Abstract

A simulation study was carried out to investigate the temporal evolution of H2S in the Huangcaoxia underground gas storage (UGS), which is converted from a depleted sulfur-containing gas field. Based on the rock and fluid properties of the Huangcaoxia gas field, a multilayered model was built. The upper layer Jia-2 contains a high concentration of H2S (27.2 g/m3), and the lower layer Jia-1 contains a low concentration of H2S (14.0 mg/m3). There is also a low-permeability interlayer between Jia-1 and Jia-2. The multi-component fluid characterizations for Jia-1 and Jia-2 were implemented separately using the Peng-Robinson equation of state in order to perform the compositional simulation. The H2S concentration gradually increased in a single cycle and peaked at the end of the production season. The peak H2S concentration in each cycle showed a decreasing trend when the recovery factor (RF) of the gas field was lower than 70%. When the RF was above 70%, the peak H2S concentration increased first and then decreased. A higher reservoir RF, a higher maximum working pressure, and a higher working gas ratio will lead to a higher H2S removal efficiency. Similar to developing multi-layered petroleum fields, the operation of multilayered gas storage can also be divided into multi-layer commingled operation and independent operation for different layers. When the two layers are combined to build the storage, the sweet gas produced from Jia-1 can spontaneously mix with the sour gas produced from Jia-2 within the wellbore, which can significantly reduce the overall H2S concentration in the wellstream. When the working gas volume is set constant, the allocation ratio between the two layers has little effect on the H2S removal. After nine cycles, the produced gas’s H2S concentration can be lowered to 20 mg/m3. Our study recommends combining the Jia-2 and Jia-1 layers to build the Huangcaoxia underground gas storage. This plan can quickly reduce the H2S concentration of the produced gas to 20 mg/m3, thus meeting the gas export standards as well as the HSE (Health, Safety, and Environment) requirements in the field. This study helps the engineers understand the H2S removal for sulfur-containing UGS as well as provides technical guidelines for converting other multilayered sour gas fields into underground storage sites.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Globally, depleted petroleum reservoirs are the most commonly selected candidates for underground gas storage (UGS) construction (Ma et al. 2018; Ma 2021; Azin and Izadpanahi 2022). The Sichuan Basin is China’s largest gas-producing province, and three (Huangcaoxia, Moujiaping, and Laowengchang) of its four gas storage facilities are planned to be converted from H2S-containing gas fields due to the extensive distribution of sour gas reservoirs in the Sichuan Basin. Therefore, it is vital to understand and optimize the H2S removal for operating UGS in the Sichuan Basin as well as other H2S-containing gas storage in the world. Conventional underground gas storages are mostly converted from sulfur-free gas reservoirs, so there is limited experience regarding the construction of H2S-containing gas storage. At present, China has built H2S-containing gas storages such as Yong-22 and Shan-224 (Lin et al. 2016; Lyu et al. 2017). Among them, the H2S concentration of the Yong-22 reservoir is 0.57–1.3 g/m3, and the H2S concentration of the Shan-224 reservoir is 0.554 g/m3. At present, the Huangcaoxia UGS has the highest initial H2S concentration among all UGS facilities in China. At the end of depletion, the H2S concentration of some wells is as high as 29.60 g/m3, which almost reached the lower limit of 30 g/m3 of high H2S-containing gas reservoirs under the China Petroleum Industry Standard. The produced gas from Huangcaoxia contains a significant amount of H2S, which is a kind of highly toxic and corrosive substance and may lead to HSE (API RP1171 or GB17820–2018 standard) accidents if not properly managed. Meanwhile, Huangcaoxia is a multilayered gas field, which is the first of its kind in China. Its Jia-1 layer only contains a minor amount of H2S with an average concentration of 0.0136 g/m3, while its Jia-2 layer contains a significant amount of H2S with an average concentration of 27.2 g/m3. Therefore, it is necessary to understand the evolution of H2S concentration during the operation of Huangcaoxia gas storage, as well as critical to managing the H2S content in the withdrawn gas to avoid the HSE risks in the field, especially for such a multi-layered H2S-containing gas field.

