Abstract

This work tested an effective and efficient Nd/La extraction and separation via flat-sheet supported liquid membrane. A microporous polypropylene film was used as the solid support for the liquid membrane and P507 as the extractant. The effect of Nd(III) and La(III) concentration in the feed, the concentration of P507, and acid solution concentration in the stripping phase on Nd and La extraction and separation were studied. The results suggest the extraction of La and Nd increases with the initial pH of the feed solution and P507 concentration. Maximum separation factor of 44.25 was obtained at the low P507 concentration of 5% (v/v).

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rare earth elements (REEs) have traditional applications in catalysis, metallurgy, ceramics, medicine, and electronics [1,2,3]. Recent high-tech fields rising sharply have expanded the application of REEs with their unique physical properties, including hybrid cars, wind turbines, and compact fluorescent lights [4,5,6]. Among the 17 REEs, light REEs (Sc, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd) with atomic number 57–63 accounts for 95% of world consumption [7, 8]. Monazite, bastnasite, and xenotime are major resources of light REEs [9].

Nowadays, the interest in neodymium extraction is increasingly significant due to the demand for commercial super magnets based on Nd2Fe14B permanent magnets and solid lasers used in the medical industry [10,11,12]. The primary resource of neodymium originates from the monazite ore. Monazite ore is an essential source of neodymium, typically containing 45% Ce, 23% La, and 17% Nd and minor amounts of Pr, Sm, Gd, and Y. Nd extraction for monazite processing requires La and Nd separation after removing thorium phosphate and insoluble CeO2 products [13]. Another resource of Nd is the recycling of spent Ni-metal hydride (Ni-MH) secondary batteries [14,15,16]. The Ni-MH batteries were subjected to acid leaching. After removing the Ni(II), Co(II), and Mn(II) either by electrodeposition or solvent extraction, La and Nd were left in the leaching solution subject to separation [17].

However, separating and purifying REEs can be difficult due to their similar chemical and physical properties [18]. In general, the separation of REEs is developed based on ion exchange and solvent extraction [19, 20]. The solvent extraction method has been commercially employed as the principal technique for separating REEs, especially for handling large volumes of diluted pregnant liquors. The fundamental theory of light REEs lies in the lanthanide contraction effect [18]. The effect demonstrates the steady decrease in the size of the atoms and ions of the rare earth elements with increasing atomic number from lanthanum (atomic number 57) through lutetium (atomic number 71). The phenomena decide the trends in the stability constants of the complexes, allowing particular distinction for element separation [21].

Various extractants have been reported to extract and separate REEs [11, 22,23,24,25]. The most common extractants can be classified as cation exchangers (or acidic extractants), solvation extraction (neutral extractants), and anion exchangers (basic extractants). Among the cations exchangers, acidic organophosphorus extractants have been studied the most. Alkylphosphorus compounds, such as di-2-ethylhexyl phosphoric acid (DEHPA; P204) [19], mono-(2-ethylhexyl) phosphoric acid (EHEHPA; P507) [19, 22, 26, 27], tri-n-butyl phosphate (TBP) [17, 20, 28], and tri-n-octyl phosphine oxide (TOPO) [17, 28], have been commercialized for the separation for the lanthanides. The P507 has gained more popularity for rare earth separation since it can be stripped at lower acidities than P204 [29]. It has also shown a superior ability for recovery and separation of Nd(III) and La(III) from acidic media by solvent extraction (SX). The SX separation of Nd(III) from La(III) with P507 is thermodynamically and kinetically favorable. However, disadvantages include third-phase formation, extractant loss, and poor selectivity [17]. In addition, the separation requires strict control of the phase variables.

