Abstract

To solve difficulties involving various groups’ decision-making problems, this work has been proposed to develop a logical aggregation approach to aggregate decision-makers’ crisp data into Pythagorean fuzzy numbers. By combining the established strategy with the Pythagorean fuzzy TOPSIS method, a hybrid Pythagorean fuzzy multiple criteria group decision-making methodology is presented. Based on fuzzy rules inference and the Takagi–Sugeno technique, a novel function is created to represent the degrees of uncertainty in decision-makers’ data. As an example, the material selection process in practical additive manufacturing designs is provided to show how the proposed methodology may be applied to actual applications. Sensitivity analysis is used to evaluate the effectiveness of the suggested methodology. The outcomes demonstrate that the plan was successful in producing a PFN that accurately reflects the decision-maker’s knowledge.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Multiple Criteria Group Decision-Making (MCGDM) is an effective methodology that Decision-Makers (DMs) can utilize in group decision-making to choose the optimal course of action for various applications in a variety of fields. Three steps make up the group decision-making (GDM) procedure. The first two steps are interpreting decision-makers' preferences, assembling their ideas into a group decision-making matrix, and selecting the best course of action. The primary phase among the three is assumed to be the gathering of decision-makers' thoughts [1]. Early Multiple Criteria Decision-Making (MCDM) problems typically displayed decision makers' preferences as clear numerical data. In addition, a number of MCDM tools, including the Technique of Order Preference Similarity to the Ideal Solution (TOPSIS), are well recognized for presenting decision problems as informational matrices based on the different assumptions that the information presented is precisely well defined. However, because the majority of these problems (i.e., engineering, management, manufacturing, medical science, economics, environment, etc.) involve numerous uncertainties, this methodology may not be appropriate in various real-world decision-making difficulties. In particular, the standard mathematical methods may not be successful in offering solutions when the uncertainty is complicated to measure. Zadeh [2] proposed the idea of fuzzy set theory to address issues involving uncertainties in mathematical applications. It has been put into use to resolve MCDM issues by allocating fuzzily defined numbers that take the fuzziness of decision makers' preferences into account. Later, Atanassov [3] proposed the idea of the intuitionistic fuzzy set (IFS) to deal with uncertainty more precisely. The ability of the IFS to describe decision makers' preferences within a set of membership grades (the degree of satisfaction) and non-membership grades (the degree of dissatisfaction) and to ensure that the sum of its membership degree and non-membership degree is always less than or equal to 1 is what distinguishes it from other decision-making systems. IFS is frequently employed in a variety of MCDM applications and issues worldwide [4,5,6,7,8,9,10,11].

Yager [12, 13] originally introduced the Pythagorean Fuzzy Set (PFS) in 2013, where the sum of the preferences of the decision-makers (represented as membership grade and non-membership grade) can be more than 1, leading to better modeling of uncertainties than IFS in practical decision-making issues. PFS has thus been applied recently in several decision-making applications [14,15,16,17,18,19].

This paper introduces an aggregation method to convert decision-makers' precise judgments into Pythagorean Fuzzy Numbers (PFNs) to address MCGDM difficulties. A hybrid MCGDM model that combines an MCDM approach with an aggregation strategy is also suggested. This hybrid model would be an effective tool to assist decision-makers (such as designers and engineers) in making educated decisions within actual group decision-making challenges for engineering and industrial applications. The justification for using precise numbers rather than linguistic terms in the decision-makers’ evaluation process is that linguistic terms typically have broader perspectives in their interpretations and depend on the designer's point of view, which limits the decision-maker's abilities to express their opinions accurately and freely. The accuracy of the decision-makers inputs may be influenced, which could impact the decisions made. Given the same decision-making situation, one designer would rate the linguistic term "very good" as 0.4 on the numerical assessment scale, while another might rate it as 0.6. A happier designer would result in different results than a more pessimistic one. Crisp values, however, are more consistent and standardized in their application than linguistic words, allowing decision-makers to communicate their views numerically more exactly and adaptively. It also reduces the impact of the designer's presumption on the decision-making process.

Motivation of the study

The limitations of approaches in the existing literature can be summarized as follows: (1) Sustainable Additive Manufacturing (AM) innovation has been exhibited as disruptive advantage for manufacturing industries. The main contribution of AM is encouraging sustainability to become mature significantly. (2) Limited research has addressed the subject of developing the aggregation phase of converting decision-makers’ crisp opinions into fuzzy numbers for MCGDM problems; however, most of these studies are devoted to generating IFS from decision-makers’ opinions [20,21,22,23,24,25,26,27,28,29]. (3) Research has focused on developing approaches to produce PFS from crisp thoughts [30]; however, the parameters and fuzzy rules inference used to control the aggregation process in this study are different and more accurate for modeling decision-makers’ uncertainty and information into PFS. (4) A few methodologies have considered measuring and aggregating the uncertainty into the aggregation approach [29]. A new aggregation methodology to convert crisp data into PFS for MCGDM is introduced to address the issues mentioned earlier. TOPSIS is one of the most popular and extensively used methodology in MCDM problems which is applied in this study under the PFN environment.

Novelties of the work

In recent era, Additive Manufacturing (AM) has emerged as a transformative technology that significantly, making it worthy of a thorough examination. AM has the potential to revolutionize industry and production practices. Various aspects, including the used materials, quality, processing time, cost, and environmental efficiency, necessitate significant enhancements within the design phases and production processes of AM. This study primarly focuses on the selection process of components for production in a systematic and scientific mannar.

This research's main contribution is to develop a methodology for GDM problems based on aggregating decision makers' crisp values into PFS that accurately reflect their satisfaction and dissatisfaction levels, improving the accuracy of decision-making results in MCGDM applications. To logically estimate the levels of uncertainty in the evaluations made by DMs, the methodology provides an aggregation strategy to construct PFS using a function that was developed based on fuzzy rules.

To aggregate the decision-makers' opinions and determine the degree of uncertainty, a pairwise function is provided in this study. The output of the function is controlled by the Takagi–Sugeno technique and fuzzy rules inference. To confirm the suitability of using the suggested aggregation approach in MCGDM applications, it is additionally integrated with PF-TOPSIS. A realistic example of materials selection application in sustainable additive manufacturing design shows the actual applicability of suggested technique. According to the results, the suggested methodology can be successfully used to solve real-world MCGDM issues in industrial applications.

Research contribution

This study works on sustainable additive manufacturing design in an uncertain environment. The ability of sustainable additive manufacturing, generally known as 3D printing, to transform conventional manufacturing methods has attracted much interest in recent years. Its benefits include lessened material waste, increased energy efficiency, and customizability. However, there are several difficulties that scholars and practitioners need to address when planning for sustainability in an unpredictable world. The contribution of this research can be summarized as follows:

-

(a)

Selection of material in a manufacturing environment for sustainable additive manufacturing design.

-

(b)

An advanced aggregating MCGDM method called TOPSIS with a modified way used in this study.

-

(c)

Multiple DM provide crisp assessments on a 0–100 scale and is converted into a Pythagorean fuzzy number to catch its hesitancy and uncertainty.

-

(d)

Sensitivity analysis is conducted to check systems stability and robustness.

While accounting for uncertain variables, designers and engineers must consider various factors, such as material selection, manufacturing processes, and product lifecycle. Another key aspect of the study might involve developing design frameworks or methodologies specifically tailored for sustainable additive manufacturing in uncertain environments. These frameworks could integrate principles of circular economy, eco-design, and system thinking to guide decision-making.

Structure of the paper

The structure of this study as follows: The “Introduction” section discusses about introduction of this study, i.e., methodology and application. The “Literature review” section is dedicated to literature review. The “Recent sustainable additive manufacturing design and MCDM study” section discusses about the recent sustainable additive manufacturing design and MCDM study. The “Preliminaries” section covers basic definitions and information about fuzzy set and PFNs. “MCDM method for group decision-making problem under Pythagorean fuzzy uncertainty” section discuss the proposed method including the aggregation approach and its integration with PF-TOPSIS. The “Sustainable additive manufacturing design problem with Pythagorean fuzzy environment application” section demonstrates the application of the developed methodology to a realistic materials’ selection problem in sustainable additive manufacturing design. The “Sensitivity analysis and comparative study” section provides the sensitivity analysis andcomparative analysis of the studies. Finally, the conclusion, limitation, and future research scope are covered in the “Conclusion, limitations, and future research scope” section.

Literature review

In this section, literature review on fuzzy set, Pythagorean fuzzy set, and its application in MCDM methodologies are carried out. Most studies and research on PFNs in the MCDM field often focus on developing operators and decision-making processes to determine the final results, without considering the first steps of converting crisp materials into PFNs. However, some techniques have addressed the aggregation methods in generating Intuitionistic Fuzzy Numbers (IFNs). Yue [20] and Yue et al. [21, 22] build an aggregation method to generate IFN from crisp numbers through applying the Golden Section. Yue et al. [23] presented an aggregation technique to derive IFN from Crisp decisions using the Minimax criterion. Alzahrani et al. [31] calculate optimal site for women educational institute using MCDM and Gazi et al. [32] select the best restaurant location selection by MCDM in uncertain environments. Yue [24] introduced an aggregation method to generate interval-valued intuitionistic fuzzy information from interval numbers to be used in MCGDM problems. Moreover, Yue and Jia [25] developed an aggregation method to derive interval-valued intuitionistic fuzzy numbers (IVIFNs) from crisp assessments for MCGDM applications. As well, Yue [26] suggested an MCGDM technique that relies on generating IVIFNs by interval values’ aggregation.

