Abstract

When high-temperature steam is used as a medium to pyrolyze organic-rich shale, water steam not only acts as heat transfer but also participates in the chemical reaction of organic matter pyrolysis, thus affecting the generation law and release characteristics of gas products. In this study, based on a long-distance reaction system of organic-rich shale pyrolysis via steam injection, the effects of steam temperature and reaction distance on gas product composition are analyzed in depth and compared with other pyrolysis processes. The advantages of organic-rich shale pyrolysis via steam injection are then evaluated. The volume concentration of hydrogen in the gas product obtained via the steam injection pyrolysis of organic-rich shale is the highest, which is more than 60%. The hydrogen content increases as the reaction distance is extended; however, the rate of increase changes gradually. Increasing the reaction distance from 800 to 4000 mm increases the hydrogen content from 34.91% to 69.68% and from 63.13% to 78.61% when the steam temperature is 500 °C and 555 °C, respectively. However, the higher the heat injection temperature, the smaller the reaction distance required to form a high concentration hydrogen pyrolysis environment (hydrogen concentration > 60%). When the steam pyrolysis temperature is increased from 500 °C to 555 °C, the reaction distance required to form a high concentration of hydrogen is reduced from 3800 to 800 mm. Compared with the direct retorting process, the volume concentration of hydrogen obtained from high-temperature steam pyrolysis of organic-rich shale is 8.82 and 10.72 times that of the commonly used Fushun and Kivite furnaces, respectively. The pyrolysis of organic-rich shale via steam injection is a pyrolysis process in a hydrogen-rich environment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Organic-rich shale is a type of high-ash mineral that is rich in solid organic matter (kerogen), from which shale oil and gas can be obtained through retorting (Demirbas 2016; Wang et al. 2021a, b; Yang et al. 2023; Su et al. 2022; Guo et al. 2022). Among them, shale oil has a quality similar to petroleum and can be used as a supplementary petroleum source. Shale gas has a high calorific value, which can be used as both gas-fired power generation and chemical synthesis gas.

The organic matter in the organic-rich shale is a polymer compound with a complex structure. During the pyrolysis process, organic matter will break from weak to strong in the order of the bond energy of the chemical bond, thus generating numerous types of free radicals. These free radicals combine to form the primary pyrolysis product, which continuously undergoes secondary reactions to form the final product (Garrison et al. 2014; Nyakuma et al. 2021). A mature ground retorting process is formed during the development of organic-rich shale retorting technology. This process uses a large-scale oxygen-free heating system on the ground to pyrolyze organic-rich shale, which is used to obtain hydrocarbon gas and shale oil. Currently, the operational retorts are the Fushun retort in China, kiviter retort in Estonia, and the Petrosix retort in Brazil (Pan et al. 2012; Al-Ayed and Hajarat 2018; Wang et al. 2019). Several scholars have studied the gas production law of organic-rich shale under direct retorting. Shi et al. (2017) studied the pyrolysis characteristics of organic-rich shale with asphalt as an intermediate product and observed that the main temperature range of hydrocarbon gas generation is 360 °C–440 °C. Furthermore, they observed that hydrogen mainly comes from the dehydrogenation reaction of aliphatic compounds in the aromatization process. Yu et al. (2018) assumed that the secondary reaction of oil and gas formed by organic-rich shale pyrolysis affects the quality of the final product, and a moderate secondary reaction can split heavy components into light ones and hydrocarbon gases. Ru et al. (2012) performed a molecular simulation of kerogen pyrolysis at different temperature ranges. Their results show that the pyrolysis reaction of organic matter is mainly a free radical reaction, and the weak bond for organic matter breaks at low temperatures to form free radicals and small molecule gases. However, the waste discharge from the ground retorting process causes environmental pollution and damages the ecosystem. Presently, several countries around the world are advocating exploiting organic-rich shale using in situ heating technology.