The supported liquid membrane (SLM) separation techniques have been attracting more attention due to the superiority of low solvent inventory, ease of operation, and simultaneous extraction and stripping [17, 30,31,32,33,34]. REEs separation using SLM method can be straightforwardly seen as a simultaneous three-step process: (1) molecule extraction from feed phase to the SLM, (2) diffusion through SLM, and (3) stripping process to the received phase. The selective transport is based on the different permeability of cations. At the same time, the permeability is related to the driving force of feed to organic strips and the thickness of the membrane. Several reports have used SLM to extract and separate REEs [30, 31, 33,34,35,36,37]. Ryan C. Smith et al. studied the REEs recovery from coal fly ash leachate using SLM [30]. They found that SLM process was more selective for heavy REEs, while the convention SX process favored the selectivity for light REEs. J. Martinez studied the factor influencing selectivity of a ternary mixture of REEs (yttrium–neodymium–dysprosium) using flat-sheet SLM (FSSLM) [33]. The results suggested that lower the pH of the stripping phase increased selectivity. Also, reducing the extractant concentration significantly improved the selectivity but increased the processing time. This work explores two typical light REEs (Nd and La) extraction and separation with flat-sheet SLM using extractant P507. The effect of feed concentration, feed pH, P507 concentration, strip solution composition, and strip acidity has been studied on the extraction and separation of La/Nd has been studied in detail. The optimal conditions determined will be used for pilot-scale research of REEs separation with hollow-fiber SLM technology.

Experimental

Regents and Materials

Chemical reagents used were of A.R. grade. La2O3 (≥ 99.9%, Sigma-Aldrich) and Nd2O3 (99.9%, Sigma-Aldrich) solid powders were used to prepare REEs salt solution by dissolved in a certain amount of acid (HCl, H2SO4, and HNO3) at 80 °C and cooled down to room temperature. A microporous polypropylene membrane of Celgard@2500 [38], 5 × 5 cm2 effective surface area, 55% porosity, 0.209 × 0.054 µm2 pore size, 25 µm thickness were used as the support. The extractant was P507 (Kopper Chemical), and the diluent was D80 (Exxsol™ D80).

Extraction Experiment

The FSSLM experiments were carried out in a two-compartment cell, as shown in Fig. 1. The hydrophobic polypropylene membrane was immersed in P507/D80 mixture with a predetermined % (v/v) and treated with an ultrasound bath for 10 min. The membrane pores were filled with carrier solution by capillary action. The membrane was then impregnated in the organic solutions and kept in the petri dish for 12 h before the extraction experiment. After removing from the carrier solution, the excess carrier solution on the surface of the membrane was then wiped out with tissue paper. Subsequently, the loaded membrane was clamped between the two compartments and was fixed firmly by using the gasket to avoid possible solution leakage from one compartment to the other. The feed and strip solutions were added into the two separate chambers. The feed solutions were 250 mL acidic solutions containing La(III) and Nd(III), and the strip solutions were acidic solutions with higher acidities.

The solutions were stirred at 350 rpm for 6 h at room temperature (20 ± 2 °C). Samples from both feed and strip solutions were taken at 0, 0.5, 1, 1.5, 2, 3, 4, 5, and 6 h for La(III) and Nd(III) concentration measurement. Amounts of 250–1000 µl solutions from both the feed and strip were withdrawn and diluted. Their concentrations were determined for both feed and strip solutions by ICP-OES (inductively coupled plasma—optical emission spectrometry) using a Perkin Elmer Optima 3000. Before and after the separation tests, the membranes were subjected to elemental analysis via PXRF (portable X-ray fluorescence spectroscopy). The P concentration from the PXRF measurement reflects the content of P507 loaded on the membranes.

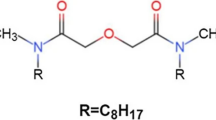

La and Nd extraction using P507 (abbreviated as H2A2) is a cation exchange process. The extraction of REEs from feed solution is accompanied by the release of three hydrogen ions from the extractants, as shown in Eq. 1–2.

According to the equation, the high acidity in the feed phase has an adverse effect on La and Nd transport. In contrast, the stripping process is promoted by increasing the acidity of the aqueous stripping solution. Therefore, it is critical to determine the optimal initial pH of feed solutions and strip acidity. The amount of P507 on the membrane is also related to the REEs extraction process and the REEs concentration in the feed phase from the above equations.

