Abstract

Ultrasonic waves have a lot of use in the particle surface cleaning. As flotation is one of the methods associated with surface properties, this paper investigates the effect of these waves on performance, particle size, reagents, and feed ash content in coal flotation. To accomplish this goal, coal samples in three size fractions, including coarse (− 800 to + 400 µm), medium (− 400 to + 100 µm) and fine (− 100 µm) with various feed ash content. The flotation experiments were evaluated by process indexes such as yield, combustible recovery, and selectivity index. The results indicated the increasing of yield. The increasing was significant in medium size. Furthermore, the results showed that in presence of ultrasonic waves, the collector and frother consumption decreased. And also, applying ultrasonic waves would result more combustible recovery and selectivity index. The ash selectivity index had the highest impact for high feed ash content.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coal is an abundant energy source, that the population growth and technology development greatly increases its consumption. The increasing use of coal and the need to reduce environmental pollutions draws more attention to the coal processing technology (Laskowski 2001).

In the existing methods for mineral processing, flotation is considered as a physicochemical method that uses the natural disparities in the properties of the minerals and is widely used to separate valuable minerals from gunges (Yuan et al. 1996; Sripriya et al. 2003; Wills and Finch 2016). Flotation is the most effective way for separating coal particles (smaller than 500 µm) from gunges. When the size of the coal particles is very small (under 50 µm) or very large (higher than 500 µm), the efficiency of the flotation is greatly reduced. Efforts to increase the recovery of these particles through increasing the oil collector dosages often results significant production of non-combustible materials with the floating coal (Maoming et al. 2010).

Physical and chemical variables and operational conditions are influential factors in flotation process. Changes in any of these variables have a significant impact on the result of flotation such as grade and recovery. Ultrasonic is one of the important treatment methods to improve the flotation process (Ozkan and Kuyumcu 2006). The ultrasonic wave propagation in a fluid will create two main mechanisms: cavitation and acoustic flow. When the ultrasonic wave is released in a liquid environment, due to the motion of the sonic wave, increase and decrease patterns will be repeated. Reducing density creates low pressure areas in which the fluid is disrupted. Due to the reduced pressure, very small bubbles will appear in areas in which the density was reduced and these bubbles are called cavitation bubbles (The Sonochemistry Centre at Coventry University Website 2016).These tiny bubbles, which are created in water phase, will expand to an unstable degree and then quickly disintegrate. The impact of cavitation phenomenon on the fluid can be expressed as follows:

-

Very high hydrodynamic shear stress which results in physical destruction of compounds (Guo et al. 2007);

-

Advancement of chemical reactions due to high stress and very high local heating (nearly 5000 °C) (Mason 1990).

Another mechanism which occurs during ultrasonic irradiation in the environment is the acoustic flow. Acoustic flow is formed at the solid–liquid interface, when solid interface vibrates with regular shakes. The main advantage of acoustic flow can be better mixed in aquatic environment, which distributes ultrasonic energy uniformly in the entire volume of pulp, and also accelerates the distribution of heat (Ghadyani et al. 2017).

Irradiation with ultrasonic waves in pulp preparation has major application in flotation of various ores, clearing impurities and surface smears, increasing the efficiency of extractive metallurgy process and improving the process of separating solid particles from the fluid. One of the studies in this regard was done by Kang et al. (2008). In this study, the impact of ultrasonic waves on surface composition and the flotation performance of high-sulfur coal was investigated and the results showed an increase in coal hydrophobicity and pyrite hydrophilicity; increase in separation efficiency and flotation selectivity; increase in the recovery of coal concentrate; a reduction in product’s sulfur and ash; and an increase in the number of bubbles sticking to particles in ultrasonic preparation (Kang et al. 2008). Ozkan (2012) studied the simultaneous effect of ultrasonic waves in flotation of hard coal fine particles and the result was the increasing of coal recovery and reduction in ash content in concentrate compared to conventional flotation, reduction reagents consumption, and increase in coal recovery due to the ultrasonic waves clean the particle surfaces (Ozkan 2012). Ozkan and Gungoren (2012) studied the improvement of colemanite flotation by ultrasonic preparation, and they resulted the removal of fine particles and increasing in flotation recovery (Ozkan and Gungoren 2012). Xia et al. (2013), reviewed the improvement of oxidized coal flotation with pre-processing methods and the results were published in three categories (Xia et al. 2013):

-

(a)

In preparation with ultrasonic waves; removing coal oxide layers and clay minerals from surfaces and therefore increasing the coal’s hydrophobicity resulted in better reagents absorption;

-

(b)

In preparation with microwave waves; moisture reduction and hydrophobicity increase and coal recovery without any changes in properties and surface oxidation; pyrite magnetic properties increase and the ability to remove them with magnetic separators was obtained;

-

(c)

In preparation with high intensity; removing layers of clay minerals from the surface and therefore an increase in coal hydrophobicity was observed.