Furthermore, Yue [27] proposed an aggregation approach for MCGDM to derive IFNs from crisp data based on their mean values. However, Yue's method has been criticized by Lin and Zhang [28] for its weakness, particularly in the assessment of DM severity, which leads to unsatisfactory results, which does not make it good for practical use. In addition, Lin and Zhang [28] proposed a new addition method for arbitrary numbers to overcome the DM weight difference in the Yue method, using the Shapley value addition with the aggregation technique. Wan et al. [29] introduced an MCGDM method on the bases of aggregating heterogenous decision information into IVIFNs.

Momena and Abu-Zahra [30] proposed an aggregation approach for MCGDM to aggregate decision information into Pythagorean fuzzy numbers for MCGDM taken into account measuring the hesitancy levels. However, the uncertainty function used to compute the hesitancy levels for the aggregation process in this study is better in smoothing and capturing the decision information. Furthermore, a different normalization approach is used which allows the aggregated PFNs to reflect more information resulting in facilitating the computational processes in MCGDM problems.

PFN-related recent study

The fuzzy number (FN) is used to deal with an uncertain data set. The PFN is a special type of FN used in this study. In 1965, Lotfi Zadeh [2] introduced the fuzzy set that attaches membership degree with every element, which denotes the possibilities of belongingness in the set. Fuzzy set [33] came to a revaluation in every science and technological field [34], especially the mathematical [35,36,37] and the computer science field [38, 39]. Singh et al. [40] and Momena et al. [41] used fuzzy numbers in medical fields. There are many studies done on fuzzy sets [42] and its analysis [43]. Zadeh [44] extended the fuzzy set to type-2 fuzzy set by considering another membership function called type-2 membership function [45] in 1975. Then, in 1976, Grat-tan-Guinness, I. [46] extended the fuzzy set differently by considering the membership function an interval function and called the interval-valued fuzzy set. Zhang et al. [47] use the hybrid-driven-based fuzzy set to solve nonlinear parabolic partial differential equation systems. Sun et al. [48] use fuzzy sets in nonlinear systems and Wan et al. [49] use for discrete-time Markov jump system. Then, Atanassov et al. [50] considered another function called the non-membership function, which assures the non-belongingness of an element in the set, called intuitionistic fuzzy set in 1989. Application of IFS is Das et al. [51], where consider decision-making problems are discussed. Smarandache, F. considered the third membership function called indeterminacy in 1999, and the set is called neutrosophic fuzzy set [52].

Pythagorean fuzzy set [53], invented by Ronald R. Yager in 2013, considers two membership functions but is slightly different from the intuitionistic fuzzy set. Operation on PFS are discussed by Peng et al. [54], Peng et al. [55], and Garg [56]. There are enormous fields of application of PFS, like in decision-making by Garg [57], pattern recognition by Ullah et al. [58] and Wei et al. [59]. PFS applied in medical diagnosis by Ejegwa [60] and Xiao et al. [61]. Mahanta et al. [62] were choosing free mask system in COVID-19 pandemic and searching best private school by similarity measure in PFS. Another study done by Yang et al. [63] where ranked the China-Pakistan Economic Corridor (CPEC). Here, we give some recent literature where PFN using various optimization techniques. Table 1 shows the author's name, year, type of uncertainty, optimization technique, and application fields in some studies.

PFS is used in the enormous field of decision-making applications; some are described briefly. PFS applied by Lin et al. [79] and Zhang et al. [80]. In medical diagnosis, PFS was applied by Xiao et al. [61] and Naeem et al. [81], also applied in cluster analysis by Hussain et al. [82] and Zhang [83]. Also, Huang et al. [84] study on industries transforming analysis and Göçer et al. [85] studied the development of products using the MULTIMOORA method in the PFS environment.

Leaturature on Pythagorean fuzzy set

In many business, engineering, and industry applications, MCGDM is one of the most widely used techniques for making crucial decisions. MCGDM techniques are frequently employed to collect data about decision-makers to facilitate efficient decision-making. The degree of hesitation, ambiguity, and uncertainty in the decision-making process should be calculated and used to increase accuracy due to the uncertainty of the group's decision. PFN is a helpful method for identifying ambiguous environmental issues. Recently, numerous investigations on MCDM and MCGDM with PFN have been carried out. Table 2 discusses a few of them.

Recent sustainable additive manufacturing design and MCDM study

This section describes the recent study on MCDM techniques and their implication for sustainable manufacturing design. The manufacturing sector may undergo a transformation thanks to additive manufacturing (AM), a rapidly expanding and developing process. However, given that AM procedures use a lot of energy and generate a lot of waste, sustainability is a major problem. MCDM is a helpful method for assessing the viability of AM processes using a variety of factors. Many studies have been conducted recently on the use of MCDM in environmentally friendly additive manufacturing. For instance, a study by Anand et al. [97] provided a methodology for choosing the most sustainable 3D printing material based on a number of factors, including cost, material qualities, and environmental impact. The Analytic Hierarchy Process (AHP) and TOPSIS were employed in the study to assess the sustainability of various materials.

Rakhade et al. [98] proposed another decision-making study for selecting the most sustainable 3D printing method based on factors like environmental impact, material qualities, and cost. The investigation was utilized by the AHP and TOPSIS to gauge the sustainability of various processes. An MCDM model was put forth in a study by Prabhu et al. [99] to assess the environmental impact, energy consumption, and waste production of various 3D printing methods. The AHP and Grey Relational Analysis (GRA) were employed in the study to evaluate the viability of various processes. A study by Kamhong et al. [100] has suggested a fuzzy MCDM model for assessing the sustainability of various 3D printing methods based on factors, including energy usage, material waste, and environmental effect. A fuzzy AHP was utilized in the study to assess the sustainability of various processes. In a review of MCDM in sustainable manufacturing, Peko et al. [101] cited AHP, TOPSIS, and PROMETHEE (Preference Ranking Organization Method for Enrichment Evaluations) as the most often employed techniques. They also talked on the opportunities and difficulties of using MCDM in sustainable manufacturing, including the need for more thorough sustainability standards and the integration of business, environmental, and social factors.

Kağızman et al. [102] focused on the application of MCDM techniques to sustainable supplier selection. They reviewed the literature from 2000 to 2017 and identified the most frequently used methods, such as AHP, Vlse Kriterijumska Optimizacija I Kompromisno Resenje (VIKOR), and TOPSIS. They also discussed the challenges and opportunities of using MCDM in sustainable supplier selection, such as the need for more accurate and reliable data and the integration of different stakeholder perspectives. Furthermore, a study by Zhang et al. [103] proposed a fuzzy MCDM model for evaluating the sustainability of different 3D printing processes based on criteria, such as energy consumption, material waste, and environmental impact. The study used a fuzzy AHP to evaluate the sustainability of different processes. Raigar et al. [104] presented a hybrid MCDM method for sustainable AM material selection, which integrated AHP and fuzzy TOPSIS. They applied this method to evaluate the sustainability of three commonly used AM materials: PLA, ABS, and Nylon. Based on the above study, the descending order of sustainability score is Nylon, PLA and ABS.

These studies demonstrate how MCDM may support sustainable decision-making in additive manufacturing. The lack of accurate sustainability metrics and the challenge of integrating numerous sustainability criteria into a single framework for decision-making are just two problems that need to be resolved. All things considered, the application of MCDM in environmentally friendly additive manufacturing has the potential to promote the development of environmentally friendly AM processes and materials. Further research is needed to develop more comprehensive sustainability measurements and decision-making frameworks that can take into account the complex relationships between various sustainability criteria.

Also, sustainable manufacturing design Agrawal [105] uses to choosing AM technology in FDM. This study uses MCDM techniques IEM, TOPSIS, MOORA, VIKOR, and SAW for optimization. Ilgin et al. [106] reviewed environmentally sensible mass produce and production salvation using MCDM techniques. They study 190 MCDM-related papers on ECMPRO (Environmentally Conscious Manufacturing and Product Recovery) and comparative analysis of different MCDM methodologies. Agrawal and Vinodh [107] studied sustainable additive manufacturing (SAM) using MCDM techniques. To identify and prioritize the prominent drivers for the SAM, the authors used the BWM method. In manufacturing industries, sustainable additive analysis was done using TOPSIS techniques by Alsaadi [108], Subramani et al. [109], and Taddese et al. [110]. Additive manufacturing with MCDM is mentioned by Raigar et al. [111], where BWM and PIV methods are used. Bai et al. [112] used the hybrid possibility MCDM technique in AM fields. Also, Menekse et al. [113] optimized the AM application by CRITIC and EDAS methods. Ma et al. [114] discussed the key component of sustainability analysis. The authors analyzed and optimized the life cycle sustainability of a coffee maker machine using the MCDM method.

Preliminaries

This section describes the basics of fuzzy sets and its extension with the Pythagorean fuzzy sets concept. Zadeh [2] introduced the fuzzy set in 1965, which consists of each element having a degree of membership value. The membership degree or membership value \(\left({\mu }_{\widetilde{F}}\left(x\right)\right)\) is between \(\left[\mathrm{0,1}\right]\) and is based on the percentage of items that are members of the fuzzy set \(\left(\widetilde{F}\right)\). There have already been significant advances made in fuzzy set theory by several researchers [115]. We employ the Pythagorean fuzzy set with a proposed application in this paper. In decision-making and modeling, Pythagorean fuzzy sets, an extension of standard fuzzy sets, provide a more thorough representation of uncertainty and imprecision. They were created to solve some of the drawbacks of traditional fuzzy sets, particularly when dealing with complicated or multi-dimensional uncertainty. In comparison to the conventional fuzzy sets, Pythagorean fuzzy sets give a deeper measurements of uncertainty, making them crucial for a variety of applications where a thorough grasp of uncertainty and ambiguity is required for efficient decision-making and modeling.

