastic shields as part of the station platform is located in an open area.

-

The trolley cannot be designed to be taller than 2 m as there is a low height limit in the subway connecting the lifts.

-

Transporting to and from Platforms 5–8 is only available using footbridge and should try to avoid those services.

-

To solve the problem of the gap between the platform and the train, the ramp devices used at present may be a solution as illustrated in Fig. 1.

4 Complementary Aspects

4.1 Material Handling System

A material handling system should be considered because it can give extra value to a running business by improving the flexibility and productivity, thus lowering the cost of operation when designed and controlled well [36,37,38]. Systems to transport bags using belts, chutes or rollers as either independent or integrated can be installed [39].

4.2 Baggage Handling System

A baggage handling system including routing, scheduling, cart management and security control have been studied in [40, 41]. A promising concept is that a baggage handling system can also be automated and designed to use destination coded vehicles (DCVs) [41,42,43].

4.3 Baggage Check-in Desk and Security

Concerns about terrorism during metro or train travel were investigated by Patil et al. [44]. Vulnerability of a transport system is discussed in [45] and should be considered when designing a baggage collection point in a railway station. There should be thorough baggage checks in public transport hubs and junctions [46].

5 System Design

A simulation model is developed to integrate the different components of the new baggage check-in system. Next the same model is used to evaluate the system performance, give feedback and suggest modifications. The simulation model is also used to carry out investigation on whether the system fulfils its objectives. Some of the actual data from the current timetables are used and implemented to study how well the system can perform. This information is also used as part of the unit integration tests.

5.1 Data

Data sets are required to feed the simulation model. These include baggage arrival pattern, the process time, and the number of check-in desks.

5.1.1 Baggage Arrival Pattern

Baggage arrival time and pattern can be estimated by studying the train timetable of Newcastle Central Station. According to the information provided by Realtime Trains, there were a total of 204 passenger services departing from Newcastle Central Station on 25 July, 2017 (Tuesday). The first train of the day leaves at 0445 to London Kings Cross with the last one at 2300 to Sunderland. However, the number of baggage items that is expected to be transferred from the passengers on to each service is different because of the fact that not all passengers would require it.

5.1.1.1 Routing Scaling Factors

A more realistic estimate to the number of baggage items can be made when we consider the number of passenger coaches used on each train service. For example, most of the First Transpennine Express services to Manchester and Liverpool are formed of three coaches and normally all of the Virgin Trains East Coast services to London and Scotland are formed of nine coaches. Therefore, it is expected that the number of baggage items that will arrive to the system would be of a 1:3 ratio.

Nevertheless, there are some exceptional cases, especially for Arriva Cross Country Trains, their Voyager trains Class 220/221 are formed of four or five coaches each, but they can be coupled to form longer trains, giving 8–10 coaches. Moreover, some of their departures are using Class 43 High Speed Trains, which is formed of seven coaches. Therefore, it may be hard to estimate these services. As a result, it is assumed that the average number of coaches for Arriva Cross Country Trains is 4.5, an average of four and five coaches from Voyager trains, as they are majority train type serving Newcastle Central Station. Therefore, it is expected that the number of baggage that will arrive to the system would be of a 1:1.5 ratio.

Apart from Arriva Cross Country Trains, Northern Rail services should also be noted. Most of the Northern Rail services are local stopping service which mainly used for commutation, this includes Tyne Valley Line connecting Newcastle to the West Coast at Carlisle, Tee Valley Line connecting Newcastle and Middlesbrough, as well as services to Chathill, which runs only two times a day. Also, their trains are usually formed of just two cars and many stations served by them are not staffed. It may be hard to sustain the baggage transfer service especially at the starting point. There are quite a number of services that terminates at the station after Newcastle Central Station, for example Morpeth, Sunderland and Metrocentre. These relatively short journeys can hardly attract passenger to use the baggage service. As a result, it is assumed that all of the Northern Trains services are assumed with no passengers using the baggage service.

For services going to Scotland via East Coast Main Line including Edinburgh, Glasgow, Aberdeen and Inverness, no matter which operators they are run by, the baggage ratio is set to 1:2. This value was taken from the average of nine coaches Virgin Trains East Coast trains and Arriva Cross Country Voyager trains of four coaches. This works out to be 6.5 coaches, which is approximately 1:2 when compared with the reference First Transpennine Express trains.

5.1.1.2 Day and Time Scaling Factors

It can be found that the usual weekday operation has more departures than Saturdays and Sundays. For example, 29 July 2017, Saturday, has 191 departures, and 30 July 2017, Sunday, has only 151 departures, both of which are less than 204, the weekday departure number. Therefore, if the system can cope with a weekday operation, then it should also be able to handle any weekend operations with no issue.

However, in the same day, but a different time slot, even for trains that are going to the same destinations, some are busier than others. This is especially obvious for very early and late departure time when compared with morning or evening peak. As a result, the amount of baggage for the system is different. In order to solve this problem, a time scaling factor can be added to the work entry point. The summary of the factors can be found in Table 2.

Early morning (before 7 am) and late night (after 8 pm) has a factor of 0.5 only as these two periods are the quietest time in the station with a limited number of departures and, therefore, passenger use. The reason 0801–1100 has a factor of 1.5 is because the baggage system is intended to provide service for long distance intercity travellers. It is more likely that the traveller would choose morning departures in order not to arrive at their destinations late. For the same reason, the period of 1801–2000 is given a factor of 0.75 when it is less likely for passengers to be travelling for long journeys. The total number of departures taken into account is 122, but not 204 because all of the exemption departures as mentioned in Sect. 5.1.1.1 are not counted, which includes all of the departures from Northern Rail as well as the 2300 Virgin Trains East Coast departure to Sunderland. After scaling the departures, the total number of departures is reduced to 119. However, this only accounts for less than 2.5% change and is acceptable related to its validity to reality.

