Abstract

The growing scarcity of conventional oil resources has intensified the focus on shale oil, known for its abundant reserves. Nevertheless, in the process of shale oil retorting, a substantial quantity of harmful waste oil shale residue (OSR) is generated. In this study, OSR and bituminous coal sourced from Fushun City served as the raw materials for the production of Si–Al–Fe alloy in a DC electric arc furnace, proposing a novel way to efficiently utilize OSR. The experiment summarized and analyzed the current oxide reduction theory, combined with the actual experimental results, focused on investigating the phase transformations of OSR during the reduction process. Based on the gaseous suboxide-carbide reaction theory, the reduction mechanism of pellet raw materials at high temperature was proposed. Results showed that the pellet raw materials will first undergo high temperature decomposition during the reduction process, and generated a large amount of carbides. Carbides subsequently reacted with metal suboxides produced in the high-temperature zone of the electric arc furnace to yield alloys. The element distribution of the obtained alloy product was non-uniform, the metallic Si phase was closely adjacent to the SiC substance, and the Fe in the alloy significantly enriched the reduced Al and Ti elements.

Graphical Abstract

Similar content being viewed by others

References

Wang L, Gao CH et al (2023) Development review and the prospect of oil shale in-situ catalysis conversion technology. Pet Sci. https://doi.org/10.1016/j.petsci.2023.08.035

Wang Z, Liu X et al (2016) Studies on the co-pyrolysis characteristics of oil shale and spent oil shale. J Therm Anal Calorim 123:1707–1714. https://doi.org/10.1007/s10973-015-5012-3

Bai F, Sun Y et al (2017) Evaluation of the porous structure of Huadian oil shale during pyrolysis using multiple approaches. Fuel 187:1–8. https://doi.org/10.1016/j.fuel.2016.09.012

Jia B, Su J (2023) Advancements and environmental implications in oil shale exploration and processing. Appl Sci 13:7657. https://doi.org/10.3390/app13137657

Jiang XM, Han XX et al (2007) New technology for the comprehensive utilization of Chinese oil shale resources. Energy 32:772–777. https://doi.org/10.1016/j.energy.2006.05.001

Xu YB, Sun PC et al (2019) Progress in exploration, development and utilization of oil shale in China. Oil Shale 36:285. https://doi.org/10.3176/oil.2019.2.03

Wang DM, Xu YM et al (2009) Investigation of mineral composition of oil shale. Asia-Pac J Chem Eng 4:691–697. https://doi.org/10.1002/apj.319

El-Hasan T, Abu-Jaber N et al (2019) Hazardous toxic elements mobility in burned oil shale ash, and attempts to attain short- and long-term solidification. Oil Shale 36:226–249. https://doi.org/10.3176/oil.2019.2s.12

Raukas A, Punning JM (2009) Environmental problems in the Estonian oil shale industry. Energy Environ Sci 2:723–728. https://doi.org/10.1039/b819315k

Sun ZX, Li QY et al (2023) Study on the release law of phenol during water-oil shale interaction process. Water. https://doi.org/10.3390/w15112017

Chen W, Li Y et al (2020) Properties and economics evaluation of utilization of oil shale waste as an alternative environmentally-friendly building materials in pavement engineering. Constr Build Mater 259:119698. https://doi.org/10.1016/j.conbuildmat.2020.119698

Liu J, Qiu J et al (2021) Calcined oil shale residue as a supplementary cementitious material for ordinary Portland cement. Constr Build Mater 306:124849. https://doi.org/10.1016/j.conbuildmat.2021.124849

Xu YM, He DM et al (2009) Characterization of oil shale processing residues and separated products. Oil Shale 26:500–513. https://doi.org/10.3176/oil.2009.4.06

Xu YM, Qi J et al (2010) Preparation of amorphous silica from oil shale residue and surface modification by silane coupling agent. Oil Shale 27:37. https://doi.org/10.3176/oil.2010.1.05

Liu R, Liu Z et al (2015) Characteristics and comprehensive utilization potential of oil shale of the Yin’e Basin, Inner Mongolia China. Oil Shale 32:293. https://doi.org/10.3176/oil.2015.4.02

Shkolnik V, Zharmenov A et al (2013) Prospects of production complex aluminum silicon alloy. In: The 13th Int. ferroalloys congress: efficient technologies in ferroalloy industry. Almaty, pp 311

Grigorovich KV, Garber AK (2011) Analysis of the complex deoxidation of carbon steel melts. Russian Metall 2011:934–941. https://doi.org/10.1134/s0036029511090151

Burnham AK (1979) Reaction kinetics between CO2 and oil-shale residual carbon. 1. Effect of heating rate on reactivity. Fuel 58:285–292. https://doi.org/10.1016/0016-2361(79)90138-8

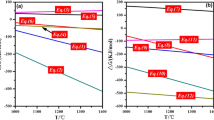

Epifano E, Monceau D (2023) Ellingham diagram: a new look at an old tool. Corros Sci 217:111–113. https://doi.org/10.1016/j.corsci.2023.111113

Chen WH, Hsu CL et al (2015) Thermodynamic analysis of the partial oxidation of coke oven gas for indirect reduction of iron oxides in a blast furnace. Energy 86:758–771. https://doi.org/10.1016/j.energy.2015.04.087

Yang J, Mori T et al (2007) Mechanism of carbothermic reduction of hematite in hematite-carbon composite pellets. Isij Int 47:1394–1400. https://doi.org/10.2355/isijinternational.47.1394