The Nd and La extraction efficiency can be quantified as the extraction fraction for a single REE extraction, which illustrates the percentage of Nd(III) or La(III) transported into the strip solution from the initial feed solution. To simplify the process, the concentration at the membrane boundaries was neglected. The equations can be written as:

where \([{La(III)]}_{Feed;0}\) and \([{Nd(III)]}_{Feed;0}\) represent the initial Nd(III) and La(III) concentration in the feed solution. To evaluate the feasibility of separating Nd(III)/La(III) using P507 in SLMs, the separation factor was introduced:

A more significant value of α means a better separation effect.

The permeability coefficients La(III) and Nd(III) in the membrane were determined experimentally by plotting the linear relationship curve for ln (Cf,t/Cf,0) vs. t as the following equation:

where Cf,0 and Cf,t are the REE ion concentration in the feed at t = 0 and time t, respectively, Q is the effective surface area (cm2), which is the product of geometric surface areas (25 cm2) and porosity (55%), V is the total feed volume (250 mL), and P is the permeability coefficient (cm/s).

Results and Discussion

Effect of Initial La(III)/Nd(III) Concentration

Extraction and separation of Nd/La were first investigated as the function of La(III) and Nd(III) concentrations at 100, 200, 500, and 1000 mg/L. The initial pH of the feed solution was 3. The strip solution was a 3 M HCl solution. The extractor was 20% (v/v) of P507 in D80 diluent.

Figure 2a, b shows extraction% of Nd and La within 6 h, respectively. It is evident that the processing time increases with the increase of the initial ion concentration. When La(III) and Nd(III) concentrations were 100 and 200 mg/L, both La and Nd extraction exceeded 90% after 6 h but with limited selectivity. However, when the concentration of La(III) and Nd(III) was 500 and 1000 mg/L, selectivity increased although with decreased extraction. The Nd(III) extraction was 96.2% in the 500 mg/L test, while La(III) extraction was only 61.2%. By increasing the ions concentration to 1000 mg/L, the extraction% of Nd and La was calculated as 88.8 and 13.7, respectively. The separation selectivity for the binary Nd/La mixture was also studied. The separation factor at 6 h was calculated based on Eq. 5, as shown in Fig. 2c. It is apparent that with the increase of the Nd(III) and La(III) concentration from 100 to 1000 mg/L, the α(Nd/La) increased from 1.03 to 6.39. Apparently, at a low feed concentration (less than 500 mg/L), the saturation of P507 was present in the membrane phase. Thereby, the transport of both La and Nd wasn’t restricted. When the ions concentration increased to > 500 mg/L, more Nd(III) was loaded on the membrane phase and recovered in the trip phase.

Effect of P507 Concentration on Nd/La Separation

The extractant concentration plays a significant role in metal ions' transportation for the SLM process. The effect of the phosphorus extractant (P507) concentration on separation of Nd from Nd-La mixed solution in P507-HCl system: 5, 10, 20, and 40% (v/v) of P507/D80 was used. The feed solution was at initial pH of 3, 1000 mg/L La(III) and Nd(III) containing HCl solution. The strip solution was a 3 M HCl solution. Figure 3a, b shows the extraction % of Nd and La within 6 h. Figure 3c shows the selectivity of Nd extraction.

In order to partially quantify the concentration of P507 loaded on the membrane, PXRF (portable X-ray fluorescence spectroscopy) scan was conducted to determine the P concentration on the loaded membrane. This is due to P507 being a phosphorus-based extractant. The results of P wt% from scanning the membrane are shown in Table 1. The table shows the P wt% increased from 0.54 at 5% (v/v) to 5.05 at 40% (v/v) P507 concentration. Moreover, the P wt% only slightly decreased for the membrane before and after the tests, which suggests negligible loss of the extractant in the acidic environment, especially the strip that had 3 M HCl. For example, the 20% P507 test had an initial P wt% of 2.81 and decreased to 2.62 wt% after REEs transport.

