Abstract

The loss of materials due to corrosion is inevitable and has gained significant attention at various stages in the process industries, including petroleum, food processing units, and tanneries. With significant detrimental effects occurring as a result of microbial activity, the research on microbial corrosion and methods to keep them under control has become essential. About 10% of the corrosion affliction to metals and non-metals is due to microbial activity. The Microbiologically Influenced Corrosion (MIC) is a consequence of the contact, which are synergetic between bacteria and metals. A typical marine electroactive bacterium shown to produce severe MIC is Pseudomonas aeruginosa. In the maritime environment, Pseudomonas aeruginosa is a bacteria that is extremely corrosive to stainless steel. However, little is known about how P. aeruginosa causes corrosion on stainless steel. Stainless steel is a beneficial material that has been employed in various applications due to its corrosion-resistant properties and mechanical strength. The property of stainless steel to strongly resist corrosion is owed to the presence of chromium in its composition. The chromium forms a passive film of chromium-rich oxide in aerobic conditions at low temperatures, which protects it from the surroundings. This layer can be harmed by harsh weather conditions. The microbial activity and their existence can modify the inorganic passive layers, raising their dissolution levels and detaching them from the surface of the metal. The review aims to study steel corrosion as a result of microbial activity. The explicated methodologies are more significant within the broader context of metal–microbe interactions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

MIC was first found more than 100 years ago. People are more conscious about this type of corrosion for the past 10 years [1]. Microbiologically influenced corrosion has been a crucial type of corrosion in a number of industrial processes, including pipeline and storage transportation, gas and oil production, raw or treated wastewater production, and power generation. MIC is the root cause of several negative effects, which can cause reservoir souring, and damage of pipeline and equipment due to corrosion, which further lead to environmental and ecological mutilation [2]. Microbes can mutilate a wide spectrum of metals like iron-based ones—steel, stainless steel, aluminum, magnesium, nickel alloys, copper, and titanium [3]. The aerobic P. aeruginosa is widely recognized as the first colonizer in the biofilm development process. Sulfate-reducing bacteria (SRB) can survive in oxygen-free zones created by them, resulting in the formation of oxygen concentration cells [4]. The production of biofilms on the surface of metallic objects that can corrode metals typically used in the sea, including stainless steel, duplex stainless steel, and even super duplex stainless steel, is thought to be facilitated by Pseudomonas aeruginosa [5]. A new copper-containing 2205 duplex stainless steel was discovered by Xia et al. to be able to prevent the development of corrosive P. aeruginosa biofilm, easing marine corrosion [6]. P. aeruginosa-induced corrosion on high-strength EH40 steel was extensively studied in simulated tidal and full-immersion zones [7]. Steel continues to stay as a supporting pillar of almost all industries owing to its recyclable nature, economic viability, constructability features like affordability, durability, and sustainability. Biocorrosion poses a major hindrance in galvanized steel and articles [8]. Stainless steel has good capability to resist corrosion due to chromium, nickel, and molybdenum present in its composition. Its competence to resist corrosion is because of the formation of a thin chromium oxide passive layer that adheres strongly to the surface. However, passive layers are also subjected to localized corrosion when kept close to chlorides and reduced Sulfur compounds [9]. Nevertheless, stainless is inadequate for MIC when kept in an aqueous environment. Passivation is the term used to describe the production of solid oxide on the surface of stainless steel to prevent corrosion. The passivated surface is a perfect spot for microbial accumulation, and hence, this layer is vulnerable to corrosion, which appears in the form of cracks under pressure or solutions composed of chlorides [10]. The oxide passive layer that emerged while the naked alloy was in the presence of an oxidizing medium plays a vital role in determining the surface properties of Stainless Steel (SS). Passivity is a phenomenon caused by the thermodynamic instability of the metal urges it to get covered by a film oxide which insulate the metal from the medium. A very thin layer having dimensions in nanometers is formed by anodic dissolution. The passive film of SS has the ability to adapt to physicochemical changes (potential, pH, ionic strength) which make it resistant to corrosion in a broad range of aqueous media [11]. Microbial microorganisms’ activity, when attached to the surface of the metal, even holds the power to damage the passive layer by inhibiting its formation or changing the rate of redox reaction at the anode or cathode terminal [12]. MIC can occur for various metals and alloys, which includes high-quality SS. 304L SS has been utilized in many environments. This metal, however, does not resist corrosion efficiently [13]. SS and duplex steel are strongly affected by MIC and pitting. The corrosion behavior in materials is different due to the difference in the adherence of the bacteria on the surface, as metals have diverse surface properties and alloy materials [14]. Other than structural damage, biocorrosion is also responsible for the deterioration of the strength of the materials by infiltration into metal matrixes, which, in a few cases, change the flow patterns by forming tubercles. The tubercles reduce the flow path. In critical appliances like nuclear reactors, where the distribution of cooling is of primordial importance, these blockages compromise safety conditions. In addition to damaging mechanical strength, MIC consumes energy in heat reactors [15]. The oil and gas components negatively affected by MIC are pipelines, separators, tanks, separators, pumps, filters, sales gas, heat exchangers, source water, filters, and the reservoir [16]. MIC has raised concerns in the aquatic and maritime industries as 20–30% of corrosion is caused by microbial activity, leading to a loss of 30–50 billion dollars per annum worldwide [13]. Biocorrosion is one of the most widespread causes of system failure in industrial processes and requires vast maintenance. Corrosion triggers major issues on metal processes like pipes, conduits, and process machinery [17]. MIC is a significant factor in the internal corrosion of gas pipelines, which causes leaks and explosions at offshore platforms in the Gulf of Mexico [18]. A notable incident involved a large oil leak and environmental damage in Alaska that released more than 950 cubic meters of crude oil [19]. In 2009, a 25.5-km-long underground pipeline in the Arab region meant to transport light-grade crude oil collapsed after 3 years of usage due to internal surface corrosion brought on by microbes, which developed several pinholes within a month [20]. A study investigated how carbon steel corrodes when Pseudomonas and Vibrio are present. For corrosion characterization, untreated, sterilized natural saltwater was used since it is more akin to the environment as it is in the wild. According to the SEM results, coupons subjected to sterilized natural seawater infected with a mixture of Pseudomonas and Vibrio exhibit more severe pitting corrosion [21]. According to Morales et al., pitting corrosion may be brought on by differential aeration cells or metal ion concentration cells created by the heterogeneous Pseudomonas aeruginosa biofilm grown on the metal surface [22]. The MIC behavior of 2707 HDSS caused by Pseudomonas aeruginosa, a marine aerobe was investigated. When P. aeruginosa biofilm was present in the 2216E medium, electrochemical tests revealed a shift in favor of corrosion potential and an increase in corrosion current density [23]. Electrochemical and surface investigations examined the microbiologically influenced corrosion (MIC) of 2205 duplex stainless steel (DSS) in Pseudomonas aeruginosa’s presence. According to the electrochemical findings, P. aeruginosa drastically decreased 2205 DSS’s corrosion resistance [24]. This review emphasizes MIC by P. aeruginosa in stainless steel. The review also focuses on mitigation strategies for P. aeruginosa-induced corrosion. The negative effects of MIC in different industries are also reviewed.

2 Economics

Economic, safety, and environmental considerations are the three main factors that determine how vital corrosion is. By reducing material and economic losses, the economic anguish can be lessened. Corrosion of turbine blades, bridges, pressure vessels, automotive steering mechanisms, boilers, airplane components, and metallic containers for toxic chemicals are some of the examples that might cause catastrophic incidents. Thus, safety while designing equipment is a must. There has to be additional investment in metal, energy, water, and human to compensate for the loss of metals by corrosion and to reconstruct the material [25]. There has not been much data released on MIC control, and prevention is also less, but, a general estimation says that 20–30% of the failures are caused by microbial activity [26]. MIC is responsible for 20% of metal corrosion [27]. A severe industrial issue, microbiologically influenced corrosion (MIC) of metals costs the global economy between $300 and 500 billion annually [28]. Data show that it costs more than 100 million dollars per year to repair the harm done by MIC to the gas and oil industry in the US. Thus, corrosion can cause massive inconvenience to the economy across the globe. The Cost of Corrosion (CoC) can be divided into two categories (i) direct costs and (ii) indirect costs. The direct costs consist mostly of capital costs (e.g., machinery, replacement of buildings, installations) and design and control costs (e.g., materials selection, repair maintenance, control agents, acid cleaning, corrosion allowances). At the same time, depreciation and interest losses, including product and production loss, insurance, additional reserves, and technical support, are the primary indirect costs. Millions of domestic hot water tanks and corroded automobile mufflers must be replaced every year due to corrosion. This itself depicts the impact of direct losses. A very current survey says that the CoC for people residing in US is 970 USD per year [29]. Jack et al., [30] made a calculation where he learnt that microorganisms in the oil company cause 34% of the corrosion harm. Back in the 1950s, the expenditure for repairing and replacing piping material for various services in U.S.A. for MIC accounted for 0.5–2 billion per year. Moreover, 250 million euros annually is spent in the U.K. to replace bio-corroded gas mains [31].

