Abstract

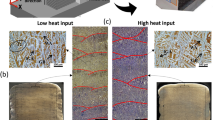

Joining of materials is an essential process step in manufacturing industry. The need to weld dissimilar thin materials is growing lately with applications in MEMS devices involving different materials. Welding of thin dissimilar materials is a challenging task in comparison to their bulk counterparts as they are quite susceptible to damage. This paper is concerned with the feasibility of welding extremely thin stainless- steel foil (AISI 304) with pure copper foil of thickness of tens of microns in lap joint configuration using a single mode nano-second pulsed fiber laser. Welds were made in “weld brazing” mode as well as in “full fusion” mode with linear heat inputs of 0.1 J/mm and 0.145 J/mm respectively. Optical microscopy and electronic microscopy were used to evaluate the weld microstructure, X-ray radiography was employed to evaluate the integrity of the weld, while tensile testing and micro-hardness measurements of the welds were carried out to ascertain the mechanical properties the weld. Welds could be made without any defects, e.g. lack of fusion, cracks and porosities. Welds made in “weld brazing” mode was found to be mechanically superior to the welds performed in “full fusion” mode. The decided advantage of the usage of nanosecond single mode laser for this application is also elucidated.

Similar content being viewed by others

References

Chen, X., Brox, D., Assadsangabi, B., Ali, M.S.M., Takhata, K.: A stainless steel based implantable pressure sensor chip and its integration by microwelding. Sensors Actuators A Phys. 257, 134–144 (2017)

Roudbari, A.J., Kuo, P.C., Khatalis, M.: A flash analog to digital convertor on stainless steel foil substrate. Solid State Electron. 54(4), 410–416 (2010)

Ely, K.J., Zhou, Y.: Microjoining in medical components and devices. In: Zhou, Y. (ed.) Micro-Joining and Nano-Joining, pp. 691–717. Woodhead publishing in materials, Cambridge (2008)

Luo, C., Lin, L.: The application of nano-second pulsed welding technology in MEMS packaging with a shadow mask. Sensors Actuators A. 97-98, 398–404 (2002)

Hassan, M.A., Ahmed, K., Takamura, N.: A developed process for deep drawing of metal foil square cups. Int. J. Mater. Prod. Technol. 212(1), 295–307 (2012)

Heimann, M., Klarner, P., Luechinger, C., Mette, A., Mueller, J.W.: Ultrasonic bonding of Aluminium Ribbons to interconnect high efficiency crystalline silicon solar cells. Energy Proceedia. 27, 670–675 (2012)

Wan, X., Wang, Y., Fang, C.: Welding defects occurrence and their effects on weld quality in resistance spot welding of AHSS steel. ISIJ Int. 54(8), 1883–1889 (2014)

Adams, R.D., Coppendale, J., Mallick, V., Al-Hamdan, H.: The effect of temperature in the strength of adhesive joints. Int. J. Adhes. Adhes. 12(3), 185–190 (1992)

Patschger, A., Hopf, A., Loose, T., Bliedtner, J., Bergmann, J.P.: New approach to clamping in microwelding. J Laser Appl. 27, S2903–S21-8 (2015)

Ventrella, V.S., Berretta, J.R., Rossi, W.: Micro welding of Ni based alloy Monel 400 thin foil by pulsed Nd-YAG laser. Phys. Procedia. 12, 347–354 (2011)

Ventrella, V.S., Berretta, J.R., Rossi, W.: Pulsed Nd YAG laser welding of Ni alloy Hastelloy C-276 foils. Phys. Procedia. 39, 569–576 (2012)

Ventrella, V.S., Berretta, J.R., Rossi, W.: Pulsed Nd-YAG laser seam welding of AISI 316L stainless steel thin foils. J. Mater. Process. Technol. 210(14), 1838–1843 (2010)

