Abstract

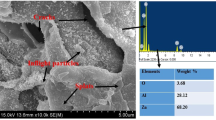

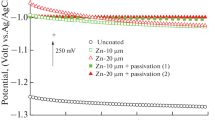

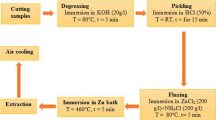

ASTM A194 steel is one of the standard steels used in the manufacture of steel nuts used in high temperature and pressure conditions in the oil and gas industry. In this study, the effect of polyurea coating on improving the corrosion resistance of this alloy and the effect of Ag nanoparticles on the corrosion properties of polyurea coating in 3.5% sodium chloride solution was investigated. Corrosion resistance of the samples was evaluated by potentiodynamic polarization test. Scanning electron microscopy (SEM) and X-ray diffraction spectroscopy (EDS) analyses were used to qualitatively evaluate the surface of the samples coated with polyurea and Ag nanoparticles. The obtained results showed that applying polyurea coating on ASTM A194 steel improved its corrosion resistance significantly. It was also found that addition of Ag nanoparticles had a positive effect on the protective properties of polyurea coating. The results of potentiodynamic polarization tests showed that adding silver nanoparticles to the polyurea coating improved the protective behavior of the coating in the short and long term. This improvement in corrosion behavior can be attributed to the barrier properties and chemical properties of silver nanoparticles in contact with destructive species present in corrosive electrolytes.

Similar content being viewed by others

References

Roberge PR (2008) Corrosion engineering: principles and practice, vol 2. McGraw-Hill, New York

Yabuki A, Fathona IW (2019) Recent trends in nanofiber-based anticorrosion coatings. In: Barhoum A, Bechelany M, Makhlouf ASH (eds) Handbook of nanofibers. Springer International Publishing, Cham, pp 905–936. https://doi.org/10.1007/978-3-319-53655-2_38

Sapkota R, Zou J, Dawka S, Bobak JE, Papadopoulos C (2018) Multi-functional thin film coatings formed via nanogrinding. Appl Nanosci 8(6):1437–1444. https://doi.org/10.1007/s13204-018-0812-y

Sai Pavan AS, Ramanan SR (2016) A study on corrosion resistant graphene films on low alloy steel. Appl Nanosci 6(8):1175–1181. https://doi.org/10.1007/s13204-016-0530-2

Ashraf PM, Anuradha R (2018) Corrosion resistance of BIS 2062-grade steel coated with nano-metal-oxide mixtures of iron, cerium, and titanium in the marine environment. Appl Nanosci 8(1):41–51. https://doi.org/10.1007/s13204-018-0650-y

Li DG, Wang JD, Chen DR, Liang P (2015) Influence of molybdenum on tribo-corrosion behavior of 316L stainless steel in artificial saliva. J Bio Tribo Corros 1(2):14. https://doi.org/10.1007/s40735-015-0014-z

Manoj A, Ramachandran R, Menezes PL (2020) Self-healing and superhydrophobic coatings for corrosion inhibition and protection. Int J Adv Manuf Technol 106(5):2119–2131. https://doi.org/10.1007/s00170-019-04758-z

McCafferty E (2010) Introduction to corrosion science. Springer Science & Business Media, Berlin

Indira K, Nishimura T (2017) In situ study of effect of chromium content and epoxy coating on localized corrosion behavior of low-alloy steel using localized electrochemical impedance spectroscopy. J Bio Tribo Corros 3(3):28. https://doi.org/10.1007/s40735-017-0088-x

Hemmati AR, Soltanieh SM, Masoudpanah SM (2018) On the interaction between erosion and corrosion in chromium carbide coating. J Bio Tribo Corros 4(1):10. https://doi.org/10.1007/s40735-018-0128-1

Vijayasarathi P (2019) Characterization and corrosion studies of TiAlN PVD coating by using the polarization test method. J Bio Tribo Corros 5(1):29. https://doi.org/10.1007/s40735-019-0220-1

Ma Y, Zhang Y, Liu J, Ge Y, Yan X, Sun Y, Wu J, Zhang P (2020) GO-modified double-walled polyurea microcapsules/epoxy composites for marine anticorrosive self-healing coating. Mater Des 189:108547. https://doi.org/10.1016/j.matdes.2020.108547

Feng L, Iroh JO (2014) Corrosion resistance and lifetime of polyimide-b-polyurea novel copolymer coatings. Prog Org Coat 77(3):590–599

Orlov V (2016) Computer simulation of optimal thickness of polyurea coating using for trenchless renovation of potable water pipes. Proc Eng 165:1168–1175

Gauch E, LeBlanc J, Shukla A (2018) Near field underwater explosion response of polyurea coated composite cylinders. Compos Struct 202:836–852. https://doi.org/10.1016/j.compstruct.2018.04.048

Beiki H, Keramati M (2019) Improvement of methane production from sugar beet wastes using TiO2 and Fe3O4 nanoparticles and chitosan micropowder additives. Appl Biochem Biotechnol 189(1):13–25. https://doi.org/10.1007/s12010-019-02987-2

Talbert R (2007) Paint technology handbook. CRC Press, Boca Raton

Alarcon EI, Griffith M, Udekwu KI (2015) Silver nanoparticle applications. Springer, New York

Qian X, Song L, Tai Q, Hu Y, Yuen RKK (2013) Graphite oxide/polyurea and graphene/polyurea nanocomposites: a comparative investigation on properties reinforcements and mechanism. Compos Sci Technol 74:228–234

Nantasetphong W, Jia Z, Amirkhizi AV, Nemat-Nasser S (2016) Dynamic properties of polyurea-milled glass composites Part I: experimental characterization. Mech Mater 98:142–153