3 Steel in Different Industries

Engineering applications utilize a broad variety of stainless steel and corrosion-resistant alloys [32]. The 11% chromium that goes into the composition of SS makes it a corrosion-resistant and durable material that can be used for water treatment plants such as valves, equipment, and delivery pipes. Still, it is subjected to corrosion by the physicochemical reaction between the SS and the environment [33]. Because of its ability to withstand corrosion, it can be used for various tasks including contact with biological substances or solutions. They are used in the food industry and in the manufacture of guide wires, vascular stents, or other orthopedic implants [34]. A molybdenum bearing austenitic steel has outstanding corrosion resistance [35]. The alloy of SS contains Cr, which makes SS-316L a self-passivated compound. The SS, when exposed to a corrosive and oxidizing environment, a layer of Cr oxide is formed. Since, mild steel has 0.05–0.25% of carbon, it is highly malleable and ductile [36]. Duplex Stainless Steel (DSSs) is a stainless steel with great mechanical properties and high resistance to corrosion properties of austenitic and ferritic phases. Hence, it is used in industrial applications [37]. SS in marine engineering, medical devices, and cooling water systems make it a very important material [38]. Stainless steel’s biocompatibility advances its use in dental implants and orthopedic. S32654 SASS has found its usage in some extremely corrosive environments such as desalination systems, pharmaceutical plants, chemical processing equipment, flue gas desulfurization systems, and pulp bleaching plants [39]. In the nuclear sector, SS 316 L is primarily utilized to create both the inside and outside reactor pressure vessels at a lower cost, time, and supply chain, even employed during the plant’s planned refueling outage [40]. Dental magnetic attachments are made of ferric or austenitic SS, which are brought in contact with root caps made of different dental metals in oral cavity [41]. It was in the 1930s that the world witnessed the orthodontic to be made of austenitic SS, before which it was made of gold. Austenitic SS has its superior strength, good resistance to corrosion, higher modulus of elasticity, and moderate costs, more strength, good resistance to corrosion, and moderate costs. American Iron and Steel Institute type 304 is the most widely used SS alloy for orthodontic wires containing 18–20% of chromium and 8–10% of nickel. SS wires have good biocompatibility, good corrosion resistance, excellent formability, high modulus of elasticity, and high yield strength [42].

4 Microbiologically Influenced Corrosion (MIC)

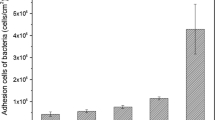

MIC are of two types: (i) Chemical MIC (CMIC), where the metal is indirectly affected when microbes produce substances and corrode it, (ii) electrical MIC (EMIC), which triggers direct corrosion by the consumption of electrons from metals. EMIC grabs more attention due to extracellular electron transfer (EET). Because microorganisms having EET properties, corrode materials faster than non-EET ones [43]. Biodeterioration, biocorrosion, or microbiologically influenced is a phenomenon in which microbes initiate the metal deterioration directly or indirectly. MIC is the root cause of 10% of all metal corrosion [44]. Biocorrosion is the methodical interaction between metal surfaces with metabolites and inherently thriving corrosive species. An electron is transferred from the metal to the external acceptor after which metal ions and the metal are exchanged with the circumfusing environment [45]. A metal surface, abiotic corrosion agents, and bacterial metabolites work together to cause biocorrosion [46]. If the concentrations of microbial products on the surface of the metal are allowed to accelerate, their corrosive action increases as the microbes might continue to proliferate on the surface of the biofilm [47]. The main variables that determine the degree of corrosion on a metal surface are the partial pressure of carbon dioxide, pH, temperature, and the makeup of biofilms [48]. Anaerobic corrosion is a chemical process [49]. Anaerobic corrosion is typically associated with the activities of sulfate-reducing bacteria, whereas aerobic corrosion is a chemical process (SRB). According to Zuo’s 2007 research, a combination of aerobic and anaerobic bacteria is typically present and may contribute to metal corrosion. Sulfur oxidizers (SOB) and iron-oxidizing bacteria comprise most of the aerobic bacteria participating in this process [50]. Figure 1 depicts the metal corrosion due to MIC.

5 Aerobic Corrosion

Corrosion on steel can occur in either the presence or absence of oxygen. If a metal has been thickly layered by an aerobic biofilm, O2 is not able to directly interact with the metal. In such cases, the sessile cells that are close to the metal surface utilize extracellular electron transfer (EET) for O2 respiration in the cytoplasm, resulting in MIC. When Pseudomonas aeruginosa covers stainless steel by forming a film over it, pitting corrosion takes place on the anodic sites by damaging the passive film by electrons that were produced by the biofilm with the help of EET through semi-conductive passive film (biocathodic sites) elsewhere [51]. An essential component of stainless steel’s passivation layer, Cr (III) oxide, was converted to Cr6+ by extracellular hydrogen peroxide generation in response to P. aeruginosa release of reduced phenazine. This made the stainless steel more susceptible to corrosion [52].

The formation of different Fe (III) oxides, oxyhydroxides regulate the corrosion action in the presence of oxygen. Goethite (a-FeOOH), maghemite (c-Fe2O3), Lepidocrocite (c-FeOOH), and hematite (a-Fe2O3) are mostly the probable formations [53]. Aerobic bacteria cause rapid pitting or corrosion underneath the biofilm [54].

Aerobic corrosion on steel can be represented by the following Eq. (1):

While in the aerobic phase, the oxygen in air is reduced to OH ions on the surface of the metal and Fe is oxidized to Fe+2. These ferrous ions further react with the dissolved oxygen to form lepidocrocite c-FeOOH compound as shown in Eq. (2).

Once the c-FeOOH completely covers the surface of the metal, the reaction slows down for 2 reasons. First, the surface of "reactive" iron depletes, and oxygen diffusion decreases due to the covering of c-FeOOH. When oxygen concentration becomes considerably low (discontinuous aerobic system), c-FeOOH combines with Fe2+ ions in aqueous phase to form magnetite layer as in Eq. (3).

Therefore, c-FeOOH acts as an oxidant toward iron like that of oxygen. Maghemite is created in continuous aerobic systems with high oxygen concentrations by dehydrating lepidocrocite after Eq. (4) reaction and/or oxidizing minute amounts of magnetite, Fe3O4 [55].

IOB can potentially deposit iron hydroxides extracellularly in an aerobic condition [56, 57]. It was demonstrated that metal dissolution and localized corrosion are enhanced because the rate of oxidation from ferrous to ferric is faster than the chemical oxidation reaction [58].

By using a process known as an oxygen concentration or differential aeration cell, aerobic biofilms can also cause MIC, which occurs when aerobic biofilms colonize unevenly or irregularly. Because of the microbial activity, the area beneath the biofilm will become an anode, and the portions that have not been colonized will serve as cathodes because they are exposed to the most oxygen, which creates a potential differential that can cause corrosion at the cathode and metal oxidation and dissolution at the anode due to oxygen reduction [59].

6 Anaerobic Corrosion

Based on the two metabolic functions of the anaerobic bacteria—respiration and fermentation—the microbial corrosion brought on by anaerobic germs is divided into type I and type II. Microbial respiration, which includes electron transport stages, leads to type I microbial corrosion. Corrosive metabolites produced by anaerobic microbial activity are the cause of type II microbial corrosion [60]. Type I is also referred to as extracellular electron transfer MIC (EET-MIC), which is brought on by microorganisms’ respiration and Type II is known as metabolite MIC (M-MIC), which is brought on by the release of corrosive metabolites [61]. Sessile cells in EET-MIC use electrons from extracellular iron oxidation by EET to reduce sulfate, which generates energy. The amount of energy required for sessile cells to survive is the only limit for EET-MIC. The energy does not go to planktonic cells. As a result, MIC’s reach is quite restricted. This is not the case for M-MIC, though [62]. Between their exterior cell membranes and extracellular solid (i.e., insoluble) objects like electrodes and minerals, electroactive bacteria are able to collect or donate electrons. Extracellular electron transfer (EET) is accomplished by a network of electroactive proteins and occasionally with the aid of electron mediators [63]. Figure 2 illustrates the mechanism of Microbiologically influenced corrosion in oxygen-free environments. Microbiologically influenced corrosion (MIC) by electroactive microbes and the extracellular electron transfer (EET) process are similar. Therefore, it is known as EET-MIC. The anaerobic microorganisms procure electrons from extracellular oxidation of insoluble energetic metal matrix by EET to maintain their energy balance inside the cytoplasm through intracellular reduction of oxidants like sulfate and nitrate [64]. There is no need for EET when an electron donor, such as organic carbon, enters the cytoplasm of a microbe to be oxidized because both oxidation and reduction reactions occur inside the cell. When the electron donor releases the electrons extracellularly, as in the case of Fe (0) corrosion, EET is necessary. Some microorganisms have been known to use insoluble minerals as Fe (0) as electron donors or energy sources. In EET-MIC, a biofilm on a metal surface can serve as a biocathode [65]. Microbes that utilize respiration metabolism cause anaerobic MIC. The process involves the transportation of electrons from metal oxidation reaction crossing the cell wall, landing on the cytoplasm to reduce non-oxygen oxidant (sulfate, nitrate) with enzyme catalysis. This is supported by their electron transport chain [66].