5.1.1.3 Summary of Baggage Arrival Pattern for Same Day Delivery

After having studied the timetable, it can first be assumed that one piece of baggage from a single passenger shall be transferred in each First Transpennine Express service to Manchester. Then the number of baggage items for the other services can be estimated. The summary of a list of major destinations, operators of the train services and the relative number of estimated baggage items is shown in Table 3.

The factors affecting the number of baggage arrival are used to estimate the overall factor, which is the product of destination factor multiplied by the time factor. The overall factor is then rounded up to give a number of actual baggage items to be transferred for each departure. As a result, the total number of baggage transferring each day through the service proposed came up to 267.

5.1.1.4 Baggage Check-in for Departures in the Future

Apart from passengers requiring a baggage transfer service within the same day, some other customers have been identified that may use this service, namely, those requiring to send baggage items earlier, up to 2 days prior to their actual departure. The number of customers requiring such a service can be assumed to be 10% of the total number of baggage items.

As a start, there are 267 pieces of luggage each day; therefore, it can be assumed that 30 extra pieces of baggage will arrive into the system. For design purposes it is also assumed that the baggage arrives into the system evenly during each hour from 0900 to 1800.

5.1.2 Check-in Procedures

A number of operations describing the check-in procedure are considered to estimate the overall check-in time: completion and verification of personal details, payments and ticket checks as well as security check. The time allocated to each operations, which is used as an input for the simulation model, is shown in Table 4.

It can be estimated that with online check-in, the total time for the completion of check-in procedure can be reduced by 50%. The time savings come from entering the personal details into the computer system by staff as well as online payment. However, a longer time would be needed in verifying the personal details. That is the reason why 30 s is added on ticket/ID check column with online check-in. It is also noted that there is an extra fixed 1 min added to both check-in ways as buffer time which results in 5 min for walk-in check-in and 2.5 min for online check-in. If half of the customers are using online check in, then the average time for check-in would be [(4 + 1.5)/2] + 1 = 3.75 min, hence this estimate is used to run the simulation model and study the respective effect on the system.

After check-in, there is an immediate security check through X-ray machine. The time allocated for the security check is an average of 1.5 min, which includes the transporting time from the check-in desk to the machine and the time for any checks on suspicious items.

5.1.3 Baggage to and from Trains

There are two ways of transporting the baggage to its destination: one is using scheduled passenger trains and the other one is using a freight train. The baggage is transported to the suitable train for departure by cart either pulled using manpower if the volume is small or pulled by small vehicles similar to the ones shown in Fig. 2. The carts are filled up with the baggage to be shipped at least 10 min before every assigned train departure by the staff at storage centre. Any loaded cart can return from the trains back to the storage centre. The staff there can then sort out the baggage items on the available shelves and wait for the passengers to reclaim their bags up to 2 days after arrival. Reclaiming after 2 days can also be considered.

5.1.3.1 Passenger Trains

A possible solution is to use passenger trains, by converting some small train compartments to transport more baggage. The main benefit of this solution is that the baggage can travel together with the passenger on the same train.

There are 122 departures included in the baggage transfer service. Some services are terminated at Newcastle Central Station meaning that some baggage items will be reclaimed by the passengers at Newcastle Central. In addition there are 43 extra services on weekdays that are assumed to terminate at Newcastle Central Station and one service that is going to Sunderland, but it is originated in London Kings Cross. This means that there would be baggage items arriving from that service as well. Similarly, there is one departure to London Kings Cross, which starts from Sunderland and this service is unlikely to have baggage items arriving at Newcastle Central. All of the departure and arrival times at Newcastle Central Station are used as input information to set up and calibrate the simulation model.

5.1.3.2 Freight Trains

The other solution is to use freight trains. However, freight trains used for bulk transport would not be very frequent. It is therefore unlikely that the baggage items can be transported without any modification of the current practice.

There are two directions that the baggage transfer system serves: one towards North to Scotland and one down south of Newcastle towards York (Fig. 3). Two freight trains can be introduced to transport bags along these routes to serve these two directions. It is adequate to consider that baggage items can further be served and transported to the end user when they have arrived into another railway station. It is likely that the freight train would run at night so there are fewer disruptions to regular passenger train services.

5.1.4 Baggage Reclaim

It is not easy to obtain a precise estimation of the number of baggage items arriving at Newcastle Central. This is because the bags arrive from numerous stations at different times. There are no data available either because there is no such system in operation in the UK at the minute. The time factor applicable to Newcastle Central Station does not quite comply with the time factors of other stations, because Newcastle Central is also a terminal station. Location of station also plays a role. We have seen that the total number of baggage items to be sent out from Newcastle Central Station was estimated to be a bit less than 300. Hence, it can be assumed that the amount of baggage arriving is similar. It is also suggested that each train has three bags to be reclaimed. With 125 trains arriving at Newcastle Central Station every day, the total number of bags comes out to 375.

The reclaim process is quicker than the check-in procedure because the staff must only check the ID of the customer and then return the baggage items from the storage area to the customer. The whole process should not take longer than 2 min on average if there are no queues.