Zhao Z, Meng F, Tang J, Liu H, Liu H, Yang L, Wang J, Xiong T (2019) A novel method of fabricating an antibacterial aluminum-matrix composite coating doped graphene/silver-nanoparticles. Mater Lett 245:211–214. https://doi.org/10.1016/j.matlet.2019.02.121

Torrico RFAO, Harb SV, Trentin A, Uvida MC, Pulcinelli SH, Santilli CV, Hammer P (2018) Structure and properties of epoxy-siloxane-silica nanocomposite coatings for corrosion protection. J Colloid Interface Sci 513:617–628. https://doi.org/10.1016/j.jcis.2017.11.069

Rahmani S, Omrani A, Hosseini SR (2019) Effects of silica nanoparticles content on the properties and corrosion behavior of electroless Ni-Ba-B alloy coatings. Silicon. https://doi.org/10.1007/s12633-019-00162-0

Manjumeena R, Venkatesan R, Duraibabu D, Sudha J, Rajendran N, Kalaichelvan PT (2016) Green nanosilver as reinforcing eco-friendly additive to epoxy coating for augmented anticorrosive and antimicrobial behavior. Silicon 8(2):277–298. https://doi.org/10.1007/s12633-015-9327-2

Kundan N, Parida B, Keshri AK, Soni PR (2019) Synthesis and characterization of the nanostructured solid solution with extended solubility of graphite in nickel by mechanical alloying. Int J Miner Metall Mater 26(8):1031–1037. https://doi.org/10.1007/s12613-019-1816-7

Coutinho TC, Tardioli PW, Farinas CS (2019) Phytase immobilization on hydroxyapatite nanoparticles improves its properties for use in animal feed. Appl Biochem Biotechnol. https://doi.org/10.1007/s12010-019-03116-9

Jiang L, Chen D, Wang Z, Zhang Z, Xia Y, Xue H, Liu Y (2019) Preparation of an electrically conductive graphene oxide/chitosan scaffold for cardiac tissue engineering. Appl Biochem Biotechnol 188(4):952–964. https://doi.org/10.1007/s12010-019-02967-6

Fard MM, Beiki H (2017) Experimental measurement of solid solutes solubility in nanofluids. Heat Mass Transfer 53(4):1257–1263. https://doi.org/10.1007/s00231-016-1894-2

Shahmohammadi P, Beiki H (2016) A numerical investigation of γ-Al2O3-water nanofluids heat transfer and pressure drop in a shell and tube heat exchanger. Transp Phenom Nano Micro Scales 4(1):29–35

Manouchehrian Fard M, Beiki H (2016) Experimental investigation of benzoic acid diffusion coefficient in γ-Al2O3 nanofluids at different temperatures. Heat Mass Transfer 52(10):2203–2211. https://doi.org/10.1007/s00231-015-1734-9

Hojjat M, Nayebzadeh H, Khadangi-Mahrood M, Rahmani-Vahid B (2017) Optimization of process conditions for biodiesel production over CaO–Al2O3/ZrO2 catalyst using response surface methodology. Chem Pap 71(3):689–698. https://doi.org/10.1007/s11696-016-0096-1

Nasehi P, Mahmoudi B, Abbaspour SF, Moghaddam MS (2019) Cadmium adsorption using novel MnFe2O4-TiO2-UIO-66 magnetic nanoparticles and condition optimization using a response surface methodology. RSC Adv 9(35):20087–20099. https://doi.org/10.1039/C9RA03430G

Beiki H, Soukhtanlou E (2019) Improvement of salt gradient solar ponds’ performance using nanoparticles inside the storage layer. Appl Nanosci 9(2):243–254. https://doi.org/10.1007/s13204-018-0906-6

Abdel-Gaber AM, Awad R, Rahal HT, Moussa D (2019) Electrochemical behavior of composite nanoparticles on the corrosion of mild steel in different media. J Bio Tribo Corros 5(2):49. https://doi.org/10.1007/s40735-019-0241-9

Chintada VB, Koona R (2018) Influence of SiC nano particles on microhardness and corrosion resistance of electroless Ni–P coatings. J Bio Tribo Corros 4(4):68. https://doi.org/10.1007/s40735-018-0186-4

El-Nour KMMA, Eftaiha AA, Al-Warthan A, Ammar RAA (2010) Synthesis and applications of silver nanoparticles. Arab J Chem 3(3):135–140

ASTM G1–03 (2003) Standard practice for preparing, cleaning, and evaluating corrosion test specimens. ASTM International, West Conshohocken, PA

Boomadevi Janaki G, Xavier JR (2019) Evaluation of mechanical properties and corrosion protection performance of surface modified nano-alumina encapsulated epoxy coated mild steel. J Bio Tribo Corros 6(1):20. https://doi.org/10.1007/s40735-019-0316-7

Jain P, Patidar B, Bhawsar J (2020) Potential of nanoparticles as a corrosion inhibitor: a review. J Bio Tribo Corros 6(2):1–12

Verma S, Mohanty S, Nayak SK (2019) A review on protective polymeric coatings for marine applications. J Coat Technol Res 16(2):307–338. https://doi.org/10.1007/s11998-018-00174-2

Abioye OP, Loto CA, Fayomi OSI (2019) Evaluation of anti-biofouling progresses in marine application. J Bio Tribo Corros 5(1):22

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Beiki, H., Mosavi, S.J. Silver Nanoparticles-Polyurea Composite Coatings on ASTM A194 Steel: A Study of Corrosion Behavior in Chloride Medium. J Bio Tribo Corros 6, 66 (2020). https://doi.org/10.1007/s40735-020-00364-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-020-00364-9