Mechanism of Microbiologically influenced corrosion in oxygen-free environments [59]

MIC can be categorized into two broad categories. In the first type of MIC, exogenous non-oxygen oxidants such as nitrate, sulfate, and CO2 serve as the terminal electron acceptor. Sessile cells situated below the biofilm are unable to access the organic carbon molecules in the bulk liquid due to the biofilm's diffusional barrier and the top layer cells' consumption. These sessile cells are compelled to convert to elemental iron as the electron donor. Because elemental iron is insoluble, biofilms must transmit electrons from extracellular elemental iron oxidation over the cell wall to the bacterial cytoplasm to reduce an oxidant under biocatalysis. Planktonic cells cannot execute this sort of MIC, which is EET-MIC, directly because they are surrounded by water and cannot transmit extracellular electrons produced by a steel surface owing to iron oxidation. Corrosive metabolites released by microorganisms, such as organic acids and proton, generate the second form of MIC. These oxidants are also reduced such as via proton reduction is even electrochemical. Metabolite MIC (M-MIC) is the name for this kind of MIC. Due to the local release of organic acids, the pH beneath a biofilm may be significantly more acidic than that of the bulk culture medium. Without biocatalysis, protons can destroy iron extracellularly [67]. A complex biofilm must form for populations of corrosive anaerobic bacteria to flourish. Aerobic cells that are respiring in the higher layers must eliminate surface oxygen. Although the anaerobic population of Vibro sp. DW1 most likely created corrosive conditions at the metal surface due to the oxygen loss, this would not have been the main effect as the bacterial layer under anaerobic conditions did not result in corrosion. It is possible that the dense DW1 suspension served as a source of nutrient that the anaerobic population could use. Since the majority of heterotrophic bacteria produce organic acids during fermentation that might oxidize metal, these processes would be of secondary consequence in our systems because the pH of the bulk was neutral [68]. Steel corrodes, releasing hydrogen into water as it disperses. The environment is altered by raising the hydrogen pressure, which in turn alters the corrosion rate [55]. Information on the anaerobic corrosion rate of carbon steel and the associated hydrogen production rate under typical conditions is crucial for safety evaluation purposes. Equations (5), (6) overall reaction results from the anaerobic corrosion of iron to liberate hydrogen [69]:

OR

7 The Ill Effects of MIC in Various Industries

Additionally, other industries, including nuclear power plants and the majority of hydropower applications, are affected by microbial corrosion. Expanding microbial corrosion is also a result of increased corporate infrastructure [70]. The most important factors in choosing metals and alloys for biomedical applications are good corrosion and wear resistance, sufficient mechanical qualities, adequate biocompatibility, and logical cost. Stainless steel is a common biocompatible and corrosion-resistant metal (SS) [71]. Localized corrosion of steel happens in the maritime environment due to the influence of bacteria, a universal phenomenon known as MIC [72]. Marine assets suffer severe economic losses as a result of MIC. In actuality, MIC has been identified as the primary factor in a number of mishaps and failures. The Alaska pipeline breach in 2006 resulted in a significant increase in global crude oil prices. The only surviving suspect in this leak was MIC [73]. The built environment can be significantly impacted by microbial colonization, which can have various consequences, including coloration and staining, bio corrosion, and biodeterioration of metallic, organic, and inorganic components. This can raise major issues for physical infrastructure, such as nuclear waste storage facilities, oil storage tanks, and sewage systems, as well as for human dwellings and cultural artifacts. Structures made of rocks, minerals, and metals can be significantly impacted by the development of various organisms, such as bacteria, lichens, and fungi [74].

Microorganisms found in raw materials, equipment, the environment, people working there, and water are the main causes of microbiological contamination in the food industry [75]. Microorganisms that are initially suspended in liquid or air can approach solid surfaces through several mechanisms [76, 77]. The two most frequent methods by which microorganisms come in contact with a surface are (i) sedimentation, which occurs solely as a result of gravity and is the main mechanism in storage or fermentation vats, and (ii) the turbulence of the suspension liquid, which is frequently observed in the extensive pipeline systems found in the food industry, particularly the dairy industry [78].

8 Bacteria Involved with MIC

The unicellular prokaryotic organisms known as bacteria are the primary microbes responsible for biocorrosion. Because of their tiny size and higher surface-to-volume ratio than larger organisms, bacteria can quickly carry out chemical reactions. Bacteria utilize simpler products created via the metabolism of organic material to produce carbon (biomass). These metabolic processes alter the local environment, which leads to the material corroding [79]. The principal varieties of microorganisms connected to failures in metal corrosion are 1. Bacteria sulfate reducing bacteria; 2. Metal oxidizing bacteria; 3. Sulfur oxidizing bacteria; and 4. Fungi microalgae. By creating a slimy biofilm that worsens corrosion, facultative or aerobic populations like Pseudomonadaceae, Enterobacteriaceae, Micrococcaceae, and Bacillaceae all contribute equally to MIC [80]. Anaerobic sulfate bacteria (SRB) and anaerobic iron bacteria (IOB) are the two main types of microorganisms that are hypothesized to be involved in biocorrosion processes [81]. Sulfur oxidizers can promote corrosion by releasing aggressive metabolites like organic or inorganic acids (acetic, succinic, isobutyric, etc.). (sulfuric). Sulfuric acid, produced by Thiobacillus, is a highly corrosive substance that is particularly harmful to concrete structures because it causes steel to corrode and carbonates to dissolve. Corrosion is known to be facilitated by filamentous bacteria from the genera Sphaerotilus, Crenothrix, Leptothrix, Clonothrix, and Lieskeella, as well as iron-oxidizing bacteria from the genus Gallionella [82].

Reducing bacteria is a significant source of biocorrosion, with Pseudomonas and Shewanella being two of the most significant groups. These microorganisms weaken the passivation layers created or deposited on metals to prevent corrosion of the metal’s bulk. Most of the substrate becomes vulnerable to various corrosion mechanisms after the protective layer is lost, making this type of biocorrosion exceedingly challenging to manage. The substrate will typically erode extremely fast after a localized corrosion zone has formed and needs to be replaced [83]. Depositing bacteria are a different class of microorganisms that are important for this corrosion. They produce metal precipitate on the surface by oxidizing dissolved metal ions, as opposed to metal-reducing bacteria. Iron is a common example. A local cell will serve as a precipitate once a certain amount of metal has been deposited on a substrate, creating a corrosion zone. Examples of this type of bacteria include Leptothrix and Gallionella [84]. The Gram-negative aerobe Pseudomonas aeruginosa, which predominates in marine environments, has attracted interest because of its capacity to create biofilms on various metal and alloy surfaces, which accelerates corrosion rates [85].

9 Extracellular Polymeric Substances (EPS)

In biofilm systems, EPS, which are organic polymers of microbial origin, are frequently in charge of tying cells and other particulate materials to one another (cohesion) and to the substrate (adhesion). EPS’s role in the development of biofilm was first known in 1990. EPS can be described as the soluble EPS (such as soluble macromolecules, colloids, and slime) and the bound EPS (such as sheaths, condensed gels, loosely bound polymers, capsular polymers, and attached organic material) [86]. The creation of a biofilm depends on the production of extracellular polymeric substances (EPS), such as proteins and polysaccharides, which is also crucial for MIC [87]. By encouraging the ionization of the metal surface, the metal cations bound by EPS alter the electrochemical properties of the metal surface and produce metal ion concentration cells. The ability of bacterial EPS to chelate metal ions has been suggested in recent years as a major factor in metal MIC [88]. There is some controversy surrounding EPS's role in the biocorrosion process. Functional groups with fast metal-binding abilities are frequently seen in EPS. The concentration of metal ions from drinking water or the metal pipe surface in the biofilm increases corrosion rates by promoting cathodic reactions. It has been demonstrated that metal corrosion is accelerated by the weak electrostatic interactions between EPS and metal ions [89]. The interactions between the anionic groups of the protein and carbohydrate components and iron ions allow EPS to quickly bind the metal surface due to their functional groups [90]. EPS is essential for promoting cell adhesion to cast iron surfaces and the growth of biofilms. EPS is thought to be polymeric conglomerates mostly made up of lipids, proteins, and polysaccharides [91]. A diverse group of planktonic cell genes, including those involved in chemotaxis, motility, exopolysaccharide production, and stress response, appear necessary for biofilm formation [92].

