Abstract

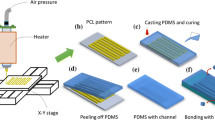

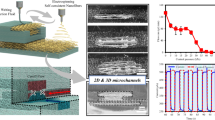

Microfluidic devices are critical in lab-on-chip, drug delivery, flexible sensors, etc. However, a formidable challenge remains in fabricating microfluidic channels with complex shapes during design and verification. Herein, we present a facile approach for manufacturing polystyrene (PS) templates by in-suit combining microscale electrohydrodynamic (EHD) printing and mesoscale direct ink writing (DIW). The desired multiscale filament width from 20 μm to > 1 mm could be obtained through appropriate voltage and pressure with continuous printing. The further process parameters for adjusting line width including deposition speed, auxiliary heating for DIW/EHD printing mode were investigated detailly. And we prove the stability and feasibility for producing microfluidics via the method by AFM, EDS and filling test. Based on the solubility of PS in the organic solvent, we can readily reconfigure the existing template by erasing and printing part of the patterns for better remanufacturing. Finally, the LM-filling PDMS microfluidic is experimented to demonstrate the future potential and advantage of the printing technology for fabricating the flexible microfluidic device.

Graphical Abstract

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article and/or its supplementary materials.

References

Ohno, K. I., Tachikawa, K., & Manz, A. (2008). Microfluidics: Applications for analytical purposes in chemistry and biochemistry. Electrophoresis, 29(22), 4443–4453.

Gold, K., Gaharwar, A. K., & Jain, A. (2019). Emerging trends in multiscale modeling of vascular pathophysiology: organ-on-a-chip and 3D printing. Biomaterials, 196, 2–17.

Tran, L. G., & Park, W. T. (2022). Biomimetic flow sensor for detecting flow rate and direction as an application for maneuvering autonomous underwater vehicle. International Journal of Precision Engineering and Manufacturing-Green Technology, 9(1), 163–173.

Song, C., Rogers, J. A., Kim, J.-M., & Ahn, H. (2014). Patterned polydiacetylene-embedded polystyrene nanofibers based on electrohydrodynamic jet printing. Macromolecular Research, 23(1), 118–123.

Cheng, S., & Wu, Z. (2010). Microfluidic stretchable RF electronics. Lab on a Chip, 10(23), 3227–3234.

MacDonald, E., & Wicker, R. (2016). Multiprocess 3D printing for increasing component functionality. Science, 353(6307), 1512.

Wehner, M., Truby, R. L., Fitzgerald, D. J., Mosadegh, B., Whitesides, G. M., Lewis, J. A., et al. (2016). An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature, 536(7617), 451–455.

Yang, H., & Gijs, M. A. (2018). Micro-optics for microfluidic analytical applications. Chemical Society Reviews, 47(4), 1391–1458.

Psaltis, D., Quake, S. R., & Yang, C. (2006). Developing optofluidic technology through the fusion of microfluidics and optics. Nature, 442(7101), 381–386.

Chen, J., Zhang, J., Luo, Z., Zhang, J., Li, L., Su, Y., et al. (2020). Superelastic, sensitive, and low hysteresis flexible strain sensor based on wave-patterned liquid metal for human activity monitoring. ACS Applied Materials & Interfaces, 12(19), 22200–22211.

Park, S., Mondal, K., Treadway, R. M., 3rd., Kumar, V., Ma, S., Holbery, J. D., et al. (2018). Silicones for stretchable and durable soft devices: beyond sylgard-184. ACS Applied Materials & Interfaces, 10(13), 11261–11268.

Coppola, S., Nasti, G., Todino, M., Olivieri, F., Vespini, V., & Ferraro, P. (2017). Direct writing of microfluidic footpaths by Pyro-EHD printing. ACS Applied Materials & Interfaces, 9(19), 16488–16494.

Su, R., Wen, J., Su, Q., Wiederoder, M. S., Koester, S. J., Uzarski, J. R., et al. (2020). 3D printed self-supporting elastomeric structures for multifunctional microfluidics. Science Advances, 6(41), eabc9846.

Manz, A., Graber, N., & Widmer, H. M. (1990). Miniaturized Total Chemical Analysis Systems a Novel Concept for Chemical Sensing. Sensors and Actuators B: Chemical, 1(1–6), 244–248.

Wilson, M. E., Kota, N., Kim, Y., Wang, Y., Stolz, D. B., LeDuc, P. R., et al. (2011). Fabrication of circular microfluidic channels by combining mechanical micromilling and soft lithography. Lab on a Chip, 11(8), 1550–1555.

