Abstract

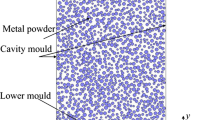

Jamming is a type of transition from a liquid-like to a solid-like state in granular matter. To test the effect of force chains on jamming during iron powder compaction, this study simulates the two-dimensional compaction of iron powder using the discrete element method. The jamming point during powder compaction is investigated. Furthermore, the distribution, strength, angle, and particle information of the force chains close to the jamming transition are assessed quantitatively. Furthermore, the effect of force chains on jamming is discussed. As indicated by the analysis of the contact number, grain loops and displacement of particles during powder compaction, the volume fraction ϕ = 84% represents a jamming point. When the force chain is shortened, an arch structure appears, the strength of force chain increases, and jamming occurs in the particle system. With the bending of the force chain, particles accumulated gradually, thereby leading to the jamming phenomenon.

Similar content being viewed by others

Data availability

All data generated during this study are included in this published study.

References

Trappe V, Prasad V, Cipelletti L, Segre PN, Weitz DA (2001) Jamming phase diagram for attractive particles. Nature 411:772–775

Cates ME, Haw MD, Holmes CB (2005) Dilatancy, jamming, and the physics of granulation. J Phys Condens Matter 17:S2517–S2531

Xiao YW, Han YL, Jia FG, Liu HR, Li GR, Chen PY, Meng XY, Bai SY (2021) Research on clogging mechanisms of bulk materials flowing through a bottleneck. Powder Technol 381:381–391

Walker DM, Tordesillas A, Brodu N, Dijksman JA, Behringer RP, Froyland G (2015) Self-assembly in a near-frictionless granular material: conformational structures and transitions in uniaxial cyclic compression of hydrogel spheres. Soft Matter 11:2157–2173

Liu AJ, Nage SR (1998) Jamming is not just cool any more. Nature 396:21–22

Torquato S, Stillinger FH (2010) Jammed hard-particle packings: from kepler to bernal and beyond. Rev Mod Phys 82:2633–2672

Radhakrishnan R, Royer JR, Poon WCK, Sun J (2020) Force chains and networks: wet suspensions through dry granular eyes. Granul Matter 22:1–10

Nan WG, Pasha M, Bonakdar T, Lopez A, Zafar U, Nadimi S, Ghadiri M (2018) Jamming during particle spreading in additive manufacturing. Powder Technol 338:253–262

Silbert LE (2010) Jamming of frictional spheres and random loose packing. Soft Matter 6:2918–2924

Wang F, Liu K, Wang W (2014) Simulation of jamming phenomenon of granular matter under single-action pressing process. Chin J Appl Mech 31:400–405

Zhang GH, Sun QC, Huang FF, Jin F (2011) Jamming phenomena of a two-dimensional frictional granular system under isotropic confining. Acta Phys Sin 60:1–7

Peters JF, Muthuswamy M, Wibowo J, Tordesillas A (2005) Characterization of force chains in granular material. Phys Rev E 72:1–8

Zhang W, Zhou J, Zhang XJ, Liu K (2019) Quantitative investigation into the relation between force chains and stress transmission during high-velocity compaction of powder. J Korean Phys Soc 74:660–673

Zhang W, Zhou J, Zhang XJ, Zhang Y, Liu K (2019) Quantitative investigation on force chain lengths during high velocity compaction of ferrous powder. Mod Phys Lett B 33:1–14

Zhu HX, Nicot F, Darve F (2016) Meso-structure organization in two-dimensional granular materials along biaxial loading path. Int J Solids Struct 96:25–37

Nicot F, Xiong H, Wautier A, Lerbet J, Darve F (2017) Force chain collapse as grain column buckling in granular materials. Granul Matter 19:1–12

Tordesillas A (2007) Force chain buckling, unjamming transitions and shear banding in dense granular assemblies. Philos Mag 87:4987–5016

Huang X, Hanley KJ, Zhang Z, Kwok C, Xu MZ (2019) Jamming analysis on the behaviours of liquefied sand and virgin sand subject to monotonic undrained shearing. Comput Geotech 111:112–125