10 Biofilm

Aluminum, stainless steel, copper, and other metals and alloys can all create biofilms, and their presence may lessen the antibacterial effects of metals like copper and zinc [93]. In the process sector, biofilm formation is a well-known phenomenon that can result in biological fouling, heat transfer losses, product quality drops, and microbiologically affected corrosion [94]. The composition of the biofilm may change over time and space, and the biggest variations are typically correlated with changes in the relative importance of autotrophic and heterotrophic microorganisms. Biofilms formed by the mutual interactions of microbial cells give rise to habitat-specific community niches [95]. The chemistry of the region immediately surrounding the surface will surely alter as a result of the growth of microbial biofilms on metal substrates. Such consequences could be immediate, where a particular microbial response or metabolic byproduct turns into a reactant in the electrochemical corrosion processes. However, indirect or non-specific effects may also be significant when the biofilm or its related polymer matrix alters the physicochemical conditions in which these reactions occur [96].

Electrolyte concentrations, pH, and dissolved oxygen levels alter in a highly localized manner due to microbial colonies growing on immersed metal surfaces [97]. Under specific circumstances, microorganisms can increase corrosion resistance and speed up the production of bacterial metabolites [98]. A microenvironment significantly different from the surrounding environment is generated after a bacterium forms a biofilm on a material's surface [99]. Additionally, they can deteriorate the surface on which they develop, weakening polymers and corroding metals through mineralization and corrosion [100]. Moreover, they may build up to the point where mechanical components are harmed structurally or functionally (biofouling) [101]. According on the hydrodynamic circumstances of the system, one of two primary forms of biofilm can develop. Biofilms are created by static circumstances and are found in water supply tanks and food industry tanks or vats. The bacteria in this kind of biofilm adhere by sedimenting in a nutritive media that may be refreshed often. In dynamic environments, biofilms tend to be thicker and are similar to those seen in pipeline systems for the food and water industries. It is widely accepted that biofilms thicken with age. In dynamic circumstances, the liquid’s flow velocity along the contaminated surface also affects the thickness of the biofilm [102].

The two extracellular electron transfer (EET) methods used in biofilm electrochemistry are called direct electron transfer (DET) and mediated electron transfer (MET). Direct metal-to-microorganism electron transfer, or electro-biocorrosion to put it simply, is corrosion in which an outer-surface electrical contact on the cell surface serves as the first electron acceptor for electrons originating from Fe0 [103]. While MET uses electron shuttles or mediators of electron transfer in the solution, DET depends on the presence of c-cytochrome molecules in contact with a metal surface or conductive nanowires linked to a metal surface. Electron carriers are electron transfer mediators because they take in electrons and release them at a different site. Flavins are frequently used as electron transfer mediators, including flavin adenine dinucleotide (FAD) and riboflavin. In a biofilm consortium, it is feasible for corrosives or non-corrosives to release electron transfer mediators to aid in the electron harvest for extracellular iron oxidation-based energy production; in comparison to a cooperative biofilm consortia, pure P.aeruginosa biofilm [104].

Phenazine-1-carboxamide (PCN) and pyocyanin (PYO) are known electron mediators used by P. aeruginosa for EET. Its MIC of 2205 duplex stainless steel was 99% lower when its phzH gene, which encodes the enzyme for converting phenazine-1-carboxylate (PCA) to PCN, was removed. The gene’s MIC ability was largely restored after it was reinserted [51]. P. aeruginosa secretes phenazine-1-carboxylate, pyocyanin (PYO), and phenazine-1-carboxamide (PCN). These electron mediators are biosynthesized by several genes (Fig. 3). When the genes were removed, P. aeruginosa lost its ability to corrode, but when the genes were added back or the electron mediators were added exogenously, P. aeruginosa regained its corrosivity, EET-MIC aptitude [63].

Illustration of mediated electron transfer—microbiologically influenced corrosion by Pseudomonas aeruginosa [63]

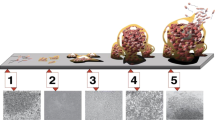

Water channels and densely packed cells make up the biofilm's two main parts. The antibacterial drugs (synthetic and natural), unfavorable circumstances, and the human immune system cannot affect the bacteria because of their structural rigidity and matrix composition. The extracellular matrix's presence of Extracellular Polymeric Substance (EPS) shields the bacteria from environmental stressors and enables the entry of minerals and other essentials [105]. Even though it has been proven that biofilms produced in seawater are helpful in catalyzing the reduction of oxygen in stainless steels and other materials, the mechanisms are still up for debate. Several theories have been put forth, one of which is the direct catalysis of adsorbed enzymes like catalase [106]. The sessile microbial community uses biofilms to survive in unfavorable conditions. Individual bacterial species cannot conduct the combined metabolic activities that synergistic microcolonies of the microorganisms present in the biofilm's matrix use to exist in harmony. Surfaces exposed to water attract biofilm bacteria, which spreads and results in microfouling phenomena, material degradation, and microbiologically influenced corrosion [107]. Microbial biofilms are widely known for causing MIC pitting. Microorganisms use biofilm development as a defensive and survival tactic to withstand and receive the energy they need for their metabolism in various environments and situations. According to a study, under famine conditions, sessile bacteria can absorb electrons from energetic materials and transmit them to the final electron acceptor, causing pitting corrosion on the surfaces of the materials [108]. The different stages of the formation of biofilm are depicted in Fig. 4.

Schematic representation of the stages of biofilm formation [109]

There have been several attempts to stop biofilm production, but, as of now, no known methods can stop or properly control the formation of biofilms without having other unintended consequences. Up until now, cleaning and sanitizing the pipelines regularly has been the most effective method of preventing the development of these bacterial accumulations. Utilizing pipe coatings with antimicrobial chemicals is another option [110]. The solid–water interface is more favorable to the growth of some species than the surrounding bulk liquid because of the nutrients that have been adsorbed on the solid surface. The resulting biofilm may then function as an impermeable deposit and a limiting barrier to ion transport, which may lessen the corrosion’s aggressiveness. The quality and chemical makeup of the metabolites that bacteria create may also be influenced by the nutritional status and the biology of the bacterium [111]. According to Hernandez et al. (1994), bacterial adhesion was required for corrosion inhibition; when in situ cells were fixed in glutaraldehyde, the inhibitory effect disappeared; when cell-covered carbon steel surfaces were transferred to nutrient-deficient synthetic seawater, the inhibitory effect persisted despite the predicted diminished respiration; and (iv) after exposure to natural seawater, the inhibitory effect vanished and Pseudomonas pseudomallei appeared [112]. A single planktonic organism can cling to a surface, develop, and create extracellular polymers that help construct a protective matrix. These quickly expanding organisms have the potential to separate from the biofilm and pollute treated drinking water. Additionally, biofilms present operational difficulties for the water sector because they create membrane surface biofouling or biocorrosion on pipes and other surfaces [113].

Biofilms are bacterial communities that develop alongside one another inside of an extracellular matrix (ECM), which serves as both a protective shield and a key structural element of the bacterial community. It protects biofilm from antimicrobials and the host immune response and sustains biofilm integrity by holding the bacterial community together. Therefore, the ECM, which mostly consists of a mixture of exopolysaccharides (EPS), extracellular DNA (eDNA), and proteins, is a vital part of this multifactorial structure. The integrity of the biofilm depends on the presence of the two major polysaccharides, Psl and Pel, in the ECM of P. aeruginosa strains. While Pel is a cationic exopolysaccharide made up of 1–4 linked galactosamine and glucosamine sugar, Psl is a neutral pentasaccharide composed of D-glucose, D-mannose, and L-rhamnose [7]. The kinetics of cathodic and/or anodic processes and the chemistry of any protective layers can be significantly altered by microbial activity inside biofilms generated on the surfaces of metallic materials, either accelerating or inhibiting corrosion [114]. Although it is easy to identify enzymatic activity in biofilms, the significance of the processes mediated by these enzymes as they relate to biocorrosion has only lately been recognized. Enzymes were studied to identify the mechanisms that raise stainless steel's free corrosion potential, commonly known as "ennoblement" in oxygenated natural waters [115].

11 Bacterial Adhesion

Microbes, often adhere to stainless steel. Elements relating to the solid substrate, microbial suspension, steel grade, surface roughness, kind of finish, etc., could influence bacterial adhesion [116]. Numerous studies on bioadhesion have been done concerning corrosion brought on by microorganisms [117]. Because bacterial communities are so adaptable, they can change their metabolic rate in response to nutrition availability or other environmental factors. A protected mode of growth called a biofilm enables bacterial colonies to flourish in unfavorable conditions [118]. The survival strategies bacteria use inside biofilms are distinct from those used by bacterial communities outside. These microorganisms create microcolonies, which result in the development of a mature biofilm's three-dimensional structure [119]. Two phases are involved in the attachment of bacteria to a solid surface: reversible and irreversible adhesion. In the first step, van der Waals forces, electrostatic forces, and hydrophobic contacts move the bacteria close enough to the surface. The locking phase, or the second step of adhesion, involves the surface and specific adhesins, like exopolysaccharides, binding through molecular means [120].

