Abstract

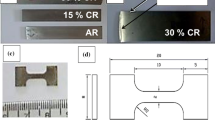

Mechanical behavior of Ti-4Al-1Mn titanium alloy has been studied in annealed, cold-rolled and heat-treated conditions. Room temperature tensile strength as well as % elongation has been found to be low with increasing amount of cold rolling. Lowering of strength in cold worked condition is attributed to premature failure. However, the same has been mitigated after heat treatment. Significant effect of cooling media (air and water) from heat treatment temperature on microstructure was not found except for the degree of fineness of α plates. Optimum properties (strength as well as ductility) were exhibited by samples subjected to 15% cold rolling and heat treatment below β transus temperature, which can be attributed to presence of recrystallized microstructure. In cold worked condition, the microstructure shows fine fragmented α plates/Widmanstätten morphology with high dislocation density along with a large amount of strain fields and twinning, which gets transformed to recrystallized equiaxed microstructure and with plate-like morphology after near β heat treatment. Prior cold work is found to have a significant effect on mechanical properties supported by evolution of microstructure. Twinning is found to be assisting in deformation as well as in recrystallization through the formation of deformation and annealing twins during cold working and heat treatment. Fracture analysis of the tested sample with prior cold work and heat-treated condition revealed quasi-ductile failure as compared to only ductile failure features seen for samples heat treated without prior cold work.

Similar content being viewed by others

References

V.N. Moiseyev, Structural Titanium Alloys in Modern Mechanical Engineering, Met. Sci. Heat Treat., 2004, 46, p 115–120

M.J. Donachie, Jr., Titanium: A Technical Guide, ASM International, Metals Park, 2000

V.N. Moiseyev, Titanium Alloys Russian Aircraft and Aerospace Applications, CRC Press, Florida, 1975, p 86–90

Z. Chen, I.P. Jones, and C.J. Small, Laves Phase in Ti-42Al-10Mn Alloy, Scr. Mater., 1996, 35(1), p 23–27

X.J. Tian, S.Q. Zhang, and H.M. Wang, The Influences of Anneal Temperature and Cooling Rate on Microstructure and Tensile Properties of Laser Deposited Ti-4Al-15Mn Titanium Alloy, J. Alloys Compd., 2014, 608, p 95–101

G.E. Dieter, H.A. Kuhn, and S.L. Semiatin, Handbook of Workability and Process Design, ASM International, Metals Park, 2003

K. Keshava Murthy, S. Sundaresan, and N.B. Potluri, Effect of Microstructural Features on the Fracture Toughness of a Welded Alpha-Beta Ti-Al-Mn Alloy, Eng. Fract. Mech., 1997, 58(1-2), p 29–41

A.K. Singh and R.A. Schwarzer, Effects of Mode of Deformation by Rolling on the Development of Texture in Binary Ti-Mn Alloys, Scr. Mater., 2001, 44, p 375–380

P.F. Santos, M. Niinomi, K. Cho, M. Nakai, H. Liu, N. Ohtsu, M. Hirano, M. Ikeda, and T. Narushima, Microstructures, Mechanical Properties and Cytotoxicity of Low Cost Beta Ti-Mn Alloys for Biomedical Applications, Acta Biomater., 2015, 26, p 366–376

Y. Jin, J.N. Wang, J. Yang, and Y. Wang, Microstructure Refinement of Cast TiAl Alloys by β Solidification, Scr. Mater., 2004, 55, p 113–117

K. Cho, M. Niinomi, M. Nakai, H. Liu, P.F. Santos, Y. Itoh, M. Ikeda, M.A.H. Gepreel, and T. Narushima, Improvement in Mechanical Strength of Low Cost β-Type Ti-Mn Alloys Fabricated by Metal Injection Molding Through Cold Rolling, J. Alloys Compd., 2016, 664, p 272–283

