Abstract

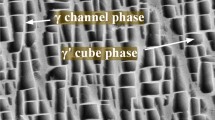

Nickel-based single crystal superalloy has no grain boundary and excellent high-temperature performance. The traditional grinding mechanism of shearing and slipping along the polycrystalline material’s grain boundary based on the theory of elastic–plastic deformation is not suitable for grinding single crystal parts. At present, there are few studies on microgrinding nickel-based single crystal superalloy. The grinding quality directly affects the workpiece’s service life. To realize high-quality and low-damage grinding nickel-based single crystal superalloy (001) crystal plane, this paper studied the surface roughness and the wear of the microgrinding tool. Firstly, it was assumed that the protrusion height of the electroplated abrasives on the grinding tool obeyed Rayleigh distribution. Based on the cutting state of abrasives, the prediction model of surface roughness of microgrinding nickel-based single crystal superalloy was established and verified by experiments. Secondly, the effect of grinding parameters on microgrinding surface roughness was analyzed through a single-factor experiment. Finally, the main wear forms, wear mechanism of grinding tool and the influence of grinding parameters on wear of grinding tool were analyzed. The results showed: although there was some error between the predicted value and the experimental value, the predicted value of the roughness and the experimental value had the same trend with the change of microgrinding parameters; with the increase in spindle speed (ng) and the decrease in grinding depth (ap), the surface roughness of microgrinding nickel-based single crystal superalloy showed a decreasing trend; with the increase in feeding rate (vw), the surface roughness increased obviously; the wear of the grinding tool could be divided into five forms; the diameter of the microgrinding tool showed a trend of rapid reduction, then steady reduction, and finally rapid reduction under all grinding parameters. This study provided an important theoretical and practical reference for the manufacturing of nickel-based single crystal superalloy microparts.

Similar content being viewed by others

References

Sun Y, Su ZP, Gong YD, Jin LY, Wen Q, Qi Y (2020) An experimental and numerical study of micro-grinding force and performance of sapphire using novel structured micro abrasive tool. Int J Mech Sci 181:1–16

Wang C (2016) Machining mechanism and technical experiment study on micro mill-grinding. Northeastern University, Shenyang

Zhang J, Wang L, Wang D, Xie G, Lu YZ (2019) Recent progress in research and development of nickel-based single crystal superalloys. Acta Metall Sin 55:1077–1094

Jin T, Zhou YZ, Wang XG, Liu JL, Sun XF, Hu ZQ (2015) Research Process on Microstructural Stability and Mechanical Behavior of Advanced Ni-based single crystal Superalloys. Acta Metall Sin 51:1153–1162

Miao Q, Ding WF, Kuang WJ, Yang CY (2020) Comparison on grindability and surface integrity in creep feed grinding of GH4169, K403, DZ408 and DD6 nickel-based superalloys. J Manuf Process 49:175–186

Ruzzi RS, Silva RB, Silva LRR, Machado AR, Jackson MJ, Hassui A (2020) Influence of grinding parameters on Inconel 625 surface grinding. J Manuf Process 55:174–185

Zhu CM, Gu P, Wu YY, Liu DH, Wang XK (2019) Surface roughness prediction model of SiCp/Al composite in grinding. Int J Mech Sci 155:98–109

Zhang ZZ, Yao P, Wang J, Huang CZ, Cai R, Zhu HT (2019) Analytical modeling of surface roughness in precision grinding of particle reinforced metal matrix composites considering nanomechanical response of material. Int J Mech Sci 157–158:243–253

Zhou WH, Tang JY, Shao W (2020) Study on surface generation mechanism and roughness distribution in gear profile grinding. Int J Mech Sci 187:1–17

Sun SY, Tang JY, Shao W, Chen CS, Liu YX (2019) Research on the matching relationship between ultrasonic-assisted grinding parameters and workpiece surface roughness. Int J Adv Manuf Technol 102:487–496

Ma LJ, Gong YD, Chen XH (2014) Study on surface roughness model and surface forming mechanism of ceramics in quick point grinding. Int J Mach Tools Manuf 77:82–92

Li BK, Ding WF, Yang CY, Li CH (2019) Grindability of powder metallurgy nickel-base superalloy FGH96 and sensibility analysis of machined surface roughness. Int J Adv Manuf Technol 101:2259–2273