Park, S.J., Ohmura, E.: Miyamoto.: micro welding of ultra-thin metal foil using Yb fiber laser. Proc. SPIE. 4830, 52–56 (2003)

Guo, Y., Wu, D., Ma, G., Guo, D.: Numerical simulation and experimental investigation of residual stresses and distortions in pulsed laser welding of Hastelloy C-276 thin sheets. Rare Metal Mater. Eng. 43, 2663–2668 (2014)

P’ng, D., Molian, P.: Q switch Nd-YAG laser welding of AISI 304 stainless steel foils. Mater. Sci. Eng. A. 486(1-2), 680–685 (2008)

Ascari, A., Fortunato, A.: Nanosecond pulsed laser welding of high carbon steels. Opt. Laser Technol. 56, 25–34 (2014)

Yao, C., Xu, B., Zhang, X., Huang, J., Wu, Y.: Interface Microstructure and Mechanical Properties of Laser Welding Copper-Steel Dissimilar Joint. Opt. Lasers Eng. 47, 807–814 (2009)

Chen, S., Huang, J., Xia, J., Zhao, X., Lin, S.: Influence of processing parameters on the characteristics of stainless steel / copper laser welding. J. Mater. Process. Technol. 222, 43–51 (2015)

Kuryntsev, S.V., Morushkin, A.E., Gilmutdinov, K.H.: Fiber laser welding of steel and commercially pure copper butt joint. Opt. Lasers Eng. 90, 101–109 (2017)

Baghjari, S.H., Gholambargani, M., Akbari Mousavi, S.A.A.: Application of the pulsed Nd: YAG laser welding to investigate the effect of laser beam position on weld characteristics of AISI 420 stainless steel to kovar alloy. Lasers Manuf Mater Process. 6(1), 14–25 (2019)

Kumar, P., Sinha, A.N.: Effect of pulse width in pulsed Nd:YAG dissimilar laser welding of austenitic stainless steel (304 L) and carbon steel (st37). Lasers Manuf Mater Process. 5(4), 317–334 (2018)

Padmanabham, G., Shanmugarajan, B.: Laser based joining of metallic and non-metallic materials. In: Dutta Majumdar, J., Manna, I. (eds.) Laser Assisted Fabrication of Materials, pp. 158–220. Springer, Heidelberg (2013)

Wang, C.P., Liu, X.J., Takaku, Y., Ohnuma, I., Kainuma, R., Ishida, K.: Formation of core type macroscopic morphologies in cu-Fe base alloys with liquid miscibility gap. Metall Mater Trans A. 35A, 1243–1253 (2004)

Chen, Q., Jin, Z.: The Fe-cu system: a thermodynamic evaluation. Metall Mater Trans A. 26A, 417–426 (1995)

Munitz, A.: Metastable liquid phase separation in tungsten inert gas and electron beam copper/stainless-steel welds. J. Mater. Sci. 30(11), 2901–2910 (1995)

Miyamoto, I.: Laser micro-welding. In: Zhou, Y. (ed.) Micro-Joining and Nano-Joining, pp. 345–412. Woodhead Publishing, Cambridge (2008)

Kim, J., Kim, S., Kim, K., Jung, W., Youn, D., Lee, J., Ki, H.: Effect of beam size in laser welding of ultra-thin stainless steel foils. J. Mater. Process. Technol. 233, 125–134 (2016)

Acknowledgements

The authors would like to acknowledge Nagendra Kumar for his help in carrying out the radiography of the welded specimens and B. K. Kumawat for carrying out the tensile testing of the welded specimens. Valuable discussions with R. N. Singh and D.B.Sathe are also acknowledged. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, A., Gupta, M.P., Banerjee, J. et al. Micro-Welding of Stainless Steel and Copper Foils Using a Nano -Second Pulsed Fiber Laser. Lasers Manuf. Mater. Process. 6, 158–172 (2019). https://doi.org/10.1007/s40516-019-00088-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-019-00088-w