Abstract

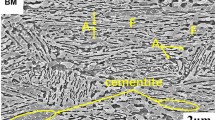

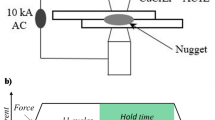

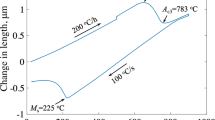

In recent years, application of high-strength steel in automobile bodies has been expanded to improve collision safety and fuel efficiency. However, it has been reported that for high-strength steels with strengths of at least 780 MPa, cross-tension strength (CTS) in resistance spot-weld joints decreases as steel strength increases. Methods of improving joint strength include post-heating. Although many studies have been conducted on post-heating, the temperature and microstructural changes required by post-heating to improve joint strength, such as a decrease in hardness and relaxation of solidification segregation elements, remain unclear. The effect of post-heating on CTS was investigated through resistance spot-weld joints of 1.5-GPa-class hot-stamped steel. We analyzed the temperature at the nugget edge during post-heating by using SORPAS, and conducted a reproducible thermal-cycle test simulating post-heating to determine the temperature range and microstructural changes necessary to improve joint strength. CTS was improved in two regions by varying the current ratio. In the tempering region, CTS varied in a wide range, and the current ratio varied in a narrow range. In the solidification segregation relaxation region, CTS did not vary, and the current ratio varied in a wide range. To improve CTS by tempering with post-heating, all solute carbon in martensite must be segregated or precipitated; the temperature for tempering with post-heating should be between 630 and 720 °C. To improve CTS by solidification segregation relaxation with post-heating, the P-enriched area fraction must be reduced; the temperature range for solidification segregation relaxation with post-heating should be between 860 and 1450 °C.

Similar content being viewed by others

References

Sato A (2005) The problem of the high strength steel and that countermeasure. Journal of the JSTP 46(534):548–551

Clare G (2008) Welding advanced high-strength steel is pushing welding technology. Penton's Weld Mag. 81(3):PP.14–16

Oikawa H, Murayama G, Sakiyama T, Takahashi Y, Ishikawa T (2007) Resistance spot weldability of high strength steel (HSS) sheets for automobile. Nippon Steel Tech Rep 95:39–45

Hirai T, Takahashi Y (1979) Resistance spot welding of high strength, IIW Doc. III-612–79

Beevers A, French EJ (1962) Post weld heat treatment of spot welds in hardenable steels. Brit Weld J pp 523–532

Defourny J, Bragard A (1984) Chemistry of high strength steel sheets for automotive industry and the criteria to define the resistance spot weldability. Revue de la Soudure 1(17):17–24

Saito T (1982) Welding technology 30:34–38

Hamatani H, Watanabe F, Miyazaki Y, Tanaka T, Maki J, Oikawa H, Nose T (2011) Characterization of cross tension strength in resistance spot welding ultrahigh strength steel sheets. Preprints of the National Meeting of JWS 89:44–45

Matsuyama K, Takahashi Y, Hasegawa K (2011) Fundamentals and practices of resistance welding, SANPO (Textbook)

Watanabe F, Furusako S, Hamatani H, Miyazaki Y, Nose T (2012) Fracture mechanical analysis of cross tension test for high-strength steel spot welded joints. Math Model Weld Phenom 10:653–667

Taniguchi K, Ikeda R, Endo S (2012) Development of resistance spot welding with pulsed current pattern for high strength steel sheets. Preprints of the National Meeting of JWS 90:240–241

Ito C, Hiratsuka K (1970) Determination of heat treatment conditions of spot welds in anti-corrosive high tensile steels. J Jpn Weld Soc 39:3

Wakabayashi C, Yasuyama M, Furusako S, Miyazaki Y (2015) Spot-welded joint-strength improvement by acceleration of auto-tempering at HAZ. Preprints of the National Meeting of JWS 96:38–39

Ramachandran DC, Figueredo B, Sherepenko O, Jin W, Park YD, Biro E (2022) A study on improving the mechanical performance by controlling the halo ring in the Q&P 980 steel resistance spot welds. J Manuf Process 75:320–330