Based on different heat sources, in situ heating methods of organic-rich shale can be divided into three categories: conduction, convection, combustion, and radiation heating (Kang et al. 2020; Wang et al. 2020). Because organic-rich shale is a dense low-permeability rock with extremely poor thermal conductivity, the technology of in situ mining organic-rich shale using convection heating is feasible. This in situ convection heating technology of organic-rich shale only requires that high-temperature fluid be injected into an orebody through a heat injection well. The products formed by the decomposition of organic matter flow through the internal pores and fractures of the orebody, and the oil and gas are then discharged through the production well. Sun et al. (2014) and Bai et al. (2015) conducted an indoor research test on organic-rich shale pyrolysis using a local chemical method and used nitrogen as the heat carrier fluid. The gas product of organic-rich shale pyrolysis mainly contains C1–C4 hydrocarbon gas. Fang et al. (2012) studied the pressure pyrolysis of organic-rich shale in the presence of water using an autoclave and observed that the yield of gas products increased as the temperature increased from 270 °C to 370 °C. Nasyrova et al. (2020) studied the effect of near-critical water on the yield of pyrolysis products of organic-rich shale and discovered that the yield of shale gas is high. Lu et al. (2022) conducted the pyrolysis test of organic-rich shale under the action of supercritical water and found that the yield of pyrolysis gas increased as the temperature increased, and the content of hydrocarbon gas in the pyrolysis gas was high. Previous studies have shown that the gas components and yields formed by organic matter pyrolysis are different if an organic-rich shale is pyrolyzed using different types of heat carrier fluids. The in situ convection heating organic-rich shale technology (Fig. 1) of the Taiyuan University of Technology uses high-temperature steam as the medium to pyrolyze organic-rich shale. Steam not only acts as a heat transfer and fluid transport but also participates in the chemical reaction of organic matter pyrolysis, which affects the generation law of gas products. The team conducted a small-scale indoor test of organic-rich shale pyrolysis using steam injection and found that the hydrogen content in the pyrolysis gas was high. However, the scale of the pyrolysis reactor was small, and the effect of steam temperature on the composition of the pyrolysis gas was unclear. Moreover, during the implementation of the in-situ mining process for organic-rich shale, the spacing between heat injection and production wells is large and can be up to several tens of meters. High-temperature steam is injected from the heat injection well. This reacts violently with organic matter and is then extracted from the production well. The small reactor dimensions are so far from the engineering scale that the conclusions obtained cannot effectively guide the on-site process.

The steam temperature and the interaction distance between steam and organic matter will inevitably have a significant impact on the composition of pyrolysis gas. In the field process, the shale organic matter near the heat injection wells undergoes cracking reactions at high temperatures, and steam carries the cracking products towards the production wells while reacting with the cracking products in secondary reactions. Heat injection temperature is different, the intensity of the secondary reaction between the cracking products and steam is bound to be different. This is reflected in the engineering as the difference in the distance of steam migration within the orebody from the starting heat injection position to the end of the chemical reaction, which is crucial to the reasonable adjustment of heat injection temperature and the regulation of heat injection production gas wells. Based on this, the study defines the distance from the steam injection position to the gas product discharge position as the reaction distance (Fig. 2). Using the long-distance reaction system of organic-rich shale pyrolysis via steam injection, the gas collected under different reaction distances is tested to study the influence of steam temperature and reaction distance on the gas components of organic-rich shale pyrolysis. Simultaneously, the advantages of organic-rich shale pyrolysis by steam injection are systematically evaluated by comparing it with the gas directly obtained from retorting.

2 Methods

2.1 Test device

The long-distance reaction system for organic-rich shale pyrolysis using steam injection is mainly composed of a high-temperature and high-pressure long-distance reaction reactor, steam generator, condenser, and other auxiliary devices (Fig. 3a). One end of the reactor is connected to the steam generator through the superheating pipe, and the other end is connected to a large condenser, which comprises the main channel for steam pyrolysis and product discharge. The reactor (Fig. 3b) has a length and an inner diameter of 4000 and 101 mm, respectively. The upper part and side of the reactor are drilled (Fig. 3c). The spacing of the holes was 600 mm. The upper holes are welded using thermocouples. The temperature is monitored in real-time through the temperature acquisition system (Fig. 3d). The side holes are connected using small condensers (Fig. 3e) to collect the gas from the branch. Seven gas product collection points and temperature measurement points (1 #–7 #) are arranged (Fig. 4).

2.2 Test processes

After the entire system is connected, the surface of the reactor is wrapped with multi-layer ceramic fiber insulation layers, and each insulation layer is firmly pasted with aluminum foil tape to minimize heat loss caused by heat conduction and radiation. The specific test steps are as follows:

-

(1)

The crushed organic-rich shale block is loaded into a long-distance reactor, which is connected to the entire test system. The steam injection valve of the reactor should be opened to conduct the organic-rich shale pyrolysis test when the steam generator produces high-temperature steam.

-

(2)

Based on the temperature at the inlet end of the reactor, different temperature points should be set. The temperature should be kept constant when it reaches a specific point. The valves at the side holes in different positions of the reactor are opened in turn, and the collection of gases at different positions of the reactor is carried out at the same time, i.e., the collection of gases at different reaction distances is carried out. The temperature is then raised to the next temperature point, and the collection of gas from different locations in the reactor at the next temperature point is carried out until all test temperatures are completed.