Most of the present studies on the multi-cycle operation of gas storage in the existing literature are based on sweet gas reservoirs, which only contain trace amounts of hydrogen sulfide. There are relatively fewer studies on the changes in hydrogen sulfide during the operation of H2S-containing gas storage (Zhang et al. 2020, 2022; Li et al. 2021, 2022; Mao 2021). Azin et al. (2014) used the compositional simulator to study the injection of sweet and sour gas into underground gas storage. They found that the presence of CO2 and H2S components in the sour gas stream decreases the compressibility factor of the injection gas and causes less pressure rise than that without CO2 and H2S. But their study mainly focused on the difference between sour gas and sweet gas during the UGS operation, rather than H2S removal. Chen et al. (2016) used compositional simulation to study the evolution of H2S production during the operation of the H2S-containing Shan-224 UGS in the Ordos Basin. They found that the injection of external clean (sweet) gas could reduce the H2S concentration surrounding a well and the peak H2S concentration in each cycle will gradually decrease and eventually fall below the safety limit (20 mg/m3) after five injection-production cycles. But the initial H2S concentration (0.554 g/m3) of Shan-224 UGS is much lower than that of Huangcaoxia UGS (27.2 g/m3). Zhao et al. (2020) based on the field monitoring data of H2S in the Yong-22 UGS, found that the H2S concentration in the withdrawn gas will keep increasing in the same operation cycle, but the peak H2S concentration in each cycle will keep decreasing; however, the initial H2S concentration in Yong-22 reservoir was also low, ranging from 0.57 to 1.3 g/m3, whose peak H2S concentration was even less than the lowest value in Huangcaoxia Jia-2 layer. Wang et al. (2022) established a mathematical model for H2S-containing gas storage based on the X gas storage, which is the first low-permeability H2S-containing gas storage in China. Their findings showed that the H2S concentration of the produced gas decreases logarithmically with the increase of operation cycles and that the H2S concentration decreases with the increase of gas production rate. But it should be noted that their research was limited to the UGS containing low concentration of H2S, and thus, the observed trends may not necessarily apply to the UGS containing medium–high concentration of H2S or more importantly multilayered H2S-containing UGS. Zeng et al. (2023) conducted a retrospective study of the Puguang gas field, which is the largest sour gas field in China as well as the second-largest sour gas field in the world. They highlighted a series of challenges faced in the development of high H2S-containing gas reservoirs, along with the corresponding key techniques. However, the primary focus of their study was on the efficient development of H2S-containing gas reservoirs, rather than on the conversion of such reservoirs into underground gas storage. It can be seen that the existing studies on H2S removal mainly focus on the single-layer UGS or the UGS containing low concentrations of H2S. Therefore, further studies are needed for the temporal evolution of H2S in the multi-layer sulfur-containing gas field such as the Huangcaoxia gas storage. This study establishes a mechanistic model for the UGS operation based on the rock and fluid properties of the Huangcaoxia gas field. Compositional simulation is utilized to study the temporal evolution of hydrogen sulfide removal in this multilayered H2S-containing gas field, which can in turn guide the optimization of the operation plan of the Huangcaoxia gas storage and provides a reference case for the construction of other H2S-containing gas storage facilities.

2 Reservoir modeling of the Huangcaoxia UGS

2.1 Overview of the Huangcaoxia gas field

The Huangcaoxia gas field is located within the Changshou and Fuling districts of Chongqing city and is located in the highly folded area of the southeastern Sichuan Basin (Fig. 1). The lower Triassic Jialingjiang formation in the Sichuan Basin is a restricted platform sedimentation with limestone, gypsum, and dolomite developed. The Jia-22 mainly consists of inner-shelf and salt-lake facies, dominated by limestone and dolomite, with gypsum developed. And the Jia-22 reservoir is mainly composed of thin-bedded dolomite. It can be divided into three layers from the bottom to the top, based on the bottom surface of Jia-1 of the Jialingjiang formation (Lei et al. 2019). The first layer is the Jia-21 – Jia-1 gas layer (hereinafter referred to as Jia-1), with an average methane molar fraction of 98.27%, as well as 0.8% of ethane, 0.17% of propane, and 0.001% of H2S. The average permeability is 15 mD, and the average porosity is 4.41%. The second layer is an interlayer, with very low porosity and hence can be treated as impermeable. The third layer is the Jia-22 layer (hereinafter referred to as Jia-2), and its major fluid component is methane, with an average molar fraction of 96.6%, as well as 0.66% of ethane, 2% of hydrogen sulfide. The average permeability is 5 mD, and its average porosity is 5.85% as shown in Table 1. Till now, the cumulative gas production from the Jia-2 gas reservoir of the Jialingjiang formation was 3.52 × 108 m3 and the cumulative water production was 193 m3, which is negligible compared with gas production. The cumulative gas production from the Jia-1 gas reservoir was 16.10 × 108 m3 and the cumulative water production was 7 m3. Since the water is mainly produced in the form of condensate rather than in the aqueous phase, it is reasonable to assume that the gas phase is the only mobile phase in the reservoir.

