Abstract

Guava fruit is a very nutritious and fairly rich source of minerals, vitamins, and dietary fiber thus medicinally rich to cure stomach-related problems. Thus it's a need of hour to produce quality fruits without any internal or external defects or disorders as well as fruits should be free from chemical residues. The problem to produce the desired quality of fruits can be overcome by the use of pre-harvest bagging technology. Thus an experiment was conducted to evaluate the performance of different bagging materials on fruit appearance and quality. The findings revealed that the maximum increase in fruit mass (36.38%), fruit length (20.64%), fruit grade (30.23%), ascorbic acid content (7.36%) and TSS (48.65%) were observed as compared to the control in perforated polythene bags bagged at 30 days after fruit set (PEBD2), newspaper bagged at 30 days after fruit set (NPBD2), perforated polythene bagged at 15 days after fruit set (PEBD1) and butter paper bagged at 15 days after fruit set (BPBD1), respectively, whereas maximum reduction in fruit scar (93.78) recorded in newspaper bagged at 15 days after fruit set (NPBD1). Findings indicated that physio-chemical attributes of bagged fruits positively altered with no scar on fruit skin and without pest infestation thus ensuring better fruit quality, optimum production and consumer acceptance. Thus, bagging is cost-effective technology, warrants physiologically improved quality fruit production with consumer satisfaction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Guava fruit popularly known as the "Apple of Tropics" belongs to the family Myrtaceae, and it is native to Tropical America. Major guava-growing countries are India, the USA, Cuba, Taiwan, Mexico, Peru, China, Malaysia and Bangladesh. Guava is the 5th most important fruit of India based on acreage and production after mango, banana, apple and citrus. Guava has become more popular in our country due to its prolific and precocious bearing habit, and wider adaptability under various agro-climatic conditions (Dolkar et al., 2014). It is a fairly rich source of ascorbic acid (Vitamin C), lycopene and other antioxidants, minerals and dietary fibers and also contains a significant amount of vitamins like- provitamin A (carotene), thiamine, riboflavin, pantothenic acid, niacin (Sing & Sing, 2005; Kherwar & Usha, 2016), micro and macronutrient such as potassium, calcium, phosphorus, iron, sodium, magnesium. Besides the guava fruits, the other plant parts like roots, leaves and bark have medicinal properties (Kherwar & Usha, 2016) and are generally used to manage stomach-related problems such as gastroenteritis, diarrhoea and dysentery. The phenolic compounds in guava help to cure cancerous cells and prevent skin ageing over time. The presence of terpenes, caryophyllene oxide and p-selinene produces relaxation effects (Naseer et al., 2018). Moreover, the processed products of guava such as juices, jelly, jam, nectar, cheese etc. are very popular in the world market. In order to reach in world trade market after the WTO regime, it is important to boost the quality and production of guava.Generally, fruits faced many biotic and abiotic barriers during development, which creates many undesired scars on fruit surfaces. The blemishes and scars on the fruits cause poor market value. Several researchers have advocated pheromone traps, pesticide use, poison food traps, field sanitation, etc. todiminish the upshot of biotic and abiotic factors (Singh et al., 2008; Sapkota et al., 2010; Wang et al., 2022), but such remedy is not cost-effective with others limitations.

The living standards of people have markedly improved and health consciousness after COVID-19 resulted in increased demand for food safety and its quality, which propound stiff challenges for conventional agriculture. The problem faced in the production of the desired quality of fruit can be overcome by the use of bagging technology (Ali et al., 2021).The use of pre-harvest fruit bagging on fruits has a number of advancements over conventional production systems. Moreover, trading in the international market required quality fruits free from undesired quality and chemical residues. Furthermore, in some countries like Japan, Australia, USA, Mexico, Chile and Argentina etc. fruit bagging has become mandatory and these countries did not import fruits unless they are properly pre-harvest bagged (Sharma et al., 2014).

