Abstract

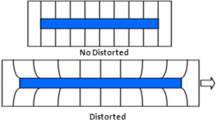

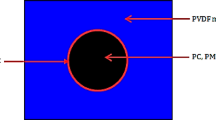

PMMA Polymethyl methacrylate polymer remains one among the well-known polymers used for POFs (Optical fibers) purposes. The optical fibers have paid a special attention to several recent researches, since they have shown attractive mechanical, electrical, and sensitive properties that bargain better insights, especially for sensing applications; this is mainly due to their lower young modulus for different studied constraints. Our study focuses on performing a comparative study of the mechanical properties obtained by reinforcing the PMMA polymer matrix with respectively the carbon, glass, and the aramid fiber using genetic algorithm. The different mechanical stresses applied to the studied materials generate a significant degradation at the interface for the glass/PMMA and aramid/PMMA composites which was confirmed by Mustafa Ertekin, and a slight lowering for the carbon/PMMA composite which has been confirmed by various recent studies highlighted the positive impact brought by the carbon fiber to perform better reinforcements for different structures and devices. The results found are in good agreement between the numerical simulation and the real behavior of the three materials. This comparative study can be very useful for a wide range of engineering and telecommunications applications, such as electromagnetic shielding of electronic devices (EMI), the manufacture of telecommunications towers and the design of the new trend of telecommunications antennas.

Similar content being viewed by others

References

Sagdic K, Eş I, Sitti M, Inci F (2022) Smart materials: rational design in biosystems via artificial intelligence. Trends Bio Technol. https://doi.org/10.1016/j.tibtech.2022.01.005

Cui Z, Guo C, Zhao D (2022) Energy-saving and economic analysis of passive radiative sky cooling for telecommunication base station in China. Build Simul. https://doi.org/10.1007/s12273-022-0894-z

Sharma DK, Rapaka GK, Pasupulla AP, Jaiswal S, Abadar K, Kaur H (2022) A review on smart grid telecommunication system. Mater Today: Proc 51:470–474. https://doi.org/10.1016/j.matpr.2021.05.581

Oberascher M, Rauch W, Sitzenfrei R (2022) Towards a smart water city: A comprehensive review of applications, data requirements, and communication technologies for integrated management. Sustain Cities Soc 76:103442. https://doi.org/10.1016/j.scs.2021.103442

Nazempour R, Zhang B, Ye Z, Lan Y, Xianli L, Xing S (2022) Emerging applications of optical fiber-based devices for brain research. Adv Fiber Mater 4:24–42. https://doi.org/10.1007/s42765-021-00092-w

Sousa EA, Lima THC, Arlindo EPS, Sanches AO, Sakamoto WK, Fuzari-Junior GC (2020) Multicomponent polyurethane carbon black composite as piezoresistive sensor. Polym Bull 77:3017–3031. https://doi.org/10.1007/s00289-019-02888-8

Tan E, Kahyaoğlu İM, Karakuş S (2021) A sensitive and smart phone colorimetric assay for the detection of hydrogen peroxide based on antibacterial and antifungal matcha extract silver nanoparticles enriched with polyphenol. Polym Bull. https://doi.org/10.1007/s00289-021-03857-w

Popa S, Mosoarca G, Macarie L, Plesu N, Ilia G, Tara-Lunga-Mihali M (2022) Copolymerization of butyl acrylate with methyl methacrylate in a bubble column reactor and the use of copolymer in corrosion protection. Polym Bull 79:763–783. https://doi.org/10.1007/s00289-020-03502-y

Zhou J, Han H, Liu J (2022) Nucleobase, nucleoside, nucleotide, and oligonucleotide coordinated metal ions for sensing and biomedicine applications. Nano Res 15:71–84. https://doi.org/10.1007/s12274-021-3483-z

Mei X, Ye D, Zhang F, Di C (2022) Implantable application of polymer-based biosensors. J Polym Sci 60:328–347. https://doi.org/10.1002/pol.20210543

Wang W, Yu S, Cao W, Guo K (2022) Review of in-vehicle optical fiber communication technology. Automot Innov. https://doi.org/10.1007/s42154-022-00184-2

Rajak DK, Wagh PH, Kumar A, Behera A, Pruncu CI (2022) Advanced Polymers in Aircraft Structures. In: Kuşhan MC, Gürgen S, Sofuoğlu MA (eds) Materials, Structures and Manufacturing for Aircraft. Sustainable Aviation, Springer, Cham. https://doi.org/10.1007/978-3-030-91873-6_3