From Fig. 3, the extraction of both Nd and La increased with higher P507 concentrations. When raised the P507 concentration from 5 to 40% (v/v), the extraction of Nd(III) and La (III) significantly increased from 51.83 to 94.11% and 1.17–28.18%, respectively, after 6-h tests. The selectivity analysis also found that the extractant concentration significantly affected the selective extraction of Nd. The separation factors, α(Nd/La), shown in Fig. 3c, depict the high dependence on the P507 concentration. The highest value of α(Nd/La) was found to be 44.25 at 5% (v/v) P507 and drastically reduced to only 6.39 and 3.23 for 20 and 40% (v/v) of P507. The phenomena provide an opportunity for the separation of Nd from La. As shown in Fig. 3d, the permeability coefficient value increased with extractant concentration for La(III) and Nd(III), respectively. Also, it was presented that the Nd(III) permeability values were higher than those of La(III) in the P507 concentration range from 5 to 40% (v/v), and the gap was widened with increasing P507 concentration. Moreover, the results indicated that the P507-Nd/La complex transport increased linearly when the P507 concentration ranged from 5 to 20% (v/v).

Effect of Feed Acidity on Nd/La Separation

According to the REEs extraction principle, the feed solution pH is another critical parameter to separate REEs using a cationic extractant. The extractant is loaded with REEs during the extraction process, and free protons are released into the feed phase, causing the pH to decrease. Based on Eqs. (1) and (2), the decreasing H+ concentration promotes the Nd(III) and La(III) to interact with the extractant in the first stage. To verify the effect of the initial feed solution pH, the SLM tests were designed with varied initial pH of 0, 1.5, 2, 3, and 4. The feed solutions contained 1000 mg/L of La(III) and Nd(III). The extractant was 20% (v/v) 507, and a 3 M HCl solution was used as the strip phase. The extraction% of Nd and La is shown in Fig. 4a and Fig. 4b, respectively. The separation factors diagram as per pH is shown in Fig. 4c.

The percentage of La and Nd extracted both increased with increasing pH. When pH is 0, no La and Nd extraction apparent was found. Increasing the pH from 1.5 to 4, the Nd extraction% rose from 42.79 to 93.10%, while the La extraction% rose from 2.22 to 44.86%. Faster Nd transportation than La was found at all pH conditions. The relationship between pH and separation factor shows an opposite trend. After 6 h of SLM test, the separation factors decreased from 19.25 at pH 1.5 to 2.08 at pH 4. It was concluded that the higher pH in weak acid conditions promoted both Nd and La extraction but reduced the Nd selectivity.

Effect of Strip Acidity on Nd/La Separation

According to the cation exchange reaction above, the acid concentration solution is supposed to affect the REEs loaded on the extractant to the inorganic acid solution. The effect of strip solution acidity was investigated for HCl solutions of 0.5, 1, 3, and 5 M. The feed phase was a 1000 mg/L Nd(III) and La(III) containing acid solution at pH 3, and the extractant was 20% (v/v) P507. The extraction and separation results are shown in Fig. 5a, b. The Nd extraction rate has no noticeable change when the HCl ranges from 0.5 to 3 M from Fig. 6a, ranging between 88.80 and 93.29%. However, further increased the HCl concentration to 5 M, the Nd% extracted drastically decreased to 77.13%. As for the La extraction, with an increase of HCl concentration from 0.5 to 5 M, the La extracted% decreased from 22.30 to 6.11%. The separation factors in the extraction for different HCl concentrations are shown in Fig. 5c. As can be seen, with the increase of the acidity, the α (Nd/La) increased from 4.18 at 0.5 M HCl and reached the maximum value of 12.63 at 5 M HCl.

As illustrated above, the cation ions transfer related to the H+ concentration in the dispersed phase. However, the nature of the acid necessarily differs for variant acids. Thereby, the mass transfer power will be unequal. To explore the role of different trip agents on Nd/La separation, HCl, H2SO4 and HNO3 with the same H+ concentration were used in the strip phase. The feed solution was a pH 3, 1000 mg/L La(III) and/Nd(III) containing HCl/H2SO4/HNO3 solution. The strip phase was an acid as same as the feed solution with 3 M H+. The extractant was 20% (v/v) P507. The extraction and separation results are shown in Fig. 6. HCl is the most efficient agent for La(III) and Nd(III) extraction, presenting the above extraction curves. The percentage of La and Nd extracted has the following order: HCl > HNO3 > H2SO4. As for the selectivity, it was found that α(Nd/La) was higher in HCl and H2SO4 system, 6.49 and 6.80, than in HNO3, 4.30. HCl solution was proven to be the most effective stripping agent for Nd and La extraction, and HCl and H2SO4 had superior effect of Nd/La separation.