-

(3)

During the test, the pyrolysis of organic-rich shale is more intense when the temperature at the inlet end of the reactor reaches 450 °C. However, it is difficult to collect gas at each measuring point. When the temperature of the inlet end reaches 500 °C, the gas cannot be collected at the 1 # measuring point, but the gas at other measuring points can be collected. Throughout the testing process, not only should gas at different reaction distance be collected, but also changes in gas production at different reaction distance should be observed. When the temperature at the inlet end of the reactor reached 555 °C, the gas production was significantly higher than that at other temperature points. Thus, the pyrolysis test was continued without changing the temperature. Table 1 summarizes the shale gas collection at different temperatures in this experiment.

(4) Agilent 7820A gas chromatograph (Fig. 5a) was used for the chromatographic analysis of the pyrolysis gas (Fig. 5b), and the carrier gas was argon. In Fig. 5c, each peak represents a gas, the ordinate is the gas abundance, the width of the peak is the residence time of a certain gas, and the percentage of each peak area to all peak areas is the gas content. The quantitative relationship between the gas composition and the reaction distance at different heat injection temperatures can be obtained (Fig. 5d). Figure 5 shows the entire gas composition analysis process.

3 Effect of temperature and reaction distance coupling on gas composition

3.1 Composition of pyrolysis gas at different temperatures and reaction distances

In some shale mining technologies, blasting or directional fracturing technology is used to reform the orebody before injecting hot fluid, which makes a large number of crisscross fracture grid structures in its interior.The representative technology is CRUSH blasting technology. The technology uses the blasting broken stone method to generate three-dimensional volume fractures in the shale (Oja et al. 2020). At the same time, limited to the experimental conditions, the shale blocks inside the reactor are randomly and tightly filled.

Kerogen is a macromolecular compound that contains numerous long-chain aliphatic, aromatic, and heteroatom groups. In terms of spatial structure, kerogen molecules use C as the skeleton, and the various groups link with each other to form a multi-layer network structure (Xiao et al. 2021; Zhang et al. 2021; Wang et al. 2021a, b). Moreover, organic-rich shale contains numerous metal ions, which have catalytic effects in the pyrolysis reaction of organic-rich shale. Therefore, the laws that govern the breaking and polymerizing of kerogen molecules to form oil and gas products are relatively complex.

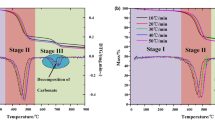

Figure 6 is a chromatogram of gas products at different temperatures and reaction distances. The left figure is the spectrum of hydrocarbon gas obtained using an FID detector, and the right is the spectrum of nonhydrocarbon gas obtained using a TCD detector. It is observed that regardless of the reaction distance, methane has the highest abundance of hydrocarbon gas, and its content is higher than those of other hydrocarbon gases. However, nonhydrocarbon gas has the highest abundance of hydrogen gas. At 540 °C, the proportion of C2–C4 hydrocarbons in hydrocarbon gas is extremely small. Furthermore, when the heat injection temperature is 555 °C, the abundance of hydrogen in non-hydrocarbon gases is significantly higher than those of other gases; thus, hydrogen occupies a dominant position in nonhydrocarbon gases. When the steam temperature is 555 °C and the pyrolysis time is 1 h, the abundance of methane in hydrocarbon gas is still significantly higher than those of other hydrocarbon gases. As the reaction distance in non-hydrocarbon gases is extended, the chromatographic peaks of gases other than hydrogen gradually disappear, and the proportion of hydrogen gradually increases.

3.2 Relationship between pyrolysis gas composition and reaction distance

Figure 7a shows the relationship between the content of various gases and the reaction distance when the steam temperature is 500 °C. Here the hydrogen content in the gas products obtained at each measuring point is the highest, followed by carbon dioxide, and then methane; the proportion of gases from other components is relatively small. The hydrogen content increased from 34.91% to 47.97% as the reaction distance increased from 800 to 1400 mm. Furthermore, the hydrogen content remained almost unchanged when the reaction distance increased from 1400 to 2600 mm. The highest hydrogen content in the entire reaction distance was 69.68%. The methane content increased slowly from 6.27% to 10.52% as the reaction distance increased.

Methane is mainly formed through the aliphatic side chains containing methoxy functional groups, cleavage of the β-methyl and aromatic ring side chains on the short-chain alkyl side chains, polycondensation of aromatic structures, and hydrogenation of methyl radicals (Given 1984; Nyoni et al. 2020). The source of hydrogen can be divided into two parts: (1) the fracture of kerogen macromolecular structure (the fracture of the C–H bond) and polycondensation reaction, such as the cyclization of aliphatic hydrocarbons to cycloalkanes and the process of cycloalkanes to aromatic hydrocarbons, and the dehydrogenation of aromatic compounds; (2) The reaction of high-temperature steam and other substances.

