Abstract

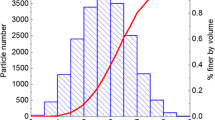

Some numerical simulations of drained and undrained triaxial tests on granular materials with different initial densities are carried out with the three-dimensional discrete element method. An in-depth particle-scale analysis is performed quantitatively to illustrate the physical mechanism of the shear mechanical behaviors, with a special attention paid to the characteristics of quasi-steady state and critical state. The simulation results show that the initial density and shear drainage condition both have significant effects on the evolution of stress–strain, coordination number, fabric anisotropy factor, force chains and clusters. The chained grains ratio and the mean length of force chains in the specimens are constantly adjusted to bear and transfer the changing external loads. The transitions between small clusters and large clusters are also continually taking place in varying degrees, correlating to volumetric contraction or dilation. For the loose undrained triaxial specimen presenting quasi-steady state during shearing, the coordination number decreases obviously to nearly 4 and then increases again; the chained grains ratio decreases after a slight increase in the initial loading stage, and then begin to increase again after a period of lower value of around 0.285; the volume ratio of small, submedium and medium clusters all first decreases and then increase gradually, meanwhile volume ratio of large clusters increases sharply to as much as 0.28 and then decreases gradually. The macroscopic critical state of granular materials is a comprehensively external manifestation when the microscopic coordination number and mesoscopic force chains and clusters all evolute to a dynamic equilibrium. At the critical state, the deviator stress, void ratio, coordination number, fabric anisotropy factor, and the volume ratio of small clusters and large clusters all manifest a respectively unique linear relationship with the mean effective stress.

Similar content being viewed by others

References

Rowe PW (1970) The relationship between the shear strength of sands in triaxial compression, plane strain and direct shear. Géotechnique 20(2):215–218. https://doi.org/10.1680/geot.1970.20.2.215

Charles JA, Watts KS (1980) The influence of confining pressure on the shear strength of compacted rockfill. Géotechnique 30(4):353–367. https://doi.org/10.1016/0148-9062(81)91010-x

Indraratna B, Ionescu D, Christie HD (1998) Shear behaviour of railway ballast based on large scale triaxial testing. J Geotech Geoenviron Eng 124(5):439–449. https://doi.org/10.1061/(ASCE)1090-0241(1998)124:5(439)

Shi WC, Zhu JG, Chiu CF, Liu HL (2010) Strength and deformation behaviour of coarse-grained soil by true triaxial tests. J Cent South Univ T 17(5):1095–1102. https://doi.org/10.1007/s11771-010-0602-5

Zhang HY, Xu WJ, Yu YZ (2016) Triaxial tests of soil-rock mixtures with different rock block distributions. Soils Found 56(1):44–56. https://doi.org/10.1016/j.sandf.2016.01.004

Chu J, Leong WK (2001) Pre-failure strain softening and pre-failure instability of sand: a comparative study. Géotechnique 51(4):311–321. https://doi.org/10.1680/geot.51.4.311.39402

Khoa HDV, Georgopoulos IO, Darve F, Laouafa F (2006) Diffuse failure in geomaterials: experiments and modelling. Comput Geotech 33(1):1–14. https://doi.org/10.1016/j.compgeo.2006.01.002

Gudehus G, Lanier J, Viggiani G, Desrues J (1997) Strain softening and shear band formation of sand in multi-axial testing. Géotechnique 47(5):1073–1077. https://doi.org/10.1680/geot.1997.47.5.1073

Been K, Jefferies MG, Hachey J (1991) The critical state of sands Géotechnique 41(3):365–381. https://doi.org/10.1680/geot.1991.41.3.365

Verdugo R, Ishihara K (1996) The steady state of sandy soils. Soils Found 36(2):81–91. https://doi.org/10.3208/sandf.36.2_81

Yang J, Dai BB (2011) Is the quasi-steady state a real behavior? A micromechanical perspective. Géotechnique 61(2):175–183. https://doi.org/10.1680/geot.8.P.129

Kanatani KI (1984) Distribution of directional data and fabric tensors. Int J Eng Sci 22(2):149–164. https://doi.org/10.1016/0020-7225(84)90090-9

Thornton C (2000) Numerical simulations of deviatoric shear deformation of granular media. Géotechnique 50(1):43–53. https://doi.org/10.1680/geot.2000.50.1.43

Sitharam TG, Dinesh SV, Shimizu N (2002) Micromechanical modelling of monotonic drained and undrained shear behavior of granular media using three-dimensional DEM. Int J Numer Anal Meth Geomech 26(12):1167–1189. https://doi.org/10.1002/nag.240

Rothenburg L, Kruyt NP (2004) Critical state and evolution of coordination number in simulated granular materials. Int J Solids Struct 41(21):5763–5774. https://doi.org/10.1016/j.ijsolstr.2004.06.001

Jiang MJ, Yu HS, Harris D (2005) A novel discrete model for granular material incorporating rolling resistance. Comput Geotech 32(5):340–357. https://doi.org/10.1016/j.compgeo.2005.05.001

Gong GB, Thornton C, Chan AHC (2012) DEM simulations of undrained triaxial behavior of granular material. J Eng Mech 138(6):560–566. https://doi.org/10.1061/(ASCE)EM.1943-7889.0000366

