Abstract

Understanding the particle history during the cold spray process is primordial to better apprehend the particle's mechanical behavior during the impact. If the particle velocity can easily be measured using a high-speed camera, measuring the particle temperature remains a challenge. A solution is to perform numerical simulations of the process using computational fluid dynamics (CFD) simulations. However, most CFD simulation results only give an idea of the particle average temperature. Although it would be valid for metallic particles which exhibit a small temperature difference between the particle core and surface with high thermal stability, it is not the case for polymeric material, because of their low thermal conductivity. In this paper, the thermal gradient of a polymer particle is investigated. While small particles exhibit a uniform temperature distribution, a large temperature gradient is observed for particle diameter larger than 30 µm. In addition, assuming that the particle is spherical without rotation during the flight, the particle exhibits melting at the front. Such a phenomenon can have considerable consequences on the particle behavior during the impact. Furthermore, the influence of the feeding rate on the particle temperature distribution is investigated. If the particles are well diluted inside the nozzle (low feeding rate), the difference in the average temperature of two successive particles is limited to 5 K.

Similar content being viewed by others

Abbreviations

- \({\mathcal{B}}_{\mathrm{i}}\) :

-

Biot number

- \({\mathcal{N}}_{\mathrm{u}}\) :

-

Nusselt number

- \({\mathcal{P}}_{\mathrm{r}}\) :

-

Prandtl number

- \({\mathcal{R}}_{\mathrm{ep}}\) :

-

Particle Reynolds number

- E:

-

Total energy per unit of mass (J kg−1)

- \({E}_{\text{melt}}\) :

-

Energy of melting of the crystalline lamellae (J)

- \({E}_{\mathrm{T}}\) :

-

Energy to increase the particle temperature (J)

- \(\mathbf{F}\) :

-

Force (N)

- \({G}_{k}\) :

-

Generation of turbulence kinetic energy due to mean velocity gradients (W m−3)

- \({G}_{\mathrm{b}}\) :

-

Generation of turbulence kinetic energy due to buoyancy (W m−3)

- \(k\) :

-

Turbulent kinetic energy (J kg−1)

- \(p\) :

-

Gas pressure (Pa)

- \(t\) :

-

Time (s)

- \(T\) :

-

Absolute temperature (K)

- \({\varvec{u}}\) :

-

Velocity (m s−1)

- \({Y}_{M}\) :

-

Contribution of the fluctuation dilatation in compressible turbulence to the overall dissipation rate (W m−3)

- \(\varepsilon \) :

-

Turbulent dissipation rate (m2 s−3)

- \(h\) :

-

Convective heat transfer coefficient (W m−2 K−1)

- H:

-

Enthalpy (J kg−1)

- \({\varvec{q}}\) :

-

Heat flux by conduction (W m−2)

- \({\mathcal{Q}}_{s}\) :

-

Heat sources by conduction (W m−3)

- \({\mathcal{Q}}_{f}\) :

-

Heat sources by convection (W m−3)

- \(\overline{\overline{\tau }}\) :

-

Viscous stress tensor (Pa)

- \({c}_{p}\) :

-

Heat capacity at constant pressure (J kg−1 K−1)

- \({d}_{\mathrm{p}}\) :

-

Particle diameter (m)

- \({H}_{100\%}\) :

-

Enthalpy of fusion of a 100% crystalline material (J kg−1)

- \({m}_{\mathrm{p}}\) :

-

Particle mass (kg)

- \({\alpha }_{p}\) :

-

Thermal expansion coefficient (K−1)

- \(\Delta T\) :

-

Temperature difference

- \(\Gamma \) :

-

Thermal conductivity (W m−1 K−1)

- \({\mu }_{g}\) :

-

Viscosity (Pa s)

- \({\mu }_{\mathrm{t}}\) :

-

Turbulent viscosity (Pa s)

- \(\rho \) :

-

Density (kg m−3)

- \(\%{\chi }_{\mathrm{c}}\) :

-

Crystallinity ratio

References

Alkhimov AP, Kosarev V, Nesterovich N, Papyrin A, Shushpanov M (1990) Device for applying coatings. Russian Patent 1,618,777, 1990

Alkhimov AP, Papyrin AN, Kosarev VF, Nesterovich NI, Shushpanov MM (1994) Gas-dynamic spraying method for applying a coating. US Patent, 1994

