Abstract

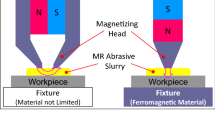

Magnetic-field assisted finishing (MAF) is a surface finishing process that utilizes a flexible brush composed of iron and abrasive particles typically mixed in a liquid medium. This paper presents an innovative approach to enhance the MAF performance by adding nano-scale solid lubricant into the brush. In particular, exfoliated graphite nanoplatelets (xGnPs), multi-layered graphene platelets with micro-scale diameter and nano-scale thickness, have been introduced into the brush. The modified brush consisting of iron particles, abrasives (cubic boron nitride, cBN), and xGnPs in silicone oil was applied to finish the surface of mold steel. While varying magnetic flux density, cBN particle sizes, and xGnP content in the MAF brush, a series of MAF experiments was conducted to examine their impact on the achieved surface quality on a workpiece and the life of MAF brush. For a given content of xGnPs in the brush, the quality of surface finish was improved and the life of MAF brush was extended significantly with larger abrasives in the brush. Furthermore, the effect of xGnPs with respect to abrasive size was investigated with various factors such as relative number and surface area coverage of xGnPs per abrasive, the relative size of xGnP to abrasives, and depth indented by abrasives on the workpiece, which enabled us to identify the change in the underlying mechanisms in relation to the abrasive size. The new MAF brush is also expected to improve the efficiencies of the overall MAF process in terms of energy consumption and material utilization.

Similar content being viewed by others

References

Beaucamp, A., Namba, Y., & Charlton, P. (2015). Process mechanism in shape adaptive grinding (SAG). CIRP Annals, 64(1), 305–308. https://doi.org/10.1016/j.cirp.2015.04.096

Beaucamp, A., & Namba, Y. (2013). Super-smooth finishing of diamond turned hard X-ray molding dies by combined fluid jet and bonnet polishing. CIRP Annals, 62(1), 315–318. https://doi.org/10.1016/j.cirp.2013.03.010

Kwak, J.-S. (2009). Enhanced magnetic abrasive polishing of non-ferrous metals utilizing a permanent magnet. International Journal of Machine Tools and Manufacture, 49(7–8), 613–618. https://doi.org/10.1016/j.ijmachtools.2009.01.013

Yamaguchi, H., Fergani, O., & Wu, P.-Y. (2017). Modification using magnetic field-assisted finishing of the surface roughness and residual stress of additively manufactured components. CIRP Annals, 66(1), 305–308. https://doi.org/10.1016/j.cirp.2017.04.084

Beaucamp, A. T. H., & Namba, Y. (2014). Technological advances in super fine finishing. In: Proceedings of the 14th euspen International Conference, Dubrovnik, p 1–19

Kim, U. S., & Park, J. W. (2019). High-quality surface finishing of industrial three-dimensional metal additive manufacturing using electrochemical polishing. International Journal of Precision Engineering and Manufacturing-Green Technology, 6(1), 11–21. https://doi.org/10.1007/s40684-019-00019-2

Chen, B., Li, S., Deng, Z., Guo, B., & Zhao, Q. (2017). Grinding marks on ultra-precision grinding spherical and aspheric surfaces. International Journal of Precision Engineering and Manufacturing-Green Technology, 4(4), 419–429. https://doi.org/10.1007/s40684-017-0047-5

Chang, G.-W., Yan, B.-H., & Hsu, R.-T. (2002). Study on cylindrical magnetic abrasive finishing using unbonded magnetic abrasives. International Journal of Machine Tools and Manufacture, 42(5), 575–583. https://doi.org/10.1016/S0890-6955(01)00153-5

Shinmura, T., Takazawa, K., Hatano, E., Matsunaga, M., & Matsuo, T. (1990). Study on magnetic abrasive finishing. CIRP Annals, 39(1), 325–328. https://doi.org/10.1016/S0007-8506(07)61064-6

Kim, S.-O., & Kwak, J.-S. (2012). Evaluations of magnetic abrasive polishing and distribution of magnetic flux density on the curvature of non-ferrous material. Transactions of the Korean Society of Mechanical Engineers A, 36(3), 259–264. https://doi.org/10.3795/KSME-A.2012.36.3.259

Yamaguchi, H., Srivastava, A. K., Tan, M., & Hashimoto, F. (2014). Magnetic Abrasive Finishing of cutting tools for high-speed machining of titanium alloys. CIRP Journal of Manufacturing Science and Technology, 7(4), 299–304. https://doi.org/10.1016/j.cirpj.2014.08.002