12 Pseudomonas aeruginosa

A gram-negative facultative bacterium is called Pseudomonas aeruginosa [121]. These bacteria are rod-shaped, gram-negative bacteria that are motile because they swiftly motile from one location to another [122]. Pseudomonas aeruginosa is a common Gram-negative bacterium that can be found in water systems, such as Waste Water Treatment Plants (WWTPs) and is one of the main causes of opportunistic human illnesses [123]. Quorum Sensing (QS) systems, which govern a variety of bioactivities, metabolic pathways, and stress responses in P. aeruginosa, are responsible for controlling biofilm development [124]. Pseudomonas aeruginosa is a widely distributed, electrochemically active bacteria that can be found in soil and water. Although P. aeruginosa-produced phenazines have substantially greater redox potentials than nicotinamide adenine dinucleotide (NADH) (E° = 320 mV), these potentials are still low enough to permit the transfer of electrons from NADH to ambient oxidants. For their producers, phenazine chemicals perform crucial physiological and metabolic tasks, act as quorum sensing signaling substances, and affect the development of biofilms [125]. Numerous microorganisms, including bacteria, fungus, and archaea, can initiate and/or cause corrosion of materials in the maritime environment. Pseudomonas aeruginosa, a pioneering bacterium for biofilm development in seawater environments, is one of these microorganisms and can produce biofilm on various kinds of metals and their alloys [126]. Pseudomonas aeruginosa is a widely dispersed environmental bacterium that may colonize a wide range of habitats, including those contaminated by people, such as sewage, oil spills, swimming pools, or water contaminated by biocides [127]. In many maritime ecosystems, mild steel, stainless steel, and aluminum alloys have been discovered to be corroded by Pseudomonas bacterial species, which are most common in industrial water and seawater environments. Because Fe (II) is more soluble and the protective Fe (III) layer has already been solubilized in the initial step, it has also been demonstrated that different Pseudomonas strain isolates can convert Fe (III) to Fe (II), exposing steel to further oxidation [128]. P. aeruginosa marine corrodes a variety of materials [129]. In marine habitats, Pseudomonas aeruginosa is frequently present. Its ability to corrode metals, even stainless steels, has been demonstrated [130]. Since P. aeruginosa is an aerobic bacteria, oxygen is its primary electron acceptor. P. aeruginosa can thus catalyze the electrochemical reduction of oxygen. P. aeruginosa contributes to the beginning, growth, and stability of the biofilm structure on metallic surfaces, which is formed by the creation of alginate (polysaccharide), a crucial element of the biofilm skeleton [131]. Additionally, P. aeruginosa biofilms can develop on catheters, eyeglasses, and lungs affected by cystic fibrosis (CF) [132]. In some extremely corrosive situations, Pseudomonas aeruginosa was discovered to be corrosive to materials like 2205 duplex stainless steel (2205 DSS), 2707 duplex stainless steel, or even S32654 super austenitic stainless steel [133]. Table 1. summarizes the various kinds of metals and their media in which they get corroded.

12.1 Influence of Pseudomonas on a Variety of SS Corrosion

A additional indication of the detrimental effects of Pseudomonas bacteria on the integrity of the passive oxide film, such as pitting corrosion, is the decreased value of a during prolonged exposure to the Pseudomonas inoculated media as compared to that of the corresponding control specimen. However, Cathodic oxygen reduction reactions may be connected to the development of a Pseudomonas bacterial biofilm on the coupons, as evidenced by the significantly higher values of the cathodic Tafel slopes compared to those of the equivalent control coupons. According to reports, the presence of Pseudomonas bacteria can affect two aspects of the cathodic reaction: (i) the kinetics of oxygen reduction can be impacted by changes in passive film composition exposure time; and (ii) Catalase can catalyze oxygen reduction when Pseudomonas bacteria are present [114]. A study analyzed the usual marine P. aeruginosa's MIC behavior and clarified the molecular biological basis of corrosion. In contrast to the simulated full-immersion zone, the results showed that P. aeruginosa accelerated the corrosion of EH40 steel, and its corrosion efficiency increased over time. P. aeruginosa responded to environmental stress in the simulated tidal zone by increasing its metabolism and energy production [115]. The MIC behavior of 2205 DSS induced by the marine aerobic P. aeruginosa biofilms was the main focus of this investigation. Pit depth measurements, LPR and EIS electrochemical analysis results, and P. aeruginosa biofilm presence tests all showed that 2205 DSS was subject to rapid pitting corrosion. Following P. aeruginosa incubation, X-ray photon electron spectography (XPS) examination showed that CrN and a soluble CrO3 compound were produced on the surface of 2205 DSS, which caused the passive film to dissolve more quickly. It is yet unknown what causes the development of CrN and CrO3 and the acceleration of pitting corrosion. The involvement of P. aeruginosa biofilm in pitting initiation, the formation of the stable pits, and its extracellular electron transport channels has to be further studied [116].

13 Mechanism

Since 1934, several models have been developed to explain why SRB-induced steel corrosion occurs. The first theory that sought to explain the corrosion brought on by SRB was the cathodic depolarization theory [134]. MIC occurs beneath the built-up biofilm in the pipelines through several mechanisms including concentration and galvanic cell formation, cathodic depolarization, and direct electron transfer [135]. The term “MIC phenomenon” describes how the presence of microorganisms, which frequently form a biofilm on the metal surface, causes corrosion processes to accelerate and/or change. Several variables, including oxygen concentration, salt concentration, pH, redox potential, and conductivity, can all affect bacterial growth and corrosion kinetics [136]. Through a change in gene expression and metabolic activity, individual bacterial cells may detect and react to various environmental situations. The ability to build biofilms or remain as planktonic cells ultimately determines whether bacteria can exist in either state [137]. Surfaces are fouled during MIC, which leads to the development of corrosive oxygen concentration cells. Particularly at metal/solution interfaces, adhering bacterial biofilms changes the kinetics of anodic and/or cathodic reactions, speeding up corrosion and eventually dissolving these metallic materials. They form communities after adhering to metal surfaces and anchor via extracellular polymeric substances (EPS) released by their biofilms [120].

SS is often susceptible to MIC due to interactions with media containing sulfate-reducing bacteria, iron-reducing bacteria, etc. [121]. Through the development of biofilms and continued colonization, these bacteria produce pitting corrosion on the steel surface. Aerobic bacteria like P. aeruginosa, which predominates in marine environments, create a biofilm coating on metal surfaces. Additionally, the biofilm layer, under aerobic circumstances typically promotes the development of differential aeration and concentration cells. The formation of these concentration cells compromises the integrity of the passive film and makes the stainless steel more vulnerable to corrosion. The passive chromium oxide layer on the SS surface could thin due to the biofilm layer, which may make it easier for corrosive ions to cause pitting and further degrade the passive chromium oxide layer in seawater settings [122].

14 Factors Affecting Microbiologically Influenced Corrosion

Environmental considerations include exposure duration, bacterial concentration, chemical treatment, and the presence of antibiotics. All of these factors can potentially change bacterial adherence and MIC by altering physical interactions or changing the surface properties of bacteria or materials [138]. Drinking water pipelines’ surface roughness influences how planktonic microorganisms cling to them in bulk water. The formation of hydroxide-oxide scale is influenced by hardness, alkalinity, temperature, pH, sulfate, chloride, and inhibitors. These traits determine the pathways microbes stimulate from initiation to maturation [139]. pH is one of the few important factors in corrosion. It relies heavily on the two or three local buffering systems produced by the microbe's metabolism. A biofilm’s metabolism and, consequently, pH have a more significant impact on the local chemistry of the corroding surface because of the restrictions of chemical exchanges between a biofilm and the bulk environment [140]. The four fundamental requirements for bacterial growth and reproduction are the right temperature, sufficient nourishment, appropriate pH level, and required gas environment. Enzymes are required to create energy, nutritional absorption, and nutrient breakdown. However, for the enzyme activity to be effective, a specific pH and temperature are required [141]. In heterogeneous biofilms, energy sources and waste products can diffuse and move across microcolonies of cells divided by interstitial channels, voids, and holes. This heterogeneity affects the rates of nutrient transport and consumption, which in turn affects biofilm activity. Similar to how the structure and morphology of biofilms can change depending on the types and amounts of energy sources present and the rate at which microbes proliferate. Although previous studies have indicated a stronger propensity to develop biofilms under low-nutrient or famine situations, environments with a plentiful supply of nutrients would favor attachment and biofilm formation. For catalytic MIC to take place, the system must include nutrients that allow bacteria to conduct out metabolic functions and multiply [142]. It is widely acknowledged that the biofilm can have a negative impact on the electrochemical state underneath it, which facilitates steel corrosion in the environment that the biofilm isolates from the outside environment. The biofilm may block electron transfer between a cathodic depolarizer and stainless steel, preventing the steel from pitting corrosion. The MIC is accelerated when the dense biofilm is eliminated or locally harmed. The gas fluid flow in natural gas pipelines will cause a shear stress on the biofilm when they are in use. The biofilm may thin out or even be eliminated, leading to exfoliation. A galvanic cell may develop, with the biofilm-covered portion acting as the cathode and the exposed steel acting as the anode. Localized corrosion develops quickly. In light of this, MIC of the steels also depends on the mechanical characteristics of the biofilm produced under particular environmental conditions [143].