A bag around a fruit controls temperature, sunlight, evaporation, humidity, and harvesting time (Kim et al., 2008; Ali et al., 2021) besides minimizing residues of pesticides or agrochemical residue (Frank, 2018; Xu et al., 2018). Thus, bagging is an admirable technique to produce fruits with a very low input or residues of pesticide. Bagging can improve the quality of the fruits through alteration in their physiology and consequently the morphology viz improvement in fruit size, fruit mass, fruit texture, fruit skin appearance, colours and glossiness, fruit ripening process besides reduction in fruit drop, lenticels discolouration, post-harvest losses, fruit spot injury, cracking, blemishing etc. (Kitagawa et al., 1992; Han et al., 2002; Li et al., 2008; Liu et al., 2013; Sharma et al., 2014; Ali et al., 2021). Moreover, Pre-harvest bagging significantly protects the fruit from biotic and abiotic stresses such as incidence of pests (Teixeira et al., 2011), birds damage (Jia et al., 2005; Sharma et al., 2014), risk of microbial pathogens and disease incidence in fruit (Hofman et al., 1997), physical and mechanical damage (Muchui et al., 2010).Furthermore, the fruit produced using bagging technology has great market value due to their clean and healthy skin with attractive colour (Ali et al., 2021).

Under North Indian conditions out of three Bahars (season of fruiting) of guava, Mrig Bahar is the most preferred crop. Which produced the best quality guava; however, sometimes late rainfall and mechanical brushing left the fruit scared which fetched poor market price. Hence, during developmental periods, scars on the fruits can be reduced with improved fruit colour through physical barriers like bagging. However, different bagging materials like newspaper bags, brown paper bags, perforated polythene bags, brown paper bags with polythene coating, muslin cloth bags, scurting bags, butter paper bags, etc. have different characteristics in vapours permeability, light transmittance, heat conductance etc. and consequently causes differential effects on the microenvironment and subsequently on fruit mass, quality, texture and appearance (Niu et al., 2003; Son & Lee, 2008; Ali et al., 2021). Moreover, the fruiting stage when it was bagged, fruit cultivars, and duration of fruit exposure to natural light after bag removal (before harvesting) also affect the fruit quality.

Thus this study investigated the various physiological and physicochemical changes in fruits due to the change of micro-climate in bags of different materials and how fruit quality enhanced under different bagging systems. Further, this experiment provides options to farmers to choose low-cost effective bagging materials for bagging guava fruits to harness quality fruits without a scar.

Materials and methods

The present experiment was conducted at ICAR- Central Institute for Subtropical Horticulture, Rehmankhera, Lucknow (Latitude 26° 50′ 21.4″N Longitude: 80° 55′ 23.27″E) in 2017 and 2018 on 3 years old guava orchard under HDP system. Guava variety Lalit grafted onto seedling rootstock was planted in sandy loam soil in 2015, at 3.0 × 3.0 m spacing and mulched with silver colour polythene having 400 gauge thicknesses. The micro irrigation system was installed for irrigation and fertigation with 1 dripper per tree with 4 LPH capacities. The study was carried out complete randomized block design with three replication of each treatment three kinds of bagging materials were used at 15 days and 30 days after the fruit set. The selection of different kinds of bags was based on their durability in frequent rainfall and heat conditions. The bags used in the aforesaid experiment were of 18 × 24 cm dimension. Further, in perforated polythene bags, two cuts were made on both corners to permit drainage of moisture due to rainfall and transpiration loss. The bagging was done 15 and 30 days after the fruit set from full bloom date.

The experiment system was comprised of the following treatments.

BPBD1—Bagging after 15 days of fruit set by butter paper bag.

BPBD2—Bagging after 30 days of fruit set by butter paper bag.

NPBD1—Bagging after 15 days of fruit set by newspaper bag.

NPBD2—Bagging after 30 days of fruit set by newspaper bag.

PEBD1—Bagging after 15 days of fruit set by a perforated polythene bag.

PEBD2—Bagging after 30 days of fruit set by a perforated polythene bag.

Control—No bagging of fruits.

Thirty fruits from each tree from different directions were randomly collected for each bagging treatment for recording the observations, while in control a similar number of the fruits from each tree was tagged without bagging. During the experiment, all the bagged fruits were routinely observed for any damage and if noticed it was immediately replaced with new ones. The well-matured fruits were harvested and subjected to physiological and physicochemical analysis.