Zaitsev I, Levytskyi A, Bereznychenko V (2022) Hybrid diagnostics systems for power generators faults: systems design principle and shaft run-out sensors. In: Kyrylenko O, Zharkin A, Butkevych O, Blinov I, Zaitsev I, Zaporozhets A (eds) Power systems research and operation, vol 388. Springer, Cham

Channi HK, Kumar R (2022) The role of smart sensors in smart city. In: Singh U, Abraham A, Kaklauskas A, Hong TP (eds) Smart sensor networks. Studies in big data (SBD), vol 92. Springer, Cham

Edouard MN, Okere CJ, Dong P, Ejike CE, Emmanuel NN, Muchiri NF (2022) Application of fiber optics in oil and gas field development: a review. Arab J Geosci 15:539. https://doi.org/10.1007/s12517-022-09659-2

Yi KJ, Jeong YS (2021) Smart factory: security issues, challenges, and solutions. J Ambient Intell Human Comput. https://doi.org/10.1007/s12652-021-03457-6

Olabi AG, Abbas Q, Al Makky A, Abdelkareem MA (2022) Supercapacitors as next generation energy storage devices: Properties and applications. Energy 248:123617. https://doi.org/10.1016/j.energy.2022.123617

Shakeel A, Rizwan K, Farooq U, Iqbal S, Altaf AA (2022) Advanced polymeric/inorganic nanohybrids: an integrated platform for gas sensing applications. Chemosphere 294:133772. https://doi.org/10.1016/j.chemosphere2022.133772

Carvalho AF, Kulyk B, Fernandes AJS, Fortunato E, Costa FM (2022) A review on the applications of graphene in mechanical transduction. Adv Mater 34:2101326. https://doi.org/10.1002/adma.202101326

Sharma A, Georgi M, Tregubenko M, Tselykh A, Tselykh A (2022) Enabling smart agriculture by implementing artificial intelligence and embedded sensing. Comput Ind Eng 165:107936. https://doi.org/10.1016/j.cie.2022.107936

Janssen MA, Anderies JM, Baeza A, Breetz HL, Jasinski T, Shin HC, Vallury S (2022) Highways as coupled infrastructure systems: an integrated approach to address sustainability challenges. Sustain Resilient Infrastruct 7:100–111. https://doi.org/10.1080/23789689.2019.1708181

Zhao Q, Yuan W, Qu J, Cheng Z, Peng G-D, Yu C (2022) Optical fiber-integrated metasurfaces: an emerging platform for multiple optical applications. Nanomater 12:793. https://doi.org/10.3390/nano12050793

Peter I, Singhwal SS (2022) 5g antenna materials and ensuing challenges. In: Matekovits L, Kanaujia BK, Kishor J, Gupta SK (eds) Printed Antennas for 5G Networks. PoliTO Springer Series, Springer, Cham. https://doi.org/10.1007/978-3-030-87605-0_11

Rao AS, Radanovic M, Liu Y, Hu S, Fang Y, Khoshelham K, Palaniswami M, Ngo T (2022) Real-time monitoring of construction sites: Sensors, methods, and applications. Autom Constr 136:104099. https://doi.org/10.1016/j.autcon.2021.104099

Rosa LG, De-Almeida G, Garcia-Pereira JC, Martínez-Hernández A, González-Aguilar J (2022) A method for determination of the transmission efficiency of a silica optical fiber cable using a solar power tower. Mater 15:1511. https://doi.org/10.3390/ma15041511

Fortin V, Aydin YO, Bernier M, Vallée R, Rochette M, Chenard F, Alvarez O, Busse LE, Shaw LB, Gattass RR, Sanghera JS (2022) Chapter 5—Post-processing soft glass optical fibers. Wood head PublSer Electron Opt Mater, p 233–302. https://doi.org/10.1016/B978-0-12-818017-4.00022-7

Maniewski P, Harvey CM, Mühlberger K, Oriekhov T, Brunzell M, Laurell F, Fokine M (2022) Rapid prototyping of silica optical fibers. Opt Mater Express 12:2426–2435. https://doi.org/10.1364/OME.459400

Xia J, Khaliliazar S, Hamedi MM, Sonkusale S (2021) Thread-based wearable devices. MRS Bull 46:502–511. https://doi.org/10.1557/s43577-021-00116-1

He R, Teng C, Kumar S, Marques C, Min R (2022) Polymer optical fiber liquid level sensor: a review. IEEE Sens J 22:1081–1091. https://doi.org/10.1109/JSEN.2021.3132098

Jiang J, Zhang N, Min R, Cheng X, Qu H, Hu X (2022) Recent achievements on grating fabrications in polymer optical fibers with photosensitive dopants: a review. Polymers 14:273. https://doi.org/10.3390/polym14020273

