Abstract

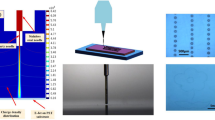

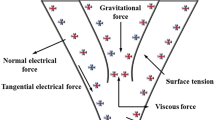

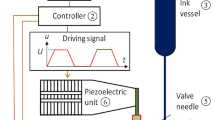

Drop-on-demand electrohydrodynamic jet (DoD E-Jet) printing is considered a well-known type of fabrication method contemporary since it can be used to print high-resolution microstructures (< 1 μm) on various insulating substrates. This paper presents a numerical study of DoD E-Jet printing using a novel combination of needle and focused electrode ring to print stable and consistent microdroplets on a Polyethylene terephthalate substrate. Primarily, a phase field method was used to generate a stable cone-jet morphology that can allow the production of high-resolution micron/nano structures on PET substrates. The numerical simulation of cone-jet morphology was performed by COMSOL multiphysics software. Further, the impact of key parameters such as flow rate and dc positive pulse voltage was studied on cone-jet morphology through numerical simulation. Subsequently, optimized operating parameters i.e., f = 5.3 × 10–15 m3 s−1, Vn = 1.9 kV and Vr = 0.7 kV were achieved by performing a series of numerical experiments. Then, optimized parameters by simulation were directly used to print arrays of stable droplets on PET substrate using the focused electrode ring in different locations by regulating distance 0.2 mm to 1.3 mm between needles to focused electrode ring. The minimum size of stable microdrop was measured 3 μm on PET substrate (thickness = 0.2 mm) using a 50 μm size quartz capillary maintaining a distance of 0.2 mm between combined needle and focused electrode ring. The experimental results proved that the simulation model is useful for printing different microstructures on insulating substrates and creating a promising production path for micro-electro mechanical system and nano-electro mechanical system (MEMS and NEMS).

Similar content being viewed by others

References

Algamili, A. S., Khir, M. H. M., Dennis, J. O., Ahmed, A. Y., Alabsi, S. S., Ba Hashwan, S. S., & Junaid, M. M. (2021). A review of actuation and sensing mechanisms in MEMS-based sensor devices. Nanoscale Research Letters, 16. https://doi.org/10.1186/s11671-021-03481-7.

Bao, M., & Wang, W. (1996). Future of microelectromechanical systems (MEMS). Sensors and Actuators, A: Physical, 56, 135–141. https://doi.org/10.1016/0924-4247(96)01274-5

Sahdom, A. S. (2019). Application of micro electro-mechanical sensors (MEMS) devices with wifi connectivity and cloud data solution for industrial noise and vibration measurements. Journal of Physics: Conference Series, 1262. https://doi.org/10.1088/1742-6596/1262/1/012025.

Abbas, Z., Wang, D., Du, Z., Qian, J., Zhao, K., & Du, Z. (2020). Numerical simulation of electrohydrodynamic jet and printing micro- structures on flexible substrate. Microsystem Technologies, 1. https://doi.org/10.1007/s00542-020-05068-1.

Chan, M. L., Yoxall, B., Park, H., Kang, Z., Izyumin, I., Chou, J., Megens, M. M., Wu, M. C., Boser, B. E., & Horsley, D. A. (2012). Design and characterization of MEMS micromotor supported on low friction liquid bearing. Sensors and Actuators, A: Physical, 177, 1–9. https://doi.org/10.1016/j.sna.2011.08.003

Lee, B., Seok, S., & Chun, K. (2003). A study on wafer level vacuum packaging for MEMS devices. Journal of Micromechanics and Microengineering, 13, 663–669. https://doi.org/10.1088/0960-1317/13/5/318

Park, Y., Oh, O., & Noh, M. D. (2015). Ejection feasibility of high viscosity fluid with magnetostrictive inkjet printhead,16, 1369–1374. https://doi.org/10.1007/s12541-015-0180-4.