Effect of Nd/La Ratio in the Feed Solution

The different mole ratio of Nd(III)/La(III) in the feed was also investigated, considering the practical application for all kinds of REEs sources, including the monazite ore and Ni-MH secondary batteries. The mole ratio was set to be Nd(III)/La(III) = 1/4, 1/2, 1, 2, 4. The extractant was 20% (v/v) P507/D80 mixture, and the strip solution was a 1 M HCl solution. The process time was 6 h for all the tests in this study. The results, including Nd, La extraction%, and the Nd selectivity, are shown in Fig. 7. As discussed above, Nd(III) is more prone to be transported through the SLM than La(III). Figure 7a indicates that the Nd extraction% has a narrow extraction percentage ranging between 87 and 95% with varied Nd(III)/La(III) mole ratios. However, the La(III) transport was retarded by the high ratio of Nd(III)/La(III). At the ratio of 4, the La(III) extraction was only 16.14%, while it increased to 45.70% at the ratio of 1/4. It can be concluded that the feed solution composition correlated with the selectivity of the Nd. Due to the faster transport of the Nd-P507 complex than La, the higher ratio of Nd/La in the feed, the higher α(Nd/La) would be obtained. The Nd selectivity shown in Fig. 7c demonstrates that the α(Nd/La) increases with the Nd(III)/La(III) mole ratio from 2.08 to 5.88.

Conclusions

The interest in neodymium (Nd) is increasing due to its vital role in high-tech sectors, such as permanent magnets (Nd2Fe14B alloys). The extraction of Nd from ores and recycling of Nd from the wastes demand effective and efficient Nd and La separation. This research used a supported liquid membrane with EHEHPA (P507) to extract and separate Nd(III) and La(III). The effect of Nd(III) and La(III) concentration in the feed, feed pH, P507 concentration, and the acidity stripping phases on Nd/La extraction and separation were discussed. The results show that the feed solution pH and P507 concentration play significant roles in Nd/La extraction and separation. When the initial concentration of La(III) and Nd(III) was 1000 mg/L, 20/80 (v/v)% P507, feed pH 3, and strip solution was 3 M HCl, 99.8% of Nd(III) was extracted after 6 h, while the extraction of La(III) was 22.2%. The tests at 5% (v/v) of P507 and feed pH of 1.5 showed the highest Nd(III)/La(III) separation factors of 44.25 and 19.25, respectively.

References

Hou Z, Pei W, Zhang X et al (2020) Rare earth oxides and their supported noble metals in application of environmental catalysis. J Rare Earths 38:819–839

Yahiro H, Eguchi K, Arai H (1989) Electrical properties and reducibilities of ceria-rare earth oxide systems and their application to solid oxide fuel cell. Solid State Ionics 36:71–75

Wang L-M, Lin Q, Yue L-J et al (2008) Study of application of rare earth elements in advanced low alloy steels. J Alloys Compd 451:534–537

Balaram V (2019) Rare earth elements: a review of applications, occurrence, exploration, analysis, recycling, and environmental impact. Geosci Front 10:1285–1303

Omodara L, Pitkäaho S, Turpeinen E-M et al (2019) Recycling and substitution of light rare earth elements, cerium, lanthanum, neodymium, and praseodymium from end-of-life applications-a review. J Clean Prod 236:117573

Dushyantha N, Batapola N, Ilankoon I et al (2020) The story of rare earth elements (REEs): occurrences, global distribution, genesis, geology, mineralogy and global production. Ore Geol Rev 122:103521

Mancheri NA (2012) Chinese monopoly in rare earth elements: supply–demand and industrial applications. China Rep 48:449–468

Navarro J, Zhao F (2014) Life-cycle assessment of the production of rare-earth elements for energy applications: a review. Front Energy Res 2:45

Mohamed M, Aly I (2006) Chemical studies on the reactivity of some organic extractants for extraction and separation of certain elements from aqueous solutions. PhD Thesis, Ain Shams University

Kim D, Powell L, Delmau LH et al (2016) A supported liquid membrane system for the selective recovery of rare earth elements from neodymium-based permanent magnets. Sep Sci Technol 51:1716–1726. https://doi.org/10.1080/01496395.2016.1171782

