Abstract

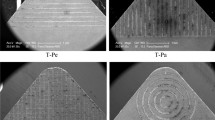

Micro-texturing has been widely proven to be an effective technology for achieving sustainable machining. However, the performance of micro-textured tools under different cooling conditions, especially their coupling effect on machined surface integrity, was scarcely reported. In this paper, the non-textured, linear micro-grooved, and curvilinear micro-grooved inserts were used to turn aluminum alloy 6061 under dry, emulsion, and liquid nitrogen cryogenic cooling conditions. The coupling effects of different micro-textures and cooling conditions on cutting force, cutting temperature, and machined surface integrity, including the surface roughness, work hardening, and residual stress, were revealed and discussed in detail. Results indicated that the micro-grooved tools, especially the curvilinear micro-grooved tools, not only reduced the cutting force and cutting temperature, but also improved the machined surface integrity. In addition, the micro-grooved tools can cooperate with the emulsion or liquid nitrogen to reduce the cutting force, cutting temperature, and improve the machined surface integrity generally, although the combination of emulsion cooling condition and micro-grooved tools generated negative coupling effects on cutting forces and surface work hardening. Especially, the combination of curvilinear micro-grooved cutting tools and cryogenic cooling condition resulted in the lowest cutting force and cutting temperature, which generated the surface with low roughness, weak work hardening, and compressive residual stress.

Similar content being viewed by others

References

Yang S, Wang T, Ren W et al (2020) Micro-texture design criteria for cemented carbide ball-end milling cutters. J Mech Sci Technol 34:127–136

Vignesh G, Barik D, Ragupathi P et al (2020) Experimental analysis on turning of AISI 4340 steel using non-textured, dimple textured and MoS2 coated dimple textured carbide cutting inserts at the rack surface. Mater Today Proc 33:2616–2620

Qian X, Duan X, Zou J (2020) Effects of different tool microstructures on the precision turning of titanium alloy TC21. Int J Adv Manuf Technol 106:5519–5526

Ahmed YS, Paiva JM, Arif AF et al (2020) The effect of laser micro-scale textured tools on the tool-chip interface performance and surface integrity during austenitic stainless-steel turning. Appl Surf Sci 510:145455. https://doi.org/10.1016/j.apsusc.2020.145455

Sivaiah P, Ajay Kumar GV, Singh MM et al (2020) Effect of novel hybrid texture tool on turning process performance in MQL machining of Inconel 718 superalloy. Mater Manuf Process 35:61–71

Duan R, Wang G, Xing Y (2022) Investigation of novel multiscale textures for the enhancement of the cutting performance of Al2O3/TiC ceramic cutting tools. Ceram Int 48:3554–3563

Ranjan P, Hiremath SS (2019) Role of textured tool in improving machining performance: a review. J Manuf Process 43:47–73

Sasi R, Kanmani SS, Palani IA (2017) Performance of laser surface textured high speed steel cutting tool in machining of Al7075-T6 aerospace alloy. Surf Coat Technol 313:337–346

Sugihara T, Enomoto T (2009) Development of a cutting tool with a nano/micro-textured surface-improvement of anti-adhesive effect by considering the texture patterns. Precis Eng 33:425–429

Liu G, Huang C, Su R et al (2019) 3D FEM simulation of the turning process of stainless steel 17–4PH with differently texturized cutting tools. Int J Mech Sci 155:417–429

Liu G, Ozel T, Li J et al (2020) Optimization and fabrication of curvilinear micro-grooved cutting tools for sustainable machining based on finite element modelling of the cutting process. Int J Adv Manuf Technol 110:1327–1338

Machado AR, Silva L, Souza F et al (2021) State of the art of tool texturing in machining. J Mater Process Technol 293:117096. https://doi.org/10.1016/j.jmatprotec.2021.117096

Elias JV, Venkatesh NP, Lawrence KD et al (2021) Tool texturing for micro-turning applications—an approach using mechanical micro indentation. Mater Manuf Process 36(1):84–93

Gupta MK, Song Q, Singh R et al (2020) Tribological behavior of textured tools in sustainable turning of nickel based super alloy. Tribiology Int 155:106775. https://doi.org/10.1016/j.triboint.2020.106775

Sivaiah P, Prasad MG, Singh MM et al (2020) Machinability evaluation during machining of AISI 52100 steel with textured tools under minimum quantity lubrication—a comparative study. Mater Manuf Process 35(15):1761–1768

Dinesh S, Senthilkumar V, Asokan P (2017) Experimental studies on the cryogenic machining of biodegradable ZK60 Mg alloy using micro-textured tools. Mater Manuf Process 32:979–987

Liu G, Huang C, Zhao B et al (2021) Effect of machined surface integrity on fatigue performance of metal workpiece: a review. Chin J Mech Eng 34(6):179–194

Rajbongshi SK, Sarma DK (2019) Performance parameters studies in machining of AISI D2 steel with dot-textured, groove-textured & non-textured cutting tool at the flank face. Int J Refract Met Hard Mater 83:104970. https://doi.org/10.1016/j.ijrmhm.2019.104970

Palanisamy D, Balasubramanian K, Manikandan N et al (2019) Machinability analysis of high strength materials with cryo-treated textured tungsten carbide inserts. Mater Manuf Process 34:502–510

Musavi S, Sepehrikia M, Davoodi B et al (2022) Performance analysis of developed micro-textured cutting tool in machining aluminum alloy 7075-T6: assessment of tool wear and surface roughness. Int J Adv Manuf Technol 119(5):3343–3362