When baggage is carried by regular passenger trains, the bags are available to be picked up 20 min after arrival. This is worked out by 8 min transporting time plus 10 min for sorting and storage at the designated point plus buffering time. Nevertheless, not all of the passengers pick up their bags straight away. It can be suggested that one passenger in every two trains leaves their baggage in the storage area overnight aiming to collect it the next day. Hence, the number of bags to be reclaimed on the same day is two and three per train. A total of 60 bags are left to be reclaimed the next day. The customers reclaiming bags are estimated to arrive at the Newcastle Central baggage collection point every 15 min from 0730 to 2200.

When baggage is carried by freight trains overnight, then the bags can only be picked up on the next day.

5.1.5 Storage Area

The staff working in the storage area load the carts with baggage items to be transported to the specified train and then unload the baggage items and store them in the designated area on the train. For allocation of baggage items to trains, a computer system should be implemented and used. The loading process should be completed within 10 min. It is noted from the time frame in Fig. 4 that the loading process begins before the cut-off time for the check-in. But in case there are any last minute arrivals of baggage items, a 5-min buffer time is implemented to ensure there is enough time for the completion of the loading process. Unloading is very similar to loading, hence it can be assumed that the time for both processes are the same, 10 min each.

5.2 Baggage Collection Point/Check-in Shop Design

5.2.1 Shop Layout

The check-in shop layout is designed as shown in Fig. 5. For the check-in side, there is a large area to accommodate customers waiting to be served. There is initially a design of three check-in desks, but this can be confirmed and changed later. Next to each counter is a luggage transporting belt, which ultimately connects to the X-ray machine at the end. If the bag passes the security check, it is then sent for storage next door.

There are two separate areas for delivery storage. A bigger one is for the same-day delivery and a smaller one is for the smaller number of customers who have checked in their bags up to 48 h prior to departure. There are also two separate areas for arrival baggage storage. These two areas function similarly, but can be separated into different origins so that the check-out process can be completed faster.

5.2.2 Storage Area

Within the storage area, there are racks in each column. The largest size of luggage available on the market is generally 32″, which has dimensions of 80 cm × 54 cm × 30 cm, thus it is important to apply some buffering when designing the racks for ease of placement and removal. Therefore, assuming each piece of baggage has the same size of 100 cm × 65 cm × 40 cm should be adequate. As such, the initial design of the rack has 100 cm depth and 65 cm height for each layer. There are three layers, so the top layer after placing the luggage does not exceed 2 m for health and safety reasons. The outline of the rack can be seen in Fig. 6.

The length of the rack varies depending on the size of the storage room. However, the minimum total length of racks for delivery should be over 40 m in order to accommodate 300 bags a day. This number should be multiplied by a factor of 1.5–2 for the future expansion of the service and prevention of a sudden, unforseen influx of baggage. Each position of the rack is numbered so that it can be linked to a computer system for more organised service. This reduces the chance of mistake and the baggage can be picked up and sent to the train more efficiently. The location of every baggage item is automatically assigned by a computer programme when checked-in at the front desk.

5.2.3 Staff and Resource Allocations

The number of check-in desks depends on the demand by potential customers and can be estimated considering the baggage arrival pattern. Figure 7 shows the number of departures and baggage for each hour. It can be seen that there is quite an even number of departures most of the time, from 0700 to 2100 weekdays. However, the baggage varies quite a lot with 9–11 am showing a spike on the graph where demands are maximum over the day. Other than that, 8–9 am and 12–8 pm shows a high usage of the system as well. This suggests that resources should be allocated accordingly. Therefore, the work shift of each check-in desk can follow this pattern as an initial input, and then after a review further adjustments with different trials can be undertaken to work out the best possible solution.

5.3 Simulation Modelling

Simulation modelling has been used to study the designed rail baggage transfer system performance. It is an evaluation technique, which helps us to understand how well the system has been designed. There is a vast amount of literature on simulation modelling that should be mentioned: [27, 47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80]. Four cases were modelled using SIMUL8. Case 1: a system of only one passenger. Case 2: freight trains being placed on the system where required, based on flight times from Newcastle Airport. Cases 3 and 4 focused on increasing track utilisation by saturating the system with freight trains. The study considered the age of the passenger, as well as the choice of transportation for different purposes of travel. For example, the average age of a leisure traveller is 47.5 years old, whereas the average age of a business traveller is 45.6 years old. Figures show that 79% of leisure trips were on the road using cars, whereas only 48% of business trips are by car [52]. These choices are influenced by the amount of luggage they travel with. Leisure trips require heavy luggage; however, business trips need less luggage.

A mesoscopic simulation modelling methodology is developed for analysing freight train operations. A rail network model was developed using SIMUL8. Two situations were examined for the study. Case 1: Freight train movement characterised with insignificant deviations from schedules. Case 2: Freight train movement characterised with significant deviations from schedules. The rail network model shows that the more structured and scheduled the network operation of freight trains with freight trains, the lower the queue in the rail network becomes. Hence, the amount of costs incurred for the company is lower, and vice versa [50].

Two potential scenarios that can occur at a railway yard were studied. Case 1: when the yard is situated between a high-speed track and a conventional track, which are both electrified. Case 2: when the yard is situated between an electrified high-speed track and a non-electrified conventional track. The first design presented was based on an interchange between an electrified high-speed line and an electrified conventional line. The second design was an interchange between an electrified high-speed line and a non-electrified conventional line. It is possible to operate a conventional train on a high-speed track through the use of an interchange yard. A secondary conclusion was that issues such as a reduced line capacity due to conventional rolling stock with a lower maximum top speed than high-speed rolling stock did occur due to operating conventional stock on a high-speed line [70]. Simulation packages with a rail focus include RailSys and OpenTrack. Other simulators and performance analysers include: XpressMP, ARENA, SIMUL8. A comprehensive discussion on simulation modelling applications for designing baggage transfer services is presented in [81] by Yeung H and Marinov M. (2017). It is suggested in that paper that SIMUL8 is the good choice of software for modelling the baggage transfer system; therefore, we shall not repeat this discussion here. Instead we now look at how SIMUL8 [51] operates and has been implemented to study the performance of the newly designed system for baggage transfer at Newcastle Central. Before we introduce the simulation model developed, we would like to remind the reader about SIMUL8’s building blocks:

-

1.