The 20 numbers of harvested fruits from each treatment were harvested for physical analysis viz., fruit mass, fruit length, fruit diameter, fruit grading and fruit with or without a scar. The fruit mass was measured using a digital electronic balance while the fruit length and fruit diameter were measured with the help of a digital vernier calliper model. For determining the percent of ‘A’ grade fruit, the harvested bagged fruits were graded as ‘A’ and B according to the fruit size (> 80 mm diameter) and qualitative traits and fruit appearance/ attractiveness. Total soluble solids (TSS) of fruit samples were determined using a digital Hand Refractometer (Erma Japan, 0 to 32°Brix). Ascorbic acid was analyzed with standard procedures as suggested by A.O.A.C. (2000). The estimation of the percentage of reducing sugars, total sugars and acidity was performed using the protocol suggested by Ranganna (1991), and lycopene content was also analysed by Rani and Vijayanchali (2017).All the experiments were performed in triplicate. The collected data were subjected to statistical analysis. Analysis of variance method (ANOVA), suitable for randomized complete block design (RCBD) was carried out with the help of SPSS 16. Significant differences among treatments were based on the F test in ANOVA, and means were calculated using Duncan's multiple range test (DMRT) at a significance level of P ≤ 0.05. The standard error means (SEM) in the vertical bar charts was computed using Sigma Plot 10 (systat software, Inc.). The correlation analysis among treatments was performed through Pearson Correlation, Sig. (2-tailed) using SPSS16 software.

Results and discussion

Effect of different bagging materials on the physical attributes of fruits

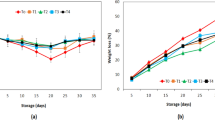

The physical parameters viz., fruit mass, fruit length, fruit diameter, fruit grading and fruit with scar were recorded. The study revealed that bagging material shave a differential effect on the aforementioned parameters of fruits. All types of applied bagging materials improved the fruit shape and consequently perk up the fruit mass as well as fruit length. The maximum augment in fruit mass was observed in PEBD2. In PEBD2, a maximum (36.38%) increment in fruit mass was observed over control (Fig. 1A). Our observations are in agreement with the results of some previous findings(Yang et al., 2009; Zhou et al., 2012; Sharma et al., 2014, Mishra et al., 2017).The increase in fruit mass in bagged systems might be due to different environmental conditions (Kutinyu, 2014).The alteration in the microenvironment also creates physiological and biochemical changes in fruit which could improve fruit size or weight (Yang et al., 2009), texture (Byers & Carbaugh, 1995; Singh et al., 2008; Muchui et al., 2010), fruit firmness (Teixeira et al., 2011; Sharma et al., 2013) and total soluble solids content (TSS) (Xu et al., 2003; Niu et al., 2003). In an earlier study, Daniells and their coworkers (2005) reported that the higher humidity and appropriate microclimate inside the bags improved overall fruit growth and development. It is well established that temperature has a positive correlation with respiratory rate as well as the ripening of fruits. In bagging conditions, the temperature of the microenvironment may alter from outer environment (Pisciotta et al., 2020). The fruits without bagged face comparatively higher temperatures and other abiotic and biotic stresses that cause higher respiration rates and consequently more oxidation of stored carbohydrates i.e., fruit starch resulting in more loss of fruit mass. Furthermore, fruit ripening triggers some biochemical changes that caused to weaken the epidermis, as well as partial solubilization of the cell wall (Jain et al., 2003) and therefore more loss of water, occur which further adds to the weight loss of fruits.