Belkheir M, Boutaleb M, Mokaddem A, Doumi B (2022) Predicting the effect of coconut natural fibers for improving the performance of biocomposite materials based on the poly (methyl methacrylate)-PMMA polymer for engineering applications. Polym Bull. https://doi.org/10.1007/s00289-022-04166-6

Mallakpour S, Behranvand V, Hussain CM (2022) worldwide fight against COVID-19 using nanotechnology, polymer science, and 3D printing technology. Polym Bull. https://doi.org/10.1007/s00289-021-04006-z

Leal-Junior A, Avellar L, Frizera A, Marques C (2020) Smart textiles for multimodal wearable sensing using highly stretchable multiplexed optical fiber system. Sci Rep 10:13867. https://doi.org/10.1038/s41598-020-70880-8

Mieloszyk M, Majewska K, Andrearczyk A (2022) Embedded optical fibre with fibre bragg grating influence on additive manufactured polymeric structure durability. Mater 15:2653. https://doi.org/10.3390/ma15072653

Falcetelli F, Martini A, Di Sante R, Troncossi M (2022) Strain modal testing with fiber bragg gratings for automotive applications. Sensor 22:946. https://doi.org/10.3390/s22030946

Denisov AN, Semjonov SL (2021) All-glass single-mode microstructured fibers with a large mode area. Dokl Phys 66:64–66. https://doi.org/10.1134/S1028335821020014

Rahman MM, Mou FA, Bhuiyan MIH, Rakibu Islam M (2022) Refractometric THZ sensing of blood components in a photonic crystal fiber platform. Braz J Phys 52:47. https://doi.org/10.1007/s13538-022-01054-2

Huang J, Boles ST, Tarascon JM (2022) Sensing as the key to battery lifetime and sustainability. Nat Sustain 5:194–204. https://doi.org/10.1038/s41893-022-00859-y

Aliee M, Mozaffari MH (2022) Photonic quasi-crystal fiber-based plasmonic biosensor: a platform for detection of coronavirus. PLASCS. https://doi.org/10.1007/s11468-022-01651-6

Puspita I, Irawati N, Madurani KA, Kurniawan F, Koentjoro S, Hatta AM (2022) Graphene- and multi-walled carbon nanotubes-coated tapered plastic optical fiber for detection of lard adulteration in olive oil. Photonic Sens 12:220411. https://doi.org/10.1007/s13320-022-0652-y

Cochrane C, Koncar V (2022) The weaving of optical fiber for cancer treatment. In: Kyosev Y, Boussu F (eds) Advanced weaving technology. Springer, Cham. https://doi.org/10.1007/978-3-030-91515-5_16

Wu Y, Zhong L, Yuan J et al (2021) Photocatalytic optical fibers for degradation of organic pollutants in wastewater: a review. Environ Chem Lett 19:1335–1346. https://doi.org/10.1007/s10311-020-01141-3

Wu J, Lu S, Wang HJ, Wang Y, Xia FB, Wang J (2021) A review on laser transmission welding of thermoplastics. Int J Adv Manuf Technol 11:2093–2109. https://doi.org/10.1007/s00170-021-07519-z

Tian C, Ma C, Han X, Zhang ZF (2022) Doping of polymer optical fiber cladding by Rhodamine 6G in aqueous solution at elevated temperature. Polym Bull. https://doi.org/10.1007/s00289-022-04224-z

Allam Z, Jones DS (2021) Future (post-COVID) digital, smart and sustainable cities in the wake of 6G: Digital twins, immersive realities and new urban economies. Land Use Policy 101:105201. https://doi.org/10.1016/j.landusepol.2020.105201

Vlachakis KV (2018) Analysis and design of a telecommunication steel tower strengthened with FRP plates. Dissertation. National Technical University of Athens.

Dugin NA, Zaboronkova TM, Belyaev GR et al (2021) The influence of carbon nanocomposite anisotropic conductivity on the parameters of a c-band horn antenna. Tech Phys 66:571–579. https://doi.org/10.1134/S106378422104006X

Sun Z, Duan B, Zhang Y, Yang D, Hu N (2022) Multi-material optimization design for mesh reflector antennas considering space thermal effects. Struct Multidisc Optim 65:165. https://doi.org/10.1007/s00158-022-03265-2

Sushko O, Medzmariashvili E, Tserodze S, Vasylenko D, Shpylka O, Khoroshylov S, Martyniuk S, Vasyliev V (2021) Design and analysis of light-weight deployable mesh reflector antenna for small multibeamsar satellite. T2 - EUSAR 2021; 13th European Conference on Synthetic Aperture Radar. IEEE explore 1–3.