Pythagorean fuzzy sets (PFSs)

In this section, we recall some basic definitions. In a fuzzy set [116], there is only one membership value (i.e., true membership value or degree of assuredness). Similarly, consider another membership degree called non-membership value which guarantees the possibility of not belongingness or falsity of the elements. Atanassov et al. [50] in 1989 gave the proper formulation of the Intuitionistic fuzzy set, as follows:

Definition 1

(Intuitionistic fuzzy set) [50] Let \(U\) be the universal set of discourses. The intuitionistic fuzzy set (IFS) \(I=\left\{\left(\xi ;{\mu }_{I}\left(\xi \right),{\nu }_{I}\left(\xi \right)\right): \xi \in U\right\}\) where \({\mu }_{I}\) is membership function and \({\nu }_{I}\) is non-membership function define by \({\mu }_{I}, {\nu }_{I}:U\to [0, 1]\) and satisfy

for all \(\xi \in U\).

Example 1

Consider a set of universes \(U={\mathbb{R}}\). Then, Intuitionistic Fuzzy Set \({I}_{1}=\{(2; {0.8,0.15}), (4; {0.7,0.2}), (5;0.65, 0.25), (7; {0.4,0.55}), (8;0.35, 0.4)\}\) have elements \(2, 4, 5, 7, 8\) in IFS \({I}_{1}\), with the degree of membership \(({{\mu }_{I}}_{1})\) and non-membership \(({\nu }_{{I}_{1}})\) values are \(\left(\mathrm{0.8,0.15}\right), \left(\mathrm{0.7,0.2}\right), \left(0.65, 0.25\right), \left(\mathrm{0.4,0.55}\right), \left(\mathrm{0.35,0.4}\right)\), respectively. Here, sum of \({{\mu }_{I}}_{1}\) and \({\nu }_{{I}_{1}}\) is always bounded by \(\left[\mathrm{0,1}\right]\). In a similar way, \({I}_{2}=\left\{\left(0.2;\mathrm{0.5,0.3}\right), \left(0.3;0.6, 0.25\right), \left(0.5;\mathrm{0.15,0.6}\right)\right\}\) be another intuitionistic fuzzy set.

The PFS is an extended and generalized form of an IFS. To capture the more ambiguousness of the data set maintaining the fuzzy set property, Yager [117] introduced this concept in 2013.

Definition 2

(Pythagorean fuzzy set) [117] A Pythagorean fuzzy set \(P\) in a fixed set \(X\) can be defined as \(P=\{ \left(x, {\mu }_{P}\left(x\right), {v}_{P}\left(x\right)\right)|x\epsilon X\)} with \({\mu }_{P}\left(x\right)\) denote the membership function and \({\nu }_{P}\left(x\right)\) denote the non-membership function define as \({\mu }_{P}, {\nu }_{P}:X\to \left[0, 1\right]\) and satisfies the condition

for all \(x\in X\) to \(P\).

The degree of belongness is represented by membership function \(\left({\mu }_{p}\right)\) and the degree of non-belongness is represented by non-membership function \(\left({\nu }_{P}\right)\) for every element \(x\) on the set \(P\).

Example 2

Assume \(X={\mathbb{R}}\) be the universal set of discourses. The Pythagorean fuzzy set \({P}_{1}=\{(10; {0.6,0.7}), (11; {0.5,0.4}), (13; {0.8,0.5}), (15; {0.5,0.8}), (16; {0.3,0.85})\}\) has elements \(10,11,13,15,16\) in the set PFS \({P}_{1}\) with membership degree value \(\left({\mu }_{{P}_{1}}\right)\) and non-membership degree value \(\left({\nu }_{{P}_{1}}\right)\) are reparented in order pair, respectively. Here, square sum of \({{\mu }_{P}}_{1}\) and \({\nu }_{{P}_{1}}\) is bounded by \(1\). Another PFS is \({P}_{2}=\big\{\left(0.5;\mathrm{0.6,0.75}\right), \left(0.6;\mathrm{0.55,0.65}\right), \left(0.8;\mathrm{0.4,0.8}\right),\big(0.9;\mathrm{0.2,0.85}\big)\big\}\) on universal set of discourses is \({\mathbb{R}}\).

Remarks 1

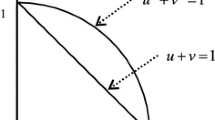

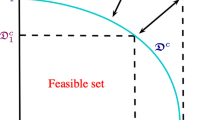

Figure 1 shows the coverage area by the IFS and PFS based on membership and non-membership functions. We easily see that PFS covers more area from the domain rather than IFS. It is probable to use PFS instead of IFS to capture more hesitancy and ambiguity. The uncertainty of PFS is described below.

For every PFS of \(P\) and \(x \epsilon X\), the degree of uncertainty is denoted by \({\pi }_{P}\) and described as

of \(x\) to \(P\). For simplification of Pythagorean Fuzzy Set (PFS) also denoted by \(\beta =P\left({\mu }_{\beta }, {v}_{\beta }\right)\), (i.e., \(\beta \left(x\right)=P\left({\mu }_{P}\left(x\right), {\nu }_{P}\left(x\right)\right)\) for each \(x\in X\)) such that \({\mu }_{\beta }, {v}_{\beta } \in [0, 1]{{(\pi }_{\beta })}^{2}=1-{{(\mu }_{\beta })}^{2}-{{(v}_{\beta })}^{2}\le 1\) and \({{0\le (\mu }_{\beta })}^{2}+{{(v}_{\beta })}^{2}\le 1\).

Remarks 2

There are some basic differences in IFS and PFS, such as

-

(a)

Boundary of PFS is \({\mu }_{P}\left(x\right)+{\nu }_{P}\left(x\right)\le 1\) or \({\mu }_{P}\left(x\right)+{\nu }_{P}\left(x\right)>1\) but in IFS \({\mu }_{P}\left(x\right)+{\nu }_{P}\left(x\right)\le 1\) always.

-

(b)

Linearity of PFS is \(0\le {\mu }_{P}{\left(x\right)}^{2}+{\nu }_{P}{\left(x\right)}^{2}\le 1\) but in IFS \(0\le {\mu }_{P}\left(x\right)+{\nu }_{P}\left(x\right)\le 1\).

-

(c)

The uncertainty of PFS is \({\pi }_{P}\left(x\right)=\sqrt{1-{\mu }_{P}{\left(x\right)}^{2}-{\nu }_{P}{\left(x\right)}^{2}}\) but in IFS \({\pi }_{P}\left(x\right)=1-{\mu }_{P}\left(x\right)-{\nu }_{P}\left(x\right)\).

From Remark 2 and Fig. 1, we conclude that the PFS captures more uncertain degree as compared to IFS. Fuzzy numbers are a special type of fuzzy set where the set of the universe \(\left(X\right)\) is a real number set \(\left({\mathbb{R}}\right)\) and satisfies some properties [118].

Example 3

Let us consider \(X={\mathbb{R}}\) be the universal set. Consider \({\Lambda }_{P} \& {\Gamma }_{P}\) are two PFS and \({\Lambda }_{I} \& {\Gamma }_{I}\) are two IFS define in \(X\). Now \({\Lambda }_{J}=\left\{x:\mathrm{0.8,0.5}\right\}\) and \({\Gamma }_{J}=\left\{y:\mathrm{0.6,0.3}\right\}\) for \(J=P,I\). Then, by definition of PFS, \({0\le ( {\mu }_{{\Lambda }_{P}}\left(x\right))}^{2}+{( {v}_{{\Lambda }_{P}}\left(x\right))}^{2}\le 1\) and \({0\le ( {\mu }_{{\Gamma }_{P}}\left(y\right))}^{2}+{( {v}_{{\Gamma }_{P}}\left(y\right))}^{2}\le 1\) holds for \({\Lambda }_{P} \& {\Gamma }_{P}\), respectively. In IFS, \(0\le {\mu }_{{\Gamma }_{I}}\left(y\right)+{v}_{{\Gamma }_{I}}\left(y\right)\le 1\) hold for \({\Gamma }_{I}\) but \(0\le {\mu }_{{\Lambda }_{I}}\left(x\right)+{v}_{{\Lambda }_{I}}\left(x\right)\le 1\) not hold for \({\Lambda }_{I}\). Therefore, \({\Lambda }_{P} \& {\Gamma }_{P}\) are PFS and \({\Gamma }_{I}\) is IFS but \({\Lambda }_{I}\) is not IFS.

Arithmetic operation on PFN

Definition 3

[119] Let \({\beta }_{1}=P\left({\mu }_{{\beta }_{1}}, {v}_{{\beta }_{1}}\right), {\beta }_{2}=P\left({\mu }_{{\beta }_{2}}, {v}_{{\beta }_{2}}\right),\) and \(\beta =P\left({\mu }_{\beta }, {v}_{\beta }\right)\), be three PFNs, then

-

1.

\({\beta }_{1}\oplus {\beta }_{2}=P\left(\sqrt{{\mu }_{\beta 1}^{2}+{\mu }_{\beta 2}^{2}-{\mu }_{\beta 1}^{2}{\mu }_{\beta 2}^{2}}, {v}_{{\beta }_{1}}{v}_{{\beta }_{2}}\right)\);

-

2.