15 Mitigation of SS Microbiologically Influenced Corrosion

Protective coatings, corrosion inhibitors, polymers, anodic and cathodic protection, and corrosion-resistant metals and alloys are currently some of the most frequently utilized corrosion control technologies [86]. MIC can be controlled in several ways, (1) physical methods, (2) chemical methods, (3) electrochemical methods, and (4) biological treatments [144]. The effects of MIC have been mitigated using a variety of methods. Some examples are the use of corrosion-resistant metals, protective coatings, pigging, anodic and cathodic protection, biocides, the introduction of rival microorganisms, and the addition or subtraction of nutrients. Other methods, including precoating with pure EPS or sol–gel coating barriers, are also being applied. The fact that biocides are usually hazardous to organisms other than bacteria is a disadvantage of using them. Therefore, adding biocides to the infrastructure of water supply or sanitation systems, or to preserve the outside of subterranean structures, pipes, or implanted medical equipment, is not practical [145]. It is critical to develop new solutions with antibacterial qualities based on natural sources because of the restrictions associated with the use of chemical biocides. We will be able to replace the risks that come with chemical products thanks to this. Nowadays, new eco-friendly and antibacterial materials are being created. It has been demonstrated that biosurfactants are among the most effective environmentally friendly anticorrosion agents for preventing biocorrosion and safeguarding materials from corrosion. [146]. Adding nitrates or removing sulfates from the available nutrients can change how corrosive biofilms are, which is one of the more recently field-tested strategies that depends on a thorough understanding of the biofilm [147].

Corrosion inhibitors are considered cost-effective in terms of corrosion control. Corrosion inhibitors are qualitatively classified as shown:

In Fig. 5, the MIC management methods for various systems are presented [148]. The majority of corrosion inhibitors used in industry are synthetic compounds. There are either organic or inorganic materials. Despite being effective at reducing microbial corrosion, they are noxious and hazardous to the environment. Hence, strict environmental controls are needed [93].

Since 2008, the International Maritime Organization (IMO) has prohibited the use of organotins. The creation of non-toxic, eco-friendly anti-biocorrosion materials is urgently needed. As seen in Fig. 6, corrosion inhibitors often create a coating over the metal substrate to prevent corrosion. The oil and gas industry regularly use film formation inhibitors, which produce a persistent monolayer coating adsorbed at the metal/solution interface [149]. An intelligent coating technology largely depends on a particular pigment, resin, or other substance that may react to environmental stimuli. Instead of directly injecting corrosion inhibitors into the coating medium, this approach encapsulates the inhibitors in tiny containers or nanocontainers dispersed equally throughout the host coating [150]. Another way to stop corrosion is to apply a polymer-made corrosion-resistant coating. However, this approach is less desirable due to its reduced practicality in ductility and conductivity [151]. One fundamental principle of biological techniques is to block the actions of bacteria that support the MIC. This idea is supported by the finding that not all bacteria encourage rusting. The phrase “Microbiologically Influenced Corrosion” recognizes that certain microbes in specific media can prevent or even change the reactive corrosion products [152]. A critical first stage in the onset of microbiologically driven corrosion is microbial colonization of metal surfaces or bacterial adherence on metal surfaces. Understanding how substrate characteristics affect bacterial cell adhesion, including the mechanism of bacterial adhesion, may help in the design or modification of substrates to inhibit bacterial adhesion and prevent material corrosion because the substrate is crucial in developing a biofilm [153].

Quorum sensing (QS) is a method of communication used by bacteria that modifies the expression of particular genes in response to the density of bacterial cells in an environment. QS is a crucial system that regulates a variety of biofilm activities. Microbial extracellular electron transfer (EET) and QS regulatory networks are crucial. Because it regulates the production of phenazines, a crucial mediator in the EET process, QS also contributes to P. aeruginosa MIC [154]. The biofilm matrix may contain protective layers or passive oxide products that are generated and trapped inside it. According to Chongdar et al. (2005), aerobic Pseudomonas cichorii can prevent mild steel from corroding in corrosive phosphate-buffered basic salt solution (BSS) [155]. Even though bacteria may create a biofilm on almost any surface made of a material, researchers are looking for ways to alter surfaces to stop microbial attachment. One illustration is a self-healing porous surface with liquid infused into it that uses nano/microstructured substrates to hold the infused lubricant [156].

In some cases, developing a biofilm by itself might result in corrosion resistance rather than an increase in corrosion rate. Some biofilm-forming bacteria may eliminate corrosion-promoting substances like oxygen as part of their metabolism, release substances that stop the growth of bacteria that cause corrosion, and create physical barriers that prevent corrosion on surfaces [157]. Metal alloys can acquire an antibacterial activity to prevent the development of biofilms by adding bactericidal metal components like copper and silver. One of the useful antibacterial components with good antibacterial capabilities is copper [158].

The main focus of MIC prevention and control in recent years has been on eradicating the microbial cell or preventing the development of biofilms. Biocides are the most successful among the methods that have been tried to circumvent the MIC. Due to the high toxicity of biocides, researchers set out to create highly effective biocorrosion inhibitors and antimicrobial agents that are environmentally friendly, renewable, and easily accessible [159]. In a hypersaline-produced water environment enriched with corrosive bacteria, garlic extract (GAE) was used as a green inhibitor to limit the MIC of API 5LXCS and 316 SS [160]. Low-alloy structural steel with high strength in its application environment, AISI 8630 is subject to severe microbiologically influenced corrosion (MIC). In order to combat this problem, AISI 8630 steel was created that contains 0.4 wt% Cu (Cu-AISI 8630) in order to make use of the antibacterial properties of Cu. In the presence of a marine Pseudomonas aeruginosa biofilm, the corrosion behavior of both Cu-AISI 8630 steel and AISI 8630 was investigated. According to the electrochemical test results, Cu-AISI 8630 steel underwent immersion cycles with a rise in Rp and a significantly positive shift in Ecorr compared to AISI 8630 steel. The maximum MIC pit depth was much less in Cu-AISI 8630 steel than in AISI 8630 steel after 14 days, according to a study of the pit morphology of the two materials [4].

16 Conclusion

P. aeruginosa accelerates corrosion of steel. Steel biocorrosion is a significant problem for many technical applications. Steel serving in seawater environments continuously deteriorates due to biocorrosion, however, the specific mechanisms relating to the MIC are still poorly known. Biocorrosion processes draw on various disciplines, including enzymology, materials engineering, electrochemistry, and microbiology. Due to the economic and environmental effects of biocorrosion, it has been extensively studied, and several models have been put out to explain its underlying mechanics. Studies on P. aeruginosa corrosion prevention have gotten little attention. They are dismissed though it poses a severe threat to crucial engineering materials like steel. P. aeruginosa causes more serious steel corrosion in an aerobic environment than it does in an anaerobic one. It has been shown that P. aeruginosa causes corrosion by using the extracellular electron transfer-MIC (EET-MIC) method rather than the metabolite-MIC (M-MIC) method. The EET-MIC may also influence the acceleration of corrosion brought on by P. aeruginosa. Despite the minimal corrosion that aerobic microbes seem to cause on the surface of metals, it is acknowledged that bacteria can modify various response pathways to influence the corrosion process. For bacterial populations, the production of biofilms is extremely favorable. It offers defense against antibiotics, sanitizers, and dynamic conditions. The biofilm might influence corrosion by creating aeration cells, the presence of biological material on the surface, and the biological activity of the cells. Microbiological, electrochemical, and metallurgical multidisciplinary techniques are needed to explore how microorganisms affect metal corrosion. The development of new corrosion detection and prevention methods appears to be made possible by interdisciplinary research of the interactions between P. aeruginosa and metals in corrosive biofilms. When introduced in modest amounts, corrosion inhibitors reduce corrosion in oil and gas pipelines. Coatings, cathodic protection, and material selection are often employed as preventative measures, whereas biocides, cathodic protection, and corrosion inhibitors are regularly used as mitigation and control methods for MIC management. Only closed or partially closed systems are suitable for biocides and corrosion inhibitors.