Location map of the Huangcaoxia gas field in the Sichuan Basin (modified from Yang et al. 2017)

2.2 Mechanistic modeling of multilayered UGS

The modeling software Petrel was used to establish the mechanistic model of the Huangcaoxia gas reservoir by combining the geological data and production data. The mechanistic model was established using a relatively neat area of the geological model (as shown in Fig. 2) as a reference. It makes the established mechanistic model more realistic. The model has a size of 1600 m × 800 m × 160 m, with a uniform grid block size of 25 m in both I and J direction, The model is divided into three major layers in the vertical K direction based on the stratification data of the Jialingjiang formation (as shown in Fig. 3): the first layer is the Jia-21 ~ Jia-1 layer of the Jialingjiang formation with its elevation ranging from − 560 m to − 660 m, which is divided into 25 sublayers. The second layer is the interlayer, with its elevation ranging from − 540 m to − 560 m, which is divided into 10 sublayers. The third layer is the Jia-22, with its elevation ranging from − 500 m to − 540 m, which is divided into 20 sublayers. The total number of grid blocks in the multilayer mechanistic model of the Huangcaoxia gas storage is 112,640. Two vertical wells are set up with a horizontal spacing of 800 m.

In this model, the initial reservoir pressure of the Jia-2 layer is 14.1 MPa, and the initial gas saturation is 0.76, which leads to an original gas in the underground of 75 million cubic meters. The initial reservoir pressure of the Jia-1 layer is 14.2 MPa and the initial gas saturation is 0.83, which leads to an original gas in the underground of 249 million cubic meters. To carry out the compositional simulation, multi-component fluid characterization for the Jia-2 and Jia-1 layers was implemented separately using the Peng-Robinson equation of state (as shown in Table 2), with the fluid composition derived from the experimental analysis of the well stream, with an initial H2S molar fraction of 0.001% (0.0136 g/m3) for the Jia-1 layer and 2% (27.2 g/m3) for the Jia-2 layer.

The mass balance equations (Eq. (1)) for compositional simulation are shown below, where a chemical species (e.g. H2S) move in phases but are conserved in terms of components. Advection of H2S can happen either in the gas (g) or water (w) phase governed by Darcy’s law (Eq. (2)). Phase equilibrium calculation is governed by the equality of the chemical potential of a species in different phases (Eq. (3)), and the cubic equations of state specifically the Peng-Robinson equation of state (PR EOS) is used (Eq. (4)).

For a pure substance, the above constants in Eq. (4) can be written as

For a mixture of multiple components, the PR EOS employed the following mixing rule by Zudkevitch and Joffe (1970)

For the base case, two vertical wells are set as cyclic injectors (also known as “huff-and-puff”). Gas is injected or produced simultaneously via two vertical wells. To simulate the effect of acidization before production, the permeability within the 150 m radius of the Jia-2 wellbore was increased from 5 to 15 mD. The base case set the maximum operating pressure to the original reservoir pressure. The well is first produced with a constant rate of 5 × 104 m3/d. If this rate cannot sustain, then it will switch to depletion under a constant bottom-hole pressure of 6.7 MPa until 95% of the OGIP (Original Gas In Place) is produced. Then the clean gas is injected until the pressure is restored to the original reservoir pressure. After that, each case is first produced at 40 × 104 m3/d (may switch to a constant bottom hole pressure of 6.7 MPa if this rate cannot be maintained) for 120 days, followed by a shut-in (simulating facility maintenance in spring) period of 16 days, and then injected at 24 × 104 m3/d (maximum bottom hole pressure of 14 MPa) for 200 days, followed by a shut-in period of 29 days (simulating facility maintenance in fall), with each operating cycle being one year. A total of 40 cycles are simulated in all cases.

