Abstract

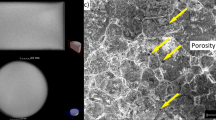

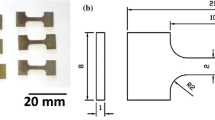

This paper documents an investigation into the compressive deformation behaviour of electron beam melting (EBM) processing titanium alloy (Ti-6Al-4V) parts under high strain loading conditions. The dynamic compression tests were carried out at a high strain rate of over 1×103/s using the split Hopkinson pressure bar (SHPB) test system and for comparison the quasi-static tests were performed at a low strain rate of 1×10−3/s using a numerically controlled hydraulic materials test system (MTS) testing machine at an ambient temperature. Furthermore, microstructure analysis was carried out to study the failure mechanisms on the deformed samples. The Vickers micro-hardness values of the samples were measured before and after the compression tests. The microstructures of the compressed samples were also characterized using optical microscopy. The particle size distribution and chemical composition of powder material, which might affect the mechanical properties of the specimens, were investigated. In addition, the numerical simulation using commercial explicit finite element software was employed to verify the experimental results from SHPB test system.

Similar content being viewed by others

References

Murr L, Gaytan SM (2014) Electron beam melting, comprehensive materials processing. Elsevier, Burlington, pp 135–161

Klöden B (2014) Additive manufacturing—electron beam melting. Available: www.ifam-dd.fraunhofer.de. Accessed 15 May 2014

Facchini L, Magalini E, Robotti P et al (2009) Microstructure and mechanical properties of Ti-6Al-4V produced by electron beam melting of pre-alloyed powders. Rapid Prototyp J 15(3):171–178

Koike M, Martinez K, Guo L et al (2011) Evaluation of titanium alloy fabricated using electron beam melting system for dental applications. J Mater Process Technol 211(8):1400–1408

Murr LE, Esquivel EV, Quinones SA et al (2009) Microstructures and mechanical properties of electron beam-rapid manufactured Ti-6Al-4V biomedical prototypes compared to wrought Ti-6Al-4V. Mater Charact 60(2):96–105

Murr LE, Quinones SA, Gaytan SM et al (2009) Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications. J Mech Behav Biomed Mater 2(1):20–32

Li X, Wang C, Zhang W et al (2009) Fabrication and characterization of porous Ti6Al4V parts for biomedical applications using electron beam melting process. Mater Lett 63(3):403–405

Harrysson OLA, Cansizoglu O, Marcellin-Little DJ et al (2008) Direct metal fabrication of titanium implants with tailored materials and mechanical properties using electron beam melting technology. Mater Sci Eng 28(3):366–373

Parthasarathy J, Starly B, Raman S et al (2010) Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J Mech Behav Biomed Mater 3(3):249–259

Murr LE, Gaytan SM, Medina F et al (2010) Characterization of Ti-6Al-4V open cellular foams fabricated by additive manufacturing using electron beam melting. Mater Sci Eng 527(7):1861–1868

Parthasarathy J, Starly B, Raman S (2011) A design for the additive manufacture of functionally graded porous structures with tailored mechanical properties for biomedical applications. J Manuf Process 13(2):160–170

Heinl P, Müller L, Körner C et al (2008) Cellular Ti-6Al-4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomater 4(5):1536–1544

Mohammadhosseini A, Fraser D, Masood SH et al (2013) Compressive properties of Ti-6Al-4V built by electron beam melting. Adv Mater Res 811:108–112

Mohammadhosseini A, Fraser D, Masood SH et al (2013) Microstructure and mechanical properties of Ti-6Al-4V manufactured by electron beam melting process. Mater Res Innov 17:106–112

Hosseini AM, Masood SH, Fraser D et al (2012) Mechanical properties investigation of HIP and as-built EBM parts. Adv Mater Res 576:216–219

Khan AS, Suh YS, Kazmi R (2004) Quasi-static and dynamic loading responses and constitutive modeling of titanium alloys. Int J Plast 20(12):2233–2248

Nemat-Nasser S, Guo WG, Nesterenko VF et al (2001) Dynamic response of conventional and hot isostatically pressed Ti-6Al-4V alloys: experiments and modeling. Mech Mater 33(8):425–439