Work Entry Point: Arrival of work items to the system and the arrival pattern can be deterministic or stochastic behaviour.

-

2.

Queue: The point where the work items are waiting for the next process.

-

3.

Work Centres: System servers or machines where process is taking place here and the output of this stage will be passed to other point of system for further working, storage or direct delivery through work exit point.

-

4.

Storage Point: As a buffer or a queue to gather (semi-)finished work items for moving up to the next process

-

5.

Work Exit Point: The point where the work items leave the system and where the service or process is meant to be completed. There can be over one Work Exit Point, for example, one exit point to the delivery of items while some defective items are sent for scrap and disposed.

-

6.

Work Items: The object that are brought to the work entry point for further process along the simulation modelling system.

-

7.

Resources: Any machines, employee, operator, signal etc. that requires fulfilling the tasks and processes at different work centres.

In the case of baggage transfer service, the work item is defined as the baggage to be or that has been transferred. The resources would be anything that is in the system including check-in desk, staff member, X-ray machine for security, carts for movement of baggage around the station, storage racks etc. The entry point is the check-in desk at the station where customers drop off their bags or the arrival of bags from other destinations prior to customer pick up. The queue is where the luggage is waiting to be checked in on arrival. The storage point is the racks behind the check-in point where the luggage is waiting to be shipped or picked up by customers. The work exit point is the point where the baggage leaves the check-in centre for shipment or pick-up.

There are a number of trials performed to study the system performance in different ways.

5.3.1 Check-in of Baggage

The first part of the modelling is for the check-in process. The aim of this simulation is to test if the check--in system is able to handle the baggage and to find the best possible resource allocation in terms of staffing check-in desks. Also, it can be used to study the effect on walk-in check-in and online check-in by inputting different sets of parameters. The clock has been set to run from 04:00 for 19 h daily until 23:00. This covers all of the check-in process as the last train with baggage transfer service leaves at 22:46. The warm-up period is set to 0 as there should not be any process that must be done prior to serving customers. The target completion time for the whole check-in process is ideally 15 min and 20 min as the bottom line. The general model for SIMUL8 is set like below in Fig. 8.

There are two work inputs, one representing the baggage for passengers with same-day departure, and the other is for passengers of future departures. They are followed by a queue where they wait to be served by the staff at the check-in desk. There are three check-in desks, which work in different shifts for better utilisation of the system. After the check-in process, the baggage is sent for a security check through conveyer belts, followed by storage prior to shipment.

Figure 9 shows the data input for the check-in desks. They follow different time shifts, and the best shifts are worked out after different trials in the simulation.

5.3.2 Transport of Baggage within Station

The next part of the modelling is for the movement of the baggage within the station to and from the train. The aim of this simulation is to find the best possible resource allocation in terms of staff for moving the bags. It can be used to evaluate whether passenger trains or freight trains provide a better service in terms of cost and time.

The clock has been set to run from 00:00 for 24 h daily because the last train to arrive is beyond 2am and the first train to depart is 4 am so it is more convenient to be set running round the clock. The warm-up period is set to 0 as the system is running 24 h a day non-stop. The target check-in process is 15 min, and this allows 15 min for loading to the carts and transporting to the designated train. The general model for the software is set as below in Fig. 10.

The time set for moving from storage point to the train platform is set to be 10 min, which includes 2 min buffering time. Eight minutes is enough for movement across any platform at the station although some take much shorter time due to distance. Loading and unloading to and from the train takes 1 min each as it has been studied in the timetable that some of the services would only stop at the station for 2 min. The return time to the storage point is set to be 8 min and does not need any buffering time. The general idea for the flow of path is illustrated below in Fig. 11.

There are three types of train services, which set Newcastle Central Station as: 1-First Stop; 2-Last Stop; 3-Mid-Stop. These are assigned to different label values in the software as in Fig. 12.

Each relates to the processes that must be undergone. 1—Omits the unloading process from train; 2—Omits the loading process to train; 3—Takes the full process. This affects how the routing path is set in the simulation modelling as shown in Fig. 13.

5.3.3 Baggage Reclaim

The third part of the simulation model is about the baggage reclaiming process. It is very similar to the check-in process, but without a security check and the time for check-out is much shorter than check-in. There are three types of customers, but basically they are just the same except for the arrival pattern. The overall modelling setup can be seen in Fig. 14.

The clock has been set to run 24 h as the last train arrives after 2am. The average process time for each check-in desk is set to be 2 min.

5.3.4 Storage Area

The last part of the simulation is a very simple setup as the aim of this model is to find the number of staff needed to complete the loading and unloading procedures of the carts. The general model can be seen in Fig. 15. Because the loading and unloading processes both take the same time, in order to keep the model simple, only one activity was set. The time for the activity was set fixed 10 min and the clock was set to run 24 h due to the train schedule.

6 Evaluation of Performance

6.1 Baggage Check-in

There are 3 sets of data tested showing the variety of time for check-in procedures.