Jiang, C., Huang, J., Jiang, Z., Qian, D., & Hong, X. (2021). Estimation of energy savings when adopting ultrasonic vibration-assisted magnetic compound fluid polishing. International Journal of Precision Engineering and Manufacturing-Green Technology, 8(1), 1–11. https://doi.org/10.1007/s40684-019-00167-5

Park, C., Kim, H., Lee, S., & Jeong, H. (2015). The influence of abrasive size on high-pressure chemical mechanical polishing of sapphire wafer. International Journal of Precision Engineering and Manufacturing-Green Technology, 2(2), 157–162. https://doi.org/10.1007/s40684-015-0020-0

Misra, A., Pandey, P. M., & Dixit, U. S. (2017). Modeling of material removal in ultrasonic assisted magnetic abrasive finishing process. International Journal of Mechanical Sciences, 131–132, 853–867. https://doi.org/10.1016/j.ijmecsci.2017.07.023

Misra, A., Pandey, P. M., & Dixit, U. S. (2017). Modeling and simulation of surface roughness in ultrasonic assisted magnetic abrasive finishing process. International Journal of Mechanical Sciences, 133, 344–356. https://doi.org/10.1016/j.ijmecsci.2017.08.056

Zhang, J., Chaudhari, A., & Wang, H. (2019). Surface quality and material removal in magnetic abrasive finishing of selective laser melted 316L stainless steel. Journal of Manufacturing Processes, 45, 710–719. https://doi.org/10.1016/j.jmapro.2019.07.044

Mulik, R. S., & Pandey, P. M. (2011). Experimental investigations and optimization of ultrasonic assisted magnetic abrasive finishing process. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 225(8), 1347–1362. https://doi.org/10.1177/09544054JEM2122

Singh, D. K., Jain, V. K., Raghuram, V., & Komanduri, R. (2005). Analysis of surface texture generated by a flexible magnetic abrasive brush. Wear, 259(7–12), 1254–1261. https://doi.org/10.1016/j.wear.2005.02.030

Mun, S.-D. (2010). Micro machining of high-hardness materials using magnetic abrasive grains. International Journal of Precision Engineering and Manufacturing, 11(5), 763–770. https://doi.org/10.1007/s12541-010-0090-4

Wu, P.-Y., & Yamaguchi, H. (2018). Material removal mechanism of additively manufactured components finished using magnetic abrasive finishing. Procedia Manufacturing, 26, 394–402. https://doi.org/10.1016/j.promfg.2018.07.047

Lee, P.-H., Chung, H., McCormick, P. S., Kwon, P., Nguyen, H., Yang, Y., & Shao, C. (2018). Experimental and statistical study on magnetic-field assisted finishing of mold steel using nano-scale solid lubricant and abrasive particles. In: Volume 3: Manufacturing equipment and systems (p. V003T02A012). Presented at the ASME 2018 13th International Manufacturing Science and Engineering Conference, College Station, Texas, USA: American Society of Mechanical Engineers.https://doi.org/10.1115/MSEC2018-6544

Bozzi, A. C., & de Mello, J. D. B. (1999). Wear resistance and wear mechanisms of WC–12%Co thermal sprayed coatings in three-body abrasion. Wear, 233–235, 575–587. https://doi.org/10.1016/S0043-1648(99)00206-9

Marinescu, I. D., Rowe, W. B., Dimitrov, B., & Ohmori, H. (2013). Loose abrasive processes. Tribology of abrasive machining processes (pp. 399–421). Elsevier. https://doi.org/10.1016/b978-1-4377-3467-6.00013-6

Gates, J. D. (1998). Two-body and three-body abrasion: a critical discussion. Wear, 214(1), 139–146. https://doi.org/10.1016/S0043-1648(97)00188-9

Yoon, S., Tu, J.-F., Lee, J. H., Yang, G. E., & Mun, S. D. (2014). Effect of the magnetic pole arrangement on the surface roughness of STS 304 by magnetic abrasive machining. International Journal of Precision Engineering and Manufacturing, 15(7), 1275–1281. https://doi.org/10.1007/s12541-014-0467-x

Chou, S.-H., Wang, A.-C., & Lin, Y.-C. (2016). Elucidating the rheological effect of gel abrasives in magnetic abrasive finishing. Procedia CIRP, 42, 866–871. https://doi.org/10.1016/j.procir.2016.03.010

Tsai, L., Wang, A.-C., Chou, S.-H., & Zhong, C.-J. (2012). Investigating of flexible self-sharpening and optimal parameters in magnetic finishing with gel abrasive. International Journal of Precision Engineering and Manufacturing, 13(5), 655–661. https://doi.org/10.1007/s12541-012-0085-4

