Abstract

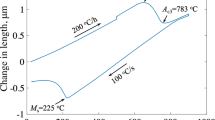

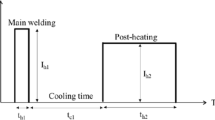

Resistance spot welding (RSW) is an extensively used joining method especially in automotive industry. In this method, Joule heating resulting from electrical current application is employed to melt and join sheet metals by squeezing sheets together with water cooled electrodes. For steels, due to heating and fast cooling during RSW process, martensitic transformation occurs at weld section. A specified holding time after the current application is used in RSW so that joint can be cooled by contact between electrodes and sheets. Therefore, holding time in RSW is a major factor for cooling behavior and hence, martensitic transformation. In this study, effects of holding time on mechanical properties and microstructures of RSW joints were investigated. It was observed that increasing holding time decreased weld nugget size due to evacuation of heat from sheets. On the other hand, mechanical properties, namely tensile-shear strengths and failure energies were increased by increasing holding time from 1 to 20 cycles for 1.2 mm thick S700MC steel sheets. However, holding time of 30 cycles had adverse effects on mechanical properties. These differences were mainly the results of more favorable martensitic transformation when holding time of 20 cycles was employed compared to other cases.

Similar content being viewed by others

Data Availability

Data sets generated during the current study are available from the corresponding author on reasonable request.

References

Nieto J, Guerrero-Mata M, Colas R, Mani A (2006) Experimental investigation on resistance spot welding of galvannealed HSLA steel. Sci Technol Weld Join 11(6):717–722

Aslanlar S, Ogur A, Ozsarac U, Ilhan E (2008) Welding time effect on mechanical properties of automotive sheets in electrical resistance spot welding. Mater Des 29(7):1427–1431

Pouranvari M, Aghajani H, Ghasemi A (2020) Enhanced mechanical properties of martensitic stainless steels resistance spot welds enabled by in situ rapid tempering. Sci Technol Weld Join 25(2):119–126

Soomro IA, Pedapati SR, Awang M (2022) A review of advances in resistance spot welding of automotive sheet steels: emerging methods to improve joint mechanical performance. Intl J Adv Manuf Technol 118(5–6):1335–1366

Dancette S, Massardier-Jourdan V, Fabrègue D, Merlin J, Dupuy T, Bouzekri M (2011) HAZ microstructures and local mechanical properties of high strength steels resistance spot welds. ISIJ Intl 51(1):99–107

Hamidinejad S, Kolahan F, Kokabi A (2012) The modeling and process analysis of resistance spot welding on galvanized steel sheets used in car body manufacturing. Mater Des 34:759–767

Anijdan SM, Sabzi M, Ghobeiti-Hasab M, Roshan-Ghiyas A (2018) Optimization of spot welding process parameters in dissimilar joint of dual phase steel DP600 and AISI 304 stainless steel to achieve the highest level of shear-tensile strength. Mater Sci Eng A 726:120–125

Long H, Hu Y, Jin X, Shao J, Zhu H (2016) Effect of holding time on microstructure and mechanical properties of resistance spot welds between low carbon steel and advanced high strength steel. Comput Mater Sci 117:556–563

Kumar R, Chohan JS, Goyal R, Chauhan P (2020) Impact of process parameters of resistance spot welding on mechanical properties and micro hardness of stainless steel 304 weldments. Intl J Struct Integr 12(3):366–377

Milititsky M, Pakalnins E, Jiang C, Thompson AK (2003) On characteristics of DP600 resistance spot welds. SAE Transac 112:244–251

Jahandideh A, Hamedi M, Mansourzadeh S, Rahi A (2011) An experimental study on effects of post-heating parameters on resistance spot welding of SAPH440 steel. Sci Technol Weld Join 16(8):669–675

Pouranvari M, Marashi S (2010) Factors affecting mechanical properties of resistance spot welds. Mater Sci Technol 26(9):1137–1144

Böhne C, Meschut G, Biegler M, Rethmeier M (2020) Avoidance of liquid metal embrittlement during resistance spot welding by heat input dependent hold time adaption. Sci Technol Weld Join 25(7):617–624

AWS C1.1 M/C1.1—Recommended practices for resistance welding. 2019, American Welding Society

Acknowledgements

The conducted work was under a project funded under the SMART EUREKA CLUSTER on Advanced Manufacturing Program. Moreover, the authors thank the Turkish Research Council for financially supporting the project 9210025.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited submission to Shape Memory and Superelasticity selected from presentations at the 12th European Symposium on Martensitic Transformations (ESOMAT 2022) held September 5–9, 2022 at Hacettepe University, Beytepe Campus, Ankara, Turkey, and has been expanded from the original presentation. The issue was organized by Prof. Dr. Benat Koҫkar, Hacettepe University.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Görtan, M.O., Yüksel, B. & Çağırankaya, F. Control of the Martensitic Transformation During Resistance Spot Welding of High Strength S700MC Steel. Shap. Mem. Superelasticity 9, 485–491 (2023). https://doi.org/10.1007/s40830-023-00461-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-023-00461-x