Steam gasification reaction of hydrocarbon gas \(2{m\text{ H}}_{2} {\text{O}} + {\text{C}}_m {\text{H}}_n \mathop{\longrightarrow}\limits^{{{\text{High}}\;{\text{temperature}},\;{\text{catalysis}}}}\left( {2\;{\text{}}m + n{\text{}}/2} \right){\text{H}}_{2} + m{\text{CO}}_{2}\).

Iron ions are often used as catalysts in the reaction between steam and residual carbon. The organic-rich shale contains more pyrites, and the iron ions separated from them can be used as the catalyst for the reaction, thus intensifying the process of hydrogen generation from the reaction between residual carbon and steam. However, in the water–gas shift reaction, carbon monoxide (CO) is produced from the reaction of steam and residual carbon; simultaneously, R–C = O in organic matter will start to break at 400 °C to form CO. In the steam gasification reaction, oil shale contains a significant amount of rare metals that serve as catalysts for this reaction. Coupled with the high-temperature conditions in the experimental environment, this leads to the vigorous reaction of steam with hydrocarbon gases, continuously generating hydrogen gas.

Figure 7b shows the relationship between the content of various gases and the reaction distance when the steam temperature is 525 °C. The proportion of hydrogen in the gas collected at each measuring point was the largest, followed by carbon dioxide and methane. As the reaction distance is extended, the hydrogen content gradually increases from 44.05% to 73.33%, and the proportion of methane slowly increases from 5.98% to 11.25%. C1–C4 hydrocarbon gas is produced from the fracture of chain hydrocarbon covalent bonds in kerogen macromolecules and shale oil molecules formed (long chain hydrocarbon will be broken into shorter chain hydrocarbons and hydrocarbon gas). The content of methane and ethane in hydrocarbon gas is relatively high, whereas the content of other alkanes and olefin gas in hydrocarbon gas is extremely small. This indicates that a high-temperature steam atmosphere will relatively inhibit the cracking reaction of shale oil, thus reducing the secondary reaction of oil and gas and improving the recovery rate of shale oil. The content of CO in the collected gas is extremely low, with the highest concentration being only 0.26%. This indicates that the water–gas shift reaction is extremely violent and a large amount of CO is converted into hydrogen. Moreover, the reaction is irreversible under the continuous injection of high-temperature steam.

Hydrogen remains the main gas when the injection temperature is 540 °C, and its content increases as the reaction distance increases (Fig. 7c). The change in hydrogen content can be divided into two stages: (1) the rapid increase stage (reaction distance ranges from 800 to 2000 mm), in which the hydrogen content increases from 49.85% to 65.00%; (2) The stable change stage (reaction distance from 2000 to 3800 mm), where the hydrogen content is almost stable and the methane content is increased only from 6.16% to 8.88%, with a small change in the range.

Based on the analysis of the reasons for the stable hydrogen content at the reaction distance of 2000–3800 mm, it is concluded that, while the covalent bonds of the organic-rich shale macromolecular structure will continue to break at high temperatures to form a small molecule structure, the hydrogen content within the reaction distance is extremely high. Under the condition of rapid steam purging, hydrogen will continue to permeate and diffuse into the rock mass to fully participate in the reaction of free radicals, which play an obvious role in inhibiting the polycondensation reaction between free radicals, thus reducing the formation of residual carbon in organic-rich shale. However, high-temperature steam will promote the conversion of free radicals formed by the cracking of kerogen macromolecules into shale oil, reduce the activity of the coking reaction of shale oil, and inhibits the formation of semi-coke. This stabilizes the reaction between steam and residual carbon and the water–gas shift reaction, thus preventing the formation of a large amount of hydrogen.

As the reaction temperature was increased to 555 °C, the hydrogen content first increased and then stabilized, methane content slowly increased, and CO content gradually decreased (Fig. 7d). The hydrogen content increased from 63.13% to 77.53% as the reaction distance increased from 800 to 2600 mm. The hydrogen content changed slightly as the reaction distance increased from 2600 to 4000 mm. Furthermore, the hydrogen content was the highest at 78.61% when the reaction distance was 4000 mm. At this temperature, the produced fracture reaction of kerogen macromolecules and those of long-chain hydrocarbons are obvious. The formation of short-chain free radical fragments is accelerated, and numerous light small molecule gases are produced. The higher the temperature, the stronger the activity of the steam molecules. This intensifies the chemical reaction between light small molecule gases and high-temperature steam, thereby forming a high concentration of hydrogen.