\({\beta }_{1}\otimes {\beta }_{2}=P\left({\mu }_{{\beta }_{1}}{\mu }_{{\beta }_{2}}, \sqrt{{v}_{\beta 1}^{2}+{v}_{\beta 2}^{2}-{v}_{\beta 1}^{2}{v}_{\beta 2}^{2}}\right)\);

-

3.

\(\lambda \beta =P\left(\sqrt{1-{\left(1-{\mu }_{\beta }^{2}\right)}^{\lambda }}, {\left({v}_{\beta }\right)}^{\lambda }\right), \lambda >0\);

-

4.

\({\beta }^{\lambda }=P\left({\left({\mu }_{\beta }\right)}^{\lambda }, \sqrt{1-{\left(1-{v}_{\beta }^{2}\right)}^{\lambda }}, \right), \lambda >0\).

Example 4

Consider two PFNs are \({\alpha }_{1}=\left(0.8, 0.5\right)\), \({\alpha }_{2}=\left(0.7, 0.4\right)\) and \(\lambda =2\) be a scalar. Then, the arithmetic operations on PFNs are

-

(A)

Addition: \({\alpha }_{1}\oplus {\alpha }_{2}=\left(0.90, 0.2\right)\);

-

(B)

Multiplication: \({\alpha }_{1}\otimes {\alpha }_{2}=\left(0.56, 0.61\right)\);

-

(C)

Scalar multiplication: \(\lambda {\alpha }_{1}=\left(0.93, 0.25\right)\);

-

(D)

Scalar power: \({\alpha }_{1}^{\lambda }=\left(0.64, 0.66\right)\).

Remarks 3

Example 1 satisfies all arithmetic operations on PFN. Here, consider scalar number \(\lambda \) always greater than \(0\). All four arithmetic operations give PFNs, i.e., closed under those operations.

Theorem 1

[119] Let \({\beta }_{1}=P\left({\mu }_{{\beta }_{1}}, {v}_{{\beta }_{1}}\right), {\beta }_{2}=P\left({\mu }_{{\beta }_{2}}, {v}_{{\beta }_{2}}\right),\) and \(\beta =P({\mu }_{\beta }, {v}_{\beta })\), be three PFNs, then

-

(a)

\({\beta }_{1}\oplus {\beta }_{2}= {\beta }_{2}\oplus {\beta }_{1}\)

-

(b)

\({\beta }_{1}\otimes {\beta }_{2}= {\beta }_{2}\otimes {\beta }_{1}\)

-

(c)

\(\lambda \left({\beta }_{1}+ {\beta }_{2}\right)= \lambda {\beta }_{1}\oplus \lambda {\beta }_{2}, \lambda >0\)

-

(d)

\({\lambda }_{1}\beta \oplus {\lambda }_{2}\beta \) = \(\left({\lambda }_{1}+ {\lambda }_{2}\right)\beta ,{\lambda }_{1},{\lambda }_{2}>0\)

-

(e)

\({\left({\beta }_{1}\otimes {\beta }_{2}\right)}^{\lambda }={{\beta }_{1}}^{\lambda }\otimes {{\beta }_{2}}^{\lambda }, \lambda >0\)

-

(f)

\({\beta }^{{\lambda }_{1}}\otimes {\beta }^{{\lambda }_{2}}= {\beta }^{{(\lambda }_{1}+{\lambda }_{2})}{\lambda }_{1}, {\lambda }_{2}>0\).

Definition 4

Let \(\beta =P({\mu }_{\beta }, {v}_{\beta })\) be a PFN; then, the score function [119] of \(\beta \) is presented as follows:

where \({\mu }_{P},{\nu }_{P}\in [\mathrm{0,1}]\) and the score function \(s\left(\beta \right)\in \left[-1, 1\right]\).

Definition 5

Consider a generalized PFN \(\beta =P\left({\mu }_{P}, {\nu }_{P}\right)\) define on \({\mathbb{R}}\); then the accuracy function [120] of PFN denoted by \(a\left(\beta \right)\) and described as

where \({\mu }_{P},{\nu }_{P}\in \left[\mathrm{0,1}\right]\).

Example 5

Consider three PFNs \({\alpha }_{1}=\left(\mathrm{0.9,0.4}\right)\), \({\alpha }_{2}=\left(\mathrm{0.8,0.4}\right)\) and \({\alpha }_{3}=\left(\mathrm{0.7,0.55}\right)\). Then, the score function and accuracy function values of PFNs are, respectively, as follows:

Theorem 2

[119] Let \({\beta }_{1}=P\left({\mu }_{{\beta }_{1}}, {v}_{{\beta }_{1}}\right)and{\beta }_{2}=P\left({\mu }_{{\beta }_{2}}, {v}_{{\beta }_{2}}\right)\) be two PFN, then

-

(A)

If \(s\left({\beta }_{1}\right)<s\left({\beta }_{2}\right)\), then \({\beta }_{1}<{\beta }_{2}\);

-

(B)

If \(s\left({\beta }_{1}\right)>s\left({\beta }_{2}\right)\), then \({\beta }_{1}>{\beta }_{2}\);

-

(C)

If \(s\left({\beta }_{1}\right)=s\left({\beta }_{2}\right)\), then accuracy functions are compared as

-

(a)

If \(a\left({\beta }_{1}\right)<a\left({\beta }_{2}\right)\), then \({\beta }_{1}<{\beta }_{2}\);

-

(b)

If \(a\left({\beta }_{1}\right)>a\left({\beta }_{2}\right)\), then \({\beta }_{1}>{\beta }_{2}\);

-

(c)

If \(a\left({\beta }_{1}\right)=a\left({\beta }_{2}\right)\), then \({\beta }_{1}\sim {\beta }_{2}\).

-

(a)

Remarks 4

To order the PFN, the score function and accuracy function are used. First score function order the PFNs if it fails, then consider the accuracy function. When both functions cannot be identified, then consider they are equivalent.

Remarks 5

From Example 3, considering three PFNs \({\alpha }_{1}\), \({\alpha }_{2}\), and \({\alpha }_{3}\) with their score values are \(s\left({\alpha }_{1}\right)=0.65\), \(s\left({\alpha }_{2}\right)=0.48\), and \(s\left({\alpha }_{3}\right)=0.1875\), respectively. Since \(s\left({\alpha }_{1}\right)>s\left({\alpha }_{2}\right)>s\left({\alpha }_{3}\right)\), then \({\alpha }_{1}>{\alpha }_{2}>{\alpha }_{3}\). By score function value of PFNs ordered those numbers, then accuracy function is not needed.

Example 6

Consider two PFNs \({\beta }_{1}=\left(\mathrm{0.8,0.5}\right)\) and \({\beta }_{2}=\left(\mathrm{0.9,0.648}\right)\), then score function values of PFNs are \(s\left({\beta }_{1}\right)=0.39\) and \(s\left({\beta }_{2}\right)=0.39\). This implies that the score function failed to order the PFNs. Now, the accuracy function values of PFNs are \(a\left({\beta }_{1}\right)=0.89\) and \(a\left({\beta }_{2}\right)=1.23\). It is easy to see that \(a\left({\beta }_{2}\right)>a({\beta }_{1})\); this implies \({\beta }_{2}>{\beta }_{1}\). Then, when score function gives the same value of two different PFNs check by the accuracy function value. Finally, if accuracy function value cannot distinguish, then we conclude that those PFNs are same.

MCDM method for group decision-making problem under Pythagorean fuzzy uncertainty

In this section, a multi-criteria decision-making method for group decision-making problem has been demonstrated. The mathematical procedure of this method is step-wise discussed. To reach a conclusion as a group, group decision-making includes combining the opinions and preferences of several people or experts. There are several articles for group decision-making with uncertainty [121,122,123,124,125]. Here, the group decision-making is followed by the Pythagorean uncertainty.

Evaluation

Each decision-maker subjectively assesses each material candidate with respect to the criteria using crisp values from (0–100), with zero being the worst and \(100\) being the best. The assessment of each decision-maker is formed as a matrix. It can be represented as follows:

\({X}_{i}={\left({r}_{kj}^{i}\right)}_{t\times n}\) show the group evaluation matrix for each alternative that each decision-maker (DM) on \(D=\left\{{d}_{k}:k=\mathrm{1,2},\dots ,t\right\}\) assesses each given criterion \(C=\left\{{C}_{j}:j=\mathrm{1,2},\dots ,n\right\}\) on the basis of the alternative \(X=\left\{{X}_{i}:i=\mathrm{1,2},\dots ,m\right\}\).

Normalization

Normalized each element \({r}_{kj}^{i}\) in the group assessment matrix \({X}_{i}\) using the Eqs. (7) and (8) describe as follows:

where the \({\text{max}}j\) represents the maximum grade and consider its value \(100\) and the \({\text{min}}j\) represents the minimum grade and consider its value \(0\). This value assumed by the decision-maker \({d}_{k}\) for further evaluation. Now, the above system of Eqs. (7) and (8) is revised as follows:

Normalized group decision matrix can be represented as follows:

where \(i=\mathrm{1,2},\dots ,m\).

Then, the satisfactory and dissatisfactory levels need to be determined by measuring the distance of each normalized element \({u}_{kj}^{i}\) to the lowest bound, which is \(0\), and to the maximum bound, which is \(1\), respectively. The satisfactory level can be calculated as

where \({o}_{kj}^{i}\) is the satisfactory level of the normalized value \({u}_{kj}^{i}\) of the jth attribute with respect to ith alternative and dissatisfactory levels can be calculated as

where \({\xi }_{kj}^{i}\) is the dissatisfactory level of the normalized value \({u}_{kj}^{i}\) of the jth attribute with respect to ith alternative.

