Abstract

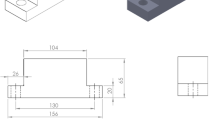

Given the serious work hardening phenomenon, high chemical activity, severe tool wear, and poor workpiece surface quality during the cutting of titanium alloys, placing micro-texture on the tool surface decreases the tool-chip contact area and friction and plays the role of wear resistance and friction reduction. In order to improve the cutting performance of cutting tools, the present study examins the effect of micro-texture parameters of a cemented carbide ball-end milling cutter on cutting force, tool wear, and workpiece surface roughness and establishes a regression analysis model via regression analysis. We consider the cutting performance of a cemented carbide micro-texture ball-end milling cutter as an evaluation standard. A genetic algorithm is applied to the multi-objective optimization of micro-texture parameters, and a regression analysis model of micro-texture design criteria is established. This provides a standardised reference to select standard micro-texture parameters in the design and preparation of a cemented carbide micro-texture ball-end milling cutter.

Similar content being viewed by others

References

Y. Shucai, W. Huanyan, Z. Yuhua and Z. Lei, Cutting performance evaluation of surface micro-texture ball end milling based on multi-objective decision making, Journal of Harbin University of Science and Technology, 21 (6) (2016) 1–5.

M. Xiaolin, X. Minggang and Z. Zhen, Finite element simulation of different surface micro-pits textures cutting tool strength based on ANSYS/workbench, Machine Tools and Hydraulic Pressure, 43 (12) (2015) 77–81.

T. Enomoto and T. Sugihara, Improvement of anti-adhesive properties of cutting tool by nano/micro textures and its mechanism, Procedia Engineering, 19 (2015) 100–105.

T. Enomoto, T. Sugihara, S. Yukinaga, K. Hirose and U. Satake, Highly wear-resistant cutting tools with textured surfaces in steel cutting, CIRP Annals - Manufacturing Technology, 61 (2012) 571–574.

T. Sugihara and T. Enomoto, Crater and flank wear resistance of cutting tools having microsurfaces, Precision Engineering, 37 (2013) 888–896.

T. Sugihara and T. Enomoto, Improving anti-adhesion in aluminium alloy cutting by microstripe texture, Precision Engineering, 36 (2012) 229–237.

W. Zhen, Research on antifriction of tool surface texture, Master Thesis, Nanjing University of Aeronautics and Astronautics (2011).

Q. Ting, Study on the Structure Design of Micro-textured Selflubricating Tools, Shandong University (2012).

S. Wenlong, D. Jianxin and W. Ze, Cutting temperature of cemented carbides base self-lubricated tools embedded with solid lubricants, Journal of Agricultural Machinery, 41 (1) (2010) 205–210.

H. Bao, D. Zilong and G. Xingjun, Analysis of cutting temperature field and tool wear of titanium alloy TC4, Journal of Liaoning University of Petrochemical Technology, 35 (2) (2015) 5–57.

H. Mulin, Analysis on effects of cutting parameters upon cutting force in TC4 titanium alloy turnery, Journal of Hefei University (Comprehensive Edition), 33 (4) (2016) 110–114.

Z. Xiansong, Experimental Study on Surface Roughness and Cutting Force of High Speed Cutting TC4 Titanium Alloy, Dalian University of Technology (2013).

W. Zhiwei, Optimization of Micro-texture for Cemented Carbide Ball End Mill Base on Friction Properties, Harbin University of Science and Technology (2016).

K. Zhang, J. Deng, Y. Xing, S. Li and H. Gao, Effect of microscale texture on cutting performance of WC/Co-based TiAIN coated tools under different lubrication conditions, Applied Surface Science, 326 (2015) 107–118.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Micro-texture preparation of cemented carbide ball end milling tool and its dynamic evolution of milling behaviour), China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Chongdu Cho

Shucai Yang is a Professor of the School of Mechanical and Power Engineering, Harbin University of Science and Technology, Harbin, China. He received his Ph.D. in Mechanical Engineering from Harbin University of Science and Technology. His research interests include mesoscopic geometry of tools, chip breaking mechanism and metal cutting.

Rights and permissions

About this article

Cite this article

Yang, S., Wang, T., Ren, W. et al. Micro-texture design criteria for cemented carbide ball-end milling cutters. J Mech Sci Technol 34, 127–136 (2020). https://doi.org/10.1007/s12206-019-1212-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-1212-2