When the steam temperature was controlled at 555 °C and the pyrolysis time was 1 h, the hydrogen content first increased and then gradually stabilized as the reaction distance increased (Fig. 7e). When the reaction distance increased from 1400 to 3200 mm, the hydrogen content increased linearly from 62.17% to 79.31%. Furthermore, when the reaction distance increased from 3200 to 4000 mm, the hydrogen content fluctuated slightly, and the change was relatively stable. High-temperature steam promotes the cracking reaction of macromolecules while inhibiting the cyclization of chain hydrocarbons and the conversion of cycloalkanes to aromatic hydrocarbons. Moreover, the activity of water molecules is significantly improved in an environment where high-temperature steam is continuously injected for a long time, which indicates that the cracking reaction of macromolecules is more intense, the formation of residual carbon is more difficult, and the steam gasification reaction of hydrocarbon gas is enhanced to generate more hydrogen.

3.3 Variation of hydrogen content at different reaction distances

Figure 8 shows the relationship between the hydrogen content in the pyrolysis gas and the reaction distance. At different heat injection temperatures, there will always be a stage where the hydrogen content increases slightly as the reaction distance is extended; this is called the stable stage.

When the injection temperature is 500 °C, 525 °C, 540 °C, and 555 °C, the reaction distance where the hydrogen content is stable is 1400–2600 mm, 2600–3200 mm, 2000–3800 mm, and 2600–3800 mm respectively. Furthermore, when the temperature is 555 °C and the pyrolysis time is 1 h, the reaction distance at which the hydrogen content is stable is 3200–4000 mm. The stable stage of hydrogen content progresses as the pyrolysis temperature increases. From the above analysis, the hydrogen in the gas is obtained from the breaking of the C–H bond within the organic macromolecules, polycondensation reaction of free radicals, and the reaction of high-temperature steam with residual carbon, CO, and hydrocarbon gas. The residual carbon is a product of the free radical polycondensation reaction, and the CO and hydrocarbon gases are obtained from the breaking of different types of macromolecule covalent bonds. The activity of water molecules, number, and the type of covalent bond breakage differ at different heat injection temperatures. At a certain reaction distance, the breaking reaction of organic macromolecules and the chemical reaction of steam and other substances will reach a certain saturation state, which is the phase stability stage. The breaking of covalent bonds in macromolecules intensifies as the temperature increases, and the reaction rate of high-temperature steam and other substances also increases. Therefore, the reaction time required for the hydrogen content to reach the relatively stable stage is prolonged, thereby showing that the hydrogen content progresses in the stable stage.

To obtain the change characteristics of hydrogen content in the long-distance reactor under different heat injection temperatures, the hydrogen content in the pyrolysis gas at different measuring points was statistically analyzed and plotted using the Origin software, and the distribution of hydrogen concentration in the reactor was obtained (Fig. 9). The reaction distance refers indeed to the axial distance of the reactor. The outline of the hydrogen concentration distribution cloud map is the projection surface of the reactor. On the projection surface, all the side holes correspond to the vertical coordinate of 50 mm, while the horizontal coordinates correspond to different reaction distances. Currently, the hydrogen content in industrial exhaust gas is between about 30% and 35%, with industrial hydrogen production not exceeded 60%. Therefore, taking hydrogen content of 35% and 60% as the limit, the hydrogen concentration is divided into three levels: low (< 35%), medium (35%–60%), and high concentration (> 60%). The hydrogen in most areas of the reactor is within the middle concentration range when the steam temperature is lower than 525 °C. The hydrogen concentration in the entire reactor is extremely high when the temperature reaches 555 °C, and the pyrolysis atmosphere of organic-rich shale is rich in hydrogen.

Figure 10 shows the quantitative analysis of the proportion of hydrogen at different concentrations. When the heat injection temperature is 500 °C, the proportion of low concentration hydrogen in the reactor is extremely small. Furthermore, when the temperature increases from 525 °C to 540 °C, the proportion of high concentration hydrogen rapidly increases from 23.6% to 57.12%, and the hydrogen concentration in the reactor changes from medium to high concentration. In the MATLAB software, the hydrogen concentration is used as the dependent variable, the reaction distance and the pyrolysis temperature are used as the independent variables, and the multiple regression analysis is performed. The influence of the coupling effect of the reaction distance (x) and the pyrolysis temperature (y) on the hydrogen concentration (Z) can be expressed using a binary quadratic mathematical model, which includes an interaction term: Z = 1271 + 0.05x − 5.26y − 8.05e−5xy − 5.25e−5x2 + 0.01y2 (Correlation coefficient R2 = 0.92). The relationship between the hydrogen concentration and the two factors (reaction distance and pyrolysis temperature) can be described using the quadratic effect surface (Fig. 11).