3 Simulation study of hydrogen sulfide removal

3.1 Effect of gas reservoir development strategies

In this paper, the removal efficiency of H2S is defined as the number of cycles required for the H2S concentration to decrease to 20 mg/m3 (China GB17820-2018 standard for Class II gas) after the conversion of the sour-gas reservoir into gas storage. Since the H2S concentration of the Jia-1 layer was already below the China Class II gas standard at the time of reservoir conversion, only the Jia-2 layer which has a high H2S concentration was simulated in this subsection.

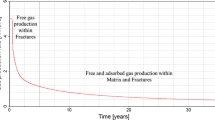

Simulation results (black solid line in Figs. 4 and 5) show that: at the beginning of each operating cycle, the H2S concentration in the withdrawn gas is the lowest because the working gas injected during the gas injection stage can drive the H2S-containing gas into the region that is far away from the wellbore. As gas production proceeds, the H2S-containing gas in this region will start to flow back towards the wellbore together with the working gas. As a whole, the H2S concentration in the produced gas gradually increases and reaches a peak (represented by the value above the black solid line in both Fig. 4 and Fig. 5) at the end of the gas production stage. This is also consistent with the trend of field data published by Zhao et al. (2020), which to some extent can be seen as the validation of the above mechanistic model. At a low depletion level, the peak H2S concentration shows a decreasing trend in each cycle (red dashed line in Fig. 4). This is similar to the simulation results by Zhang (2016) and Chen et al. (2016). However, at a higher depletion level (red dashed line in Fig. 5), the peak H2S concentration in each cycle will increase first and then starts to decrease after a peak. This is because the external clean (i.e., cushion and working gas) was injected to supplement the highly depleted reservoir and it can dilute the original H2S-containing gas near the well as well as displace the sour gas into the region that is far away from the wellbore. Therefore, the gas produced in the early cycles was mainly external clean gas injected during the initial construction of gas storage, whose H2S concentration was very low. Then, the H2S-containing gas will start to flow back to the near-well region, and the peak H2S concentration in each cycle would gradually increase. Finally, the peak H2S concentration in each cycle would start to decrease, as the original H2S-containing gas was being depleted.

3.1.1 Gas recovery factor at the time of gas storage construction

To further demonstrate the effect of the gas recovery factor on the operation of H2S-containing gas storage, the H2S concentration variation in each cycle was obtained by simulating the establishment of gas storage after different levels of depletion (50%, 60%, 70%, 80%, 95%). Every curve in Fig. 6 represents the peak H2S concentration in each cycle after different levels of reservoir depletion. For example, the black curve with the square marker in Fig. 6 corresponds with the red dashed line in Fig. 4 and the purple curve with a diamond marker in Fig. 6 corresponds with the red dashed line in Fig. 5. It can be seen that a higher depletion level at the time of gas storage construction corresponds with less remaining H2S in the gas reservoir, hence will witness a lower H2S concentration during the cyclic injection and production stage.

The peak H2S concentration at the end of each cycle decreases rapidly with the increase of the number of operating cycles when the gas recovery factor is 70% or less (black, red, and blue curve shown in Fig. 6). However, when the gas recovery factor is above 70%, the peak H2S concentration at the end of each cycle increases first and then decreases (green and purple curve shown in Fig. 6). Therefore, a higher gas recovery factor will be more favorable for the H2S removal during the operation of H2S-containing gas storage.

It is also recommended to increase the depletion level of acid gas reservoirs as much as possible if it is not conflicting with the project deadline. At present, the gas recovery factor of both layers in the Huangcaoxia gas field is around 90%, so the subsequent calculations also assume the gas reservoir recovery factor as 95% before starting the simulation of the gas storage operation.

3.1.2 Maximum operating pressure for underground gas storage

The maximum operating pressure is the highest value that can be reached during the normal operation of underground gas storage. Specifically, for an injector well in this study, gas is first being injected at a constant rate of 24 × 104 m3/d. Then if the bottom-hole pressure (BHP) reaches the maximum operating pressure, the well then switches to constant BHP injection. So, the maximum operating pressure determines the upper limit of the gas storage capacity. In this study, its value is first set as 14MPa, which is the original reservoir pressure. And the effects of different maximum operating pressures (11.2 MPa, 12.6 MPa, 14 MPa, 15.4 MPa, 16.8 MPa) on H2S removal were then simulated. As shown in Fig. 7, under a higher maximum operating pressure, more external clean gas can be injected and hence the original H2S in the reservoir can be better diluted; thus significantly reducing the H2S concentration in the produced gas. Eventually, it can improve the removal efficiency of H2S in sulfur-containing gas storage.