Göncü F, Durán O, Luding S (2010) Constitutive relations for the isotropic deformation of frictionless packings of polydisperse spheres. CR Mec 338:570–586

Stasiak M, Tomas J, Molenda M, Rusinek R, Mueller P (2010) Uniaxial compaction behaviour and elasticity of cohesive powders. Powder Technol 203:482–488

Thomas A, Clayton J (2022) Stress distribution in a powder column under uniaxial compression. Powder Technol 408:117768

Velicky B, Carol C (2002) Pressure dependence of the sound velocity in a two-dimensional lattice of Hertz-Mindlin balls: mean-field description. Phys Rev E 65:1–14

Mindlin RD, Deresiewicz H (1953) Elastic spheres in contact under varying oblique forces. J Appl Mech 20:327–344

Liu Q, Fang L, Xiong Z, Yang J, Tan Y, Liu Y, Zhang Y, Tan Q, Hao C, Cao L, Li J, Gao Z (2021) The response of dislocations, low angle grain boundaries and high angle grain boundaries at high strain rates. Mater Sci Eng A 822:141704

Aste T, Saadatfar M, Senden TJ (2005) Geometrical structure of disordered sphere packings. Phys Rev E 71:1–15

Fu LL, Zhou SH, Guo PJ, Wang S, Luo Z (2019) Induced force chain anisotropy of cohesionless granular materials during biaxial compression. Granul Matter 21:1–16

Massimo PC, Antonio C (2009) Jamming at zero temperature, zero friction, and finite applied shear stress. Phys Rev Lett 103:1–4

Fu R, Hu X, Yang B, Wang H, Zhou B (2021) An insight into the meso-scale topological structure nature of granular materials subjected to quasi-static shearing. Comput Geotech 137:104257

Zhu H, Nguyen H, Nicot F, Darve F (2016) On a common critical state in localized and diffuse failure modes. J Mech Phys Solids 95:112–131

Tordesillas A, Walker D, Lin Q (2010) Force cycles and force chains. Phys Rev E 81:011302

Tordesillas A, Muthuswamy M (2009) Stick-slip and force chain buckling. Am Inst Phys 1145:313–316

Walker DM, Tordesillas A, Matthew R, Kuhn MA (2017) Spatial connectivity of force chains in a simple shear 3D simulation exhibiting shear bands. J Eng Mech 143:1–10

Aqoub K, Mohamed M, Sheehan T (2018) Analysis of sequential active and passive arching in granular soils. Int J Geotech Eng 15:598–607

Kulaviak L, Hladil J, Ruzicka MC, Drahos J, Saint-Lary L (2013) Arching structures in granular sedimentary deposits. Powder Technol 246:269–277

Tordesillas A, Hunt G, Shi JY (2011) A characteristic length scale in confined elastic buckling of a force chain. Granul Matter 13:215–218

Sun Q, Jin F, Liu J (2010) Understanding force chains in dense granular materials. Int J Mod Phys B 24:5743–5759

Acknowledgements

The authors are grateful to the Natural Science Foundation of Fujian Province (Grant No. 2020J01869) and the Initial Scientific Research Fund in Fujian University of Technology (Grant No. GY-Z19123) for providing financial support to this study.

Author information

Authors and Affiliations

Contributions

W Z was involved in the methodology, funding acquisition, and writing—review and editing; C Y contributed to writing—original draft and software; W X assisted in the data curation and validation. G L contributed to conceptualization; N Z performed the supervision and project administration; T Z assisted in writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exists in the submission of this manuscript, and the manuscript is approved by all authors for publication. I would like to declare on behalf of my co-authors that the work described was original research that has not been published previously, and not under consideration for publication elsewhere, in whole or in part. All the authors listed have approved the manuscript that is enclosed.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, W., Yuan, C., Xiao, W. et al. Effects of force chain on the jamming during iron powder compaction. Comp. Part. Mech. 11, 615–625 (2024). https://doi.org/10.1007/s40571-023-00642-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-023-00642-6