6.1.1 Case 1: Walk-in Check-in

The time for check-in procedures takes 5 min. This makes the overall service time up to 21.94 min even if three check-in counters are open all day. This means the system is saturated as the target check-in time is within 15 min. As a result, the only way to solve this problem is an addition of one check-in counter to accommodate the need.

As a result, the new shifts of check-in desks have been worked out as 1: 0400–2230; 2: 0600–1100; 3: 0700–1930; 4: 0600–1830. This gives an overall service time between 2.43 and 14.84 min. The detailed time for the baggage to be checked-in can be found below in Fig. 16.

Over 50% of the baggage can be processed in 8 min. Seventy-five percent can be finished within 10 min. The average time for the process is 8.32 min. If an extra X-ray machine is added to the system, the average time is reduced to 6.89 min and the range becomes 1.68–12.76 min, which is not very significant and not worth spending extra resources to improve. The detailed performance data of one X-ray machine and four check-in desks can be found in Table 5.

6.1.2 Case 2: Online Check-in

The time for procedures at check-in desks after online check in is only 2.5 min, which is the same time as the security check. After running different trials it is proven that the security part is the bottleneck of the system as only one X-ray machine is available, although three desks are working at the same time. Therefore, there are two cases in this scenario (2A and 2B).

6.1.2.1 Case 2A: One X-ray Machine

For only one X-ray machine is available, it can be seen from Fig. 17 that there are up to six pieces of baggage waiting for security check. This contributes to long service time as a whole.

For this case, the best possible solution for the shift of each of the baggage check in desk is 1: 0400–2230; 2: 0630–1230; 3: 0730–2000. The overall result can be seen in Fig. 18. Over half of the baggage can be checked in in 5 min and over 96% can be completed in 10 min. The maximum service time is 13.73 min, which is acceptable.

The KPIs of the queues and overall task can be found in Table 6. The overall waiting time is 59.45% and the working time is 40.55% for the security check and the average time for the check-in process is 5.69 min.

6.1.2.2 Case 2B: Two X-ray machines

As the resources for the security check is the limiting factor of the system, in order to see the effect of removing this factor, an extra X-ray machine is proposed to perform parallel as the existing one. Therefore, all the data are kept the same as the previous model, including baggage arrival time and batch size, time for the security check and the service time for each check in desk.

Figure 19 shows the result of the queue for security check; there is a drastic decrease in waiting items compared to before. The overall service time for the system has consequently also decreased by half for the maximum value and the average time has also been reduced. A majority of the customers can finish their check-in process in just 4 min. The details of the major performance can be found in Table 7 Summary of Performance for Case 2B.

6.1.2.3 Comparisons between the Two Cases

This is no change in the queue for check in as it is not altered for both cases. There is, however, quite a big difference in terms of queue for security and also the overall procedures. The summary of comparisons of the two cases can be found in Table 8.

There is an average reduction of queuing time of over 80% if an extra X-ray machine is installed. The overall check-in process time is also greatly reduced by over 30% to just under 4 min for the new system. However, this does not mean it is a must to install an extra X-ray machine. If over 10 min overall process time is acceptable, then it is not necessary for such an investment.

6.1.3 Case 3: Mixed Walk-in and Online Check-in

It has been tested that the best solution for the shift of each of the baggage check in desk is 1: 0400–2230; 2: 0630–1230 and 1700–1930; 3: 0700–1900.

Figure 20 shows the overall time for the baggage to be checked in. A majority of the bags can be checked in around 7 min. Eighty-eight percent of the baggage can be processed within 10 min and the maximum service time is 13.22 min, which is below the 15 min target and is, therefore, acceptable.

Figure 21 shows the queue for waiting to be served at the check-in desk. There are a few times when there are three baggage items waiting to be processed, but all of these occur when all the three check--in desks are opened, which means the full capacity of the line. There are three waiting because of the arrival of five bags for peak time departure to London.

But in reality, it is unlikely that the five baggage items arrive at the same time, rather than dispersed over time. The waiting time can only be improved by speeding up the check-in process or addition of extra desks for service. But given that the occasion of this phenomenon is not often, this is acceptable at this stage.

The performance of the queues and overall task can be found in Table 9. The overall waiting time is 59.45% and the working time is 40.55% for the security check and the average time for the check-in process is 7.11 min.

6.1.4 Summary of All Three Cases

After consideration of three different cases for walk-in or online check-in, the overall service performance can be compiled and summarised as shown in Table 10.

It can be seen that both Case 2A and Case 2B have the minimum number of working hours and average process time than Case 1 and Case 3. The average time for Case 2B is even more than half less than that of Case 1. The total number of working hours for Case 1 is at least 10 h more than the rest of the cases, which contributes to extra operation costs.

6.2 Baggage Movement Around the Rail Station

The number of carts is assumed to be unlimited, which means the loading and unloading of baggage at the storage point is not yet the investigation area at this point. The simulation experiment begins at the moment where the carts are completely loaded and ready to be shipped away. The aim of this model is to find the number of staff members and vehicles needed in order to complete the loading and unloading on the train within any disruption to the service.

It has been studied that a minimum of nine staff members are needed and an average of 2.24 for the whole day operation. The result can be found in Fig. 22. This has been verified as there is 0 for queuing time. There is a total of 49.1% of the work items (in this case the staff) finished at 20 min and the rest are at 19 min. This fits the number of inputs where 81 services are intermediate stop and need 20 min for completion of the work, which validates the model.

However, it has been proven that nine sets of staff/vehicles are required during peak time, so there should always be at least one or two as a spare. In case there is a delay in train arrival, then the demand for the resources may, therefore, be increased.