Effect of different bagging systems on A- Fruit mass, B- Fruit length, C- Fruit diameter, D- “A” grade fruits. *Error bars represented a standard error of the mean (SE), while the different letters on top of the error bars show significant differences at P ≤ 0.05. The same letter on the bar showed no significant difference. Control- No bagging of fruits, BPBD1- Bagging after 15 days of fruit set by butter paper bag, BPBD2- Bagging after 30 days of fruit set by butter paper bag, NPBD1- Bagging after 15 days of fruit set by newspaper bag, NPBD2- Bagging after 30 days of fruit set by newspaper bag, PEBD1- Bagging after 15 days of fruit set by perforated polythene bag, PEBD2- Bagging after 30 days of fruit set by a perforated polythene bag

The insoluble stored starch in fruit causes improves the shape and their grade, as compared to the control, the fruit length in NPBD2 was found to be a maximum of 20.64% (Fig. 1B). However, fruit diameters were not significantly altered due to bagging (Fig. 1C). As compared to the control, all bagged fruits have comparatively the least scar and high-grade quality. The fruit bagged with newspaper found much better results. The best results in terms of fruit grading were observed in NBPD2, which was 30.23% increments as compared to the control (Fig. 1D). The severity of fruit scar reduces significantly in all bagged fruits; however, the best upshot was reported in NBPD1, which was estimated at merely 6.22%, and the severity of scars on the fruit surface in control was more than 50% (Fig. 2). The bagging system protects the fruit from both abiotic as well as biotic stresses and as a result, the fruit under-bagged was found with the least scar and high-grade quality. Our findings are in line with the previously reported observations (Muchui et al., 2010; Liu et al., 2013; Sharma et al., 2014).

Effect of different bagging treatments on the physio-chemical attributes of fruits

The bagging system in fruits not only improved the physical parameters but also altered the chemical parameter of fruits. The chemical parameters viz., ascorbic acid content (vitamin C), acidity, total sugars content and total soluble solid were examined. The ascorbic acid content was increased in bagged fruit with perforated polythene bags. As compared to the control, a 7.36% increase in ascorbic acid content was observed in the PEDB1 treatment (Fig. 3A). Our observation coincided with the result of Silva et al., (1998) however; some contradictory observations were also reported by other research groups (Kader, 2002). The phyto-nutrient vitamin C is temperature-sensitive. The increased vitamin C concentration in the bagged fruit may be attributed to the selective solar permeability of the bags and the microenvironment (temperature, humidity, and moisture) surrounding the fruit. In another study, Zhou et al. (2019) observed that the colour and texture of bagging material also significantly impacted the vitamin C content in apples and pears. The titratable acidity was found significantly lower in the bagged fruit's system. Fruit bagging after 15 days of fruit set (D1) system the more reduction in titratable acidity was reported. Moreover, the best results were observed in butter Paper bags followed by newspaper bags and perforated polythene bag systems, respectively. As compared to the control, a maximum 39.30% reduction was recorded in BPBD1 among all treatments (Fig. 3B). Our observation concurred with the results of Meena et al., (2016), who reported that the highest titratable acidity was recorded under un-bagged fruit conditions (control). The alteration in ascorbic acid and titratable acidity contents might be due to the differential micro-environment under the bagging system that changed the rate of metabolic activities. The total sugar content was significantly higher in control, while in BPBD2 system fruits, the least sugar content was reported. However, among bagging systems, no significant variations were observed in sugar content. As compared to the control, 21.34% less sugar content was observed in fruits of the BPBD2 system (Fig. 3C). Similar trends in the result were observed by other researchers (Abbasi et al., 2014). The un-bagged fruits have to face comparatively higher temperatures which cause earlier ripening of the fruits. During the ripening process, the organic acid is converted into sugars making guava sweeter. Moreover, a possible explanation for the greater sugar content in fruit is the breakdown of complex carbohydrates like starch, pectin, and cellulose during ripening (Tafera et al., 2008; Islam et al., 2017). Furthermore, the un-bagged fruits have to face many physical injuries which leave scars on the surface of the fruit that trigger their ripening and consequently alter sugar content also. On the other hand under the bagged system, the conversion of acid to sugar is hampered to some extent due to the limit of O2 in the bag. This might be the reason for the lowering of sugar content in bagged fruits. The total soluble solid (TSS) contents in bagged fruits were found to be higher than the control. Among all treatments, maximum TSS contents were recorded in the BPBD1 system. As compared to the control, a 48.65% of increment in TSS was noticed in BPBD1 (Fig. 3D). Improvement in the total soluble solids in bagged fruit has also been reported earlier in guava (Edirimanna et al., 2015; Sharma et al., 2020), mango (Chonhenchob et al., 2011), banana (Rubel et al., 2019) and tomato (Sohag et al., 2023). The alteration in TSS might be due to different intensities of sunlight and other abiotic factors in bagged conditions. The content of lycopene was higher in fruit covered with butter paper as compared to other bagging materials (Fig. 4). The greater lycopene concentration in the bagged fruits may be due to the enhanced transformation of carotenoid like lycopene caused by decreased light penetration in the covered fruits. Moreover, the bagging barrier could alter the micro-environment of fruit during development (Son & Lee, 2008) and consequently improved the fruit colouration and attractiveness. Sharma et al. (2013) also observed that pre-harvest fruit bagging increased anthocyanin synthesis and lycopene content in apples, which ultimately improved fruit colour and firmness.