Guo N, Zhao JD (2013) The signature of shear-induced anisotropy in granular media. Comput Geotech 47:1–15. https://doi.org/10.1016/j.compgeo.2012.07.002

Gu XQ, Huang MS, Qian JG (2014) DEM investigation on the evolution of microstructure in granular soils under shearing. Granul Matter 16(1):91–106. https://doi.org/10.1007/s10035-013-0467-z

Cil MB, Alshibli KA (2013) 3D analysis of kinematic behavior of granular materials in triaxial testing using DEM with flexible membrane boundary. Acta Geotech 9(2):287–298. https://doi.org/10.1007/s11440-013-0273-0

Nguyen HBK, Rahman MM, Fourie AB (2018) Characteristic behavior of drained and undrained triaxial compression tests: DEM study. J Geotech Geoenviron Eng 144(9):04018060. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001940

Huang X, Kwok CY, Hanley KJ, Zhang ZX (2018) DEM analysis of the onset of flow deformation of sands: linking monotonic and cyclic undrained behaviours. Acta Geotech 13(5):1061–1074. https://doi.org/10.1007/s11440-018-0664-3

Qu TM, Feng YT, Wang Y, Wang M (2019) Discrete element modelling of flexible membrane boundaries for triaxial tests. Comput and Geotech 115:103154. https://doi.org/10.1016/j.compgeo.2019.103154

Li ZF, Chow JK, Li JH, Tai P, Zhou ZS (2022) Modeling of flexible membrane boundary using discrete element method for drained/undrained triaxial test. Comput Geotech 145:104687. https://doi.org/10.1016/j.compgeo.2022.104687

Adesina P, O’Sullivan C, Wang T (2023) DEM study on the effect of particle shape on the shear behaviour of granular materials. Comp Part Mech. https://doi.org/10.1007/s40571-023-00632-8

Peters JF, Muthuswamy M, Wibowo J, Tordesillas A (2005) Characterization of force chains in granular material. Phys Rev E 72(4):041307. https://doi.org/10.1103/PhysRevE.72.041307

Sun QC, Jin F, Liu JG, Zhang GH (2010) Understanding force chain in dense granular materials. Int J Mod Phys B 24(29):5743–5759. https://doi.org/10.1142/S0217979210055780

Tordesillas A, Walker DM, Lin Q (2010) Force cycles and force chains. Phys Rev E 81(1):011302. https://doi.org/10.1103/PhysRevE.81.011302

Tordesillas A, Steer CAH, Walker DM (2014) Force chain and contact cycle evolution in a dense granular material under shallow penetration. Nonlinear Process Geophys 21(2):505–519. https://doi.org/10.5194/npg-21-505-2014

Zhu HX, Nicot F, Darve F (2016) Meso-structure evolution in a 2D granular material during biaxial loading. Granul Matter 18(1):3. https://doi.org/10.1007/s10035-016-0608-2

Zhu HX, Nicot F, Darve F (2016) Meso-structure organization in two-dimensional granular materials along biaxial loading path. Int J Solids Struct 96:25–37. https://doi.org/10.1016/j.ijsolstr.2016.06.025

Liu Y, Li S (2018) Numerical simulation and analysis of meso-mechanical structure characteristic at critical state for granular media. Rock Soil Mech 39(6):2237–2248. https://doi.org/10.16285/j.rsm.2016.1966. (In Chinese)

Liu JY, Nicot F, Zhou W (2018) Sustainability of internal structures during shear band forming in 2D granular materials. Powder Technol 338:458–470. https://doi.org/10.1016/j.powtec.2018.07.001

Liu JY, Wautier A, Bonelli S, Nicot F, Darve F (2020) Macroscopic softening in granular materials from a mesoscale perspective. Int J Solids Struct 193:222–238. https://doi.org/10.1016/j.ijsolstr.2020.02.022

Wanjura CC, Gago P, Matsushima T, Blumenfeld R (2020) Structural evolution of granular systems: theory. Granul Matter 22(4):91. https://doi.org/10.1007/s10035-020-01056-4

Lin MC, Zhou W, Liu JY, Ma G, Cao XX (2022) A topological view on microscopic structural evolution for granular material under loading and unloading path. Comput Geotech 141:104530. https://doi.org/10.1016/j.compgeo.2021.104530

Itasca C (2014) PFC 3D manual, Version 5.0. Itasca consulting group, Minneapolis

Midi GDR (2004) On dense granular flows. Eur Phys J E 14(4):341–365. https://doi.org/10.1140/epje/i2003-10153-0

Chueire J (2023) Generalization of 3D mesostructures for a microstructural approach of soil behavior. Dissertation, Université de Lyon

Chueire J, Daouadji A, Nicot F, Wautier A (2023) On the extension of the grain loop concept from 2D to 3D granular assemblies. Granul Matter 25:57. https://doi.org/10.1007/s10035-023-01353-8

Acknowledgements

The authors are very grateful to Dr. Jo \(\widetilde{a}\) o Chueire of INSA Lyon for his valuable guidance on some of the research work. This work is supported by the National Natural Science Foundation of China (Grant Nos. 12002121, 42107175).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jin, L., Li, J., Ye, Y. et al. 3D DEM-based particle-scale analysis of drained and undrained triaxial behaviors of granular materials. Comp. Part. Mech. (2024). https://doi.org/10.1007/s40571-024-00743-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40571-024-00743-w