Abstract

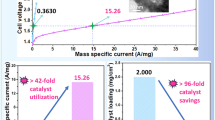

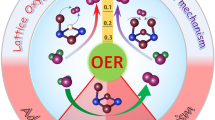

High-temperature annealing is widely recognized as an effective way to improve the durability of Pt/C cathode catalysts used in proton exchange membrane fuel cells (PEMFCs), yet systematic studies on its effects on PEMFC performance are still lacking. Herein, we explore the effect of high-temperature annealing on the PEMFC performance, based on a thorough comparative analysis of Pt/C catalysts annealed at temperatures ranging from 500–900°C. Our results reveal that high-temperature annealing not only enhances the catalyst durability but also substantially increases Pt utilization, which in turn drives the increase in mass activity and the enhancement of low-current-density performance. Based on an array of electrochemical and physical characterization results, we infer that the increased utilization of Pt might stem from nanoparticle migration induced by high-temperature annealing, leading to closer proximity between Pt nanoparticles and ionomers. This reduced distance potentially enhances the accessibility of protons to the Pt nanoparticles, thereby improving the Pt utilization.

摘要

高温退火被认为是提升质子交换膜燃料电池中铂碳阴极催化剂 耐久性的有效方法, 但关于其对燃料电池性能的影响尚缺乏研究报道. 本文通过对不同温度制备的铂碳催化剂进行详细对比分析, 探讨了高 温退火对燃料电池性能的影响. 结果表明, 高温退火不仅增强了催化剂 的耐久性, 还显著提升了铂的利用率, 进而提高了其质量活性和低电流 密度性能. 基于一系列电化学和物理表征结果, 我们推测铂利用率的提 升源于高温退火导致的铂纳米颗粒迁移行为, 进而缩短了铂纳米颗粒 与离子聚的间距. 而较短的间距有利于提高质子对铂纳米颗粒的可及 性, 最终实现了铂纳米颗粒利用率的提升.

Similar content being viewed by others

References

Borup RL, Kusoglu A, Neyerlin KC, et al. Recent developments in catalyst-related PEM fuel cell durability. Curr Opin Electrochem, 2020, 21: 192–200

Takahashi T, Ikeda T, Murata K, et al. Accelerated durability testing of fuel cell stacks for commercial automotive applications: A case study. J Electrochem Soc, 2022, 169: 044523

Kongkanand A, Mathias MF. The priority and challenge of high-power performance of low-platinum proton-exchange membrane fuel cells. J Phys Chem Lett, 2016, 7: 1127–1137

Li C, Yu K, Bird A, et al. Unraveling the core of fuel cell performance: Engineering the ionomer/catalyst interface. Energy Environ Sci, 2023, 16: 2977–2990

Orfanidi A, Madkikar P, El-Sayed HA, et al. The key to high performance low Pt loaded electrodes. J Electrochem Soc, 2017, 164: F418–F426

Ott S, Orfanidi A, Schmies H, et al. Ionomer distribution control in porous carbon-supported catalyst layers for high-power and low Pt-loaded proton exchange membrane fuel cells. Nat Mater, 2020, 19: 77–85

Yarlagadda V, Carpenter MK, Moylan TE, et al. Boosting fuel cell performance with accessible carbon mesopores. ACS Energy Lett, 2018, 3: 618–621

Zhao Z, Hossain MD, Xu C, et al. Tailoring a three-phase microenvironment for high-performance oxygen reduction reaction in proton exchange membrane fuel cells. Matter, 2020, 3: 1774–1790

Chen F, Chen S, Wang A, et al. Blocking the sulfonate group in Nafion to unlock platinum’s activity in membrane electrode assemblies. Nat Catal, 2023, 6: 392–401

Doo G, Yuk S, Lee JH, et al. Nano-scale control of the ionomer distribution by molecular masking of the Pt surface in PEMFCs. J Mater Chem A, 2020, 8: 13004–13013

Wen Z, Wu D, Banham D, et al. Micromodification of the catalyst layer by CO to increase Pt utilization for proton-exchange membrane fuel cells. ACS Appl Mater Interfaces, 2022, 15: 903–913

Jinnouchi R, Kudo K, Kodama K, et al. The role of oxygen-permeable ionomer for polymer electrolyte fuel cells. Nat Commun, 2023, 12: 4956

Shimizu R, Park YC, Kakinuma K, et al. Effects of both oxygen permeability and ion exchange capacity for cathode ionomers on the performance and durability of polymer electrolyte fuel cells. J Electrochem Soc, 2018, 165: F3063–F3071

Yamada K, Hommura S, Shimohira T. Effect of high oxygen permeable ionomers on MEA performance for PEFC. ECS Trans, 2013, 50: 1495–1501

Sheng W, Chen S, Vescovo E, et al. Size Influence on the oxygen reduction reaction activity and instability of supported Pt nanoparticles. J Electrochem Soc, 2011, 159: B96–B103

Yu K, Groom DJ, Wang X, et al. Degradation mechanisms of platinum nanoparticle catalysts in proton exchange membrane fuel cells: The role of particle size. Chem Mater, 2014, 26: 5540–5548

Matsutani K, Hayakawa K, Tada T. Effect of particle size of platinum and platinum-cobalt catalysts on stability against load cycling. Platinum Met Rev, 2010, 54: 223–232