Follansbee PS, Gray GT (1989) An analysis of the low temperature, low and high strain-rate deformation of Ti-6Al-4V. Metall Trans A 20(5):863–874

Biswas N, Ding JL, Balla VK et al (2012) Deformation and fracture behavior of laser processed dense and porous Ti6Al4V alloy under static and dynamic loading. Mater Sci Eng 549:213–221

Wu XJ, Gorham DA (1997) Stress equilibrium in the split Hopkinson pressure bar test. J de Phys IV 7(C3):C3-91–C3-96

Gray G (2003) Classic split-Hopkinson pressure bar testing. ASM Handbook, Ohio, pp 462–476

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates, and high temperatures. In: Proceedings of the seventh international symposium on ballistics, The Hague, The Netherlands, pp 541–547

Field JE, Walley SM, Proud WG et al (2004) Review of experimental techniques for high rate deformation and shock studies. Int J Impact Eng 30(7):725–775

Edwards M (2006) Properties of metals at high rates of strain. Mater Sci Technol 22(4):453–462

Davoodi B, Gavrus A, Ragneau E (2005) A technique for measuring the dynamic behaviour of materials at elevated temperatures with a compressive SHPB. WIT Trans Eng Sci 51:153

Dodd B (1992) Adiabatic shear localization: occurrence, theories, and applications. Pergamon Press, New York

Zener C, Hollomon J (1944) Effect of strain rate upon plastic flow of steel. J Appl Phys 15(1):22–32

Peirs J, Tirry W, Amin-Ahmadi B et al (2013) Microstructure of adiabatic shear bands in Ti6Al4V. Mater Charact 75:79–92

Yin WH, Xu F, Ertorer O et al (2013) Mechanical behavior of microstructure engineered multi-length-scale titanium over a wide range of strain rates. Acta Mater 61(10):3781–3798

Odeshi AG, Al-Ameeri S, Bassim MN (2005) Effect of high strain rate on plastic deformation of a low alloy steel subjected to ballistic impact. J Mater Process Technol 162–163:385–391

Odeshi AG, Bassim MN, Al-Ameeri S et al (2005) Dynamic shear band propagation and failure in AISI 4340 steel. J Mater Process Technol 169(2):150–155

Song WQ, Sun S, Zhu S et al (2012) Compressive deformation behavior of a near-beta titanium alloy. Mater Des 34:739–745

Murr LE, Ramirez AC, Gaytan SM et al (2009) Microstructure evolution associated with adiabatic shear bands and shear band failure in ballistic plug formation in Ti-6Al-4V targets. Mater Sci Eng 516(1):205–216

Lee G, Lee YH, Lee S et al (2004) Dynamic deformation behavior and ballistic impact properties of Ti-6Al-4V alloy having equiaxed and bimodal microstructures. Metall Mater Trans A 35(10):3103–3112

Guden M, Celik E, Akar E et al (2005) Compression testing of a sintered Ti6Al4V powder compact for biomedical applications. Mater Charact 54(4):399–408

Tu Z, Lu Y (2009) Evaluation of typical concrete material models used in hydrocodes for high dynamic response simulations. Int J Impact Eng 36(1):132–146

Zhou X, Hao H, Kuznetsov VA et al (2006) Numerical calculation of concrete slab response to blast loading. Trans Tianjin Univ 12(Suppl):94–99

Shui-Sheng YU, Yu-Bin LU, Yong CAI (2013) The strain-rate effect of engineering materials and its unified model. Latin Am J Solids Struct 10(4):833–844

Almasri AH, Voyiadjis GZ (2007) Effect of strain rate on the dynamic hardness in metals. J Eng Mater Technol 129(4):505–512

Acknowledgments

The authors would like to acknowledge Victorian Direct Manufacturing Centre (VDMC), Camplex Pty Ltd for their financial support to this project and also the Titanium Technologies Theme of the Future Manufacturing Flagship within CSIRO.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohammadhosseini, A., Masood, S.H., Fraser, D. et al. Dynamic compressive behaviour of Ti-6Al-4V alloy processed by electron beam melting under high strain rate loading. Adv. Manuf. 3, 232–243 (2015). https://doi.org/10.1007/s40436-015-0119-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-015-0119-0