Ravi K, Sulen WL, Bernard C, Ichikawa Y, Ogawa K (2019) Fabrication of micro-/nano-structured super-hydrophobic fluorinated polymer coatings by cold-spray. Surf Coat Technol 373:17–24. https://doi.org/10.1016/j.surfcoat.2019.05.078

Caldona EB, Smith DW, Wipf DO (2020) Protective action of semi-fluorinated perfluorocyclobutyl polymer coatings against corrosion of mild steel. J Mater Sci 55:1796–1812. https://doi.org/10.1007/s10853-019-04025-2

Schmidt T, Gärtner F, Assadi H, Kreye H (2006) Development of a generalized parameter window for cold spray deposition. Acta Mater 54:729–742. https://doi.org/10.1016/j.actamat.2005.10.005

Hassani-Gangaraj M, Veysset D, Nelson KA, Schuh CA (2018) In-situ observations of single micro-particle impact bonding. Scr Mater 145:9–13. https://doi.org/10.1016/j.scriptamat.2017.09.042

Nastic A, Jodoin B (2018) Evaluation of heat transfer transport coefficient for cold spray through computational fluid dynamics and particle in-flight temperature measurement using a high-speed IR camera. J Therm Spray Technol 27:1491–1517. https://doi.org/10.1007/s11666-018-0787-y

Fiebig J, Gagnon J-P, Mauer G, Bakan E, Vaßen R (2022) In-flight measurements of particle temperature and velocity with a high-speed IR camera during cold gas spraying of In718 and TiAlCrNb. J Therm Spray Technol 31:2013–2024. https://doi.org/10.1007/s11666-022-01426-9

Alletto M, Breuer M (2012) One-way, two-way and four-way coupled LES predictions of a particle-laden turbulent flow at high mass loading downstream of a confined bluff body. Int J Multiph Flow 45:70–90. https://doi.org/10.1016/j.ijmultiphaseflow.2012.05.005

Katanoda H (2008) Numerical simulation of temperature uniformity within solid particles in cold spray. J Solid Mech Mater Eng 2:58–69. https://doi.org/10.1299/jmmp.2.58

Raoelison RN, Guéchi MR, Padayodi E (2020) In-flight temperature of solid micrometric powders during cold spray additive manufacturing. Int J Therm Sci 157:106422. https://doi.org/10.1016/j.ijthermalsci.2020.106422

Bernard C, Bahlouli N, Wagner-Kocher C, Lin J, Ahzi S, Rémond Y (2018) Multiscale description and prediction of the thermomechanical behavior of multilayered plasticized PVC under a wide range of strain rate. J Mater Sci 53:14834–14849. https://doi.org/10.1007/s10853-018-2625-5

Deplancke T, Lame O, Rousset F, Seguela R, Vigier G (2015) Mechanisms of chain reentanglement during the sintering of UHMWPE nascent powder: effect of molecular weight. Macromolecules 48:5328–5338. https://doi.org/10.1021/acs.macromol.5b00618

Humbert S, Lame O, Vigier G (2009) Polyethylene yielding behaviour: What is behind the correlation between yield stress and crystallinity? Polymer 50:3755–3761. https://doi.org/10.1016/j.polymer.2009.05.017

Richeton J, Ahzi S, Vecchio K, Jiang F, Adharapurapu R (2006) Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: characterization and modeling of the compressive yield stress. Int J Solids Struct 43:2318–2335. https://doi.org/10.1016/j.ijsolstr.2005.06.040

Bernard C, Takana H, Diguet G, Ravi K, Lame O, Ogawa K, Cavaillé J-Y (2020) Thermal gradient of in-flight polymer particles during cold spraying. J Mater Process Technol 286:116805. https://doi.org/10.1016/j.jmatprotec.2020.116805

Bacha TW, Singh NK, Nault IM, Koohbor B, Haas FM, Stanzione JF (2021) Thermal gradients govern impact dynamics in thermoplastic polymer cold spray. J Therm Spray Technol 30:2034–2049. https://doi.org/10.1007/s11666-021-01271-2

Deplancke T, Lame O, Rousset F, Aguili I, Séguéla R, Vigier G (2014) Diffusion versus cocrystallization of very long polymer chains at interfaces: experimental study of sintering of UHMWPE nascent powder. Macromolecules 47:197–207. https://doi.org/10.1021/ma402012f

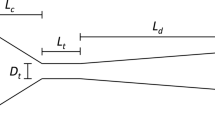

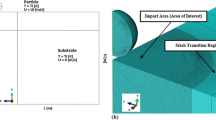

Bernard CA, Takana H, Lame O, Ogawa K, Cavaillé J-Y (2022) Influence of the nozzle inner geometry on the particle history during cold spray process. J Therm Spray Technol 31:1776–1791. https://doi.org/10.1007/s11666-022-01407-y