Abbas, Z., Wang, D., Du, Z., Zhao, K., Du, Z., & Lu, L. (2021). Microelectronic Engineering Numerical simulation of stable electrohydrodynamic cone-jet formation and printing on flexible substrate. Microelectronic Engineering, 237, 111496. https://doi.org/10.1016/j.mee.2020.111496

Riheen, M. A., Saha, T. K., & Sekhar, P. K. (2019). Inkjet printing on PET substrate. Journal of the Electrochemical Society, 166, B3036–B3069. https://doi.org/10.1149/2.0091909jes

Hebner, T. R., Wu, C. C., Marcy, D., Lu, M. H., & Sturm, J. C. (1998). Ink-jet printing of doped polymers for organic light emitting devices. Applied Physics Letters, 72, 519–521. https://doi.org/10.1063/1.120807

Sirringhaus, H., Kawase, T., Friend, R. H., Shimoda, T., Inbasekaran, M., Wu, W., & Woo, E. P. (2000). High-resolution inkjet printing of all-polymer transistor circuits. Science, 290, 2123–2126. https://doi.org/10.1126/science.290.5499.2123

Choi, J., Lee, S., Kim, Y. J., Son, S. U., & An, K. C. (2012). High aspect ratio EHD printing with high viscosity ink ejection. In Technical Proceedings of the 2012 NSTI Nanotechnology Conference and Expo, NSTI-Nanotech 2012 (pp. 267–270).

Choi, J., Kim, Y. J., Lee, S., Son, S. U., Ko, H. S., Nguyen, V. D., & Byun, D. (2008). Drop-on-demand printing of conductive ink by electrostatic field induced inkjet head. Applied Physics Letters, 93, 87–90. https://doi.org/10.1063/1.3020719

Wei, C., Qin, H., Chiu, C., Lee, Y., & Dong, J. (2015). Drop-on-demand E-jet printing of continuous interconnects with AC-pulse modulation on highly insulating substrates. Journal of Manufacturing Systems, 37, 505–510. https://doi.org/10.1016/j.jmsy.2014.07.005

Wang, D., Abbas, Z., Lu, L., Zhao, X., Xu, P., Zhao, K., Yin, P., & Liang, J. (2022). Numerical modeling and analysis of coaxial electrohydro dynamic jet printing. Scientific Reports, 12, 1–17. https://doi.org/10.1038/s41598-022-05596-y

Yuan, S., Si, T., Liu, Z., & Xu, R. X. (2014). Microfabrication of curcumin-loaded microparticles using coaxial electrohydrodynamic atomization. Reporters, Markers, Dyes, Nanoparticles, and Molecular Probes for Biomedical Applications VI, 8956, 895618. https://doi.org/10.1117/12.2041070

Kim, J., Oh, H., & Kim, S. S. (2008). Electrohydrodynamic drop-on-demand patterning in pulsed cone-jet mode at various frequencies,39, 819–825. https://doi.org/10.1016/j.jaerosci.2008.05.001.

Emission, A., Hakiai, K., Ishida, Y., Asano, T., Driving, I., Ishida, Y., Sogabe, K., Electrospray, D., Ishida, Y., Sogabe, K., Lee, S., Kim, J., Driving, I., & Emission, A. (2005). Electrostatic droplet ejection using planar needle inkjet head. https://doi.org/10.1143/JJAP.44.5781.

Rahman, K., Ali, K., Muhammad, N. M., Hyun, M. T., & Choi, K. H. (2013). Fine resolution drop-on-demand electrohydrodynamic patterning of conductive silver tracks on glass substrate. Applied Physics A: Materials Science and Processing, 111, 593–600. https://doi.org/10.1007/s00339-012-7267-x

Li, J., & Zhang, P. (2009). Formation and droplet size of EHD drippings induced by superimposing an electric pulse to background voltage. Journal of Electrostatics, 67, 562–567. https://doi.org/10.1016/j.elstat.2008.11.007

Rahman, K., Ko, J., Khan, S., Kim, D., & Choi, K. (2010). Simulation of droplet generation through electrostatic forces † 24, 307–310.

Rahman, K., Khan, A., Nam, N. M., Choi, K. H., & Kim, D. (2011). Study of drop-on-demand printing through multi- step pulse voltage,12, 663–669. https://doi.org/10.1007/s12541-011-0086-8.

Wang, C., & Smith, K. A. (2011). Numerical simulation of cone-jet formation in electrohydrodynamic atomization,57, 57–78. https://doi.org/10.1002/aic.