Overall, both the increase in water vapor temperature and the increase in reaction distance contributes to the increase in hydrogen content in the pyrolysis gas. High temperatures increase the activity of water molecules. The pyrolysis gas component has a high content of hydrocarbon gases except hydrogen, and the higher the temperature, the lower the energy required for the activation of hydrocarbon gases under the action of high-energy water molecules, and the easier it is for hydrocarbon gases to be converted to hydrogen. At the same time, the reaction between high-energy water vapor and the residual carbon formed by shale pyrolysis at high temperatures becomes more and more intense; the combined effect of these two aspects contributes to the increase of hydrogen concentration in pyrolysis gas at high temperatures. When the injection temperature is constant, the hydrogen content increases as the reaction distance increases, but the increase rate changes gradually. The size of the spacing between heat injection and extraction wells affects the composition and quality of the shale pyrolysis products when applied in a field process of in-situ mining organic-rich shale by steam injection.

3.4 Comparative analysis of pyrolysis gas components of organic-rich shale under different pyrolysis modes

The main constituent elements of kerogen in organic-rich shale are mainly C and H, which are followed by O, N, and S. Therefore, the gas formed by organic-rich shale pyrolysis is hydrocarbon gas, hydrogen, CO, and carbon dioxide. The components of pyrolysis gas will be different when organic-rich shale is pyrolyzed using different heating methods.

Lai et al. (2015) performed a retort test on organic-rich shale in an internal component fixed-bed reactor and conducted gas chromatography analysis on the collected pyrolyzed gas. Their results showed that hydrogen had the highest content of pyrolyzed gas at 45.51%, followed by carbon dioxide at 22.62%, and methane at 16.17%. Wang et al. (2015) used the FTIR-MS technology to analyze the change of gas components with temperature during organic-rich shale pyrolysis and believed that when the temperature of pyrolysis is high, the hydrogen content will increase because of the decomposition of hydrogen-rich matrix and aromatic compounds. However, the overall output remains low. The content of carbon monoxide is also low, and the cause of this is complex because of the fracture of the ether bond and heteroepoxy.

Successfully operated organic-rich shale retort furnaces in the world include the Fushun, Kevit, Glott (in Estonia), and Petrosix (in Brazil) furnaces.

Among them, the content of methane in the gas obtained from the pyrolysis of the Xinjiang organic-rich shale using the Fushun furnace is low (13.53%), while the content of other hydrocarbon gases is high because the gas component contains gaseous light oil, which is undiluted by the circulating retort gas. Among the non-hydrocarbon gases, the carbon dioxide content was high (18.31%) and the hydrogen content was low (only 7.92%). Overall, the calorific value of the retorted gas was relatively low. The gas obtained from the pyrolysis of organic-rich shale in the Kivite furnace has a large volume with a low calorific value, and its hydrogen content (6.5%) is lower than that used in the Fushun furnace. However, the hydrogen content in the retort gas obtained via pyrolysis of organic-rich shale in the Glott furnace can reach 17.9%, and the gas calorific value is relatively high. The volume of the retort gas formed via pyrolysis of organic-rich shale in the Petrosix furnace is small, but it has a high calorific value, and the hydrogen content can reach 25.9%.

During the pyrolysis of organic-rich shale in the internal component fixed-bed reactor, the heating temperature reaches 500 °C, and the pyrolyzed products move from the outside to the center of the furnace during the migration process, thereby passing through the particle bed with a long reaction distance. The height of the Fushun furnace is more than 10 m, and the pyrolyzed products of the organic-rich shale rise from the bottom to the top of the furnace for discharge. The reaction distance was long. When organic-rich shale is pyrolyzed in other furnaces, the reaction distance from the formation of pyrolytic products to the discharge is long, and the heating temperature is more than 500 °C. To further analyze the difference between the gas products obtained from the pyrolysis of organic-rich shale via high-temperature steam and the pyrolysis gas obtained from the pyrolysis of organic-rich shale using direct retorting, the pyrolysis gas obtained when the steam pyrolysis temperature is 500 °C, and a reaction distance of 4000 mm is selected for comparison. Table 2 shows the main component content of the pyrolysis gas of organic-rich shale under different heating methods.

Table 2 shows that the hydrogen content in the gas obtained via pyrolysis of organic-rich shale under direct retorting is between 6.5% and 31.2%, and the hydrogen content in the gas obtained via pyrolysis of organic-rich shale with high-temperature steam is 2.23−10.72 times of that under direct retorting. The total content of CO and hydrocarbon gas in the gas obtained via pyrolysis of organic-rich shale using high-temperature steam is 27.5%, whereas in the gas from pyrolysis of organic-rich shale in the Fushun furnace is 70.2%, which shows the accuracy of the water–gas shift reaction and steam gasification reaction of hydrocarbon gas. When high-temperature steam is used as a heat carrier fluid to pyrolyze organic-rich shale, the content of hydrogen in the pyrolysis gas is significantly increased and the content of CO is significantly reduced. This pyrolyzes the organic-rich shale in a hydrogen-rich environment, which is also an advantage of organic-rich shale pyrolysis via steam injection.