6.3 Baggage Reclaim

It is considered that baggage reclaim is not as hectic as baggage check-in; therefore, the allowable time for the customers to wait can be a bit longer. Also, as the reclaim process is faster than the baggage check-in, only two check-out desks are available. However, in order to save resources and cut costs, there are some periods of time that are less busy, which require only one desk for work. To identify which period requires more than one check-in desk, a simulation has been run with only one check-out desk. The result of the queue can be seen in Fig. 23. It can be seen that during the period of 0900–2200, there are numerous times that there are five or more people waiting to reclaim their baggage while at other times only two or three people are waiting. There are even up to 10 people waiting and, therefore, another desk has been added to work for the abovementioned period to help reduce the customers’ waiting time.

After addition of the check-out desk, the maximum number of people waiting to be served decreased greatly to four. The average number of people waiting is 0.44. The overall check-out time can be seen below in Fig. 24. Half of the process can be completed in around 3 min. The range of time for the service 0.85–9.89 min and the average service time is 3.26 min.

6.4 Storage Area

Under the assumption that the numbers of carts are unlimited, the aim of this simulation experiment is to determine the number of staff members required to complete the loading and unloading of baggage to and from the carts. One of the most important points is that the loading of the carts must be completed on time so that they can be transported away without disrupting the train schedules.

It has been studied from the model that a minimum of eight staff members are needed and an average of 1.87 for the whole day's operation. The result can be found in Fig. 25. This has been verified as there is 0 for queuing time and 100% of the items completed in 10 min.

During day time, the storage point requires 3–7 people to sustain the service. However, eight staff members are required during peak time. Also, there should always be at least one or two extra staff members as a spare, the same as the case in movement within station. In case there is a delay in train arrival or an extra amount of luggage upon arrival causing extra time in sorting out the baggage, it will not affect the overall performance of the service.

6.5 Service Time

In order to allow the baggage service to be able to work as a “drop and go” idea, the overall check-in time needed should not be long. A desirable check-in time would be around 30 min prior to departure. As the service needs at least 10 min for transporting the baggage from the storage centre to the departure train, all the bags needed to be checked in should be dropped off at the shop at least 30 min before departure so it allows the targeted 15 min check-in process time and 5 min for buffering.

To save time, online check-in can reduce the overall check-in process by half on average. This can save time for the passengers as well as saving the operation cost as less member of staff is needed. It is thus advisable to introduce online check-in, which benefits both parties.

If security check is not needed, then the overall check-in time can be even faster, but it is not preferred for safety reasons. It is, however, not advised to increase further resources on the security check as the average waiting time is only around 1 min so it is not worth spending extra money on that especially for walk-in check-in one.

6.6 Trains

6.6.1 Passenger Trains

Passenger trains can be used for onward journeys because some of the compartments of the train are converted to a storage area, which allows the transfer of baggage. This can provide real-time services, which means that the passenger can travel together with their bags, but just at a different location. This will make it possible for the passengers to pick up their bags very soon upon arrival.

In cases when everyone sends their baggage at the last minute, there may not be enough time to complete the check-in and loading. Then extra resources must be allocated to cater to these passengers. Also, the shorter time for the staff to work, the greater the chances for errors.

Moreover, there may be some difficulties in implementing this proposal because it takes up space in the train compartment, which was originally for passenger seats. This means that there is a reduction in train capacity, as a result increasing the operation cost and reducing the income and net profit for the train operators. Unless it can be proven that the baggage service brings the train operators extra passengers to use their service, it can be hard for them to accept this mode of transport.

6.6.2 Freight Trains

Another way of transporting the baggage is the use of freight trains. The advantage here is cost reduction. As bulk transport is usually cheaper than specific transport in logistic terms, this can be beneficial to the price setting of the service.

The amount of staff required at the storage point for loading and unloading the carts is less than the case when using passenger trains. This is because there are not many trains arriving in a very short period of time, so that the loading and unloading process does not need to be rushed to get finished.

It is advised that two services, one transporting to north and one to the south, are needed. This then allows the baggage to be further divided when they arrive into the other hub for further transport. This can effectively utilise the rail network and is able to transfer the baggage to every part of the country where trains are accessible.

However, freight trains are less frequent than passenger trains. This means that it is impossible for the passenger to pick up their baggage once arriving at their destination unless they have shipped their bags beforehand. It is more likely that the baggage needs at least 1 day for transport. But this would mean a very similar service to the current courier services available in the UK, making it unattractive to the passengers.

6.6.3 Comparison

There are different pros and cons for using freight or passenger trains. The summary can be found in Table 11.

It is suggested that a combined passenger and freight train transit mode should be used. As there are some people who check in their bags 1 or 2 days prior to departure, these baggage items can be gathered and use one freight train to get transported overnight. This can save up some spaces in the train compartment of normal passenger trains. Service for normal passenger trains should also be retained as this has the attractive benefits to the passengers of fast check-in and reclaim after a short period of time upon arrival.

7 Conclusions and Recommendations for Future Work

7.1 Conclusions

A baggage transfer system at a railway station to serve different destinations has been designed and investigated. Specifically, this study designed a baggage collection point to be installed in Newcastle Central Station, northeast England. There is currently no similar baggage transfer service provided in the country; therefore, it is beneficial to launch such a service as there are potential markets for it due to passenger growth and reduction in luggage racks in the future train fleet.

A simulation model using SIMUL8 has been developed for evaluating the baggage transfer system performance. The resources required for each part of the new system have been identified and evaluated. The new system is feasible and compatible with the input data from the actual timetable.