El-Geassy AA, Halim KSA et al (2013) Carbothermic reduction of Fe2O3/C compacts: comparative approach to kinetics and mechanism. Ironmak Steelmak 40:534–544. https://doi.org/10.1179/1743281212y.0000000076

Lee HC, Dhage S et al (2010) A simulation study on the direct carbothermal reduction of SiO2 for Si metal. Curr Appl Phys 10:S218–S221. https://doi.org/10.1016/j.cap.2009.11.053

Martello E, Tranell G et al (2013) Trace elements in the Si furnace. Part I: behavior of impurities in quartz during reduction. Metall Mater Trans B 44:233–243. https://doi.org/10.1007/s11663-012-9717-4

Sloman B, Please C et al (2017) A heat and mass transfer model of a silicon pilot furnace. Metall Mater Trans B 48B:2664–2676. https://doi.org/10.1007/s11663-017-1052-3

Martello ED, Tranell G et al (2011) Study of pellets and lumps as raw materials in silicon production from quartz and silicon carbide. Metall Mater Trans B 42:939–950. https://doi.org/10.1007/s11663-011-9529-y

Legemza J, Findorák R et al (2021) New approach in research of quartzes and quartzites for ferroalloys and silicon production. Metals 11:670. https://doi.org/10.3390/met11040670

Sakaguchi Y, Ishizaki M et al (1992) Production of high purity silicon by carbothermic reduction of silica using AC-arc furnace with heated shaft. Isij Int 32:643–649. https://doi.org/10.2355/isijinternational.32.643

Jacobson NS, Lee KN et al (1992) Reactions of silicon carbide and silicon(IV) oxide at elevated temperatures. J Am Ceram Soc 75:1603–1611. https://doi.org/10.1111/j.1151-2916.1992.tb04232.x

Filsinger DH, Bourrie DB (1990) Silica to silicon: key carbothermic reactions and kinetics. J Am Ceram Soc 73:1726–1732. https://doi.org/10.1111/j.1151-2916.1990.tb09820.x

Ringdalen E, Tangstad M (2012) Reaction mechanisms in carbothermic production of silicon, study of selected reactions. Miner Metals Mater Soc. https://doi.org/10.1002/9781118364765.ch24

Tangstad M, Beukes JP et al (2019) Coal-based reducing agents in ferroalloys and silicon production. In: Suárez-Ruiz I, Diez MA, Rubiera F (eds) New trends in coal conversion. Woodhead Publishing, Sawston, pp 405–438. https://doi.org/10.1016/b978-0-08-102201-6.00014-5

Yokokawa H, Fujishige M et al (1984) Volatilization of aluminum oxycarbides and of alumina with carbon in reduction of alumina. Trans Japan Institute Metals 25:187–196. https://doi.org/10.2320/matertrans1960.25.187

Cox JH, Pidgeon L (1963) An investigation of the aluminum–oxygen–carbon system. Can J Chem 41:671–683. https://doi.org/10.1139/v63-095

Folomeikin YK, Demonis IM et al (2006) Investigation into the vaporization of Al2O3 in the presence of carbon at high temperatures. Glass Phys Chem 32:191–195. https://doi.org/10.1134/s1087659606020118

Yu QC, Yuan HB et al (2012) Carbothermic reduction of alumina with carbon in vacuum. J Central South Univ 19:1813–1816. https://doi.org/10.1007/s11771-012-1213-0

Liu D, Zhang G et al (2016) Solid state carbothermal reduction of alumina. In: Bearne G, Dupuis M, Tarcy G (eds) Essential readings in light metals: Volume 2 aluminum reduction technology. Springer, Cham, pp 1076–1081. https://doi.org/10.1007/978-3-319-48156-2_157

Balomenos E, Panias D et al (2007) Theoretical investigation of the volatilization phenomena occurring in the carbothermic reduction of alumina. World Metall 64:312–320

Halmann M, Frei A et al (2007) Carbothermal reduction of alumina: thermochemical equilibrium calculations and experimental investigation. Energy 32:2420–2427. https://doi.org/10.1016/j.energy.2007.06.002

Kemper C, Balomenos E et al (2016) EAF carbothermic co-reduction of alumina and silica for the direct production of Al-Si master alloy. In: Grandfield J (ed) Light metals. Springer, Cham, pp 789–794. https://doi.org/10.1007/978-3-319-48144-9_133

Saavedra AF, Kibby RM (1988) Investigating the viability off carbothermic alumina reduction. J Metal 40:32–36. https://doi.org/10.1007/bf03258807

Su M, Zhou Y et al (2015) Highly transparent AlON sintered from powder synthesized by direct nitridation. J Eur Ceram Soc 35:1173–1178. https://doi.org/10.1016/j.jeurceramsoc.2014.10.036

Acknowledgements

This work has been financially supported by (1) Inner Mongolia 2020 Science and Technology Innovation Guidance Project [No. NMGKJCX202007]; (2) Xuzhou City 2022 Scientific and Technological Achievements Transformation Project [No. KC22450]; and (3) Inner Mongolia 2018 Talent Project Lead Support Project. Thanks to the shale oil plant Fushun Mining Group Co., Ltd., Liaoning Province, China for providing experimental raw materials.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Mansoor Barati.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qu, Y., Luo, H., Zhi, Z. et al. Carbothermal Reduction of Oil Shale Residue (OSR) in DC Electric Furnace to Prepare Si–Al–Fe Alloy. J. Sustain. Metall. (2024). https://doi.org/10.1007/s40831-024-00826-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40831-024-00826-1