Thelen, J., Dickey, M. D., & Ward, T. (2012). A study of the production and reversible stability of EGaIn liquid metal microspheres using flow focusing. Lab on a Chip, 12(20), 3961–3967.

Chen, C., Mehl, B. T., Munshi, A. S., Townsend, A. D., Spence, D. M., & Martin, R. S. (2016). 3D-printed microfluidic devices: fabrication, advantages and limitations-a mini review. Analytical Methods, 8(31), 6005–6012.

Yuk, H., Zhang, T., Parada, G. A., Liu, X., & Zhao, X. (2016). Skin-inspired hydrogel-elastomer hybrids with robust interfaces and functional microstructures. Nature Communications, 7(1), 12028.

Chen, H., Bian, F., Sun, L., Zhang, D., Shang, L., & Zhao, Y. (2020). Hierarchically Molecular Imprinted Porous Particles for Biomimetic Kidney Cleaning. Advanced Materials, 32(52), e2005394.

Lai, X., Pu, Z., Yu, H., & Li, D. (2020). Inkjet Pattern-Guided Liquid Templates on Superhydrophobic Substrates for Rapid Prototyping of Microfluidic Devices. ACS Applied Materials & Interfaces, 12(1), 1817–1824.

Parekh, D. P., Ladd, C., Panich, L., Moussa, K., & Dickey, M. D. (2016). 3D printing of liquid metals as fugitive inks for fabrication of 3D microfluidic channels. Lab on a Chip, 16(10), 1812–1820.

Chi, X., Zhang, X., Li, Z., Yuan, Z., Zhu, L., Zhang, F., et al. (2020). Fabrication of Microfluidic Chips Based on an EHD-Assisted Direct Printing Method. Sensors (Basel), 20(6), 1559.

Alam, M., Hossain, F., Vale, A., & Kouzani, A. (2017). Design and fabrication of a 3D printed miniature pump for integrated microfluidic applications. International Journal of Precision Engineering and Manufacturing, 18(9), 1287–1296.

Kim, S., Lee, J., & Choi, B. (2016). 3D printed fluidic valves for remote operation via external magnetic field. International Journal of Precision Engineering and Manufacturing, 17(7), 937–942.

Homan, K. A., Kolesky, D. B., Skylar-Scott, M. A., Herrmann, J., Obuobi, H., Moisan, A., et al. (2016). Bioprinting of 3D Convoluted Renal Proximal Tubules on Perfusable Chips. Scientific Reports, 6, 34845.

Kolesky, D. B., Homan, K. A., Skylar-Scott, M. A., & Lewis, J. A. (2016). Three-dimensional bioprinting of thick vascularized tissues. Proceedings of the National Academy of Sciences, 113(12), 3179–3184.

Castiaux, A. D., Pinger, C. W., Hayter, E. A., Bunn, M. E., Martin, R. S., & Spence, D. M. (2019). PolyJet 3D-printed enclosed microfluidic channels without photocurable supports. Analytical Chemistry, 91(10), 6910–6917.

Bressan, L. P., Lima, T. M., da Silveira, G. D., & da Silva, J. A. F. (2020). Low-cost and simple FDM-based 3D-printed microfluidic device for the synthesis of metallic core–shell nanoparticles. SN Applied Sciences, 2(5), 1–8.

Wang, Y., & Willenbacher, N. (2022). Phase-change enabled, rapid, high-resolution direct ink writing of soft silicone. Advanced Materials, 34(15), 2109240.

Hansen, C. J., Saksena, R., Kolesky, D. B., Vericella, J. J., Kranz, S. J., Muldowney, G. P., et al. (2013). High-throughput printing via microvascular multinozzle arrays. Advanced Materials, 25(1), 96–102.

Skylar-Scott, M. A., Gunasekaran, S., & Lewis, J. A. (2016). Laser-assisted direct ink writing of planar and 3D metal architectures. Proceedings of The National Academy of Sciences of The United States of America, 113(22), 6137–6142.

Ren, L. Q., Li, B. Q., Song, Z. Y., Liu, Q. P., Ren, L., & Zhou, X. L. (2019). 3D printing of bioinspired structural materials with fibers induced by doctor blading process. International Journal of Precision Engineering and Manufacturing-Green Technology, 6(1), 89–99.

Sharma, A., Mondal, S., Mondal, A. K., Baksi, S., Patel, R. K., Chu, W. S., et al. (2017). 3D Printing: it’s microfluidic functions and environmental impacts. International Journal of Precision Engineering and Manufacturing-Green Technology, 4(3), 323–334.