B.A. Kolachev, Y.V. Gorshkov, V.V. Shevchenko, and Y.N. Artsybasov, Structure and Properties of Alloys OT4 and OT4-1 After Vacuum Annealing, Met. Sci. Heat Treat., 1972, 14(5), p 378–381

O.D. Lai, W.K. Lu, and C.U.I. Xia, Dynamic Recrystallization of Ti-6Al-2Zr-1Mo-1V in Beta Forging Process, Trans. Nonferrous Met. Soc. China, 2012, 22(4), p 761–767

E.A. Metzbower, Stacking Fault Probability Determinations in HCP Ti-AI, Alloys, Metall. Mater. Trans., 1971, 2(11), p 3099–3103

Z. Guo, A.P. Miodownik, N. Saunders, and J.P. Schillé, Influence of Stacking Fault Energy on High Temperature Creep of Alpha Titanium Alloys, Scr. Mater., 2006, 54(12), p 2175–2178

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed., Elsevier Science, New York, 2004

F.J. Humphreys, A Unified Theory of Recovery, Recrystallization and Grain Growth, based on the Stability and Growth of Cellular Microstructures-I. The Basic Model, Acta Mater., 1997, 45(10), p 4231–4240

E.A. Holm, K.J. Healey, and C.C. Battaile, Coupled Computer Simulations of Recrystallization in Deformed Polycrystals, Mater. Sci. Forum, 2004, 467-470, p 641–646

J. Go, W.J. Poole, M. Militzer, and M.A. Wells, Modelling Recovery and Recrystallisation During Annealing of AA 5754 Aluminium Alloy, Mater. Sci. Technol., 2003, 19(10), p 1361–1368

J.W. Won, T. Lee, S. Hong, Y. Lee, J.H. Lee, and C.S. Lee, Role of Deformation Twins in Static Recrystallization Kinetics of High-Purity Alpha Titanium, Met. Mater. Int., 2016, 22(6), p 1041–1048

M. Blicharski, S. Nourbakhsh, and J. Nutting, Structure and Properties of Plastically Deformed α-Ti, Met. Sci., 1979, 13(9), p 516–522

H. Takebe, K. Mori, K. Takahashi, and H. Fujii, Effects of Thickness and Grain Size on Tensile Properties of Pure Titanium Thin Gauge Sheets, Proceedings of the 13th World Conference on Titanium, The Minerals, Metals and Materials Society, 2016, p 491–494.

T. Fukumaru, H. Hidaka, T. Tsuchiyama, and S. Takaki, Effect of Wire Diameter and Grain Size on Tensile Properties of Austenitic Stainless Steel Wire, Bull. Iron Steel Inst. Jpn., 2005, 91, p 828–833

Z. Guo, S. Malinov, and W. Sha, Modelling Beta Transus Temperature of Titanium Alloys Using Artificial Neural Network, Comput. Mater. Sci., 2005, 32(1), p 1–12

G. Garcés, P. Pérez, and P. Adeva, Thermal Stability of Metastable Mg-30%Ti-2%Al-0.9%Mn (wt.%) Alloy Synthesised by PVD, J. Alloys Compd., 2005, 387(1-2), p 115–120

Acknowledgments

The authors thank the National Facility for texture and OIM Lab, IIT Bombay for the support provided in EBSD work. The authors also acknowledge the support of MCD, HWMD/MMG/MME/VSSC and IFF/MME/VSSC for heat treatment, characterization and fabrication support extended by them. The authors also thankfully acknowledge DD, MME/VSSC for providing guidance during this work and Director, VSSC for kind permission to publish the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gaur, R., Gupta, R.K., AnilKumar, V. et al. Effect of Cold Rolling and Heat Treatment on Microstructure and Mechanical Properties of Ti-4Al-1Mn Titanium Alloy. J. of Materi Eng and Perform 27, 3217–3233 (2018). https://doi.org/10.1007/s11665-018-3412-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3412-9