By combining the result findings from background studies and simulation experiments, it is suggested that the baggage transfer service is implemented with a mixture of walk-in and online check-in. It is also suggested that the baggage is transported using a combination of freight trains and regular passenger trains to provide best possible solution.

7.2 Recommendations for Future Work

This study ought to be expanded to investigate the possibility for introducing baggage transfer services at other railway stations in the UK. A national baggage transfer system should then be introduced and modelled across the whole country. Comparisons ought to be made when considering different modes of transport including railroad intermodal operations. An econometric model can also be built to work out the actual costs of running the service and show at what level the price of the service would generally be accepted by the public/potential user. In order to make the service attractive to public, the price is one of the major considerations. As there is no such baggage transfer system in the UK, so the proposal should be comparing with similar courier services [52, 82, 83]. The price of the baggage transfer service should be set in such a way that would attract more people to use rail.

References

”Satistical Release- Provisional Road Traffic Estimates Great Britain: April 2016–March 2017,” Department for Transport (2017)

“UK Government GHG Conversion Factor for Company Reporting,” Department of Energy and Climate Change (2016)

“National Rail Passenger Survey Spring 2016 Main Report,” Transport Focus (2016)

“National Rail Conditions of Carriage,” National Rail (2015)

“Cabin luggage: Guide to hand baggage sizes and weight restrictions,” Skyscanner, 21 June 2017. [Online]. Available: https://www.skyscanner.net/news/cabin-luggage-guide-hand-baggage-sizes-and-weight-restrictions. Accessed 21 June 2017

Holloway C, Thoreau R, Roan T-R, Boampong D, Clarke T, Watts D, Tyler N (2016) Effect of vertical step height on boarding and alighting time of train passengers. J Rail Rapid Transp 230(4):1234–1241

“Rail Trends Factsheet,” Department for Transport (2017)

“Rail Passenger Factsheet,” Department for Transport (2017)

“Public attitudes towards train services: results from the February 2015 Opinions and Lifestyle Survey,” Department for Transport (2015)

“National Travel Survey,” Department for Transport (2016)

Wearden G (2007) “UK train times back on track,” The Guardian

C. o. E. R. a. I. Companies(CER) (2004) “Rail freight quality: meeting the challenge”. In: CER-UIC-CIT Freight Quality Charter, Brussels

Transpennine Express, “Seating Plans,” [Online]. Available: https://www.tpexpress.co.uk/travelling-with-us/onboard-facilities/seating-plan. Accessed 15 July 2017

Cross Country Trains, “Seating Plans,” [Online]. Available: https://www.crosscountrytrains.co.uk/on-board-with-crosscountry/our-trains. Accessed 15 Aug 2017

Virgin Trains East Coast, “Your Seat Selector,” [Online]. Available: https://www.virgintrainseastcoast.com/rail-travel/your-journey/seating/. Accessed 15 Aug 2017

Association of Train Operating Companies. [Online]. Available: http://www.projectmapping.co.uk/Reviews/national_rail_atoc_maps.html. Accessed 30 June 2017

“Send a Parcel”. In: Post (2017) [Online]. Available: https://www.inpostdirect.co.uk/. Accessed 20 June 2017

“Free In-town Check-in Services,” MTR (2017) [Online]. Available: http://www.mtr.com.hk/en/customer/services/complom_checkin.html. Accessed 21 June 2017

“MTR Intercity Through Train Customer Service,” MTR, [Online]. Available: http://www.it3.mtr.com.hk/b2c/frmCustomerService.asp?strLang=Eng&strPageName=CustomerService. Accessed 21 June 2017

“Luggage,” SBB, [Online]. Available: https://www.sbb.ch/en/station-services/services/luggage-and-flight-luggage/luggage.html. Accessed 18 May 2017

“Transport times for international luggage/international door-to-door luggage,” SBB, [Online]. Available: https://www.sbb.ch/content/dam/sbb/en/pdf/en_bahnhof-services/en_dienstleistungen/en_gepaeck/Fristen_RG_Int-EN.pdf. Accessed 18 May 2017

“Flight luggage product comparison”. SBB, [Online]. Available: https://www.sbb.ch/en/station-services/services/luggage-and-flight-luggage/flight-luggage/flight-luggage-price-comparison.html. Accessed 18 May 2017

“Haus-Haus-Gepäck: your personal luggage handler,” OEBB (2017) [Online]. Available: http://www.oebb.at/en/leistungen-und-services/haus-haus-gepaeck. Accessed 22 June 2017

Magrath A (2014) “Virgin Trains launches new luggage delivery service allowing passengers to post presents home in time for Christmas… wrapped up by elves,” Mail Online, 22 November 2014. [Online]. Available: www.dailymail.co.uk/travel/travel_news/article-2842377/Virgin-Trains-launches-new-Bag-Magic-luggage-delivery-service.html. Accessed 24 April 2017

“Bag Magic has come to an end,” Virgin Trains, [Online]. Available: https://www.virgintrains.co.uk/bagmagic. Accessed 13 June 2017

“Welcome to Bag Magic,” P4D, [Online]. Available: https://www.p4d.co.uk/bagmagic/. Accessed 13 June 2017

Reece D, Marinov M (2015) “Facilitating the movement of passengers by introducing baggage collection systems for travel from north shields to Newcastle International Airport,” Urban Rail Transit, 2015.