Aggregation phase

Decision-makers’ weights are measured using sugeno fuzzy measures and Shapley value as in [30]. After that, the weighted average of the satisfactory level and the dissatisfactory level values are determined using the weight of each decision-maker. Decision-makers’ weights should be assigned based on their expertise, authority, and expertise levels in which \(\left(\sum_{k=1}^{t}{w}_{k}=1\right)\). The weighted average of the satisfactory level and the dissatisfactory level values can be displayed, respectively, as follows:

where \({\kappa }_{ij}\) is the weighted average satisfactory degree and \({\varsigma }_{ij}\) is the weighted average dissatisfactory degree and \(w\) denotes weight of each DM where \({w}_{k}\in [\mathrm{0,1}]\) with \(k=\mathrm{1,2},\dots ,t\).

For the aggregation process to be more efficient, the hesitancy level in decision-makers’ provided opinions need to be computed and gauged in the aggregated PFNs. To effectively calculate the uncertainty degree of our decision-makers’ crisp evaluations, a function has been developed based on fuzzy inference rules. The purpose of creating fuzzy inference rules is to define the local input–output relationship between the data use in the function [126]. Takagi–Sugeno approach [127] is adopted to develop the uncertainty function. The fuzzy base rules are formed based on

-

(I)

How far is the satisfactory value \({\kappa }_{ij}\) from the satisfactory bound, which is 1;

-

(II)

How far is the dissatisfactory value \({\varsigma }_{ij}\) from the dissatisfactory bound, which is 0; and

-

(III)

The amount of space (distance) between the satisfactory values and the dissatisfactory values and it can be represented by \(\left({\sigma }_{1}={\kappa }_{ij}-{\varsigma }_{ij}\right)\mathrm{if }{\kappa }_{ij}>{\varsigma }_{ij}or\left({\sigma }_{2}={\varsigma }_{ij}-{\kappa }_{ij}\right)\mathrm{ if }{\kappa }_{ij}<{\varsigma }_{ij}\).

For simplification, \({\kappa }_{ij}\) and \({\varsigma }_{ij}\) are rewritten, respectively, as \(\kappa \) and \(\varsigma \). This can be demonstrated using the fuzzy inference rules as follows:

-

(A)

1st function modeling rules (when \(\kappa >\varsigma \)):

-

\({R}_{a}^{1}\): IF \(\kappa \) is close to \(1\left({Q}_{E1}\left(\kappa \right)=\kappa \right)\) and \(\kappa -\varsigma \) is close to \(1 ( {Q}_{Z1}\left({\sigma }_{1}\right)=\kappa -\varsigma )\) THEN \({f}_{a}\left(\kappa , \varsigma \right)=0\).

-

\({R}_{a}^{2}\): IF \(\varsigma \) is close to \(0\left({Q}_{H1}\left(\varsigma \right)=1-\varsigma \right)\) and \(\kappa -\varsigma \) is close to \(1\left({Q}_{Z1}\left({\sigma }_{1}\right)=\kappa -\varsigma \right)\) THEN \({f}_{a}\left(\kappa , \varsigma \right)=0\).

-

\({R}_{a}^{3}\): IF \(\kappa -\varsigma \) is close to \(0\left({Q}_{Z2}\left({\sigma }_{1}\right)=1-\kappa +\varsigma \right)\) THEN \({f}_{a}\left(\kappa , \varsigma \right)=1\).

-

-

(B)

2nd function modeling rules (when \(\kappa < \varsigma \)):

-

\({R}_{b}^{1}\): IF \(\kappa \) is close to \(1\left({Q}_{E1}\left(\kappa \right)=\kappa \right)\) and \(\varsigma -\kappa \) is close to \(1 ( {Q}_{S1}\left({\sigma }_{2}\right)=\varsigma -\kappa )\) THEN \({f}_{b}\left(\kappa , \varsigma \right)=0\).

-

\({R}_{b}^{2}\): IF \(\varsigma \) is close to \(0\left({Q}_{H1}\left(\varsigma \right)=1-\varsigma \right)\) and \(\varsigma -\kappa \) is close to \(1\left({Q}_{S1}\left({\sigma }_{2}\right)=\varsigma -\kappa \right)\) THEN \({f}_{b}\left(\kappa , \varsigma \right)=0\).

-

\({R}_{b}^{3}\): IF \(\varsigma -\kappa \) is close to \(0\left({Q}_{S2}\left({\sigma }_{2}\right)=1-\varsigma +\kappa \right)\) THEN \({f}_{b}\left(\kappa , \varsigma \right)=1\).

-

For more clarification, in the 1st function rules, specifically in \({R}_{a}^{1}\), \(\kappa \) is near to 1 which can be represented by a fuzzy subset let \({E}_{1}\) with a membership function\(\left({Q}_{E1}\left(\kappa \right)=\kappa \right)\).

Therefore, the mathematical representation of the uncertainty pair wise function can be shown as follows:

where \({\tau }_{ij}\) is denoted the uncertainty degree. The final step is to evaluate the \({\kappa }_{ij}, {\varsigma }_{ij}\) and \({\tau }_{ij}\) value for satisfy the PFN condition in Eqs. (2) and (3). The values of \({\kappa }_{ij}, {\varsigma }_{ij}\) and \({\tau }_{ij}\) are evaluated as follows:

Definition 6

We call

a PFS where \({\mu }_{ij}\) and \({v}_{ij}\) are the induced PFNs that satisfy the condition displayed in Eq. (3).

Remark 6: If \({\kappa }_{ij}=1\) and \({\kappa }_{ij}-{\varsigma }_{ij}=1\), then according to Eq. (16), the uncertainty degree will be the lowest \({\tau }_{ij}=0\). Accordingly, the PFNs the degree of satisfactory, dissatisfactory and uncertainty will be measured by Eqs. (17)–(19) as\({ \mu }_{ij}=1\),\({\upsilon }_{ij}=0\) & \({\pi }_{ij}=0\), respectively.

Remark 7

If \({\varsigma }_{ij}=1\) and \({\varsigma }_{ij}-{\kappa }_{ij}=1\) , then according to Eq. (16), the uncertainty degree will be the lowest \({\tau }_{ij}=0\). Accordingly, in the PFNs, the degree of satisfactory, dissatisfactory, and uncertainty will be measured by Eqs. (17)–(19) as \({\mu }_{ij}=0\),\({\upsilon }_{ij}=1\) and \({\pi }_{ij}=0\), respectively.

Remark 8

If \({\kappa }_{ij}-{\varsigma }_{ij}=0\) or \({\varsigma }_{ij}-{\kappa }_{ij}=0\), then according to Eq. (16), the uncertainty degree will be at the highest \({\tau }_{ij}=1\). Accordingly, in the PFNs, the uncertainty degree will be measured by Eq. (19) as \({\pi }_{ij}=1\).

Therefore, the combined estimation of Pythagorean fuzzy numbers of decision matrix \(U={\left({C}_{j}\left({x}_{i}\right)\right)}_{m\times n}\) is presented as follows:

where each matrix entry \(P\left({\mu }_{ij},{v}_{ij}\right)\) is a PFN, this implies that the degree of each alternative \(x=\left\{{x}_{i}:i=\mathrm{1,2},\dots ,m\right\}\) satisfies the criterion \(C=\left\{{C}_{j}:j=\mathrm{1,2},\dots ,n\right\}\) is the value is \({\mu }_{ij}\) and the degree of the each alternative \(x=\left\{{x}_{i}:i=\mathrm{1,2},\dots ,m\right\}\) is not satisfied the criterion \(C=\left\{{C}_{j}:j=\mathrm{1,2},\dots ,n\right\}\) is the value \({v}_{ij}\).

Integration with MCDM methods

An MCDM tool should be included to evaluate the efficacy of the suggested MCGDM applications and the introduced aggregation approach. A suitable MCDM technique should be chosen to suit the application's goals, since our decision-making process will be applied to a materials selection problem in the manufacturing setting.

AHP, ELECTRE, and TOPSIS were highlighted in the previous studies and research as some of the most prominent MCDM methods for materials selection; nevertheless, the authors cited a number of implementation issues with AHP and ELECTRE. According to Jahan et al. [128], one of ELECTRE's flaws is that no explicit algebraic values are provided to inform users of the differences between different types of materials. The fact that ELECTRE analyzes the alternatives on the basis of each criterion separately, which is irrelevant to the materials selection problem, because all criteria must be taken into account when evaluating each option, which is another drawback of ELECTRE in the application of materials selection. Additionally, Mousavi-Nasab and Sotoudeh-Anvari [129] demonstrated that AHP has its own restrictions when it comes to the application of materials selection, including the fixed number of material alternatives and criteria to be included in the operation as well as its inability to handle benefit and cost criteria at the same time. The effectiveness of TOPSIS in relation to the nature and components of materials selection decision-making problems, such as processing qualitative and quantitative data, has been recognized by numerous studies as one of the most applicable MCDM tools in the field of materials’ selection, Large-scale consideration of material alternatives and criteria, simultaneous consideration of cost and benefit criteria, unambiguous criterion compromises, and presentation of the decision-making outcomes in a preference ranking order [130,131,132,133,134,135,136].

Numerous research has incorporated the usage of TOPSIS in a fuzzy environment to treat the ambiguity and vagueness of the decision that may arise in the decision-making process, since TOPSIS has demonstrated its significance in materials’ selection applications [137,138,139,140,141,142]. But because the newly introduced MCGDM matrix has PFNs, the integrated TOPSIS approach ought to be able to handle a Pythagorean fuzzy environment.