Correlation studies of observed physical and chemical attributes of fruits

Correlation studies of physicochemical characters in guava would bestow an idea, which could be used for an assortment of advantageous factors for the impenitent breeding lineup in guava. The positive correlation is congruent for breeders as it can facilitate in simultaneous amelioration of both physical and chemical characteristics. While a negative correlation will hamper the corresponding expression of both aforesaid characters. The correlations among observed physio-chemical parameters of fruits were presented in Table 1. A significant positive correlation of fruit mass was observed with fruit length (0.577), fruit diameter (0.688)and fruit grades (0.440) while it showed a significant negative correlation with fruit scar (−0.499). The fruit length is highly positively correlated with fruit mass (0.577) and fruit diameter (0.781). The significant positive correlation of fruit diameter with fruit mass (0.688) and fruit length (0.781) was reported, while with TSS (−0.442), a significant negative correlation was observed. The TSS character of fruits showed a negative correlation with fruit diameter (−0.442), acidity (−0.615) and fruit scar (−0.452). The fruit acidity had a significantly positive correlation with vitamin C content (0.571), sugar content (0.649) and fruit scars (0.670), whereas it showed a significant negative correlation with TSS (−0.615) and fruit grading (−0.498). Vitamin C content had a significantly positive correlation with acidity (0.571). The grading of fruit showed a positive correlation only with fruit mass (0.440), while a significant negative correlation was observed with acidity (-0.498), sugar content (−0.500) and fruit scar (−0.660). The strong positive correlation of sugar content of fruits was examined with fruit acidity (0.649) and fruit scar (0.786) while it showed a negative correlation with fruit grade (−0.500). The scars on the fruit surface had a significant positive correlation with acidity (0.670) and sugar content (0.786), whereas the negative correlation of the aforementioned parameter was observed with fruit mass (−0.499), TSS (−0.452) and fruit grades (−0.660).

On the basis of the aforementioned analysis and discussion, it can be concluded that bagging with materials has a positive impact on the fruit quality in terms of fruit size, weight, texture and physio-chemical traits. Pre-harvest fruit bagging significantly affects fruit development and increased fruit size and weight (A-grade fruits) due to alterations in microclimatic conditions inside bags around the fruits. Thus pre-harvest fruit bagging is easy and cost-effective (the total cost incurred including labour was Rs 1.50–2.0 for bagging of single fruit) and the grower's friendly technology ensures quality guava fruit production which in turn ensures better market price. Further, the foremost advantage of pre-harvest fruit bagging is that it reduces the cost involved in plant protection measures because no chemical spray is required to control disease and insect pests. Thus fruits are completely free from harmful chemical residues which in turn offer consumers safety. So it's a win–win situation for both (growers and consumers).

Data availability and materials

The data used in this manuscript will be available upon reasonable request.

References

Abbasi, N. A., Chaudhary, M. A., Ali, M. I., Hussain, A., & Ali, I. (2014). On the tree fruit bagging influences the quality of guava harvested at different maturity stages during summer. International Journal of Agriculture and Biology, 16, 543–549.