Song H, Jeon H, Im D, Çakmakçı N, Shin KY, Jeong Y (2022) Free-standing carbon nanotube film for high efficiency monopole antenna. Carbon 187:22–28. https://doi.org/10.1016/j.carbon.2021.10.068

Zhang H, Liu T, Huang Z, Cheng J, Wang H, Zhang D, Ba X, Zheng G, Yan M, Cao M (2022) Engineering flexible and green electromagnetic interference shielding materials with high performance through modulating WS2 nanosheets on carbon fibers. J Materiomics 82:327–334. https://doi.org/10.1016/j.jmat.2021.09.003

Sharma A, Babu MS, Kumar AV, Sarathi R, Subramanian V (2022) Electromagnetic shielding efficiency of carbon fibre fabric-sandwiched epoxy–MWCNT nanocomposites. Bull Mater Sci 45:44. https://doi.org/10.1007/s12034-021-02629-6

Pathak AK, Dhakate SR (2022) Carbon nanomaterial-carbon fiber hybrid composite for lightweight structural composites in the aerospace industry: synthesis, processing, and properties. In: Mazlan N, Sapuan S, Ilyas R (eds) Advanced composites in aerospace engineering applications. Springer, Cham. https://doi.org/10.1007/978-3-030-88192-4_23

Abbas TM, Hussein SI (2022) Improving the mechanical properties, roughness, thermal stability, and contact angle of the acrylic polymer by graphene and carbon fiber doping for waterproof coatings. J Inorg Organomet Polym. https://doi.org/10.1007/s10904-022-02384-z

Choi HW, Shin DW, Yang J et al (2022) Smart textile lighting/display system with multifunctional fibre devices for large scale smart home and IoT applications. Nat Commun 13:814. https://doi.org/10.1038/s41467-022-28459-6

Delhaes P, Olry P (2006) Fibres de carbone et matériaux composites. L’Act Chim 295:42–46

Coulson M (2018) Conductivité, diffusivité, émissivité thermiques de composites Poly (EtherKetoneKetone)/Charges Carbonées : Fibres continues et particules. PhD Thesis. Toulouse Univeristy.

Fitzer E (1989) Pan-based carbon fibers present state and trend of the technology from the viewpoint of possibilities and limits to influence and to control the fiber properties by the process parameters. Carbon 27:621–645. https://doi.org/10.1016/0008-6223(89)90197-8

Crawford D, Johnson DJ (1971) High-resolution electron microscopy of high-modulus carbon fibres. J Microsc 94:51–62. https://doi.org/10.1111/j.1365-2818.1971.tb02360.x

Johnson DJ, Crawford JBF (1973) Observations of a three-phase structure in high-modulus PAN-based carbon fibres. J Mater Sci 8:286–290. https://doi.org/10.1007/BF00550678

Wicks BJ, Coyle RA (1976) Microstructural in homogeneity in carbon fibres. J Mater Sci 11:376–383. https://doi.org/10.1007/BF00551449

Donnet JB, Bansel RC (1984) Carbon N. Y. 360:5

Chaabani C (2018) Composites à fibres de carbone: récupération des fibres par solvolyse hydrothermale. Impact sur la qualité des fibres et valorisation de la phase liquide. Dissertation. Toulouse University.

Witten E, Jahn B (2013) Composites Market Report. Carbon Composites. Industrie evereinigungVerstarkteKunststoffe.

Boufaida Z. (2015) Analyse des propriétés mécaniques de composites taffetas Verre/matrice acrylique en relation avec les propriétés d’adhésion des fibres sur la matrice. PhD Thesis. Lorraine University. https://hal.univ-lorraine.fr/tel-01751805

CevahirA, (2017) Fiber technology for fiber-reinforced composites. Wood head Pub Comp Sc Eng. https://doi.org/10.1016/B978-0-08-101871-2.00005-9

Mhatre AM, Chappa S, Ojha S, Pandey AK (2019) Functionalized glass fiber membrane for extraction of iodine species. Sep Sci Technol. https://doi.org/10.1080/01496395.2018.1520729

Ertekin M (2017) Fiber technology for fiber-reinforced composites. Wood head Pub Comp Sc Eng, p 153–167. https://doi.org/10.1016/B978-0-08-101871-2.00007-2

Ratner BD (2012) Polymeric implants. Polymer science: a comprehensive reference 9: 397-411. https://doi.org/10.1016/B978-0-444-53349-4.00230-2

Sadeq HM, Salih SI, Braihi AJ (2020) Development on mechanical properties of PMMA by blending it with natural rubber or silicone rubber and reinforced by nanoparticle. Int J Nano Electron Mater 13:131–144

Weibull W (1939) A Statistical Theory of the Strength of Materials. Royal Swedish Academy of Eng. Sci Proc 151:1–45

Grange S, Prenseir JL (2006) Détermination des paramètres de Weibull Le modèle de Weibull: un critère de rupture probabiliste. Université de Paris Saclay. http://eduscol.education.fr/sti/si-ens-cachan/. Consulted on 02.05.2022.