Schnitzer, O., & Yariv, E. (2015). The Taylor-Melcher leaky dielectric model as a macroscale electrokinetic description. Journal of Fluid Mechanics, 773, 1–33. https://doi.org/10.1017/jfm.2015.242

Saville, D. A. (1997). Electrohydrodynamics: The Taylor-Melcher leaky dielectric model. Annual Review of Fluid Mechanics, 29, 27–64. https://doi.org/10.1146/annurev.fluid.29.1.27

Jacqmin, D. (1999). Calculation of two-phase Navier-Stokes flows using phase-field modeling. Journal of Computational Physics, 155, 96–127. https://doi.org/10.1006/jcph.1999.6332

Herrada, M. A., Vega, E. J., Montanero, J. M., & Popinet, S. (2021). Numerical simulation of electrospray in the cone-jet mode,026305, 1–8. https://doi.org/10.1103/PhysRevE.86.026305.

Boyer, F., Lapuerta, C., Minjeaud, S., Piar, B., & Quintard, M. (2010). Cahn-Hilliard/Navier-Stokes model for the simulation of three-phase flows. Transport in Porous Media, 82, 463–483. https://doi.org/10.1007/s11242-009-9408-z

Sheehy, P., & Owkes, M. (2017). Numerical study of electric Reynolds number on electrohydrodynamic (EHD) assisted atomization, 27, 645–664.

Kim, S. Y., Kim, Y., Park, J., & Hwang, J. (2010). Design and evaluation of single nozzle with a non-conductive tip for reducing applied voltage and pattern width in electrohydrodynamic jet printing (EHDP). Journal of Micromechanics and Microengineering, 20 (2010). https://doi.org/10.1088/0960-1317/20/5/055009.

Zhao, X., Wang, D., Lin, Y., Sun, Y., Ren, T., Liang, J., & Madou, M. (2019). Numerical simulation of coaxial electrohydrodynamic jet and printing nanoscale structures. Microsystem Technologies. https://doi.org/10.1007/s00542-019-04499-9

Lastow, O., & Balachandran, W. (2006). Numerical simulation of electrohydrodynamic (EHD) atomization. Journal of Electrostatics, 64, 850–859. https://doi.org/10.1016/j.elstat.2006.02.006

Zhao, X., Wang, D., Lin, Y., Sun, Y., Ren, T., Liang, J., & Madou, M. (2019). Numerical simulation of coaxial electrohydrodynamic jet and printing nanoscale structures. Microsystem Technologies, 25, 4651–4661. https://doi.org/10.1007/s00542-019-04499-9

Yin, Z., Huang, Y. A., Duan, Y., & Zhang, H. (2017). Electrohydrodynamic direct-writing for flexible electronic manufacturing. https://doi.org/10.1007/9789811047596.

Rahman, T. T., Arman, M. S., Perez, V., Xu, B., & Li, J. (2021). Analysis of the operating conditions of pulse electric field–assisted EHD for sodium alginate printing using design of experiment approach. International Journal of Advanced Manufacturing Technology, 115, 2037–2047. https://doi.org/10.1007/s00170-021-07042-1.

Han, Y., & Dong, J. (2018). Electrohydrodynamic printing for advanced micro/nanomanufacturing: Current progresses, opportunities, and challenges. Journal of Micro and Nano-Manufacturing, 6. https://doi.org/10.1115/1.4041934.

Wang, D., Zhao, X., Lin, Y., Liang, J., Ren, T., Liu, Z., & Li, J. (2018). Nanoscale coaxial focused electrohydrodynamic jet printing. Nanoscale, 10, 9867–9879. https://doi.org/10.1039/c8nr01001c

Kang, D. K., Lee, M. W., Kim, H. Y., James, S. C., & Yoon, S. S. (2011). Electrohydrodynamic pulsed-inkjet characteristics of various inks containing aluminum particles. Journal of Aerosol Science, 42, 621–630. https://doi.org/10.1016/j.jaerosci.2011.06.009

Acknowledgements

This research was supported by National Key R&D Program of China (2018YFA0703200), National Natural Science Foundation of China (51975104, 62074138), and Ningbo Institute of Dalian University of Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abbas, Z., Wang, D., Lu, L. et al. The Focused Electrode Ring for Electrohydrodynamic Jet and Printing on Insulated Substrate. Int. J. Precis. Eng. Manuf. 23, 545–563 (2022). https://doi.org/10.1007/s12541-022-00634-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-022-00634-1