Zhang et al. [119] proposed the Pythagorean fuzzy TOPSIS approach for the first time to successfully tackle MCDM issues using PFNs. This method is built on the premise that the best option should be the furthest away from the Positive Ideal Solution and the closest to the Negative Ideal Solution.

Initially, the Pythagorean fuzzy PIS and the Pythagorean fuzzy NIS are measured using the score function and rules in Definitions 4 and 5 for comparison purposes. The Pythagorean fuzzy PIS and NIS are denoted by

where \(B\) denoted the beneficial criteria and \(C\) denoted the cost criteria or non-beneficial criteria.

Thus, the shortest distance between the alternative \({x}_{i}\) and the Pythagorean fuzzy PIS \({x}^{+}\) is calculated as follows:

where \(i=\mathrm{1,2},\dots ,m\) and the longest distance between the alternative \({x}_{i}\) and the Pythagorean fuzzy NIS \({x}^{-}\) is calculated as follows:

where \(i=\mathrm{1,2},\dots ,m\).

Usually, consider the shortest the distance from the PIS the better the alternative \({x}_{i}\) as \({D}_{min}\left({x}_{i}, {x}^{+}\right)=\underset{1\le i\le m}{{\text{min}}}D\left({x}_{i}, {x}^{+}\right)\), and the farthest the distance from the NIS the better the alternative \({x}_{i}\) as \({D}_{max}\left({x}_{i}, {x}^{-}\right)=\underset{1\le i\le m}{{\text{max}}}D\left({x}_{i}, {x}^{-}\right)\).

Finally, to rank the alternatives, the revised closeness has been used and it can be evaluated as follows:

where the alternatives can be ranked as \(\zeta \left({x}^{*}\right)=0\) being the best alternative and the larger value of \(\zeta \left({x}_{i}\right)\) the suitable for the alternative.

Algorithm for the proposed Pythagorean fuzzy MCGDM method

The algorithm of the previous methodological explanation for the Pythagorean fuzzy TOPSIS method is described in this section. The algorithm can be implacable in the following steps:

-

Step 1. For each alternative (ith), the decision-maker \(D=\{{d}_{k}:k=\mathrm{1,2},\dots ,t\}\) give their opinion in the form of decision matrix \({X}_{i}={({r}_{kj}^{i})}_{t\times n}\) for the criteria \({\text{C}}=\left\{{C}_{j}:j=\mathrm{1,2},\dots ,n\right\}\) based on the alternative \(x=\{{x}_{i}:i=\mathrm{1,2},\dots ,m\}\) which shows mathematically in Eq. (5).

-

Step 2. Using Eqs. (9) and (10), collected decision matrix \({X}_{i}={({r}_{kj}^{i})}_{t\times n}\) convert into normalized group decision matrix \({R}_{i}={({u}_{kj}^{i})}_{t\times n}\).

-

Step 3. Determine the satisfactory and dissatisfactory levels by applying Eqs. (12) and (13), respectively, for each normalized decision matrix value in \({R}_{i}\).

-

Step 4. Calculated each decision-maker’s weight using sugeno fuzzy measures and Shapley value.

-

Step 5. Evaluate the weighted average height and dissatisfaction for each parameter vector in the ith alternative relative to each weighted DM in \({R}_{i}\) using Eqs. (14) and (15), respectively.

-

Step 6. The uncertainty degree of every decision matrix entry is determined using Eq. (16) for each criterion vector in \({R}_{i}\).

-

Step 7. Calculate the final PFNs by performing Eqs. (17) and (18), respectively.

-

Step 8. In the Pythagorean fuzzy decision matrix \(U={\left(P({\mu }_{ij},{v}_{ij})\right)}_{m\times n}\), each decision-maker aggregated to a single Pythagorean fuzzy decision matrix \(P({\mu }_{ij},{v}_{ij})\) using Eq. (21).

-

Step 9. Identifies the Pythagorean fuzzy PIS and the Pythagorean fuzzy NIS using score and accuracy function utilizing Definitions 4 and 5, respectively.

-

Step 10. Weight for each criterion \(w=\left({w}_{{C}_{1}},{w}_{{C}_{2}},\dots ,{w}_{{C}_{j}}\right)\) assigned with alternative \({x}_{i}\). Then find the distances between the ith alternative \(({x}_{i})\) and the Pythagorean fuzzy PIS \({x}^{+}\) using Eq. (24), similarly for the Pythagorean fuzzy NIS \({x}^{-}\) using Eq. (25).

-

Step 11. The revised closeness \(\zeta \left({x}_{i}\right)\) of every alternative \({x}_{i} (i=\mathrm{1,2},\dots ,m)\) are calculated using Eq. (26).

-

Step 12. Determine the alternative ranking based on the relative closeness coefficient \(\zeta \left({x}_{i}\right)\) in descending order and conclude the optimal solution from the alternatives.

Ranked the alternatives into order of decrease order of \(\zeta \left({x}_{i}\right) (i=\mathrm{1,2},\dots ,m)\). The highest relative closeness value \(\zeta ({x}_{i})\) gets the optimal solution and then ranks in descending order. Figure 2 shows a depicts of the proposed methodology.

Pseudo code for the said method

This paper considers n number of criteria and m number of alternatives with k number of the decision-maker (DM). DM give their input variable on a 1–100 crisp rating scale. Ratings are converted into satisfactory, dissatisfactory, and uncertainty degrees, and using those degrees, they are transformed into Pythagorean fuzzy numbers. Then, using the TOPSIS method, rank the alternatives based on those data sets. The pseudo-code of the proposed modem is as follows:

INPUT: DMs ratings on alternatives based on criteria | |

OUTPUT: Ranking the alternatives | |

COMPUTE: Satisfactory, dissatisfactory, uncertainty degrees and Pythagorean fuzzy numbers | |

INITIALIZE: 1–100 rating scale | |

OPERATION: Satisfactory, dissatisfactory, uncertainty degrees, PFN and TOPSIS | |

1. FOR Satisfactory, dissatisfactory, uncertainty degrees | |

2. NORMALAZATION convert input data to normalized crisp value | |

3. THEN find satisfactory and dissatisfactory degree using Eqs. (14) and (15) | |

4. AND based on satisfactory and dissatisfactory degree find uncertainty degreeusing Eq. (16) | |

5. END | |

6. CONVERT PFN | |

7. USE using satisfactory, dissatisfactory, uncertainty degrees on Eqs. (17)–(19) get true, falsity and indeterminacy degree respectively | |

8. END | |

9. BEGIN TOPSIS | |

10. FINDfind out the PIS and NIS based on beneficial and non-beneficial criteria | |

11. MEASURES calculate the distance between each alternative and PIS and NIS | |

12. COMPUTES determine the relative closeness value using Eq. (26) andrank alternativesbased on those value in ascending order | |

13. END TOPSIS |

Sustainable additive manufacturing design problem with Pythagorean fuzzy environment application

A crucial component of sustainable additive manufacturing (AM) design issues is uncertainty or fuzzyness. Utilizing procedures that minimize environmental effect, maximize resource consumption, and take into account social and economic sustainability constitutes sustainable additive manufacturing. In several contexts, such as material qualities and performance, process parameters and optimisation, life cycle assessment, design for environment, supply chain and resource availability, regulatory compliance and standards, etc., ambiguity or fuzziness plays an important role in the decision-making process that related to the design phase. This section describe the criteria and alternatives that have been selected of the problems model formulation with data collection from the DMs. Also, numerical simulation and result analysis are performed for validation.

Problem definition

A numerical example of material selection in a sustainable additive manufacturing design application is shown here to clarify and demonstrate the method proposed in the above section. The purpose is to select the best material that fits the triple bottom line requirements of sustainable addictive manufacturing in Fused Deposition Modeling (FDM) technology. FDM is known as a leading technology of industry 4.0 that characterized by its ability to build customized implants, advanced biomedical equipment, and sustainable engineering devices. FDM can be described as a production process that utilizes a movable machine's nozzle to extrude a polymer material's fibers layer by layer to organizational design. As well, FDM can be used in mechanical prototyping, design, and manufacturing. These techniques utilize in the melt evocation process to create designs from thermoplastic polymers. X–y nozzle position technology manages every layer's structure and sometimes differs or is optional for every layer. FDM methodology has created 3D scaffolds in composites and high-density polymers. In 3D printing, the material and fibers of thermoplastic care melt and are thrown down through the front of the nozzle. The criteria for material selection for sustainable additive manufacturing in FDM will be based on meeting the triple bottom line concept of sustainability, which include the material's environmental impact, its social implications, and its economic feasibility. Considering the guidelines for Design for Environment (DFE) and Design for Additive Manufacturing (DfAM) in setting the DM criteria. The hierarchical structure of this study is shown in Fig. 3.

Data collection

From two studies, Medellin-Castillo et al. [143] and Agrawal et al. [144] on FDM collected the initial data. Considered five criteria and four alternatives for evaluation are discussed later. Five decision-makers (DMs) give their opinion based on their knowledge and experiences. DM's weight assigned in these studies is based on their experiences and professionalism in the field. Thus, according to the studies, the selected criteria are c. The weights for the criteria are assigned to ensure the environment focus in the decision-making process. Based on reviewed literatures and studies [143, 144], the most popular material alternatives used in FDM are Polylactic Acid (PLA), Polycarbonates (PC), Acrylonitrile Butadiene Styrene (ABS), and Polypropylene (PP). A committee of decision-makers is formed for the evaluation process as follow: d1: Operation director, d2: Senior consultant, d3: Production manager, d4: Manufacturing engineer, and d5: Materials engineer. The committee members’ initial subset weights are assigned as \({d}_{1}=\) 0.8, \({d}_{2}=\) 0.4, \({d}_{3}=\) 0.4, \({d}_{4}=\) 0.2, and \({d}_{5}=\) 0.2. The primary weights of the DMs are assigned as \(\mu \left(\left\{{d}_{1}\right\}\right)=\) 0.8, \(\mu \left(\left\{{d}_{2}\right\}\right)=\) 0.4, \(\mu \left(\left\{{d}_{3}\right\}\right)=\) 0.4, \(\mu \left(\left\{{d}_{4}\right\}\right)=\) 0.2, and \(\mu \left(\left\{{d}_{5}\right\}\right)=\) 0.2. Figure 3 shows the hierarchical structure.