Among the studies that have been done on flotation with ultrasonic waves in recent years, Barry et al. (2015a, b), Gungoren et al. (2016), Videla et al. (2016), Ozkan (2017), Vasseghian et al. (2017) and Ghadyani et al. (2017), can be named and in general it can be concluded that flotation with ultrasonic waves result an increase in recovery and flotation process efficiency and a reduction in reagents consumption, and this is due to the removal of impurities and smears from particle surfaces and the optimal absorption of chemicals at their surface (Barry et al. 2015a, b; Gungoren et al.2016; Videla et al. 2016; Ozkan 2017; Vasseghian et al. 2017; Ghadyani et al. 2017).

To investigate the relationship between frequency and cavitation bubble dimensions was presented by Young (Eq. (1)) (Young1989).

In which, RCB is the radius of the cavitation bubble (meter); \(\emptyset\) is the specific heat coefficient of gas inside the bubble (for air in 20 °C equals 1/41); Pair is the air pressure; ρwater is the water density; ω is the angular frequency (rad/s).

As a result, at 20 °C and at atmosphere pressure, the relationship between the frequency of the device and the radius of the cavitation bubble can be calculated using Eq. (2) (Young1989).

where, f is the frequency, Hz.

Therefore, at a constant output power, the higher the frequency of the ultrasonic device, the smaller the cavitation bubbles, and as a result of the collapse, it produces less energy than large bubbles (Haghi 2016).In order to justify this phenomenon, it can be stated that at lower frequencies, the wavelength is larger and as a result, cavitation bubbles have more time to grow and they grow larger and produce high levels of energy before the collapse (Young1989).

The removal of pollutants from the surface of the particles requires adequate energy as well as proper contact angle of cavitation (Cleaning Technologies Group Website 2017). Although the energy released from the collapse of large cavitation bubbles is much higher, but this energy will be partly amortized in the fluid path, in the distance between the location of the cavitation bubble collapse and the point of contact with the particle and the angle of contact might also be ineffective. On the other hand, although smaller cavitation bubbles have less energy, but they hit the particle at a more appropriate angle and this contact can be more effective in breaking the weaker pollutant bonds in smaller particles. Therefore, it can be concluded that in order to affect the smaller particles, higher frequency is better and in order to affect the larger particles, lower frequency would be more appropriate. Thus, it is expected that with a further reduction in the wavelengths, recovery of fine particles will improve (Haghi 2016).

The effect of ultrasonic waves on different feed ash content with the same size in flotation has not been reported yet. This factor was separately studied in this article. Also the amount of chemical consumption and particle size were studied as other independent factors.

2 Materials and methods

2.1 Coal samples

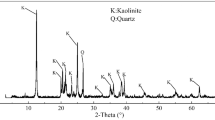

The coal samples for this study were collected from east Alborz mines, which are located in Semnan province in north of Iran. The samples were consisted of coals with three groups of ash percentage which after separate crushing with laboratory jaw crusher, were divided into three size fractions using screen analysis method by ASTM series: coarse (− 800 to + 400 µm), medium (− 400 to + 100 µm) and fine (− 100 µm).

After sample preparation and grading, ash percentage was determined based on ASTM D-3174 standard for each size fraction. Figure 1 shows the final samples categories and the results are presented in Table 1.

2.2 Reagents

Reagents used in flotation experiments included kerosene, as a collector to help coal surface hydrophobicity and methyl isobutyl carbonyl (MIBC) in order to create sustainable froth in flotation.

2.3 Flotation experiments

In order to carry out the experiments, a Denver type mechanical flotation machine with a cell volume of 1 L, and for irradiation, an ultrasonic bath manufactured by Elma co. in Germany was used. The system which was set for performing flotation tests is shown in Fig. 2.

Several parameters are involved in the efficiency of the flotation process and the flotation rate can be increased through determining the optimal conditions. The parameters and their variation levels are expressed in Table 2. Also, fixed parameters are considered as follows:

-

(1)

Solid content: 7%;

-

(2)

Collector type: kerosene;

-

(3)

Frothier type: MIBC;

-

(4)

Temperature: room temperature (25 °C);

-

(5)

pH: neutral (7);

-

(6)

Rotor speed: 1000 rpm;

-

(7)

Ultrasonic device power (80 W);

-

(8)

Preparation time (8 min)

Considering the operational parameters and their levels presented in Table 2; the response surface experimental design with 25 experiments was selected. Table 3 shows the operational conditions of the experiments.