4 Conclusions

In the process of organic-rich shale pyrolysis and gas production via steam injection, the fracture of kerogen and the combination of free radicals are complex. This study focuses on the influence of heat injection temperature and reaction distance on the gas products of organic-rich shale pyrolysis. The main conclusions are as follows:

-

(1)

The volume concentration of CO in the gas product of organic-rich shale pyrolysis via steam injection is the lowest, which is below 0.28%, and the volume concentration of hydrogen is the highest. When the hydrogen concentration in the gas product reaches 60%, the reaction distances required for the steam temperatures of 500 °C, 525 °C, 540 °C, and 555 °C are 3800, 2600, 2000, and 800 mm respectively. Therefore, the higher the heat injection temperature, the smaller the reaction distance required to form a pyrolysis environment with a high concentration of hydrogen.

-

(2)

No matter how high the pyrolysis temperature is, the hydrogen content in the pyrolysis gas increases as the reaction distance is extended, but the rate of increase changes gradually. Increasing the reaction distance from 800 to 4000 mm increases the hydrogen content from 34.91% to 69.68% when the steam temperature is 500 °C, and from 63.13% to 78.61% when the steam temperature is 555 °C.

-

(3)

Under the same conditions, the volume concentration of hydrogen obtained from organic-rich shale pyrolysis via steam injection is 8.82 and 10.72 times that of the Fushun and Kivite furnaces, which are commonly used at home and abroad. The CO content is only 5% and 7% of that in the Fushun and Kivite furnaces, respectively.

-

(4)

The organic-rich shale pyrolysis via steam injection is in a hydrogen-rich environment, and the pyrolyzed products will migrate to a hydrogen-rich high-temperature environment, thus continuing the pyrolysis reaction of hydrogenation. Therefore, the gas quality obtained from organic-rich shale pyrolysis via steam injection is significantly better than that of other pyrolysis processes, which is also an advantage of organic-rich shale pyrolysis via steam injection.

This paper focuses on the effects of steam temperature and reaction distance on pyrolysis gas components, based on the field actuality of in situ convection heating organic-rich shale technology. During the test process, the steam pressure is kept at a low level, and the shallow buried orebody is subjected to less original rock stress. Through reservoir transformation technology and pyrolysis of high-temperature steam, large-scale pore and fracture structures can be formed inside the orebody, which can provide a good channel for the transportation of steam and the drainage of gas products. The effect of increasing steam pressure on reservoir modification is less effective and also increases the cost of heat injection, so the effect of steam pressure on gas components is not considered in the study.

References

Al-Ayed OS, Hajarat RA (2018) Shale oil: Its present role in the world energy mix. Global J Energy Technol Res Updates 5:11–18

Bai F, Sun Y, Liu Y et al (2015) Thermal and kinetic characteristics of pyrolysis and combustion of three oil shales. Energy Convers Manage 97:374–381

Demirbas A (2016) Conversion of oil shale to liquid hydrocarbons. Energy Sources Part a Recovery Util Environ Effects 38(18):2698–2703

Fang C, Li S, Ma G et al (2012) Reaction mechanism and kinetics of pressurized pyrolysis of Chinese oil shale in the presence of water. Pet Sci 9:532–534

Garrison TF, Kessler MR, Larock RC (2014) Effects of unsaturation and different ring-opening methods on the properties of vegetable oil-based polyurethane coatings. Polymer 55(4):1004–1011

Given PH (1984) An essay on the organic geochemistry of coal. Academic Press, In Coal science

Guo W, Zhang X, Deng S et al (2022) Enhanced pyrolysis of Huadian oil shale at high temperature in the presence of water and air atmosphere. J Petrol Sci Eng 215:110623

Kang Z, Zhao Y, Yang D (2020) Review of oil shale in-situ conversion technology. Appl Energy 269:115121

Lai D, Chen Z, Shi Y et al (2015) Pyrolysis of oil shale by solid heat carrier in an innovative moving bed with internals. Fuel 159:943–951

Lu Y, Wang Z, Kang Z et al (2022) Comparative study on the pyrolysis behavior and pyrolysate characteristics of Fushun oil shale during anhydrous pyrolysis and sub/supercritical water pyrolysis. RSC Adv 12(26):16329–16341