Ni’am AC, Wang YF, Chen SW et al (2020) Simultaneous recovery of rare earth elements from waste permanent magnets (WPMs) leach liquor by solvent extraction and hollow fiber supported liquid membrane. Chem Eng Process Process Intensif 148:107831. https://doi.org/10.1016/j.cep.2020.107831

Kim D, Powell LE, Delmau LH et al (2015) Selective extraction of rare earth elements from permanent magnet scraps with membrane solvent extraction. Environ Sci Technol 49:9452–9459. https://doi.org/10.1021/acs.est.5b01306

Xu Y, Liu H, Meng Z et al (2012) Decomposition of bastnasite and monazite mixed rare earth minerals calcined by alkali liquid. J Rare Earths 30:155–158. https://doi.org/10.1016/S1002-0721(12)60014-3

Müller T, Friedrich B (2006) Development of a recycling process for nickel-metal hydride batteries. J Power Sources 158:1498–1509

Vander Hoogerstraete T, Binnemans K (2014) Highly efficient separation of rare earths from nickel and cobalt by solvent extraction with the ionic liquid trihexyl (tetradecyl) phosphonium nitrate: a process relevant to the recycling of rare earths from permanent magnets and nickel metal hydride bat. Green Chem 16:1594–1606

Yun XIA, Liansheng X, Jiying T et al (2015) Recovery of rare earths from acid leach solutions of spent nickel-metal hydride batteries using solvent extraction. J Rare Earths 33:1348–1354

Anitha M, Ambare DN, Kotekar MK et al (2013) Studies on permeation of Nd (III) through supported liquid membrane using DNPPA + TOPO as carrier. Sep Sci Technol 48:2196–2203. https://doi.org/10.1080/01496395.2013.793199

Zhang J, Zhao B, Schreiner B (2016) Separation hydrometallurgy of rare earth elements. Springer, Cham

Chang H, Li M, Liu Z et al (2010) Study on separation of rare earth elements in complex system. J Rare Earths 28:116–119. https://doi.org/10.1016/S1002-0721(10)60270-0

Xie F, Zhang TA, Dreisinger D, Doyle F (2014) A critical review on solvent extraction of rare earths from aqueous solutions. Miner Eng 56:10–28. https://doi.org/10.1016/j.mineng.2013.10.021

Ramasamy DL, Khan S, Repo E, Sillanpää M (2017) Synthesis of mesoporous and microporous amine and non-amine functionalized silica gels for the application of rare earth elements (REE) recovery from the waste water-understanding the role of pH, temperature, calcination and mechanism in Light REE and Heavy REE separation. Chem Eng J 322:56–65. https://doi.org/10.1016/j.cej.2017.03.152

Jiang F, Yin S, Srinivasakannan C et al (2018) Separation of lanthanum and cerium from chloride medium in presence of complexing agent along with EHEHPA (P507) in a serpentine microreactor. Chem Eng J 334:2208–2214. https://doi.org/10.1016/j.cej.2017.11.173

Gras M, Papaiconomou N, Chainet E et al (2017) Separation of cerium(III) from lanthanum(III), neodymium(III) and praseodymium(III) by oxidation and liquid-liquid extraction using ionic liquids. Sep Purif Technol 178:169–177. https://doi.org/10.1016/j.seppur.2017.01.035

Habibpour R, Dargahi M, Kashi E, Bagherpour M (2018) Comparative study on Ce (III) and la (III) solvent extraction and separation from a nitric acid medium by D2EHPA and Cyanex272. Metall Res Technol. https://doi.org/10.1051/metal/2017083

Huang XW, Li JN, Zhang YQ et al (2008) Synergistic extraction of Nd and Sm3+ from sulfuric acid medium with D2EHPA-HEHEHP in kerosine. Zhongguo Youse Jinshu Xuebao/Chin J Nonferrous Met 18:366–371. https://doi.org/10.19476/j.ysxb.1004.0609.2008.02.030