2.4 Process indicator

Equations (3)–(6) were used to calculate yield, combustible recovery, ash recovery in tail, and ash selectivity index, respectively (Wills and Finch 2016; Ghadyani et al. 2017).

where, \(R_{\text{Combustible}}\) is the combustible recovery in concentrate, %; \(R_{\text{Non - combustible}}\) is the ash recovery in tail, %; \(SI_{\text{Non - combustible}}\) is the ash selectivity index; \(f_{\text{ash}}\), \(c_{\text{ash}}\), \(t_{\text{ash}}\) are the average ash (%) in feed, concentrate and waste, respectively; F and C are the feed and concentrate weight, g, respectively.

3 Results and discussion

Figure 3 shows the effect of ultrasonic waves on the yield for different size fractions. With the increase in the ultrasonic frequency, the yield of particles in different sizes increases comparing to the absence of ultrasonic wave. Of course the best results were in 37 kHz. This improvement was more than 35% in coarse particles, and in the case of medium and fine particles, there was a 40% and 25% increase in recovery, respectively. This result is consistent with the results of previous researches (Young1989; Haghi 2016; Cleaning Technologies Group 2017).

Figure 4a shows the effect of ultrasonic waves on yield in the collector dosages of 200–2000 g/t. It can be observed that the use of ultrasonic waves in the whole range of collector changes improves yield by more than 30%. The highest recovery rate is achieved at 37 kHz, which is due to a better clean-up of coal particles at this wavelength, and thereby improving the collector’s performance in the flotation. Further increase in the frequency of the waves leads to a reduction in recovery. However, even a reduction in recovery at a higher frequency is higher than the recovery rate in the absence of waves.

Also according to Fig. 4b, ash selectivity index in the presence of ultrasonic waves experienced an increase of about 1 unit. From 37 kHz, the selectivity index is almost constant. However, by increasing the dosage of collectors, the selectivity index decreases. Therefore, in order to raise the selectivity in the presence of waves in high frequencies, the amount of required collector dosage is reduced. The reason is that the particle surface is cleaned and the collector delivers a better performance.

Figure 5a, b show the effect of ultrasonic waves on the yield and combustible recovery. By increasing the frother dosage due to the stability and minifying of the bubble sizes, recovery and combustible recovery has increased. The effect of an increase in the frother dosage by using ultrasonic waves, results in an increase of more than 30 and 20 percent in recovery and an increase of 25% and 10% in recovery of combustibles in 37 and 80 kHz waves, respectively, and this indicates the greater stability of the fine cavitation bubbles generated in the presence of waves and increasing in the density of these bubbles in the liquid and cleaning the surface of the particles. The highest recovery and combustible recovery was achieved at 37 kHz frequencies. Although increasing frequency reduces the recovery and the combustible recovery, these values are higher rather than the absence of waves. Therefore, it can be concluded that by using ultrasonic waves such as collectors, the amount of consumed frother will be reduced.

Figures 6a and b indicate that using ultrasonic waves will improve the combustible recovery in various feed ash and the ash selectivity index has also increased. This proves that surfaces of the particles have been cleaned. As shown in Fig. 5a, the amount of combustible recovery increase is about 15% in low-feed ash, 20% in medium-feed ash, and about 10% in high-feed ash and Fig. 5b shows the highest effect of ash selectivity in feed with high ash.

4 Conclusions

The most important results of this study can be summarized as follows:

-

(1)

With the reduction of ultrasonic wavelengths (frequency increase), particle yield increased in different sizes. This increase was more than 35% in coarse particles, more than 40% in medium particles, and nearly 25% in fine particles.

-

(2)

The use of ultrasonic waves, after increasing the dosage of the collector, improved the yield by more than 30%. The highest recovery was achieved at the frequency of 37 kHz. The ash selectivity index also increased with ultrasonic, indicating a cleaner particle surface and more efficient collector performance. Hence, the use of ultrasonic waves significantly reduces the amount of collector consumed.

-

(3)

The effect of an increase in frother dosage using ultrasonic waves resulted in a 20% and 30% increase in yield and a 25% and 10% increase in combustible recovery in 37 and 80 kHz waves, respectively. This indicates the greater stability of the small cavitation bubbles generated in the presence of waves and an increase in the density of these bubbles in the liquid and that the particle surface was cleaned. Using ultrasonic waves helps to reduce the required frother dosage.