3.1.3 Working gas ratio

The working gas ratio represents the ratio of working gas volume to total storage capacity when the gas storage is operating. Unlike the cases studying the maximum operating pressure above, the cases here change the working gas ratio by adjusting the minimum operation pressure of gas storage under a constant storage capacity. We hence simulated different work gas ratios including 20%, 30%, 40%, 50%, 60%, and 65%. As shown in Fig. 8, a higher working gas ratio corresponds with a larger amount of external clean gas that can be injected in each cycle. Hence the initial H2S-containing gas can be better diluted, which leads to a higher H2S removal efficiency. Consequently, fewer cycles are hence required for the produced gas to reach the Chinese National Standard for Class II gas, whose H2S concentration needs to be below 20 mg/m3.

3.1.4 Gas withdrawal rate

The effect of different withdrawal rates on the removal effect of H2S was investigated by setting the single well production rates as 38 × 104, 46 × 104, 54 × 104, 62 × 104, and 70 × 104 m3/d, respectively. As shown in Fig. 9, a lower withdrawal rate will only slightly improve the H2S removal effect for underground gas storage under a constant working gas volume. This is because under a constant working gas capacity, a lower gas withdrawal rate corresponds to a longer production time. Thus, the injected clean gas has more time to contact and mix with the H2S-containing gas, which is similar to adjusting the soaking time during cyclic gas injection into an oil reservoir (Tian et al. 2021). But in general, the impact of the withdrawal rate on the H2S removal efficiency is minor under a constant working gas volume.

The comparison of different simulation cases above shows that if the underground gas storage is constructed only on the high H2S-containing Jia-2 layer, it will require more than 22 cycles to reduce the H2S concentration to be less than 20 mg/m3 which is tediously long and hence impractical. Therefore, we propose to adjust the injection and production strategy, such as combining the medium H2S-containing Jia-2 reservoir with the low H2S-containing Jia-1 reservoir to reduce the overall H2S concentration within the produced gas of this underground gas storage.

3.2 Influence of injection and production strategy

Similar to developing multi-layered oil and gas fields, the operation of multi-layer gas storage can also be divided into multi-layer commingled injection and production (hereafter referred to as commingled operation) and independent injection and production by each layer (hereafter referred to as separate operation). The commingled operation refers to the development of multiple layers through the same well, where the produced gas from each layer can be mixed directly in the wellbore, thus effectively reducing the H2S concentration in the wellbore. In contrast, the separate operation is the development of each layer by deploying multiple wells (or multiple branching wellbores) at the same location, where the produced gas from each layer does not have direct contact with each other. For the same layer, injection and production methods can also be divided into single-well huff-n-puff and inter-well flood. The single well huff-n-puff scheme is the same as the cases discussed in the earlier section. For the inter-well flood scheme, the gas storage is set to inject gas for 160 days during the injection period of each cycle and shut down the injector wells during the gas withdrawal period (e.g., winter). The production wells will produce for 160 days during the gas withdrawal period of each cycle and will shut down during the gas injection period (e.g., summer). The number of days for well shutdown and maintenance is the same as that of the single well huff-n-puff scheme.

The above combinations can lead to four different operating regimes, that is (1) Commingled operation plus flood, (2) Commingled operation plus huff-n-puff, (3) Separate operation plus flood, and (4) Separate operation plus huff-n-puff. Figure 10 compares the simulation H2S concentration concerning time for these four different schemes. It can be seen that the H2S removal efficiency of the inter-well flood is consistently higher than that of the single well huff-n-puff whether under commingled or separate operation. The inter-well flood can make the H2S concentration in the product gas to be less than 20 mg/m3 (Chinese National Standard for Class II gas) after 9 cycles. Meanwhile, the single well huff-n-puff scheme will need more than 23 operating cycles to reach the same standard.

The temporal evolution of H2S concentration in the produced gas under different gas allocation ratios between the two layers was further investigated for the inter-well flood scheme, as shown in Fig. 11. The simulation results show that when the total working gas capacity is set constant, more gas injection/withdrawal within the Jia-2 layer will witness a higher H2S peak concentration for early operating cycles. However, gas allocation ratios between the two layers overall have very limited effects on the H2S removal efficiency as all scenarios can reduce the H2S concentration of the produced gas to be below 20 mg/m3 around the 9th cycle.

