Abstract

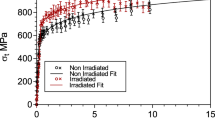

The nondestructive nature of X-ray microtomography (µCT) associated with its suitable temporal resolution, obtained with the use of high energy polychromatic radiation from electron acceleration rings, allows in situ investigations of the damage evolution process during tensile loading in composite materials. In this context, the development of adequate scientific instrumentation as well as the understanding of the corresponding technology by research groups is paramount to guarantee reliability of the obtained results. In the present work, a miniaturized universal testing machine (tensile, compression and fatigue) was developed to be applied in in situ µCT experiments using synchrotron radiation with innovative technology. The equipment has a uniaxial load capacity of up to 300 N with 1 N resolution and can impose 0.01 mm resolution displacements following controlled deformation rates. In order to validate the developed equipment, tensile test results performed on sub-sized and standard annealed copper specimens were compared and in situ µCT tensile tests were performed in glass-fiber-reinforced polypropylene matrix composites at the Laboratório Nacional de Luz Síncrotron (LNLS) in Campinas (SP, Brazil). Data analysis was performed by applying image processing techniques to successive tomograms in order to monitor crack propagation in the initial stages of damage evolution. The results obtained allowed the clarification of crack propagation mechanisms in the investigated composite materials and demonstrated the viability of the equipment’s intended application.

Similar content being viewed by others

References

Joost WJ (2012) Reducing vehicle weight and improving U. S. energy efficiency using integrated computational materials engineering. JOM 64:1032–1038. https://doi.org/10.1007/s11837-012-0424-z

Babikian R, Lucakchko SP, Waitz IA (2002) The historical fuel efficiency characteristics of regional aircraft from technological, operational, and cost perspectives. J Air Transp Manag 8:389–400. https://doi.org/10.1016/S0969-6997(02)00020-0

Matzenmiller A, Lubliner J, Taylor RL (1995) A constitutive model for anisotropic damage in fiber-composites. Mech Mater 20:125–152. https://doi.org/10.1016/0167-6636(94)00053-0

Wang C, Liu Z, Xia B, Duan S, Nie X, Zhuang Z (2015) Development of a new constitutive model considering the shearing effect for anisotropic progressive damage in fiber-reinforced composites. Compos Part B Eng 75:288–297. https://doi.org/10.1016/j.compositesb.2015.01.048

Oréfice R, West J, Lattore G, Hench L, Brennan A (2010) Effect of long-term in vitro testing on the properties of bioactive glass–polysulfone composites. Biomacromolecules 11:657–665. https://doi.org/10.1021/bm901228a

Karger-Kocsis J, Mahmood H, Pegoretti A (2015) Recent advances in fiber/matrix interphase engineering for polymer composites. Prog Mater Sci 73:1–43. https://doi.org/10.1016/j.pmatsci.2015.02.003

Awaja F, Zhang S, Tripathi M, Nikiforov A, Pugno N (2016) Cracks, microcracks and fracture in polymer structures: formation, detection, autonomic repair. Prog Mater Sci 83:536–573. https://doi.org/10.1016/j.pmatsci.2016.07.007

Naebe O, Abolhasani MM, Khayyam H, Amini A, Fox B (2016) Crack damage in polymers and composites: a review. Polym Rev 56:31–69. https://doi.org/10.1080/15583724.2015.1078352

Maire E, Buffière JY, Salvo L, Blandin JJ, Ludwig W, Létang JM (2001) On the application of X-ray microtomogrpahy in the field of materials science. Adv Eng Mater 3:539–546. https://doi.org/10.1002/1527-2648(200108)3:8%3c539:AID-ADEM539%3e3.0.CO;2-6

Ludwig W, Buffière JY, Savelli S, Cloetens P (2003) Study of the interaction of a short fatigue crack with grain boundaries in a cast Al alloy using X-ray microtomography. Acta Mater 51:585–598. https://doi.org/10.1016/S1359-6454(02)00320-8

Pyzalla AR, Camin B, Buslaps T, Kaminski H, Kottar A, Pernack A, Reimers W (2005) Simultaneous tomography and diffraction analysis of creep damage. Science 308:92–95. https://doi.org/10.1126/science.1106778