Yang S, Yu S, He C (2019) The surface integrity of titanium alloy when using micro-textured ball-end milling cutters. Micromachines 10(1):21. https://doi.org/10.3390/mi10010021

Chen Y, Guo X, Zhang K et al (2019) Study on the surface quality of CFRP machined by micro-textured milling tools. J Manuf Process 37:114–123

Gupta MK, Song Q, Singh R et al (2020) Tribological behavior of textured tools in sustainable turning of nickel based super alloy. Tribiology Int 155:106775. https://doi.org/10.1016/j.triboint.2020.106775

Samuel AU, Araoyinbo AO, Elewa RR et al (2021) Effect of machining of aluminium alloys with emphasis on aluminium 6061 alloy–a review. In: IOP conference series: materials science and engineering, IOP publishing 1107, international conference on engineering for sustainable world (ICESW 2020), 10–14 August, Ota, Nigeria. https://doi.org/10.1088/1757-899X/1107/1/012157

Javidikia M, Sadeghifar M, Songmene V et al (2021) Low and high speed orthogonal cutting of AA6061-T6 under dry and flood-coolant modes: tool wear and residual stress measurements and predictions. Mater 14(15):4293. https://doi.org/10.3390/ma14154293

Javidikia M, Sadeghifar M, Songmene V et al (2021) 3D FE modeling and experimental analysis of residual stresses and machining characteristics induced by dry, MQL, and wet turning of AA6061-T6. Macj Sci Technol 25(6):957–983

Javidikia M, Sadeghifar M, Songmene V et al (2020) Effect of turning environments and parameters on surface integrity of AA6061-T6: experimental analysis, predictive modeling, and multi-criteria optimization. Int J Adv Manuf Technol 110:2669–2683

Sadeghifar M, Sedaghati R, Jomaa W et al (2018) A comprehensive review of finite element modeling of orthogonal machining process: chip formation and surface integrity predictions. Int J Adv Manuf Technol 96(9):3747–3791

Sadeghifar M, Sedaghati R, Jomaa W et al (2018) Finite element analysis and response surface method for robust multi-performance optimization of radial turning of hard 300M steel. Int J Adv Manuf Technol 94(5):2457–2474

Zhao G, Wang D (2017) Study on cutting simulation under different cooling conditions. Mach Electron 35(3):22–24

Matiga H, Viktor S, Franci P et al (2017) The procedure of solving the inverse problem for determining surface heat transfer coefficient between liquefied nitrogen and Inconel 718 workpiece in cryogenic machining. Procedia CIRP 58(6):617–622

Li C, Qiu X, Yu Z et al (2020) Novel environmentally friendly manufacturing method for micro-textured cutting tools. Int J Precis Eng Manuf Green Technol 8:1–12

Sugihara T, Kobayashi R, Enomoto T (2021) Direct observations of tribological behavior in cutting with textured cutting tools. Int J Mach Tools Manuf 168B:103726. https://doi.org/10.1016/j.ijmachtools.2021.103726

Liu J, Han R, Sun Y (2005) Research on experiments and action mechanism with water vapor as coolant and lubricant in green cutting. Int J Mach Tools Manuf 45:687–694

Zhao G, Xin L, Li L, et al. (2022) Cutting force model and damage formation mechanism in milling of 70wt% Si/Al composite. Chinese J Aeronaut. https://doi.org/10.1016/j.cja.2022.07.018

Özel T, Altan T (2000) Determination of workpiece flow stress andfriction at the chip-tool contact for high-speed cutting. Int J Mach Tools Manuf 40:133–152

Duan PF (2020) Research on cryogenic cutting technology for Aluminum alloy 6061. Dissertation, University of Jinan, Jinan

Gong L, Bertolini R, Bruschi S et al (2021) Surface integrity evaluation when turning Inconel 718 alloy using sustainable lubricating-cooling approaches. Int J Precis Eng Manuf Green Tech 9:25–42

Mantle AL, Aspinwall DK (1997) Surface integrity and fatigue life of turned gamma titanium aluminide. J Mater Process Technol 72(3):413–420

Liu G, Huang C, Sun S et al (2021) Effect of microstructure on high-speed cutting modified anti-fatigue performance of Incoloy A286 and titanium alloy TC17. Int J Adv Manuf Technol 113(3):855–866

Leadebal Jr W, Melo A, Oliveira A et al (2018) Effects of cryogenic cooling on the surface integrity in hard turning of AISI D6 steel. J Braz Soc Mech Sci Eng 40(1):15. https://doi.org/10.1007/s40430-017-0922-6

Umbrello D, Micari F, Jawahir IS (2012) The effects of cryogenic cooling on surface integrity in hard machining: a comparison with dry machining. CIRP Ann Manuf Technol 61:103–106

Gerstenmeyer M, Zanger F, Schulze V (2018) Influence of complementary machining on fatigue strength of AISI 4140. CIRP Ann 67(1):583–586

Chen Z, Moverare J, Peng RL et al (2016) Surface integrity and fatigue performance of Inconel 718 in wire electrical discharge machining. Procedia CIRP 45:307–310

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (Grant Nos. 52005281, 52005215 and 52074161), the Natural Science Foundation of Shandong Province (Grant No. ZR2020QE181), and the Open Research Fund of State Key Laboratory of High Performance Complex Manufacturing, Central South University (Grant No. Kfkt2020-06).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, GL., Zheng, JT., Huang, CZ. et al. Coupling effect of micro-textured tools and cooling conditions on the turning performance of aluminum alloy 6061. Adv. Manuf. 11, 663–681 (2023). https://doi.org/10.1007/s40436-022-00432-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-022-00432-y