Abstract

Die filling is an important part of the powder compaction process chain, where defects in the final part can be introduced—or prevented. Simulation of this process is therefore a goal for many part producers and has been studied by some researchers already. In this work, we focus on the influence of the surrounding air on the powder flow. We demonstrate the implementing and coupling of the discrete element method for the granular powder and the smoothed particle hydrodynamics method for the gas flow. Application of the method to the die filling process is demonstrated.

Similar content being viewed by others

Notes

The computational cost depends very much on the case of application. Without local refinement, the spatial resolution dx is dictated by the smallest feature that is to be resolved. In the case of 3d simulations, the number of particles scales with d\(x^{3}\). E.g., with the die depth of 30 mm as the smallest feature, this results in approx. 25,000 SPH particles in our simulations. A die of 15 mm width requires already approx. 500,000 SPH particles. For a narrow die of only 6 mm width the number jumps to approx. 6,500,000 SPH particles. The number of DEM particles scales similarly, as the coarse graining is also limited by the smallest geometrical feature. In addition to the number of particles, the computational time step drops for both methods, as the particle size decreases—for the given examples by approx. one order of magnitude.

References

Brewin PR, Coube O, Doremus P, Tweed JH (eds) (2008) Modelling of powder die compaction. Springer, London

German RM (1996) Sintering theory and practice. Wiley, New York

Coube O, Cocks ACF, Wu CY (2005) Experimental and numerical study of die filling, powder transfer and die compaction. Powder Technol 48(1):68–76

Riera MD, Isturiz A, Prado JM, Cante JC, Oliver J, Gonzalez C (2005) Experimental and numerical study of the die filling stage in powder metallurgy, PM modelling workshop, pp 339–344

Cundall PA, Starck ODL (1979) Discrete numerical model for granular stresses. Geotechnique 29(1):47–65

Bierwisch C, Kraft T, Riedel H, Moseler M (2009) Three-dimensional discrete element models for the granular statics and dynamics of powders in cavity filling. J Mech Phys Solids 57(1):10–31

Bierwisch C, Kraft T, Riedel H, Moseler M (2009) Die filling optimization using three-dimensional discrete element modeling. Powder Technol 196(2):169–179

Wu CY, Cocks ACF (2006) Numerical and experimental investigations of the flow of powder into a confined space. Mech Mater 38(4):304–324

Wu CY, Cocks ACF, Gillia OT (2003) Die filling and powder transfer. Int J Powder Metall 39(4):51–64

Wu CY, Cocks ACF, Gillia OT, Thompson DA (2003) Experimental and numerical investigations of powder transfer. Powder Technol 138(2–3):216–228

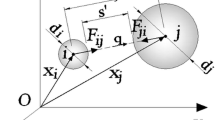

Guo Y, Kafui KD, Wu CY, Thornton C, Seville JPK (2009) A coupled DEM/CFD analysis of the effect of air on powder flow during die filling. AIChE J 55(1):49–62

Guo Y, Wu KCY, Kafui D, Thornton C (2011) 3D DEM/CFD analysis of size-induced segregation during die filling. Powder Technol 206(1–2):177–188

Guo Y, Wu KCY, Thornton C (2011) The effects of air and particle density difference on segregation of powder mixtures during die filling. Chem Eng Sci 66(4):661–673

Gingold RA, Monaghan JJ (1977) Smoothed particle hydrodynamics—theory and application to non-spherical stars. Mon Not R Astron Soc 181:375–389

Monaghan JJ (2005) Smoothed particle hydrodynamics. Rep Prog Phys 68:1703–1759

Gao D, Herbst JA (2009) Alternative ways of coupling particle behaviour with fluid dynamics in mineral processing. Int J Comput Fluid Dyn 23:109–118

Shahriari S, Maleki H, Hassan I, Kadem L (2012) Evaluation of shear stress accumulation on blood components in normal and dysfunctional bileaflet mechanical heart valves using smoothed particle hydrodynamics. J Biomech 45(15):2637–2644

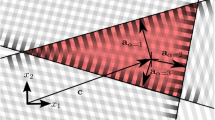

Breinlinger T, Wonisch A, Kraft T (2011) Simulation of particulate flows using coupled SPH and DEM simulations. In: Proc 6th Int SPHERIC workshop, pp 66–71, ISBN 978-3-89220-658-3

Lagger HJ, Breinlinger T, Korvink JG, Moseler M, Di Renzo A, Di Maio F, Bierwisch C (2015) Influence of hydrodynamic drag model on shear stress in the simulation of magnetorheological fluids. J Non-Newton Fluid 218:16–26

Di L, Sigalotti G, Klapp J, Sira E, Meleán Y, Hasmy A (2003) SPH simulations of time-dependent Poiseuille flow at low Reynolds numbers. J Comput Phys 191–8(2):622–638

Colagrossi A, Bouscasse B, Antuono M, Marrone S (2012) Particle packing algorithm for SPH schemes. Comput Phys Commun 183(8):1641–1653

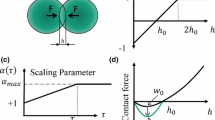

Hertz H (1881) Über die Berührung fester elastischer Körper. J Reine Angew Math 92:156–171

Landau ED, Lifshitz EM (1970) Theory of elasticity. Pergamon Press, NewYork

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Geotechnique 29(1):47–65

Li P, Lan X, Xu C, Wang G, Lu C, Gao J (2009) Drag models for simulating gas-solid flow in the turbulent fluidization of FCC particles. Particuology 7:269–277

Day MA (1990) The no-slip condition of fluid dynamics. Erkenntnis 33:285–296

Wassen E (1998) Entwicklung paralleler Algorhitmen zur numerischen Simulation von Gas-Partikel-Strömungen unter der Berücksichtigung von Partikel-Partikel-Kollisionen. PhD thesis, Chemnitz

Robinson M, Ramaioli M, Luding S (2014) Fluid–particle flow simulations using two-way-coupled mesoscale SPH–DEM and validation. Int J Multiph Flow 59:121–134

Acknowledgments

This work has been funded with budget funds of the Federal Ministry of Economics and Technology (BMWi) via the German Federation of Industrial Research Associations “Otto von Guericke” e.V. (AiF) (IGF-Nr.: 430 ZBG).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Breinlinger, T., Kraft, T. Coupled discrete element and smoothed particle hydrodynamics simulations of the die filling process. Comp. Part. Mech. 3, 505–511 (2016). https://doi.org/10.1007/s40571-015-0063-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-015-0063-6