Each decision-maker assesses every criterion based on the material option by crisp data using a scale of 0 (being worst) to 100 (being best). Decision makers’ crisp information are displayed in Table 3.

Fit the model with proposed methodology

Data are normalized as shown in Table 4.

Satisfactory and dissatisfactory levels are measured and expressed as \(\left({o}_{kj}^{i}, {\xi }_{kj}^{i}\right)\) as displayed in Table 5. Decision-makers’ weights are calculated as the following:

The weighted average satisfactory value and dissatisfactory value are determined and the proposed uncertainty function is used to determine the level of hesitancy, as shown in Table 6.

Final aggregated PFNs are measured and a collective evaluation Pythagorean fuzzy multiple criteria group decision-making matrix is formed, as shown in Table 7.

Pythagorean fuzzy PIS \({x}^{+}\) and NIS \({x}^{-}\) are identified and the shortest distances between the alternative \({x}_{i}\) and the Pythagorean fuzzy PIS and the farest distances between the alternative \({x}_{i}\) and the Pythagorean fuzzy NIS are calculated, respectively. The revised coefficients are determined and materials’ alternatives are ranked as displayed in Table 8.

Solution and discussion

As seen in Table 8, ranked the material alternatives established on basis of the relative closeness coefficient results in descending order. Due to its best performance in meeting the target of the distance between the alternatives and minimum length of the PIS and the maximum length of the NIS, the corresponding adjustment is used instead of the corresponding coefficient. The ranking order of alternatives of the PF-MCGDM TOPSIS method is PC ≻ PP ≻ PLA ≻ ABS with PC, which is polycarbonate plastics, being the optimal material to be used in sustainable additive manufacturing and ABS, which is Acrylonitrile Butadiene Styrene, occur the worst alternative.

As shown in Fig. 4, the optimal alternative PC getting the closeness coefficient 0, recommended that PC has fulfilled the stipulation of having the nearest from the PIS and the farthest from the NIS at the similar time. The 2nd most favored alternative is PP with a revised − 0.54 relative closeness coefficient score. This result concludes that the variance among the coefficient of the preeminent material alternative PC and the 2nd best alternative PP is contemplate very small value (− 0.54), which indicates the material PP performance close to the best alternative PC. Finally, it also significant that there is no indicative differences in coefficients between 2nd last and last material alternatives PLA ≻ ABS; in individual, the difference among PLA and ABS is in total noticed, and this relative closeness coefficient shows that last two materials have almost same performances.

Remarks 6

Alternative polycarbonates (PC) get maximum score on the basis of relative closeness and become most popular material alternatives used in FDM. Then, polypropylene (PP) gets the second rank followed by Polylactic Acid (PLA). Whereas Acrylonitrile Butadiene Styrene (ABS) gets minimum score and least popular material as alternative used in FDM.

Remarks 7

Alternatives Polycarbonates (PC) and Polypropylene (PP) relative closeness score slight difference, so they are near to use. Similarly, Acrylonitrile Butadiene Styrene (ABS) and Polylactic Acid (PLA) are almost the same relative closeness score but are far from the first group of alternatives. Therefore, they are the least used advisees in this study.

Computational complexity

In this section, we compute the computational complexity of the proposed Pythagorean fuzzy MCGDM techniques. This is not a new concept [31, 32], but here we describe it based on this model. Time complexity is denoted by Tc and accomplished by calculating based on the total number of mathematical operations. Here, \(n\) number of criteria, \(m\) number of alternatives, and \(k\) number of the decision-makers (DMs) consider in this study. Then, the computational complexity is calculated by the following steps:

-

(a)

For finding the satisfactory, dissatisfactory and uncertainty degrees, \(mn\) entries with k DMs get \(kmn\) entries. Then, for normalized ,the decision matrix \(kmn\) operation conduct. Then calculate values by another \(kmn\) operation. Now, calculate satisfactory and dissatisfactory levels by another \(2kmn\) operation. \(3mn\) calculations computed the aggregated satisfactory, dissatisfactory, and uncertainty degrees. The total number of calculations conducted is \(kmn+kmn+2kmn+3mn=4kmn+3mn\).

-

(b)

For calculating the Pythagorean fuzzy number from \(3mn\) entries, another 3 mn operation is calculated. Then, finding score values of PFN, \(mn\) calculations are conducted. A total of \(3mn+mn= 4mn\) operation was conducted.

-

(c)

For the TOPSIS method, the weighted aggregated decision matrix has \(mn\) entries. Finding PIS and NIS, \(2n\) calculations are operating. Then find the relative closeness coefficient of each alternative with another \(2m\) operations. Finally, \(m\) operations give the total relative closeness coefficient. Total operations conduct is \(2n+2m+m=2n+3m\).

Then, the total number of operations or time complexity (Tc) of this study is \(4kmn+3mn+4mn+2n+3m=4kmn+7mn+3m+2n\).

Time complexity of this paper is calculated based on criteria number \(n=5\), alternative number \(m=4\) and number of DMs is \(k=5\) and calculated as follows:

-

(i)

For the satisfactory, dissatisfactory, and uncertainty degrees, \(4\times 5\times 4\times 5+3\times 4\times 5=400+60=460\) operation conducted.

-

(ii)

For calculating the Pythagorean fuzzy number, \(4\times 4\times 5=80\) calculation calculated.

-

(iii)

For the TOPSIS method, \(2\times 5+3\times 4=22\) operation calculated.

Then, the total number of operations or time complexity (Tc) is \(460+80+22=562\).

Sensitivity analysis and comparative study

In this section, a sensitivity analysis along with comparative analysis is conducted to check the systesms stability and unbiasedness.

Sensitivity analysis by changing the DMs weight

Finding the elements that are crucial for making a decision is something, we are sometimes quite interested in doing. We must conduct a sensitivity analysis to accomplish that. The accuracy of the final result may therefore be affected by initial criteria, parameters, data, and measures, so doing a sensitivity analysis will aid in identifying these factors. The goal of creating the proposed model in this study is to effectively collect decision-makers' clear viewpoints and incorporate them into the group decision-making process. Therefore, the conducted sensitivity analysis should evaluate how well the integrated MCGDM model responds to small changes in important input parameters, particularly the weights of decision-makers.

To do so, the initial decision-makers’ weights (fuzzy density value) are used in the previous case of section \(\mu (\{d\_1 \})=\) 0.8, \(\mu (\{d\_2 \})\)= 0.4, \(\mu (\{d\_3 \})\)= 0.4, \(\mu (\{d\_4 \})\)= 0.2, and \(\mu (\{d\_5 \})\)= 0.2 have been compared to the following scenarios:

-

(a)

Decreasing the first decision-maker (the most influential one) (DM1) weight of by 50% and 75%.

-

(b)

Increasing and decreasing the second decision-maker (DM2) weight by 50%.

-

(c)

Increasing and decreasing the third decision-maker (DM3) weight by 50%.

-

(d)

Increasing the fourth decision-maker (DM4) weight by 50%, 100% and 200%.

-

(e)

Increasing the fifth decision-maker (DM5) weight by 50%, 100% and 200%.

Figure 5 shows how the material option for this investigation has moved up and down in the ranking of alternatives after increasing DM1 weight by 50% and 75%. The material moved from the fourth position to the third position in the new ranking system as a result of the alternative ABS revised proximity coefficient score increasing in comparison to the other materials. The optimistic evaluation of the material alternative ABS by DM1 is what caused the relative closeness coefficient to grow.

When DM2 weight was reduced by 50%, the alternatives were ranked the same. However, when the DM2 weight was increased by 50%, the ranking order of the alternatives was altered, as shown in Fig. 6. The final order ranking of the third and fourth materials has been greatly impacted by the variation of the relative closeness coefficient of the alternatives. More specifically, the positions of the alternatives ABS and PLA have been switched from their initial rankings. As a result, it was clear how changing the weight of DM2 had an impact on the ABS alternative, since it led to a modest increase in the material's re-evaluate closeness coefficient value shift from (− 4.3329) to (− 4.1300), which allowed ABS to outrank PLA in the ranking process.

By raising DM3 weight by 50%, no significant ranking changes are seen. Similar to this, alternative rankings hold true even after a 50% reduction in DM3 weight. The ranking options cannot be significantly impacted by changing the weight of DM3. As can be seen in Fig. 7, the alternative ABS's relative proximity coefficient increases, while the alternative PLA's decreases, and they switch places after increasing the DM4's weight by 50%, 100%, and 200%. The high evaluation of DM4 to the alternative ABS is the cause of this unanticipated rise in the ABS relative proximity coefficient. The ranking of the options will therefore be affected by any adjustment to the DM4 weight.