“Airport Rail Link a model of failure,” The Nation, 18 September 2014. [Online]. Available: http://www.nationmultimedia.com/news/opinion/today_editorial/30243536. [Accessed 22 June 2017]

Virgin Trains East Coast, “irgin unveils the Virgin Azuma!,” [Online]. Available: https://www.virgintrainseastcoast.com/news/new-announcement/. Accessed 22 July 2017

Rogers A, Robinson C, Agatsuma K, Iwasaki M, Inarida S, Yamamoto T, Konishi K, Mochida T (2014) Development of Class 800/801 high-speed rolling stock for UK Intercity Express Programme. Hitachi Rev 63(10):646–654

Bradbury N, Dyall K (2014) Report on rail future visit to the Hitachi IEP mock up at DCA design. Rolling Stock Design Panel

“Estimates of station usage,” Office of Rail and Road, 2016. [Online]. Available: http://www.orr.gov.uk/statistics/published-stats/station-usage-estimates. Accessed 10 Mar 2017

“Work begins on Virgin Trains’ East Coast Main Line fleet,” BBC, 5 May 2017. [Online]. Available: http://www.bbc.co.uk/news/uk-england-39808537. Accessed 15 May 2017

Larkinson J (2016) East Coast Main Line decision letter. Office of Rail and Road

“Newcastle Ground Floor,” National Rail, 2017. [Online]. Available: http://www.nationalrail.co.uk/stations-and-destinations/stations-made-easy/newcastle-station-plan. Accessed 10 April 2017

Automation R, “AUTOMATED MATERIAL HANDLING SYSTEMS,” 2017. [Online]. Available: http://www.rockwellautomation.com/global/capabilities/machine-equipment-builders. Accessed 01 Aug 2017

Johnstone M, Creighton D, Nahavandi S (2015) Simulation-based baggage handling system merge analysis. Simul Model Pract Theory 53:45–49

Gunal A, Sadakane S, Williams E (1996) Modeling of chain conveyors and their equipment interfaces. In: Winter simulation conference

Vickers K, Chinn R (1998) Passenger terminal baggage handling systems. IEE Colloq Syst Eng Aerosp Proj 6:1–7

Zeinaly Y, Schutter BD, Hellendoorn H (2015) An integrated model predictive scheme for baggage-handling systems: routing, line balancing, and empty-cart management. IEEE Trans Control Syst Technol 23(4):1536–1545

de Neufville R (1994) The baggage system at Denver: prospects and lessons. J Air Transp Manag 1(4):229–236

Tarau AN, Schutter BD, Hellendoorn H (2010) Model-based control for route choice in automated baggage handling systems. IEEE Trans Syst Man Cyber C 40(3):341–351

Tarau A, Schutter BD, Hellendoorn H (2008) Travel time control of destination coded vehicles in baggage handling systems. In: IEEE multi-conference on systems and control, San Antonio

Patil S, Potoglou D, Lu H, Robinson N, Burge P (2013) Trade-off across privacy, security and surveillance in the case of metro travel in Europe. In: 41st European transport conference, Frankfurt

Salter MB (2008) Political science perspectives on transportation security. J Transp Secur 1:29–35

Luczak M (2005) Transit security what more can be done. Railway age, pp 37–43

Abril M, Barber F, Ingolotti L, Salido MA, Tormos P, Lova A (2008) An assessment of railway capacity. Transp Res E 44(5):774–806

Nash A, Huerlimann D (2004) Railroad simulation using OpenTrack. Comput Railways IX 74:45–54

Powell JP, Fraszczyk A, Cheong CN, Yeung HK (2016) Potential benefits and obstacles of implementing driverless train operation on the Tyne and Wear Metro: a simulation exercise. Urban Rail Transit 2(3–4):114–127

Marinov M, Viegas J (2009) A simulation modelling methodology for evaluating flat-shunted yard operations. Simul Model Pract Theory 17:1106–1129

Marinov MV, Viegas JM (2011) Tactical management of rail freight transportation services: evaluation of yard performance. Transp Plan Technol 34(4):363–387

Brice D, Marinov M, Rüger B (2015) A newly designed baggage transfer system implemented using event-based simulations. Urban Rail Transit 1(4):194–214

Nance RE (1993) A history of discrete event simulation programme languages. Department of Computer Science, Virginia Polytechnic Institue and State University, Blacksburg

Özgün O, Barlas Y (2009) Discrete vs. continuous simulation: when does it matter? In: The 27th international conference of the system dynamics society, Albuquerque

Sedláček M (2014) The use of simulation models for the optimization of transport and logistic company process. Int J Transp Logist 14:1–7

Pouryousef H, Lautala P, White T (2015) Railroad capacity tools and methodologies in the U.S. and Europe. J Mod Transp 23(1):30–42

Lawley M, Parmeshwaran V, Richard J-P, Turkcan A, Dalal M, Ramcharan D (2008) A time–space scheduling model for optimizing recurring bulk railcar deliveries. Transp Res B 42:438–454

Kuby M, Xu Z, Xie X (2001) Railway network design with multiple project stages and time sequencing. J Geogr Syst 3:25–47

Cha MH, Mun D (2014) Discrete event simulation of Maglev transport considering traffic waves. J Comput Des Eng 1(4):233–242

OpenTrack, “Railway Simulation,” 2017. [Online]. Available: http://www.opentrack.ch/opentrack/opentrack_e/opentrack_e.html. Accessed 01 Aug 2017

Darlton AO, Marinov M (2015) Suitability of tilting technology to the Tyne and Wear Metro system. Urban Rail Transit 1(1):47–68

Chen Z, Han BM (2014) Simulation study based on OpenTrack on carrying capacity in district of Beijing–Shanghai high-speed railway. Appl Mech Mater 505–506:567–570