Wang, Y., Wu, Y., & Mitsuyoshi, N. (2016). A novel magnetic field-assisted polishing method using magnetic compound slurry and its performance in mirror surface finishing of miniature V-grooves. AIP Advances, 6(5), 056602. https://doi.org/10.1063/1.4942952

Sharma, A. K., Tiwari, A. K., & Dixit, A. R. (2016). Effects of minimum quantity lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: a comprehensive review. Journal of Cleaner Production, 127, 1–18. https://doi.org/10.1016/j.jclepro.2016.03.146

Nguyen, T. K., Do, I., & Kwon, P. (2012). A tribological study of vegetable oil enhanced by nano-platelets and implication in MQL machining. International Journal of Precision Engineering and Manufacturing, 13(7), 1077–1083. https://doi.org/10.1007/s12541-012-0141-0

Xu, X., Huang, S., Wang, M., & Yao, W. (2017). A study on process parameters in end milling of AISI-304 stainless steel under electrostatic minimum quantity lubrication conditions. The International Journal of Advanced Manufacturing Technology, 90(1–4), 979–989. https://doi.org/10.1007/s00170-016-9417-3

Marinescu, I. D., Rowe, W. B., Dimitrov, B., & Ohmori, H. (2013). Forces, friction, and energy. Tribology of abrasive machining processes (pp. 95–136). Elsevier. https://doi.org/10.1016/b978-1-4377-3467-6.00005-7

Rowe, W. B. (2009). Temperatures in grinding. Principles of modern grinding technology (pp. 365–398). Elsevier. https://doi.org/10.1016/b978-0-8155-2018-4.50024-0

Nguyen, T. K., Kwon, P. Y., & Park, K.-H. (2013). A critical factor in enhancement of MQL lubricants: platelet thickness. In Volume 2: Systems; Micro and Nano Technologies; Sustainable Manufacturing (p. V002T03A014). In: Presented at the ASME 2013 International Manufacturing Science and Engineering Conference collocated with the 41st North American Manufacturing Research Conference, Madison, Wisconsin, USA: American Society of Mechanical Engineers. https://doi.org/10.1115/MSEC2013-1145

Park, K. H., Ewald, B., & Kwon, P. Y. (2011). Effect of nano-enhanced lubricant in minimum quantity lubrication balling milling. Journal of Tribology. https://doi.org/10.1115/1.4004339

Kwon, P., & Drzal, L. T. (2015). Nanoparticle graphite-based minimum quantity lubrication method and composition. Retrieved from https://patents.google.com/patent/US9080122B2/en

Kien Nguyen, T., Park, K.-H., & Kwon, P. Y. (2016). Experimental results on lamellar-type solid lubricants in enhancing minimum quantity lubrication machining. Journal of Manufacturing Science and Engineering, 138(10), 101011. https://doi.org/10.1115/1.4033995

World Leading Graphene Company | XG Sciences. (n.d.). Retrieved May 13, 2020, from https://xgsciences.com/

Guo, J., Tan, Z. E., Au, K. H., & Liu, K. (2017). Experimental investigation into the effect of abrasive and force conditions in magnetic field-assisted finishing. The International Journal of Advanced Manufacturing Technology, 90(5–8), 1881–1888.

Yang, S., & Li, W. (2018). Surface quality and finishing technology. Surface finishing theory and new technology (pp. 1–64). Springer Berlin Heidelberg. https://doi.org/10.1007/978-3-662-54133-3_1

Okman, O. (2005). Free forming of locally induction heated specimens (PhD Thesis). Middle East Technical University

Johnson, K. L., & Johnson, K. L. (1987). Contact mechanics. Cambridge University Press.

D’Evelyn, M. P., & Zgonc, K. (1997). Elastic properties of polycrystalline cubic boron nitride and diamond by dynamic resonance measurements. Diamond and Related Materials, 6(5–7), 812–816. https://doi.org/10.1016/S0925-9635(96)00631-0

Rabinowicz, E., Dunn, L. A., & Russell, P. G. (1961). A study of abrasive wear under three-body conditions. Wear, 4(5), 345–355. https://doi.org/10.1016/0043-1648(61)90002-3

Acknowledgements

This research was supported by LG Electronics, 2020 MTRAC award, and Michigan State University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Poudel, B., Lee, Ph., Song, G. et al. Innovative Magnetic-Field Assisted Finishing (MAF) Using Nano-Scale Solid Lubricant: A Case Study on Mold Steel. Int. J. of Precis. Eng. and Manuf.-Green Tech. 9, 1411–1426 (2022). https://doi.org/10.1007/s40684-021-00404-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-021-00404-w