Li BK, Miao Q, Li M, Zhang X, Ding WF (2020) An investigation on machined surface quality and tool wear during creep feed grinding of powder metallurgy nickel-based superalloy FGH96 with alumina abrasive wheels. Adv Manuf 8:160–176

Su H, Yang CY, Gao SW, Fu YC, Ding WF (2019) A predictive model on surface roughness during internal traverse grinding of small holes. Int J Adv Manuf Technol 103:2069–2077

Liu ZM, Tang Q, Zhang YF, Liu N (2019) An analytical method for surface roughness prediction in precision grinding of screw rotors. The Int J Adv Manuf Technol 103:2665–2676

Khare SK, Agarwal S (2015) Predictive modeling of surface roughness in grinding. Procedia CIRP 31:375–380

Agarwal S, Rao PV (2012) Predictive modeling of undeformed chip thickness in ceramic grinding. Int J Mach Tools Manuf 56:59–68

Chen ZZ, Xu JH, Ding WF (2015) Grinding temperature during high-efficiency grinding Inconel718 using porous CBN wheel with multilayer defined grain distribution. Int J Adv Manuf Technol 77:165–172

Zhao ZC, Fu YC, Xu JH (2016) An investigation on high-efficiency profile grinding of directional solidified nickel-based superalloys DZ125 with electroplated CBN wheel. Int J Adv Manuf Technol 83:1–11

Wen XL, Gong YD, Cheng J, Ba DC (2017) Mechanism analysis and experimental research on wear of electroplated diamond micro-grinding tool. J Mech Eng 51:177–185

Miao Q, Ding WF, Gu YL, Xu JH (2019) Comparative investigation on wear behavior of brown alumina and microcrystalline alumina abrasive wheels during creep feed grinding of different nickel-based superalloys. Wear 426–427:1624–1634

Gong YD, Huang XJ, Wen XL, Zhou J (2017) Experimental research on wear mechanism of micro-grinding tool in grinding soda-lime glass. J Northeastern Univ (Nat Sci) 38:1128–1132

Zhou YG, Ma LJ, Gong YD, Zhang L, Yin GQ (2019) Study on the mechanism of chip forming and the microhardness of micro-grinding nickel-based single-crystal superalloy. Int J Adv Manuf Technol 103:281–295

Malkin S (2008) Grinding technology theory and applications of machining with abrasives. Industrial Press Inc., New York

Cheng J, Gong YD, Wu ZZ (2012) Experimental study on mechanism of surface formation for micro-grinding of hard brittle material. J Mech Eng 48:190–198

Hecker RL, Liang SY (2003) Predictive modeling of surface roughness in grinding. Int J Mach Tools Manuf 43:755–761

Zhou Y, Ma L, Gong Y (2019) Study on force and temperature characteristics of micro-grinding nickel-based single-crystal superalloy. J Braz Soc Mech Sci Eng 41:1–18

Gong YD, Huang XJ, Wen XL (2017) Experimental research on wear mechanism of micro-grinding tool in grinding soda-lime glass. J Northeastern Univ (Nat Sci) 38:1128–1132

Li F, Su HH, Ding WF, Zhang ZW (2011) Wear of electroplated CBN wheels in high speed grinding of superalloy. Diamond Abrasives Eng 31:39–32

Chen ZZ, Xu JH, Ding WF, Ma CY (2014) Wear behavior of porous composite-bonded CBN abrasive wheels. J Mech Eng 50:201–207

Acknowledgements

This work is supported by the National Natural Science Foundation of China: 51905083, 51975113; the Natural Science Foundation of Hebei Province: E2019501094, E2018501041; the Fundamental Research Funds for the Central Universities: N2123025, N2003024; the Science and Technology Research Project for Higher School of Hebei Province: QN2019321; and the Scientific Research Initiating Funds for Northeastern University at Qinhuangdao: XNY201806.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exists in the submission of this manuscript, and the manuscript is approved by all authors for publication. I would like to declare on behalf of my co-authors that the work described was original research that has not been published previously, and not under consideration for publication elsewhere, in whole or in part. All the authors listed have approved the manuscript that is enclosed.

Additional information

Technical Editor: Monica Carvalho.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, Y., Wen, X., Yin, G. et al. Study on theoretical model of roughness and wear of the microgrinding tool in microgrinding nickel-based single crystal superalloy. J Braz. Soc. Mech. Sci. Eng. 43, 317 (2021). https://doi.org/10.1007/s40430-021-03034-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-03034-0