Liu XD, Xu YB, Misra RD, Peng F, Wang Y, Du YB (2019) Mechanical properties in double pulse resistance spot welding of Q&P 980 steel. J Mater Process Tech 263:186–197

Eftekharimilani P, van der Aa EM, Hermans MJ, Richardson IM (2017) The microstructural evolution and elemental distribution of a 3rd generation 1 GPa advanced high strength steel during double pulse resistance spot welding. Weld World, pp.691–701

Sherepenko O, Juttner S (2019) Transient softening at the fusion boundary in resistance spot welded ultra-high strengths steel 22MnB5 and its impact on fracture processes. Weld World, pp.151–159

Taniguchi K, Matsuda H, Ikeda R (2016) Heat distribution in welds by short-time high-current post-heating and its improving effect on cross tension strength: development of resistance spot welding with pulsed current pattern for ultrahigh-strength steel sheets. Weld Int 30:817–825

Jahandideh A, Hamedi M (2011) An experimental study on effects of post-heating parameters on resustance spot welding of SAPH440 steel. Sci Technol Weld Joining 16:669–675

Yuanfang W, Kai D, Bingge Z, Yuanheng Z, Guanzhi W, Tao W, Hua P, Yulai G (2020) Highly enhanced cross tensile strength of the resistance spot welded medium manganese steel by optimized post-heating pulse, TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings, pp.1871–1880

Wakabayashi C, Furusako S, Miyazaki Y (2015) Strengthening spot weld joint by autotempering acceleration at heat affected zone. Sci Technol Weld Joining 20:468–472

Wei S, Liu D, Lin L, Guo Y (2014) Similar and dissimilar resistance spot welding of advanced high strength steels: welding and heat treatment procedures, structure and mechanical properties. Sci Technol Weld Joining 19:427–435

Jahandideh A, Hamedi M, Mansourzadeh S, Eisazadeh H, Rahi A (2010) Investigating the effects of post heating parameter on the quality of automotive body joints in resistance spot welding,” 63rd Annual Assembly & International Conference of the International Institute of Welding, pp.733–737

Taniguchi K, Okita Y, Ikeda R (2015) Development of next generation development of next generation improving the weld properties of advanced high strength steel sheets. JFE Tech Rep 20:85–91

Hiroshi M, Koichi T, Rinsei I, Kenji O (2020) Microstructure and its hardness estimation of resistance spot weld of ultra-high strength steel sheets: development of resistance spot welding with pulsed current pattern for ultra-high strength steel sheets. Weld Int 34:166–175

Koichi T, Hiroshi M, Rinsei I (2019) Influence of the pulsed current pattern on cross-tension strength of spot-welded joint with nugget diameter variation. Development of resistance spot welding with a pulsed current pattern for ultra-high-strength steel sheets. Weld Int 33:211–222

Yuanfang W, Kai D, Bingge Z, Yuanheng Z, Guanzhi W, Tao W, Hua P, Yulai G. Effect of the cooling time on the cross tensile strength of the resistance spot welded medium manganese steel, TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings, pp.515–523, 2020.

Maruyama N, Tabata S (2018) Atom prove analysis of carbon distribution in low and medium carbon as-quench martensite, CAMP-ISIJ Vol.31:943

Cracknell A, Petch N (1955) Frictional force on dislocation arrays at the lower yield point in iron. Acta Metall 3:186–189

Takaki S (2019) Work hardening in ferritic steel. Tetsu-to-Hagané 105:10

Paul SG (1976) Diffusion in solids, CORONA PUBLISHING CO., LTD

Furusako S, Miyazaki Y, Hamatani H, Akiniwa Y (2015) Consideration of decision guidelines for welding condition by analytic solution of heat conduction equation. Quarterly J Jpn Weld Soc 33(2):160–170

Oikawa H (1982) Lattice diffusion in iron. Tetsu Hagane 68:10

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Taniguchi, T., Furusako, S. & Kodama, S. Examination of post-heating conditions to improve CTS in resistance spot-weld joints. Weld World 67, 1359–1366 (2023). https://doi.org/10.1007/s40194-023-01477-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-023-01477-8