Ali, M. M., Anwar, R., Yousef, A. F., Li, B., Luvisi, A., De Bellis, L., Aprile, A., & Chen, F. (2021). Influence of bagging on the development and quality of fruits. Plants (basel, Switzerland), 10(2), 358. https://doi.org/10.3390/plants10020358

Byer, R. E., & Carbaugh, D. H. (1995). Chemical, culture, and physiological factors influencing ‘Stayman’fruit cracking. Bulletin of Virginia Agriculture Experimental Station, 95, 1–33.

Chonhenchob, V., Kamhangwong, D., Kruenate, J., Khongrat, K., Tangchantra, N., Wichai, U., & Singh, S. P. (2011). Preharvest bagging with wavelength-selective materials enhances development and quality of mango (Mangifera indica L.) cv. Namdokmai. Journal of the Science of Food and Agriculture, 91(4), 664–671. https://doi.org/10.1002/jsfa.4231

Dolkar, D., Bakshi, P., Wali, V. K., Bhushan, B., & Sharma, A. (2014). (2014) Growth and yield attributes of commercial guava (Psidium guajava L.) cultivars under sub-tropical condition. Indian Journal of Plant Physioogy, 19, 79–82. https://doi.org/10.1007/s40502-014-0076-9

Edirimanna, E. R. S. P., Amarathunga, D., Amarasena, B., & Kirinde, T. (2015). Effect of bagging materials and bag colour on fruit weight and quality of guava (Psidum guajava L.). Annuals of Sri Lanka Department of Agriculture, 17, 297–302.

Frank, D. (2018). Evaluation of fruit bagging as a pest management option for direct pests of apple. Insects, 9, 178.

Hofman, P. J., Smith, L. G., Joyce, D. C., Johson, G. I., & Mebug, G. F. (1997). Bagging of mango (Mangifera indica cv. ‘Keitt’) fruit influences fruit quality and mineral composition. Postharvest Biology and Technology, 12, 89–91.

Islam, M. T., Rahman, M. S., Shamsuzzoha, M., Chowdhury, A. K. M. M. B., & Alom, R. (2017). Influence of pre-harvest bagging on fruit quality of mango (Mangifera indica L.) cv. Mishribhog. International Journal of Biosciences, 11, 59–68. https://doi.org/10.12692/ijb/11.3.59-68

Jain, N., Kamal, D., Malhotra, S., & Singh, R. (2003). Biochemistry of fruit ripening of guava (Psidium guajava L.): Compositional and enzymatic changes. Plant Foods for Human Nutrition, 58, 309–315.

Jia, H. J., Araki, A., & Okamoto, G. (2005). Influence of fruit bagging on aroma volatiles and skin coloration of ‘Hakuho’ peach (Prunus persica Batsch). Post Harvest Biology and Technology, 35, 61–68.

Kader, A. A. (2002). Postharvest technology of horticultural crops, 3rd edition (pp. 331–535). University of California.

Kherwar, D., & Usha, K. (2016). Genetic variations, character association and path analysis studies in guava (Psidium guajava L.) for bioactive and antioxidant attributes. Indian Journal of Plant Physiology, 21, 355–361. https://doi.org/10.1007/s40502-016-0230-7

Kim, Y. H., Kim, H. H., Youn, C. K., Kweon, S. J., Jung, H. J., & Lee, C. H. (2008). Effects of bagging material on fruit coloration and quality of “janghowon hwangdo” peach. Acta Horticulture, 772, 81–86.

Kitagawa, H., Manabe, K., & Esguerra, E. B. (1992). Bagging of fruit on the tree to control disease. Acta Horticulturae, 321, 871–875.

Kutinyu, R. (2014). The evaluation of different banana bunch protection materials on selected banana cultivars for optimum fruit production and quality parameters in Nampula province, Mozambique. M.Sc. Thesis, University of South Africa, Republic of South Africa. p. 100.

Li, E. M., Shi, D. C., Xu, Y. H., Chen, F., & Zhai, H. (2008). Changing characteristics of temperature and humidity in different type bags for bagging apple and their effects on fruit appearance quality. Chinese Journal of Apple Ecology, 19, 208–212.