After raising the DM5's weight by 50% and 100%, there was no discernible difference in the ranking options. However, after increasing the weight of the same decision-maker by 200%, as shown in Fig. 8, there has been a noticeable difference in the alternative ranking of material traits. Particularly, PC has been replaced as the preferred option with the material alternative PP. Additionally, various PPs have increased the Pythagorean fuzzy acceptable numbers and decreased the Pythagorean fuzzy dissatisfactory numbers to their values as a result of the progressive increase in the weight of DM5. As a result, this caused the PP revised coefficient to gradually rise until it took the first spot in the final ranking order. Additionally, the PC's relative proximity coefficient dropped to (− 0.0082) when the weight of the DM5 was increased by up to 200%, demoting PC from first to second place.

A summary of the sensitivity analysis results is displayed in Table 9. Changing the weight of the DMs and the corresponding exchange of the alternate ranking are briefly shown in this table.

Remarks 8

We perform sensitivity analysis to assess the stability of our ranking methodology and outcome. The effects of altering the weight of the decision-makers are provided. This demonstrates how adaptable the procedures are to DMs weight and the objectivity of the outcome.

Sensitivity analysis by changing the criteria weight

In this section, a sensitivity analysis is conducted by removing the wegiht of some criteria (setting its weight to 0) and check the system’s stability and robustness. As well, the analysis can show the level of accuracy of the orginal decision-making outcomes. To conduct the analysis, four scenarios have been proposed as follows:

-

(a)

Removing the weight of the criterion Part Cost \(({C}_{1})\)

-

(b)

Removing the weight of the criterion Energy Consume \(({C}_{2})\)

-

(c)

Removing the weight of the criterion Environmental Resist \(({C}_{3})\)

-

(d)

Removing the weight of the criterion Quality \(({C}_{5})\).

All four cases provides the same results as shown in Table 10 and compared with the original ranking result. In this analysis, Polycarbonates (PC) has been ranked as 1st, Polypropylene (PP) as 2nd, and Acrylonitrile Butadiene Styrene (ABS) and Polylactic Acid (PLA) have been placed as 3rd and 4th, respectively. The graphical representation of the sensitivity analysis results compared with the original ranking is depicted in Fig. 9.

Remarks 9

In this sensitivity analysis, we consider four scinarios by removeing the entire weight of each selected criterion in each scinario. The criteria that have been selected for testing are Part Cost \(({C}_{1})\), Energy Consume \(({C}_{2})\), Environmental Resist \(({C}_{3})\), and Quality \(({C}_{5})\). All four cases have been given the same results as shown in Table 10. Figure 9 illustrates a geometric diagram of comparative ranking analysis based on the original ranking and after removing criteria weight ranking. The results shows robustness and flexibility of the main original ranking outcomes.

Comparative analysis

We perform a comparison analysis to verify the consistency of the outcome and the objectivity of the technique. Instead of using the PFN in this case, we examine an intuitionistic fuzzy number (IFN) and employ the suggested MCGDM method. After receiving the outcome, we visually display the variations in the relative rankings of the alternatives.

Remarks 10

In the comparative analysis, we consider the Intuitionistic fuzzy number (IFN) and use the TOPSIS MCDM methodology. Table 11 gives the ranking of alternatives using IFN and PFN. Also, Fig. 10 shows the alternatives ranking stability.

Remarks 11

Table 11 and Fig. 10 show that alternative PC and PP are the same ranks as before. However, alternative ABS becomes the third priority, and PLA becomes the fourth. We conclude from the above analysis that our proposed MCGDM model is robust and unbiased.

Conclusion, limitations, and future research scope

Using the MCGDM approach to resolve actual group decision-making issues has been successful in numerous sectors. Engineers and designers can apply the new hybrid MCGDM approach presented in this study to solve team decision-making issues in engineering and manufacturing. The innovative aspect of the proposal is the creation of a brand-new aggregation technique that combines the final judgments of the DMs into a PFN-based joint decision-making application for the MCGDM problem. To compute the hesitation levels in decision-makers' information, a paired function based on the Takgai–Sugeno method and fuzzy inference rules has also been presented. To rank the final choices, a novel hybrid MCGDM methodology has been provided by incorporating the aggregation strategy into PF-TOPSIS in accordance with the recommended integrated approach.

The usefulness of the suggested hybrid MCGDM PF-TOPSIS methodology in engineering applications was further demonstrated using a realistic group decision-making challenge for sustainable additive manufacturing design. Additionally, a sensitivity analysis was carried out to compile the decision-makers' views and assess the suggested strategy's effectiveness. Results demonstrated that the suggested methodology successfully produced PFNs that accurately reflect decision-makers' knowledge for group decision-making challenges. Additionally, sensitivity analysis revealed that the aggregation strategy was particularly adaptable to shifting factors pertaining to decision-makers' weights and priorities. This shows that this method is efficient at gathering information from decision-makers and is thus a useful tool for actual group decision-making applications.

The directions for future research

This study addresses the material selection process in a sustainable additive manufacturing design application, wherein various materials are evaluated as alternatives based on different criteria. The process of identifying relevant alternatives and criteria has been perfromed by experts consultation and directed by a thorough literature review. The proposed hybrid MCGDM PF-TOPSIS methodologies may be expanded to include logistics, project management, healthcare, finance, and facility placements. Additionally, the aggregation strategy for MCGDM can be improved to encompass both subjective and objective data, and the findings can be validated by comparing it to other aggregation approaches. Different MCGDM methodologies can be applied for determining criteria weight and alternative selection. In future studies, other uncertainty like, intuitionistic fuzzy set, interval-valued fuzzy set, and neutrosophic set can be considered. As well, different related sub criteria can be taken for every criteria to get more appropriate result.

This article may helpful to decision experts, industrialists, and engineers who work on AM projects with various uncertain environments. The results of this paper should be encouraged and applied to more realistic tools and methodologies for materials selection with accurate applicable outcomes.

Data availability

In the manuscript already mentioned the used data. Additionally, the sources of the data are clearly explicit.

Abbreviations

- ABS:

-

Acrylonitrile butadiene styrene

- AHP:

-

Analytic hierarchy process

- AM:

-

Additive manufacturing

- BWM:

-

Best–worst method

- COVID-19:

-

COronaVIrus Disease of 2019

- CPEC:

-

China–Pakistan Economic Corridor

- CRITIC:

-

CRiteria importance through intercriteria correlation

- DM:

-

Decision-making

- DfAM:

-

Design for additive manufacturing

- DFE:

-

Design for environment

- ECMPRO:

-

Environmentally conscious manufacturing and product recovery

- EDAS:

-

Evaluation based on distance from average solution

- ELECTRE:

-

ÉLimination Et Choix Traduisant la REalité (Elimination and Choice Translating Reality)

- FDM:

-

Fused deposition modeling

- FN:

-

Fuzzy number

- FPFLPP:

-

Fully Pythagorean fuzzy linear programming problems

- GDM:

-

Group decision-making

- GRA:

-

Grey relational analysis

- IEM:

-

Information entropy method

- IFN:

-

Intuitionistic fuzzy number

- IVIFN:

-

Interval-valued intuitionistic fuzzy number

- IVPF-WDBA:

-

Interval-valued pythagorean fuzzy-weighted distance based approximation

- I-IVPFHA:

-

Interval-valued Pythagorean fuzzy hybrid averaging operator

- I-IVPFOWA:

-

Interval-valued Pythagorean fuzzy ordered weighted averaging operator

- MCDM:

-

Multiple criteria decision-making

- MCGDM:

-

Multiple criteria group decision-making

- MOORA:

-

Multi-objective optimization on basis of ratio analysis

- NIS:

-

Negative ideal solution

- PC:

-

Polycarbonates

- PFHSIWA:

-

Pythagorean fuzzy hypersoft interaction weighted average

- PFMCDM:

-

Pythagorean fuzzy multiple criteria decision-making

- PFN:

-

Pythagorean fuzzy number

- PFS:

-

Pythagorean fuzzy set

- PFSTP:

-

Pythagorean fuzzy species transportation problem

- PF-TOPSIS:

-

Pythagorean fuzzy-technique for order performance by similarity to ideal solution

- PIS:

-

Positive ideal solution

- PIV:

-

Proximity indexed value

- PLA:

-

Polylactic acid

- PP:

-

Polypropylene

- PROMETHEE:

-

Preference ranking organization method for enrichment evaluation

- QUALIFLEX:

-

QUALItative FLEXible multiple criteria method

- SAW:

-

Simple additive weighting

- TC:

-

Time complexity

- TODIM:

-

Tomada de decisao interativa e multicritévio

- TOPSIS:

-

Technique for order performance by similarity to ideal solution

- VIKOR:

-

VIekriterijumsko KOmpromisno Rangiranje

- \({\mathbb{R}}\) :

-

Set of real numbers

References

Herrera F, Herrera-Viedma E, Verdegay JL (1996) Direct approach processes in group decision-making using linguistic OWA operators. Fuzzy Sets Syst 79:175–190. https://doi.org/10.1016/0165-0114(95)00162-X

Zadeh LA (1965) Fuzzy sets. Inf Control 8:338–353. https://doi.org/10.1016/S0019-9958(65)90241-X

Atanassov KT (1986) Intuitionistic fuzzy sets. Fuzzy Sets Syst 20:87–96. https://doi.org/10.1016/S0165-0114(86)80034-3

Hashemi SS, Hajiagha SHR, Zavadskas EK, Mahdiraji HA (2016) Multicriteria group decision-making with ELECTRE III method based on interval-valued intuitionistic fuzzy information. Appl Math Model 40:1554–1564. https://doi.org/10.1016/j.apm.2015.08.011

An X, Wang Z, Li H, Ding J (2018) Project delivery system selection with interval-valued intuitionistic fuzzy set group decision-making method. Gr Decis Negot 27:689–707. https://doi.org/10.1007/s10726-018-9581-y