Ngyen DC (2016) Caractérisation de l'interface fibre/matrice. Application aux composites polypropylène/chanvre. PhD Thesis. Troyes University.

Li Y, Pickering K, Farrell R (2009) Determination of interfacial shear strength of white rotfungi treated hemp fibre reinforced polypropylene. Compos Sci Technol 69:1165–1171. https://doi.org/10.1016/j.compscitech.2009.02.018

Lem J, Chaboche JL (1988) Mechanics of solid materials. Edition Dunod.

Cox HL (1952) The elasticity and strength of paper and other fibrous materials Br. J Appl Phys 3(3):72–79. https://doi.org/10.1088/0508-3443/3/3/302

Mokaddem A, Alami M, Ziani N, Beldjoudi N, Boutaous A (2014) Prediction by a genetic algorithm of the fiber–matrix interface damage for composite material. Part 2. Study of shear damage in graphite/epoxy nanocomposites. Strength Mater 46:548–552. https://doi.org/10.1007/s11223-014-9581-3

Mokaddem A, Alami M, Boutaous A (2012) A study by a genetic algorithm for optimizing the arrangement of the fibers on the damage to the fiber–matrices interface of a composite material. J Text Inst 103:1376–1382. https://doi.org/10.1007/s00289-022-04166-6

Atig K, Mokaddem A, Meskine M, Doumi B, Belkheir M, Elkeurti M (2019) Using genetic algorithms to study the effect of cellulose fibers ratio on the fiber-matrices interface damage of biocomposite materials. Curr Mater Sci 12:83–90. https://doi.org/10.2174/1874464812666190408144801

Belkheir M, Doumi B, Mokaddem A, Boutaous A (2020) Using genetic algorithm for investigating the performance of carbonbasalt / polyester hybrids composite material. Curr Mater Sci 13:120–128. https://doi.org/10.2174/2666145413999201124224238

Kaouche N, Mebrek M, Mokaddem A, Doumi B, Belkheir M, Boutaous A (2021) Theoretical study of the effect of the plant and synthetic fibers on the fiber-matrix interface damage of biocomposite materials based on PHAs (polyhydroxyalkanoates) biodegradable matrix. Polym Bull. https://doi.org/10.1007/s00289-022-04166-6

Benyamina B, Mokaddem A, Doumi B, Belkheir M, Elkeurti M (2021) Study and modeling of thermomechanical properties of jute and Alfa fiber-reinforced polymer matrix hybrid biocomposite materials. Polym Bull 78:1771–1795. https://doi.org/10.1007/s00289-020-03183-7

Belhadj FA, Belkheir M, Mokaddem A, Doumi B, Boutaous A (2022) Numerical characterization of the humidity effect on the fiber-matrix interface damage of hybrid composite material based on vinyl ester polymer matrix for engineering applications. Emergent Mater 5:591–600. https://doi.org/10.1007/s42247-022-00353-3

Belkheir M, Rouissat M, Mokaddem A, Doumi B, Boutaous A (2022) Studying the effect of polymethyl methacrylate polymer opticals fibers (pofs) on the performance of composite materials based on the polyether ether ketone (PEEK) polymer matrix. Emerg Mater. https://doi.org/10.1007/s42247-022-00392-w

Acknowledgements

The authors acknowledge the financial support from the General Direction of Scientific Research and Technological Development of the Ministry of Higher Education and Scientific Research of Algeria.

Funding

This work was supported by the General Direction of Scientific Research and Technological Development of the Ministry of Higher Education and Scientific Research of Algeria. (PRFU: B00L02CU320120190002).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Belkheir, M., Rouissat, M., Mokaddem, A. et al. Using genetic algorithm for studying the effect of Polymethyl methacrylate (PMMA) polymer matrix on composites materials interface based on carbon, glass and aramid fibers for engineering and telecommunication applications. Comp. Part. Mech. 10, 405–414 (2023). https://doi.org/10.1007/s40571-022-00504-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-022-00504-7