Liu, J. H., Li, B. Z., Hang, L. S., Uan, D. Z., Li, Y. R., & Lie, Y. M. (2013). The effect of bagging on the quality and pesticide residual of ‘Red Fuji’ apple. Journal of Northwest Sci-Tech University of Agriculture and Forestry, 10, 16–18.

Meena, K., Maji, S., Kumar, S., Parihar, D., & Meena, D. (2016). Effect of bagging on fruit quality of guava. International Journal of Bio-Res Stress Management, 7, 330–333.

Mercado-Silva, E., Benito-Bautista, P., & Velasco, M. A. G. (1998). Fruit development, harvest index and ripening changes of guavas produced in Central Mexico. Postharvest Biology and Technology, 13(2), 143–150.

Mishra, K. K., Pathak, S., & Chaudhary, M. (2017). Effect of pre harvest spraying of nutrients and bagging with different colours of polythene on physico-chemical quality of rainy season guava (Psidium guajava L.) Fruits cv. L-49. International Journal ofCurrent Microbiology and Applied Science, 6(9), 3797–3807.

Muchui, M. N., Mathoolo, F. M., Njoroge, C. K., Kahangi, E. M., Onyango, C. A., & Kimani, E. M. (2010). Effect of perforated blue polyethylene bunch covers on selected postharvest quality parameters of tissue cultured bananas (Musa Spp.) cv. Williams in Central Kenya. Journal of Stored Product and Post Harvest Research, 1, 29–41.

Naseer, S., Hussain, S., Naeem, N., Pervaiz, M., & Rahman, M. (2018). The phytochemistry and medicinal value of Psidium guajava (guava). Clinical Phytoscience, 4, 32.

Niu, T. Q., Zhang, H. R., Li, M. L., & Hao, Y. Y. (2003). Influences on fruit quality under the micro-environment of bagging and analysis about its mechanism. Journal of Shangxi Agricultural University, 23, 255–259.

Pisciotta, A., Planeta, D., Giacosa, S., Paissoni, M. A., Di Lorenzo, R., & Rolle, L. (2020). Quality of grapes grown inside paper bags in mediterranean area. Agronomy, 10, 792.

Ranganna, S. C. (1991). Handbook of Analysis and Quality Control of Fruit and Vegetable Products (pp. 279–309). Tata Mc Graw Hill Publishing Co.

Rani, D. J., & Vijayanchali, S. S. (2017). Phytochemical, antioxidant activity and lycopene analysis of red guava fruitsJournal of Research. Extension and Development, 6(2), 25–30.

Rubel, M. H. K., Hossain, M. M., Hafiz, M. M. H., Rahman, M. M., & Khatun, M. R. (2019). Effect of banana bunch covering technology for quality banana production in Bangladesh. Progressive Agriculture, 30, 238–252.

Sapkota, R., Dahal, K., & Thapa, R. (2010). Damage assessment and management of cucurbit fruit flies in spring-summer squash. Journal of Entomology Nematology, 2(1), 7–12.

Sharma, R. R., Nagaraja, A., Goswami, A. K., Thakre, M., Kumar, R., & Varghese, E. (2020). Influence of on-the-tree fruit bagging on biotic stresses and postharvest quality of rainy-season crop of ‘Allahabad Safeda’ guava (Psidium guajava L.). Crop Protection, 135, 105216. https://doi.org/10.1016/j.cropro.2020.105216

Sharma, R. R., Pal, R. K., Asrey, R., & Rana, M. R. (2013). Pre-harvest fruit bagging influences fruit color and quality of apple cv. Delicious. Agricultural Science, 04(09), 443–448.

Sharma, R. R., Reddy, S. V. R., & Jhalegar, M. J. (2014). Pre-harvest fruit bagging a review. Journal of Horticultural Science and Biotechnology, 89(2), 101–113.

Sing, S., & Sing, S. (2005). Commercial Fruits. Kalyani Publishers.

Singh, H., Verghese, A., Stonehouse, J., Mumford, J., George, S., Naik, G., & Pandey, V. (2008). Developing bait and lure-based integrated pest management module for mango fruit fly (Bactrocera dorsalis) management in Orissa. Indian Journal of Agricultural Science, 78(7), 609–613.