Meier JC, Galeano C, Katsounaros I, et al. Design criteria for stable Pt/C fuel cell catalysts. Beilstein J Nanotechnol, 2014, 5: 44–67

Ramaswamy N, Kumaraguru S, Gu W, et al. High-current density durability of Pt/C and PtCo/C catalysts at similar particle sizes in PEMFCs. J Electrochem Soc, 2021, 168: 024519

Yin P, Zuo LJ, Zeng WJ, et al. Synthesis of platinum intermetallic nanoparticle fuel cell catalysts within secure inter-particle distance on carbon blacks. Appl Catal B-Environ, 2023, 328: 122543

Gasteiger HA, Kocha SS, Sompalli B, et al. Activity benchmarks and requirements for Pt, Pt-alloy, and non-Pt oxygen reduction catalysts for PEMFCs. Appl Catal B-Environ, 2005, 56: 9–35

Shao M, Peles A, Shoemaker K. Electrocatalysis on platinum nano-particles: Particle size effect on oxygen reduction reaction activity. Nano Lett, 2011, 11: 3714–3719

Mayrhofer KJJ, Blizanac BB, Arenz M, et al. The impact of geometric and surface electronic properties of Pt-catalysts on the particle size effect in electrocatalysis. J Phys Chem B, 2005, 109: 14433–14440

Takasu Y, Ohashi N, Zhang XG, et al. Size effects of platinum particles on the electroreduction of oxygen. Electrochim Acta, 1996, 41: 2595–2600

Markovic N, Gasteiger H, Ross PN. Kinetics of oxygen reduction on Pt (hkl) electrodes: Implications for the crystallite size effect with supported Pt electrocatalysts. J Electrochem Soc, 1997, 144: 1591–1597

Kinoshita K. Particle size effects for oxygen reduction on highly dispersed platinum in acid electrolytes. J Electrochem Soc, 1990, 137: 845–848

Greeley J, Rossmeisl J, Hellmann A, et al. Theoretical trends in particle size effects for the oxygen reduction reaction. Z für Physikalische Chem, 2007, 221: 1209–1220

Moreno NG, Molina MC, Gervasio D, et al. Approaches to polymer electrolyte membrane fuel cells (PEMFCs) and their cost. Renew Sustain Energy Rev, 2015, 52: 897–906

Yoshida T, Kojima K. Toyota MIRAI fuel cell vehicle and progress toward a future hydrogen society. Interface Mag, 2015, 24: 45–49

Liu Y, Murphy MW, Baker DR, et al. Proton conduction and oxygen reduction kinetics in PEM fuel cell cathodes: Effects of ionomer-to-carbon ratio and relative humidity. J Electrochem Soc, 2009, 156: B970

Kreuer KD, Paddison SJ, Spohr E, et al. Transport in proton conductors for fuel-cell applications: simulations, elementary reactions, and phenomenology. Chem Rev, 2004, 104: 4637–4678

Wang C, Cheng X, Lu J, et al. The experimental measurement of local and bulk oxygen transport resistances in the catalyst layer of proton exchange membrane fuel cells. J Phys Chem Lett, 2017, 8: 5848–5852

Weber AZ, Kusoglu A. Unexplained transport resistances for low-loaded fuel-cell catalyst layers. J Mater Chem A, 2014, 2: 17207–17211

Greszler TA, Caulk D, Sinha P. The impact of platinum loading on oxygen transport resistance. J Electrochem Soc, 2012, 159: F831–F840

Acknowledgements

We acknowledge the funding support from the National Natural Science Foundation of China (22325903, 22221003, and 22071225), the National Key Research and Development Program of China (2018YFA0702001), the Plan for Anhui Major Provincial Science & Technology Project (202203a0520013 and 2021d05050006), and the USTC Research Funds of the Double First-Class Initiative (YD2060002032). This work was partially carried out at the USTC Center for Micro and Nanoscale Research and Fabrication.

Author information

Authors and Affiliations

Contributions

Author contributions Tong L and Liang H conceived and designed the experiments. Li J prepared the catalysts. Li J and Li Z conducted the RDE and PEMFCs tests. Xu C, Li S, and Li A provided the technical support for the MEAs diagnostics. Tong L, Liang H and Li J co-wrote the manuscript. All authors contributed to the general discussion.

Corresponding authors

Ethics declarations

Conflict of interest The authors declare that they have no conflict of interest.

Additional information

Supplementary information Experimental details and supporting data are available in the online version of the paper.

Junjie Li is presently a Master student at the University of Science and Technology of China (USTC). His research interest is the development of advanced Pt-based fuel cell cathode catalysts.

Lei Tong received his PhD degree from USTC in 2020, mentored by Prof. Haiwei Liang. Currently, he is an associate research fellow at USTC working with Prof. Haiwei Liang. His research interest is Pt-based cathode catalysts for fuel cell applications.

Haiwei Liang received his PhD degree from USTC in 2011, mentored by Prof. Shuhong Yu. His postdoctoral work was at Max Planck Institute for Polymer Research, collaborating with Profs. Klaus Müllen and Xinliang Feng. In 2016, he became a full professor at USTC. His research specializes in developing carbon-supported Pt and Pt alloy catalysts for fuel cells.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Li, J., Li, Z., Li, S. et al. High-temperature annealing improves Pt utilization of proton exchange membrane fuel cell cathode catalysts. Sci. China Mater. (2024). https://doi.org/10.1007/s40843-024-2871-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40843-024-2871-1