ANSYS Inc. (2017) Ansys fluent tutorial guide. ANSYS Inc., Canonsburg, PA, USA

Ravi K, Ichikawa Y, Deplancke T, Ogawa K, Lame O, Cavaille J-Y (2015) Development of ultra-high molecular weight polyethylene (UHMWPE) coating by cold spray technique. J Therm Spray Technol 24:1015–1025. https://doi.org/10.1007/s11666-015-0276-5

Ravi K, Ichikawa Y, Ogawa K, Deplancke T, Lame O, Cavaille J-Y (2016) Mechanistic study and characterization of cold-sprayed ultra-high molecular weight polyethylene-nano-ceramic composite coating. J Therm Spray Technol 25:160–169. https://doi.org/10.1007/s11666-015-0332-1

Bicerano J (2002) Prediction of polymer properties. CRC Press, USA

Van Krevelen DW, Te Nijenhuis K (2009) Properties of polymers: their correlation with chemical structure; their numerical estimation and prediction from additive group contributions. Elsevier, USA

Schmidt T, Assadi H, Gärtner F, Richter H, Stoltenhoff T, Kreye H, Klassen T (2009) From particle acceleration to impact and bonding in cold spraying. J Therm Spray Technol 18:794–808. https://doi.org/10.1007/s11666-009-9357-7

Assadi H, Schmidt T, Richter H, Kliemann J-O, Binder K, Gärtner F, Klassen T, Kreye H (2011) On parameter selection in cold spraying. J Therm Spray Technol 20:1161–1176. https://doi.org/10.1007/s11666-011-9662-9

Winnicki M, Małachowska A, Dudzik G, Rutkowska-Gorczyca M, Marciniak M, Abramski K, Ambroziak A, Pawłowski L (2015) Numerical and experimental analysis of copper particles velocity in low-pressure cold spraying process. Surf Coat Technol 268:230–240. https://doi.org/10.1016/j.surfcoat.2014.11.059

Ravi K, Deplancke T, Ogawa K, Cavaillé J-Y, Lame O (2018) Understanding deposition mechanism in cold sprayed ultra high molecular weight polyethylene coatings on metals by isolated particle deposition method. Addit Manuf 21:191–200. https://doi.org/10.1016/j.addma.2018.02.022

Singh NK, Uddin KZ, Muthulingam J, Jha R, Koohbor B (2021) Analyzing the effects of particle diameter in cold spraying of thermoplastic polymers. J Therm Spray Technol 30:1226–1238. https://doi.org/10.1007/s11666-021-01219-6

Koivuluoto H (2022) A review of thermally sprayed polymer coatings. J Therm Spray Technol. https://doi.org/10.1007/s11666-022-01404-1

Ranz WE, Marshall JR (1952) Evaporation from drops—Part I. Chem Eng Prog 48:141–146

Borgnakke C, Sonntag RE (2014) Fundamentals of thermodynamics, SI version. Wiley

Sutherland W (1895) The viscosity of mixed gases. Lond Edimb Dunlin Philos Mag J Science 40:421–431. https://doi.org/10.1080/14786449508620789

Hilsenrath J, Beckett C, Benedict W, Fano L, Hoge H, Masi J, Nuttall R, Touloukian Y (1960) Tables of thermodynamic and transport properties of air, argon, carbon dioxide, carbon monoxide, hydrogen, nitrogen, oxygen, and steam. Pergamon Press

Ravi K (2018) Mechanistic understanding of high strain rate impact behavior of ultra-high molecular weight polyethylene and the mechanism of coating formation during cold spraying. PhD Thesis, Tohoku University and INSA Lyon

Acknowledgements

The authors would like to acknowledge the Institute of Fluid Science at Tohoku University, which supported this research through the Grants J21Ly08 and J22Ly09 under the label of the LyC Collaborative Research Project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

In the following, the subscript "p" refers to the particle while the subscript "g" refers to the gas. Parameters in bold are vectors. ̿ refers to 3×3 tensors.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bernard, C.A., Takana, H., Diguet, G. et al. Thermal gradient in polymeric particles during the cold spray process. Comp. Part. Mech. 10, 1697–1716 (2023). https://doi.org/10.1007/s40571-023-00583-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-023-00583-0