Sohag, M. A., Rahman, M. H., Kayess, M. O., & Ifty, M. F. (2023). Effect of pre-harvest fruit bagging on yield, postharvest quality and shelf life of tomato (Solanum lycopersicum L.) cv. BARI Tomato. Journal of Applied and Natural Science, 15(1), 220–226. https://doi.org/10.31018/jans.v15i1.4261

Son, I. C., & Lee, C. H. (2008). The effects of bags with different light transmittance on the berry cracking of grape ‘Kyoho’. Horticulture Environment and Biotechnology, 49, 98–103.

Tefera, A., Seyoum, T., & Woldetsadik, K. (2008). Effects of disinfection, packaging and evaporatively cooled storage on sugar content of mango. African Journal of Biotechnology, 7, 65–72.

Teixeira, R., Boff, M. I. C., Amarante, C. V. T. D., Steffens, C. A., & Boff, P. (2011). Efeito do ensacamento dos frutos no controle de pragas e doenças e na qualidade e maturação de maçãs’ Fuji Suprema’. Bragantia, 70, 688–695.

Wang, H. L., Ding, B. J., Dai, J. Q., Nazarenus, T. J., Borges, R., Mafra-Neto, A., Cahoon, E. B., Hofvander, P., Stymne, S., & Löfstedt, C. (2022). Insect pest management with sex pheromone precursors from engineered oilseed plants. Nat Sustain, 5, 981–990. https://doi.org/10.1038/s41893-022-00949-x

Xu, G., Nie, J., Wu, Y., Yan, Z., & Ye, M. (2018). The effects of fruit bagging on residue behavior and dietary risk for four pesticides in apple. Scientific Reports, 8, 14348.

Xu, J. Z., Lu, M. Y., Fu, Z. H., Huang, D. J., Huang, G. X., Zue, J. J., Lu, K. R., & Li, Y. C. (2003). Effect of bagging on fruiting and fruit quality of Litchi chinensis Sonn. Cv. Feiziziao. Journal of Guangxi Agricultural and Biological Science, 22(2), 100–102.

Yang, W. H., Zhu, X. C., Bu, J. H., Hu, G. B., Wang, H. C., & Huang, X. M. (2009). Effects of bagging on fruit development and quality in cross-winter off-season longan. Scientia Horticulturae, 120, 194–200.

Zhou, H., Yu, Z., & Ye, Z. (2019). Effect of bagging duration on peach fruit peel color and key protein changes based on iTRAQ quantitation. Scientia Horticulture, 246, 217–226. https://doi.org/10.1016/j.scienta.2018.10.072

Zhou, J., Zhong, G., Lin, Z., & Xu, H. (2012). The effects of bagging on fresh fruit quality of Canarium album. Journal of Food Agriculture and Environment, 10(1), 505–508.

Acknowledgements

The authors are thankful to Director, ICAR-Central Institute for Subtropical Horticulture, Lucknow, India for providing necessary logistics support during the investigation.

Funding

The entire financial assistance is provided by the host institute.

Author information

Authors and Affiliations

Contributions

Conceptualization of research (K.K. Srivastava and Dinesh Kumar); Designing of the experiments (K.K. Srivastava and Dinesh Kumar); Contribution of experimental materials (K.K. Srivastava and Dinesh Kumar); Execution of field/lab experiments and data collection (K.K. Srivastava and Dinesh Kumar); Analysis of data and interpretation (Sumit K. Soni, S.K. Dwivedi); Preparation of the manuscript (K.K. Srivastava, Sumit K.Soni, S.K. Dwivedi).

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest among them of any kind.

Consent for publication

We give our consent for the publication of identifiable details within the manuscript to be published in the above Journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Srivastava, K.K., Soni, S.K., Kumar, D. et al. Effect of different bagging materials on guava fruit physiology and its quality attributes. Plant Physiol. Rep. 28, 238–246 (2023). https://doi.org/10.1007/s40502-023-00733-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40502-023-00733-9