When the two layers are combined to build the underground gas storage, the gas allocation ratio between Jia-2 and Jia-1 is determined by the ratio of each layer’s deliverability, which is estimated to be 1:3. Therefore, the temporal variation of H2S concentration under commingled operation is approximately the same as that of the scheme with an allocation ratio of 1:3.

However, the clean gas produced from the Jia-1 layer will spontaneously mix with the medium H2S-containing gas produced from the Jia-2 layer in the wellbore during the commingled operation which can significantly reduce the overall H2S concentration in the well stream. This can further significantly reduce the corrosion possibility of the wellbore, wellhead, as well as other surface facilities associated with H2S. Our simulation hence recommends combining Jia-2 and Jia-1 layers to establish the underground gas storage. The gas storage should first be operated by the inter-well flood in order to reduce the H2S concentration of the product gas to be below 20 mg/m3 as soon as possible, thus meeting the market standard and the HSE requirements.

4 Conclusions

-

(1)

The H2S content gradually increased during the same operation cycle and peaked at the end of the production stage. The peak H2S concentration in each cycle showed a decreasing trend when the depletion level of the gas reservoir was lower than 70%. When the depletion level was above 70%, the peak H2S content in each cycle increased first and then decreased.

-

(2)

A higher reservoir depletion level, a higher maximum working pressure, and a higher working gas ratio will lead to a higher H2S removal efficiency. Under the condition of constant working gas volume, a lower withdrawal rate will only slightly improve the removal of H2S, and the overall effect on the removal efficiency is negligible.

-

(3)

The H2S removal efficiency under the inter-well flood is significantly higher than that of single well huff-n-puff, whether the commingled or separate operation. The inter-well flood can make the H2S concentration of the produced gas lower than 20 mg/cm3 after 9 operation cycles, while the single-well huff-n-puff scheme needs over 23 cycles.

-

(4)

When the working gas volume is set constant, the allocation ratio of the two layers has little effect on the H2S removal. The produced gas’s H2S concentration can be lowered to 20 g/cm3 after the 9th cycle. When the two layers are combined to build the gas storage, the clean gas produced from the Jia-1 layer can spontaneously mix with the sour gas produced from the Jia-2 layer within the wellbore, which can significantly reduce the overall H2S concentration in the well stream.

-

(5)

In summary, this study recommends combining Jia-2 and Jia-1 to build the Huangcaoxia underground gas storage. It can be operated with inter-well flood first in order to dilute the original sulfur-containing gas, which can quickly reduce the H2S concentration of the produced gas to 20 mg/m3, thus meeting the gas export standards as well as the HSE requirements in the field.

References

American Petroleum Institute (2015) Functional integrity of natural gas storage in depleted hydrocarbon reservoirs and aquifer reservoirs (API RP1171)

Azin R, Izadpanahi A (2022) Gas injection for underground gas storage. Fundam Pract Aspects Gas Inject. https://doi.org/10.1007/978-3-030-77200-0

Azin R, Malakooti R, Helalizadeh A et al (2014) Investigation of underground sour gas storage in a depleted gas reservoir. Oil Gas Sci Technol Revue d’IFP Energ Nouv 69(7):1227–1236. https://doi.org/10.2516/ogst/2012003

Chen Z, Liao X, Zhao X, et al (2016) Optimization of injection and production parameters for sour gas storages: a case study. In: Offshore Technology Conference Asia. OnePetro. https://doi.org/10.4043/26686-MS

China National Standardization Administration (2018) Natural gas (GB17820-2018)

Lei H, Zhang Q, Li X (2019) Preliminary numerical modeling of CO2 geological storage in the Huangcaoxia gas reservoir in the Eastern Sichuan Basin, China. Geofluids 2019:1–23. https://doi.org/10.1155/2019/9545723

Li J, Zhao G, Qi Z et al (2021) Stress sensitivity of formation during multi-cycle gas injection and production in an underground gas storage rebuilt from gas reservoirs. Pet Explor Dev 48(4):835–842. https://doi.org/10.1016/S1876-3804(21)60081-2