Lee, J., Kim, H. C., Choi, J. W., & Lee, I. H. (2017). A review on 3D printed smart devices for 4D printing. International Journal of Precision Engineering and Manufacturing-Green Technology, 4(3), 373–383.

Noroozi, R., Mashhadi Kashtiban, M., Taghvaei, H., Zolfagharian, A., & Bodaghi, M. (2022). 3D-printed microfluidic droplet generation systems for drug delivery applications. Materials Today: Proceedings, 70, 443–446.

Muluneh, M., & Issadore, D. (2014). A multi-scale PDMS fabrication strategy to bridge the size mismatch between integrated circuits and microfluidics. Lab on a Chip, 14(23), 4552–4558.

Sun, T., Hui, J., Zhou, L., Lin, B., Sun, H., Bai, Y., et al. (2022). A low-cost and simple-fabricated epidermal sweat patch based on “cut-and-paste” manufacture. Sensors and Actuators B: Chemical, 368, 132184.

Kramer, R., Verlinden, E. J., Angeloni, L., van den Heuvel, A., Fratila-Apachitei, L. E., van der Maarel, S. M., et al. (2020). Multiscale 3D-printing of microfluidic AFM cantilevers. Lab on a Chip, 20(2), 311–319.

Zhou, L., Fu, J., Gao, Q., Zhao, P., & He, Y. (2019). All-Printed Flexible and Stretchable Electronics with Pressing or Freezing Activatable Liquid-Metal–Silicone Inks. Advanced Functional Materials, 30(3), 1906683.

Yuk, H., & Zhao, X. (2018). A New 3D Printing Strategy by Harnessing Deformation, Instability, and Fracture of Viscoelastic Inks. Advanced Materials, 30(6), 1704028.

Wei, C., & Dong, J. (2013). Direct fabrication of high-resolution three-dimensional polymeric scaffolds using electrohydrodynamic hot jet plotting. Journal of Micromechanics and Microengineering, 23(2), 025017.

Liashenko, I., Rosell-Llompart, J., & Cabot, A. (2020). Ultrafast 3D printing with submicrometer features using electrostatic jet deflection. Nature Communications, 11(1), 753.

Park, J. U., Hardy, M., Kang, S. J., Barton, K., Adair, K., Mukhopadhyay, D. K., et al. (2007). High-resolution electrohydrodynamic jet printing. Nature Materials, 6(10), 782–789.

Abbas, Z., Wang, D., Lu, L., Du, Z., Zhao, X., Zhao, K., et al. (2022). The Focused Electrode Ring for Electrohydrodynamic Jet and Printing on Insulated Substrate. International Journal of Precision Engineering and Manufacturing, 23(5), 545–563.

Olanrewaju, A., Beaugrand, M., Yafia, M., & Juncker, D. (2018). Capillary microfluidics in microchannels: From microfluidic networks to capillaric circuits. Lab on a Chip, 18(16), 2323–2347.

Zhang, K., Wang, H., Yao, K., He, G., Zhou, Z., & Sun, D. (2020). Surface roughness improvement of 3D printed microchannel. Journal of Micromechanics and Microengineering, 30(6), 065003.

Javidanbardan, A., Azevedo, A. M., Chu, V., & Conde, J. P. (2021). A systematic approach for developing 3D high-quality PDMS microfluidic chips based on micromilling technology. Micromachines, 13(1), 6.

Liu, H.-B., & Gong, H.-Q. (2009). Templateless prototyping of polydimethylsiloxane microfluidic structures using a pulsed CO2 laser. Journal of Micromechanics and Microengineering, 19(3), 037002.

Ayoib, A., Hashim, U., Arshad, M. M., & Thivina, V. (2016). Soft lithography of microfluidics channels using SU-8 mould on glass substrate for low cost fabrication. In: IEEE EMBS Conference on Biomedical Engineering and Sciences, pp. 226–229

Lin, Y., Gordon, O., Khan, M. R., Vasquez, N., Genzer, J., & Dickey, M. D. (2017). Vacuum filling of complex microchannels with liquid metal. Lab on a Chip, 17(18), 3043–3050.

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (Grant No. 51875253, No. 51905216, and No. 21788102) and the China Scholarship Council.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interests

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file2 (MP4 2635 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, J., Hong, H., Wang, Z. et al. Multiscale Prototyping Approach via In-situ Switching Electrohydrodynamics for Flexible Microfluidic Design. Int. J. of Precis. Eng. and Manuf.-Green Tech. 11, 353–364 (2024). https://doi.org/10.1007/s40684-023-00543-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-023-00543-2