-

(4)

Ultrasonic waves improved the recovery of combustibles in different ash percentages and the ash selectivity index also increased. The amount of combustible recovery was increased by 15% in low feed ash, 20% in medium feed ash, and nearly 20% in high feed ash.

References

Barry B, Klima, Cannon FS (2015a) Effect of hydroacoustic cavitation treatment on the spiral processing of bituminous coal. Int J Coal Prep Util 35(2):76–87

Barry B, Klima MS, Cannon FS (2015b) Effect of ultrasonic cavitation treatment on liberation and hydrocyclone separation of bituminous coal. Miner Metall Process 32(3):138–145

Cleaning Technologies Group (2017) Ultrasonics-effect of frequency removing particles. https://www.ctgclean.com/ultrasonic-cleaning-fundamental-theory-and-application

Ghadyani A, Noaparast M, ShafaeiTonkaboni SZ (2017) A study on the effects of ultrasonic irradiation as pretreatment method on high-ash coal flotation and kinetics. Int J Coal Prep Util 38:1–18

Gungoren C, Baktarhan Y, Demir İ, Senol-Arslan D, Ozdemir O, Ozkan S (2016) Evaluation of coal preparation plant tailings by ultrasonic flotation. In: 16th International symposium on environmental issues and waste management in energy and mineral production (SWEMP 2016), Istanbul, Turkey, pp 1–5

Guo Z, Feng R, Zheng Y, Fu X (2007) Improvement in properties of coal water slurry by combined use of new additive and ultrasonic irradiation. Ultrason Sonochem 14(5):583–588

Haghi H (2016) Investigating the effect of ultrasonic-microwave waves on the pre-processing of industrial silicate minerals. PhD thesis, Tehran University (in Persian)

Kang W, Xun H, Hu J (2008) Study of the effect of ultrasonic treatment on the surface composition and the flotation performance of high-sulfur coal. Fuel Process Technol 89(12):1337–1344

Laskowski JS (2001) Coal preparation. Dev Miner Process 14:1–8

Maoming FAN, Daniel TAO, Honaker R et al (2010) Nanobubble generation and its application in froth flotation (part I): nanobubble generation and its effects on properties of microbubble and millimeter scale bubble solutions (in Chinese). Min Sci Technol 20(1):1–19

Mason TJ (1990) The uses of ultrasound in chemistry. RSC, Cambridge, pp 20–56

Ozkan SG (2012) Effects of simultaneous ultrasonic treatment on flotation of hard coal slimes. Fuel 93:576–580

Ozkan SG (2017) Further investigations on simultaneous ultrasonic coal flotation. Minerals 7(10):177

Ozkan SG, Gungoren C (2012) Enhancement of colemanite flotation by ultrasonic pre-treatment. Physicochem Probl Miner Process 48(2):455–462

Ozkan SG, Kuyumcu HZ (2006) Investigation of mechanism of ultrasound on coal flotation. Int J Miner Process 81(3):201–203

Sripriya RPVT, Rao PVT, Choudhury BR (2003) Optimisation of operating variables of fine coal flotation using a combination of modified flotation parameters and statistical techniques. Int J Miner Process 68(1–4):109–127

The Sonochemistry centre at Coventry University (2016) Introduction to sonochemistry. http://www.sonochemistry.info/introdution.htm

Vasseghian Y, Ahmadi M, Joshaghani M (2017) Ultrasound assisted ash and sulphur removal from bitumen using column flotation technique: experimental, RSM and ANN methods in modelling and optimization of process. Iran J Sci Technol Trans A Sci 41(4):1149–1163

Videla AR, Morales R, Saint-Jean T, Gaete L, Vargas Y, Miller JD (2016) Ultrasound treatment on tailings to enhance copper flotation recovery. Miner Eng 99:89–95

Wills BA, Finch JA (2016) Wills’ mineral processing technology, 8th edn. Elsevier, Amsterdam

Xia W, Yang J, Liang C (2013) A short review of improvement in flotation of low rank/oxidized coals by pretreatments. Powder Technol 237:1–8

Young FR (1989) Cavitation. Inperial College Press, London, p 418

Yuan XM, Palsson BI, Forssberg KSE (1996) Statistical interpretation of flotation kinetics for a complex sulphide ore. Miner Eng 9(4):429–442

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ebrahimi, H., Karamoozian, M. Effect of ultrasonic irradiation on particle size, reagents consumption, and feed ash content in coal flotation. Int J Coal Sci Technol 7, 787–795 (2020). https://doi.org/10.1007/s40789-020-00307-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40789-020-00307-2