Nasyrova ZR, Kayukova GP, Vakhin AV et al (2020) Heavy oil hydrocarbons and kerogen destruction of carbonate–siliceous domanic shale rock in sub-and supercritical water. Processes 8(7):800

Nyakuma BB, Jauro A, Akinyemi SA et al (2021) Physicochemical, mineralogy, and thermo-kinetic characterisation of newly discovered Nigerian coals under pyrolysis and combustion conditions. Int J Coal Sci Technol 8:697–716

Nyoni B, Duma S, Bolo L et al (2020) Co-pyrolysis of South African bituminous coal and scenedesmus microalgae: kinetics and synergistic effects study. Int J Coal Sci Technol 7:807–815

Oja V, Suuberg EM (2020) Oil shale processing, chemistry, and technology. Fossil Energy. Springer New York, New York, NY, pp 47–83

Pan Y, Zhang XM, Liu SH et al (2012) A review on technologies for oil shale surface retort. J Chem Soc Pak 34(6):1331–1338

Ru X, Cheng Z, Song L et al (2012) Experimental and computational studies on the average molecular structure of Chinese Huadian oil shale kerogen. J Mol Struct 1030:10–18

Shi J, Ma Y, Li S et al (2017) Characteristics of Estonian oil shale kerogen and its pyrolysates with thermal bitumen as a pyrolytic intermediate. Energy Fuels 31(5):4808–4816

Su Y, Qinghao S, Wendong W, Xincheng G, Jilong X, Guanqun L, Xiugang P, Wenzhong H, Zhannan S (2022) Spontaneous imbibition characteristics of shale oil reservoir under the influence of osmosis. Int J Coal Sci Technol 9(1):69. https://doi.org/10.1007/s40789-022-00546-5

Sun Y, Bai F, Liu B et al (2014) Characterization of the oil shale products derived via topochemical reaction method. Fuel 115:338–346

Wang Q, Xu X, Chi M et al (2015) FTIR study on composition of oil shale kerogen and its pyrolysis oil generation characteristics. J Fuel Chem Technol 43(10):1158–1166

Wang Q, Hou Y, Wu W et al (2019) A deep insight into the structural characteristics of Yilan oil shale kerogen through selective oxidation. Carbon Resour Conver 2(3):182–190

Wang L, Yang D, Zhao Y et al (2020) Evolution of pore characteristics in oil shale during pyrolysis under convection and conduction heating modes. Oil Shale 37(3):224–241

Wang L, Yang D, Kang Z (2021a) Evolution of permeability and mesostructure of oil shale exposed to high-temperature water vapor. Fuel 290:119786

Wang S, Yao X, Feng Q et al (2021b) Molecular insights into carbon dioxide enhanced multi-component shale gas recovery and its sequestration in realistic kerogen. Chem Eng J 425:130292

Xiao Q, Liu B, Ma X et al (2021) An experimental investigation on the ignition sensitivity and flame propagation behavior of mixed oil shale–coal dust. Combust Sci Technol 193(8):1359–1377

Yang Y, Longxin L, Xia W, Nan Q, Ruihan Z, Yulong Z, Ye T (2023) Simulation study of hydrogen sulfide removal in underground gas storage converted from the multilayered sour gas field. Int J Coal Sci Technol 10(1):71. https://doi.org/10.1007/s40789-023-00631-3

Yu X, Luo Z, Li H et al (2018) Effect of vibration on the separation efficiency of oil shale in a compound dry separator. Fuel 214:242–253

Zhang Z, Chai J, Zhang H et al (2021) Structural model of Longkou oil shale kerogen and the evolution process under steam pyrolysis based on ReaxFF molecular dynamics simulation. Energy Sour Part a Recovery Utilization Environ Effects 43(2):252–265

Acknowledgements

This work was funded by Basic research program of Shanxi Province (20210302124136 and 20210302123177), National Key R&D Program of China (2019YFA0705501) , Key R & D and promotion projects in Henan Province (212102310010) and National Natural Science Foundation of China (52104144, U23B2088). We thank Shiyanjia Lab (www.shiyanjia.com) for their linguistic assistance during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Lei Wang: Conceptualization, Writing - Review & Editing. Rui Zhang: Data Curation, Formal analysis. Guoying Wang: Supervision, Validation. Jing Zhao: Investigation. Dong Yang: Visualization, Funding acquisition. Zhiqin Kang: Software. Yangsheng Zhao: Methodology.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, L., Zhang, R., Wang, G. et al. Effect of long reaction distance on gas composition from organic-rich shale pyrolysis under high-temperature steam environment. Int J Coal Sci Technol 11, 34 (2024). https://doi.org/10.1007/s40789-024-00689-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-024-00689-7