Li T, Ma Y, Zeng D et al (2022) Research progress and prospect of formation sulfur deposition in high sulfur gas reservoirs. Fault-Block Oil Gas Field 29(4):433–440. https://doi.org/10.6056/dkyqt202204001

Lin H, Zhang S, Yu B et al (2016) Numerical Simulation for movement laws of hydrogen sulfide during UGS injection and production. Oil Gas Storage Transp 35(11):1173–1178. https://doi.org/10.6047/j.issn.1000-8241.2016.11.007

Lyu J, Li Z, Fu J et al (2017) Compositional variation laws of produced gas from underground gas storage tanks rebuilt from sour gas reservoirs: a case study of Shaan 224 UGS in the Ordos Basin. Nat Gas Ind 37(8):96–101. https://doi.org/10.3787/j.issn.1000-0976.2017.08.012

Ma X (2021) Potential reservoir candidates for the construction of UGS facilities in Central and Western China. In: Handbook of underground gas storages and technology in China, Springer Singapore, Singapore, pp 511–527. https://doi.org/10.1007/978-981-33-4734-2_21

Ma X, Zheng D, Shen R et al (2018) Key technologies and practice for gas field storage facility construction of complex geological conditions in China. Pet Explor Dev 45(3):489–499. https://doi.org/10.11698/PED.2018.03.14

Mao Y (2021) Design optimization technology of key indicators for the gas storage in Gujiazi Gas Field. Pet Geol Oilfield Dev Daqing 40(1):96–102. https://doi.org/10.19597/j.issn.1000-3754.201911008

Tian Y, Zhang C, Lei Z et al (2021) An improved multicomponent diffusion model for compositional simulation of fractured unconventional reservoirs. SPE J 26(05):3316–3341. https://doi.org/10.2118/204010-PA

Wang D, Han X, Li J et al (2022) The numerical simulation of gas injection-production in X acid gas storage. In: Proceedings of the international field exploration and development conference 2021, Springer Nature Singapore, Singapore, pp 1269–1277. https://doi.org/10.1007/978-981-19-2149-0_117

Yang G, Huang D, Huang P et al (2017) Control factors of high and stable production of Jurassic Da’anzhai member tight oil in central Sichuan Basin, SW China. Pet Explor Dev 44(5):866–875. https://doi.org/10.1016/S1876-3804(17)30098-8

Zeng D, Zhang Q, Li T et al (2023) Key technologies for long-period high and stable production of the Puguang high-sulfur gas field, Sichuan Basin. Nat Gas Ind 43(1):65–75. https://doi.org/10.3787/j.issn.1000-0976.2023.01.007

Zhang J, Fang F, Lin W et al (2020) Research on injection-production capability and seepage characteristics of multi-cycle operation of underground gas storage in gas field—case study of the Wen 23 gas storage. Energies 13(15):3829. https://doi.org/10.3390/en13153829

Zhang Y, Fu Y, Ai Q et al (2016) The study of sour gas variation in low sulfur gas storage. Petrochem Ind Appl 35(3):89–91. https://doi.org/10.3969/j.issn.1673-5285.2016.03.023

Zhang G, Yang S, Mo C et al (2022) Experimental research on capacity expansion simulation of multi-cycle injection-production in reconstruction of oil reservoir to underground gas storage. J Energy Storage 54:105222. https://doi.org/10.1016/j.est.2022.105222

Zhao J, Xie J, Zhao L et al (2020) Analysis on the factors influencing the operation of Y22 underground gas storage containing hydrogen sulfide to reach capacity and production and countermeasures. Mud Logging Eng 31(4):121–128. https://doi.org/10.3969/j.issn.1672-9803.2020.04.019

Zudkevitch D, Joffe J (1970) Correlation and prediction of vapor-liquid equilibria with the Redlich-Kwong equation of state. AIChE J 16(1):112–119. https://doi.org/10.1002/aic.690160122

Acknowledgements

This work is supported by the China Postdoctoral Science Foundation (2022M722637) as well as the Natural Science Foundation of Sichuan Province (2022NSFSC0190). The authors would also like to acknowledge the anonymous reviewers, whose constructive comments were very helpful in preparing this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship, or publication of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, Y., Li, L., Wang, X. et al. Simulation study of hydrogen sulfide removal in underground gas storage converted from the multilayered sour gas field. Int J Coal Sci Technol 10, 71 (2023). https://doi.org/10.1007/s40789-023-00631-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-023-00631-3