Chen K, He Y, Srinivasakannan C et al (2019) Characterization of the interaction of rare earth elements with P507 in a microfluidic extraction system using spectroscopic analysis. Chem Eng J 356:453–460. https://doi.org/10.1016/j.cej.2018.09.039

Wu W, Zhang F, Bian X et al (2013) Effect of loaded organic phase containing mixtures of silicon and aluminum, single iron on extraction of lanthanum in saponification P507-HCl system. J Rare Earths 31:722–726. https://doi.org/10.1016/S1002-0721(12)60348-2

Banda R, Jeon H, Lee M (2012) Solvent extraction separation of Pr and Nd from chloride solution containing la using Cyanex 272 and its mixture with other extractants. Sep Purif Technol 98:481–487. https://doi.org/10.1016/j.seppur.2012.08.015

Reddy MLP, Prasada RAOT, Damodaran AD (1993) Liquid-liquid extraction processes for the separation and purification of rare earths. Miner Process Extr Metall Rev 12:91–113. https://doi.org/10.1080/08827509508935254

Smith RC, Taggart RK, Hower JC et al (2019) Selective recovery of rare earth elements from coal fly ash leachates using liquid membrane processes. Environ Sci Technol 53:4490–4499. https://doi.org/10.1021/acs.est.9b00539

Xu D, Shah Z, Sun G et al (2019) Recovery of rare earths from phosphate ores through supported liquid membrane using N, N, N′, N′-tetraoctyl diglycol amide. Miner Eng. https://doi.org/10.1016/j.mineng.2019.105861

Pavón S, Fortuny A, Coll MT, Sastre AM (2019) Improved rare earth elements recovery from fluorescent lamp wastes applying supported liquid membranes to the leaching solutions. Sep Purif Technol 224:332–339. https://doi.org/10.1016/j.seppur.2019.05.015

Martínez J, Rodríguez Varela R, Forsberg K, Rasmuson A (2018) Factors influencing separation selectivity of rare earth elements in flat sheet supported liquid membranes. Chem Eng Sci 191:134–155. https://doi.org/10.1016/j.ces.2018.06.018

Swain B, Tanaka M (2018) Separation of yttrium from europium using a hollow fiber-supported liquid membrane with 2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester as an extractant. Chem Eng Commun 205:1484–1493. https://doi.org/10.1080/00986445.2018.1458025

Hu Y, Lu C, Chen Q et al (2021) Pertraction of Nd(III) and U(VI) through flat sheet supported liquid membrane containing N, N’-dimethyl-N, N’-dioctyl-3-oxadiglcolamide as carrier. Solvent Extr Ion Exch 00:1–21. https://doi.org/10.1080/07366299.2021.1914910

Ramakul P, Mooncluen U, Yanachawakul Y, Leepipatpiboon N (2012) Mass transport modeling and analysis on the mutual separation of lanthanum(III) and cerium(IV) through a hollow fiber supported liquid membrane. J Ind Eng Chem 18:1606–1611. https://doi.org/10.1016/j.jiec.2012.02.020

Lu S, Wang Y, Pei L, Li W (2018) A study on DSLM transporting the rare earth metal la (III) with a carrier of PC-88A. Int J Anal Chem. https://doi.org/10.1155/2018/9427676

Sarada T, Sawyer LC, Ostler MI (1983) Three dimensional structure of celgard® microporous membranes. J Membr Sci 15(1):97–113

Acknowledgements

The authors wish to thank Dr. Paramee Kumkrong, Judy Kung, and Cindy Jiang from Energy, Mining, and Environment Research Centre, National Research Council Canada for the ICP-OES analysis. Financial support of the Office of Energy Research and Development (OERD) of Natural Resources Canada is greatly appreciated.

Funding

Open Access provided by National Research Council Canada.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest. The funders had no role in the design of the study, in the collection, analyses, or interpretation of the data, in the writing of the manuscript, and in the decision to publish the results.

Additional information

The contributing editor for this article was Zhi Sun.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, L., Davis, K., King, A. et al. Efficient Separation of Nd(III) and La(III) Via Supported Liquid Membrane Using EHEHPA (P507) as a Carrier. J. Sustain. Metall. 8, 1215–1224 (2022). https://doi.org/10.1007/s40831-022-00560-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-022-00560-6