16.1 Future Scope

As comprehensive research has shown, microbial corrosion is a severe economic issue that imperils industry, human health, and the environment. However, there are insufficient techniques to definitively detect and sustainably control this destructive activity because the process needs to be understood. Understanding the microorganisms that cause corrosion and how they do it is crucial. Although the molecular characterization of corrosion communities will be crucial, more thorough mechanistic studies are needed. Although efforts are being made to discover genes that may point to a microbial community’s high propensity for microbial corrosion, it is still not possible to infer the mechanisms of corrosion from the presence of certain genes. Due to the integrative and transdisciplinary nature of MIC, experts from various disciplines (such as microbiology, biotechnology, mathematics, environmental science, chemical engineering, chemistry, material science, corrosion science, and electrochemistry) must work together to develop practical solutions. All of the techniques for using microbes to control corrosion have yet to be successfully implemented in practice. Green (eco-friendly) coatings embedded with microbial corrosion inhibitors made of marine natural materials may be a successful method for preventing and managing microbial corrosion.

16.2 Challenges

The unique species composition and environmental factors significantly influence the corrosive potential of a biofilm. This variety has made it more difficult to determine a broad, causal connection between the presence of bacteria and corrosion. The community cannot generalize corrosion potential, mechanisms, and rates because of this complexity. Assessing and managing P. aeruginosa MIC is difficult and necessitates a thorough knowledge of corrosion and microbiological conditions. Combining the findings of published works revealed that MIC, comprising microbiological activity and chemical conditions, has a dynamic nature that is challenging to forecast. By preventing, managing, and minimizing P. aeruginosa MIC contributing elements, such as microbes, metal–fluid interactions, chemicals, and environmental conditions, a MIC management plan must be provided. Due to the variety of affected regions, ranging from produced water to tanks and flowlines and affecting other sections, it is still difficult to comprehend MIC. Therefore, further and in-depth analysis of the oil, solid, and aqueous phases is required to define a complete picture of MIC. Different bacterial strains' capacity to build biofilms on metal surfaces, particularly the genetically modified mutants, is underappreciated and may impact the biofilm's corrosivity. To understand the underlying MIC mechanism of stainless steels, suitable genetic mutants are required for all these issues.

Data Availability

Not Applicable.

References

Kobisy AS, Nassar HN, Tawfik SM, Elshatoury EH, Aiad I (2021) Mitigation of eco-unfriendly and costly microbial induced corrosion using novel synthesized Schiff base cationic surfactants. J Chem Technol & Biotech 96(4):941–952

Cote C, Rosas O, Sztyler M, Doma J, Beech I, Basseguy R (2014) Corrosion of low carbon steel by microorganisms from the ‘pigging’operation debris in water injection pipelines. Bioelectrochemistry 97:97–109

Lekbach Y, Liu T, Li Y, Moradi M, Dou W, Xu D, Lovley DR (2021) Microbial corrosion of metals: the corrosion microbiome. Adv Microb Physiol 78:317–390

Thi MTT, Wibowo D, Rehm BH (2020) Pseudomonas aeruginosa biofilms. Int J Mol Sci 21(22):8671

Liu Z, Cui T, Chen Y, Dong Z (2023) Effect of Cu addition to AISI 8630 steel on the resistance to microbial corrosion. Bioelectrochemistry 152:108412

Zhou E, Ren G, Sun Y, Fan Y, Yang Y, Sun M, Xu D, Lu Y, Wang J, Li H, Wang F (2022) Antibacterial activities of a novel Cu-bearing high-entropy alloy against multi-drug-resistant Acinetobacter baumannii and Staphylococcus aureus. Rare Met 41:570–579

Li C, Wu J, Zhang D, Wang P, Zhu L, Gao Y, Wang W (2023) Effects of Pseudomonas aeruginosa on EH40 steel corrosion in the simulated tidal zone. Water Res 232:119708

Deepa MJ, Arunima SR, Riswana G, Riyas AH, Sha MA, Suneesh CV, Shibli S (2019) Exploration of Mo incorporated TiO2 composite for sustained biocorrosion control on zinc coating. Appl Surf sci 494:361–376

Javed MA, Neil WC, Wade SA (2022) Effect of test media on the crevice corrosion of stainless steel by sulfate reducing bacteria. Mater Degrad 6(1):1–14

Manu SK, Manivannan R (2021) A review on the role of eco-friendly inhibitors for mitigation of microbial influenced corrosion of steel and its impacts. IOP conf ser 1057(1):012002

Landoulsi J, Cooksey KE, Dupres V (2011) Review–interactions between diatoms and stainless steel: focus on biofouling and biocorrosion. Biofouling 27(10):1105–1124

Liu H, Gu T, Asif M, Zhang G, Liu H (2017) The corrosion behaviour and mechanism of carbon steel induced by extracellular polymeric substances of iron-oxidizing bacteria. Corros Sci 114:102–111

Khan MS, Li Z, Yang K, Xu D, Yang C, Kalnaowakul P (2019) Microbiologically influenced corrosion of titanium caused by aerobic marine bacterium Pseudomonas aeruginosa. J Mater Sci Techol 35(1):216–222

Lekbach Y, Dong Y, Li Z, Xu D, El Abed S, Yi Y, Wang F (2019) Catechin hydrate as an eco-friendly biocorrosion inhibitor for 304L stainless steel with dual-action antibacterial properties against Pseudomonas aeruginosa biofilm. Corros Sci 157:98–108

Tran TT, Kannoorpatti K, Padovan A, Thennadil S (2021) A study of bacteria adhesion and microbial corrosion on different stainless steels in environment containing Desulfovibrio vulgaris. R Soc open Sci 8(1):201577

Wan Q, Ding H, Yousaf MI, Chen YM, Liu HD, Hu L, Yang B (2016) Corrosion behaviors of TiN and Ti-Si-N (with 2.9 at% and 5.0 at% Si) coatings by electrochemical impedance spectroscopy. Thin Solid Films 616:601–607

Jenneman GE, De Leόn KB (2022) Environmental stressors alter the susceptibility of microorganisms to biocides in upstream oil and gas systems. Int Biodeterior Biodegrad 169:105385

Heitz E, Flemming HC, Sand W (1996) Microbially influenced corrosion of materials. Chapter 8:105–120

Stewart PS, William CJ (2001) antibiotic resistance of bacteria in biofilms. The Lancet 358:135–138

Fu Q, Wei B, Xu J, Qin Q, Bai Y, Yu C, Sun C (2023) Corrosion mechanism of Pseudomonas stutzeri on X80 steel subjected to Desulfovibrio desulfuricans under elastic stress and yield stress. Corros Sci 216:111084

Li H, Zhou E, Zhang D, Xu D, Xia J, Yang C, Yang K (2016) Microbiologically influenced corrosion of 2707 hyper-duplex stainless steel by marine Pseudomonas aeruginosa biofilm. Sci Rep 6(1):20190

Rao TS, Sairam TN, Viswanathan B, Nair KVK (2000) Carbon steel corrosion by iron oxidising and sulphate reducing bacteria in a freshwater cooling system. Corros Sci 42:1417

la Fuente De, Díaz D, Simancas I, Chico J, Morcillo M (2011) Long-term atmospheric corrosion of mild steel. Corros Sci 53:604

Wen J, Zhao K, Raad II GuT (2009) A green biocide enhancer for the treatment of sulfate-reducing bacteria (SRB) biofilms on carbon steel surfaces using glutaraldehyde. Int Biodeterior Biodegrad 63:1102

Yang Y, Rouxhet PG, Chudziak D, Telegdi J, Dupont-Gillain CC (2014) Influence of poly (ethyleneoxide)-based co polymer on protein adsorption and bacterial adhesion on stainless steel: modulation by surface hydrophobicity. Bioelectrochemistry 97:127–136

Shahid M (2011) Corrosion protection with eco-friendly inhibitors. Adv Nat Sci Nanosci Nanotechnol 2(4):043001

Koch B, Worm J, Jensen LE et al (2001) Carbon limitation induces s-dependent gene expression in Pseudomonas fluorescens in soil. Appl Environ Microbiol 67:3363–3370

Flemming HC (1996) Biofouling and microbiologically influenced corrosion (MIC)-an economical and technical overview. Microbial Deterioration of Materials

Javaherdashti R (2017) Microbiologically Influenced corrosion: an engineering insight, 2nd edn. Springer, UK

Koch GH, Brongers MP, Thompson NG, Virmani YP, Payer JH (2002) Corrosion cost and preventive strategies in the United States (No. FHWA-RD-01-156, R315-01). United States. Federal Highway Administration

Jack RF, Ringelberg DB, White DC (1992) Differential corrosion rates of carbin steel by combinations of Bacillus sp, Hafnia alvei, and Desulfovibrio gigas established by phospholipid analysis of electrode biofilm. Corr Sci 33:1843–1853

Beech IB, Gaylarde CC (1999) Recent advances in the study of biocorrosion: an overview. Rev Microbiol 30:117–190

Cushman AS, Gardner HA (1910) The corrosion and preservation of iron and steel. McGraw-Hill book company, Columbus

Ziadi I, Akrout H, Hassairi H, El-Bassi L, Bousselmi L (2019) Investigating the biocorrosion mechanism of 304L stainless steel in raw and treated urban wastewaters. Eng Fail Anal 101:342–356

Whitehead KA, Benson PS, Verran J (2011) The detection of food soils on stainless steel using energy dispersive X-ray and Fourier transform infrared spectroscopy. Biofouling 27(8):907–917

Manam NS, Harun WS, Shri W, Ghani DNA, Kurniawan IMH (2017) Study of corrosion in biocompatible metals for implants: a review. J Alloys Compd 701:698–715

Abdullah W, Johari WR, Farahin Ibrahim NA, Syazrinni Rooshde N, Mohd Ghazali MS (2019) Comparison of biocorrosion behavior of stainless steel 316 L and mild steel induced by slime producing bacteria. Int J Mech Eng Technol 10(3):404–411

Li H, Zhou E, Ren Y, Zhang D, Xu D, Yang C, Yang K (2016) Investigation of microbiologically influenced corrosion of high nitrogen nickel-free stainless steel by Pseudomonas aeruginosa. Corros Sci 111:811–821

Steinsmo U, Rogne T, Drugli J (1997) Aspects of testing and selecting stainless steels for seawater applications. Corrosion 53(12):955–964

Li H, Yang C, Zhou E, Yang C, Feng H, Jiang Z, Yang K (2017) Microbiologically influenced corrosion behavior of S32654 super austenitic stainless steel in the presence of marine Pseudomonas aeruginosa biofilm. J Mater Sci Technol 33(12):1596–1603

Ettefagh AH, Guo S, Raush J (2021) Corrosion performance of additively manufactured stainless steel parts: a review. Addit Manuf 37:101689

Takada Y, Nakamura K, Kimura K, Okuno O (2005) Corrosion behavior of the stainless steel composing dental magnetic attachments. Int Congr Ser 1284:314–315

Castro SM, Ponces MJ, Lopes JD, Vasconcelos M, Pollmann MC (2015) Orthodontic wires and its corrosion—the specific case of stainless steel and beta-titanium. J Dent Sci 10(1):1–7

Wakai S, Eno N, Miyanaga K, Mizukami H, Sunaba T, Miyano Y (2022) Dynamics of microbial communities on the corrosion behavior of steel in freshwater environment. Mater Degrad 6(1):1–11

Videla HA, Herrera LK (2005) Microbiologically influenced corrosion: looking to the future. Int Microbiol 8(3):169

Ouyang Y, Zhao J, Qiu R, Shi Z, Hu S, Zhang Y, Wang P (2019) Liquid infused surface based on hierarchical dendritic iron wire array: an exceptional barrier to prohibit biofouling and biocorrosion. Prog Org Coat 136:105216

Jin J, Guan Y (2014) The mutual co-regulation of extracellular polymeric substances and iron ions in biocorrosion of cast iron pipes. Bioresour Technol 169:387–394

Geesey G (1991) What is biocorrosion? Biofouling and biocorrosion in industrial water systems. Springer, Heidelberg, pp 155–164

Fan MM, Liu HF, Dong ZH (2013) Microbiologically influenced corrosion of X60 carbon steel in CO2-saturated oilfield flooding water. Mater Corros 64(3):242–246

Dinh HT, Kuever J, Mußmann M, Hassel AW, Stratmann M, Widdel F (2004) Iron corrosion by novel anaerobic microorganisms. Nature 427(6977):829–832

Zuo R (2007) Biofilms: strategies for metal corrosion inhibition employing microorganisms. Appl Microbiol Biotech 76(6):1245–1253

Gu T, Wang D, Lekbach Y, Xu D (2021) Extracellular electron transfer in microbial biocorrosion. Curr Opin Electrochem 29:100763

Zhou E, Zhang M, Huang Y, Li H, Wang J, Jiang G, Wang F (2022) Accelerated biocorrosion of stainless steel in marine water via extracellular electron transfer encoding gene phzH of Pseudomonas aeruginosa. Water Res 220:118634

Saha JK (2012) Corrosion of constructional steels in marine and industrial environment: frontier work in atmospheric corrosion. Springer, New York

Tiller AK, Howsam P (1990) Biocorrosion in civil engineering. Microbiology in civil engineering. Taylor & Francis, New York, pp 24–38

El Hajj H, Abdelouas A, El Mendili Y, Karakurt G, Grambow B, Martin C (2013) Corrosion of carbon steel under sequential aerobic–anaerobic environmental conditions. Corros Sci 76:432–440

Starosvetsky J, Pokroy B, Hilel T, Armon R (2008) Electrochemical behaviour of stainless steels in media containing iron-oxidizing bacteria (IOB) by corrosion process modeling. Corros Sci 50(2):540–547

Wang H, Ju LK, Castaneda H, Cheng G, Newby BMZ (2014) Corrosion of carbon steel C1010 in the presence of iron oxidizing bacteria Acidithiobacillus ferrooxidans. Corros Sci 89:250–257

El-Bassi L, Ziadi I, Belgacem S, Bousselmi L, Akrout H (2020) Investigations on biofilm forming bacteria involved in biocorrosion of carbon steel immerged in real wastewaters. Int Biodeterior Biodegrad 150:104960

Barton F, Shaw S, Morris K, Graham J, Lloyd JR (2022) Impact and control of fouling in radioactive environments. Prog Nuc Energy 148:104215

Victoria SN, Sharma A, Manivannan R (2021) Metal corrosion induced by microbial activity–mechanism and control options. J Indian Chem Soc 98(6):100083

Wang D, Liu J, Jia R, Dou W, Kumseranee S, Punpruk S, Gu T (2020) Distinguishing two different microbiologically influenced corrosion (MIC) mechanisms using an electron mediator and hydrogen evolution detection. Corros Sci 177:108993

Amendola R, Acharjee A (2022) Microbiologically influenced corrosion of copper and its alloys in anaerobic aqueous environments: a review. Front Microbiol 13:806688

Zhou E, Lekbach Y, Gu T, Xu D (2022) Bioenergetics and extracellular electron transfer in microbial fuel cells and microbial corrosion. Curr Opin Electrochem 31:100830

Jia R, Tan JL, Jin P, Blackwood DJ, Xu D, Gu T (2018) Effects of biogenic H2S on the microbiologically influenced corrosion of C1018 carbon steel by sulfate reducing Desulfovibrio vulgaris biofilm. Corros Sci 130:1–11

Hu S, Lu Q, Xu Y (2008) Biosensors based on direct electron transfer of protein. Electrochemical Sensors, Biosensors and their Biomedical Applications, p. 531

Enning D, Garrelfs J (2014) Corrosion of iron by sulfate-reducing bacteria: new views of an old problem. Appl Environ Microbiol 80(4):1226–1236

Jia R, Yang D, Xu D, Gu T (2017) Anaerobic corrosion of 304 stainless steel caused by the Pseudomonas aeruginosa biofilm. Front Microbiol 8:2335

Pedersen A, Hermansson M (1991) Bacterial corrosion of iron in seawater in situ, and in aerobic and anaerobic model systems. FEMS Microbiol Lett 86(2):139–147

Smart NR, Reddy B, Rance AP, Nixon DJ, Diomidis N (2017) The anaerobic corrosion of carbon steel in saturated compacted bentonite in the Swiss repository concept. Corros Eng Sci Technol 52:113–126

El-Shamy AM (2020) A review on: biocidal activity of some chemical structures and their role in mitigation of microbial corrosion. Egypt J Chem 63(12):5251–5267

Talha M, Ma Y, Kumar P, Lin Y, Singh A (2019) Role of protein adsorption in the bio corrosion of metallic implants—a review. Colloids Surf B 176:494–506

Arunima SR, Deepa MJ, Nair AJ, Shibli SMA (2021) Exploration of WO3/BiVO4 composite based hot-dip zinc coating to combat biocorrosion. Mater Sci Eng B 271:115302

Zhou E, Li H, Yang C, Wang J, Xu D, Zhang D, Gu T (2018) Accelerated corrosion of 2304 duplex stainless steel by marine Pseudomonas aeruginosa biofilm. Int Biodeterior Biodegrad 127:1–9

Zhao J, Csetenyi L, Gadd GM (2020) Biocorrosion of copper metal by Aspergillus niger. Int Biodeterior Biodegrad 154:105081