Isaac A, Dzieciol K, Sket F, Borbély A (2011) In-situ microtomographic characterization of single-cavity growth during high-temperature creep of leaded brass. Metall Mater Trans A 42:3022–3030. https://doi.org/10.1007/s11661-011-0781-1

Dzieciol K, Borbély A, Sket F, Isaac A, Di Michiel M, Cloetens P, Buslaps Th, Pyzalla AR (2011) Void growth in copper during high-temperature power law creep. Acta Mater 59:671–677. https://doi.org/10.1016/j.actamat.2010.10.003

Sket F, Dzieciol K, Isaac A, Borbély A, Pyzalla AR (2010) Tomographic method for evaluation of apparent activation energy of steady-state creep. Mater Sci Eng A 527:2112–2120. https://doi.org/10.1016/j.msea.2009.11.058

Maire E, Withers PJ (2014) Quantitative X-ray tomography. Int Mater Rev 59:1–43. https://doi.org/10.1179/1743280413Y.0000000023

Böhm J, Gruber P, Spolenak R, Stierle A, Wanner A, Arzt E (2004) Tensile testing of ultrathin polycrystalline films: a synchrotron-based technique. Rev Sci Instrum 75:1110–1119. https://doi.org/10.1063/1.1669124

Geandier G, Thiaudière D, Randriamazaoro RN, Chiron R, Djaziri S, Lamongie B, Diot Y, Le Bourhis E, Renault PO, Goudeau P, Bouaffad A, Castelnau O, Faurie D, Hild F (2010) Development of a synchrotron biaxial tensile device for in situ characterization of thin films mechanical response. Rev Sci Instrum 81:103903. https://doi.org/10.1063/1.3488628

Haboub A, Bale HÁ, Nasiatka JR, Cox BN, Marshal DB, Ritchie RO, Macdowell AA (2014) Tensile testing of materials at high temperatures above 1700°C with in situ synchrotron X-ray micro-tomography. Rev Sci Instrum 85:083702. https://doi.org/10.1063/1.4892437

Cendre E, Duvauchelle P, Peix G, Buffière JY, Babot D (1999) Conception of a high resolution X-ray computed tomography device; application to damage initiation imaging inside materials. In: 1st world congress on industrial process tomogrpahy. Buxton (England)

Buffière JY, Maire E, Cloetens P, Lormand G, Fougères R (1999) Characterization of internal damage in a MMCp using X-ray synchrotron phase contrast microtomography. Acta Mater 47:1613–1625. https://doi.org/10.1016/S1359-6454(99)00024-5

Buffière JY, Maire E, Adrien J, Masse JP, Boller E (2010) In situ experiments with X-ray tomography: an attractive tool for experimental mechanics. Exp Mech 50:289–305. https://doi.org/10.1007/s11340-010-9333-7

Buffière JY, Ferrie E, Proudhon H, Ludwig W (2006) Three-dimensional visualisation of fatigue cracks in metals using high resolution synchrotron X-ray micro-tomography. Mater Sci Technol 22:1019–1024. https://doi.org/10.1179/174328406X114135

Singh SS, William JJ, Hruby P, Xiao X, De Carlo F, Chawla N (2014) In situ experimental techniques to study the behavior of materials using X-ray synchrotron tomography. Integr Mater Manuf Innov 3:9. https://doi.org/10.1186/2193-9772-3-9

Yu B, Blanc R, Soutis C, Withers PJ (2016) Evolution of damage during the fatigue of 3D woven glass-fibre reinforced composites subjected to tension–tension loading observed by time-lapse X-ray tomography. Compos Part A Appl Sci Manuf 82:279–290. https://doi.org/10.1016/j.compositesa.2015.09.001

Rolland H, Saintier N, Wilson P, Merzeau J, Robert G (2017) In situ X-ray tomography investigation on damage mechanisms in short glass fibre reinforced thermoplastics: effect of fibre orientation and relative humidity. Compos Part B Eng 109:170–186. https://doi.org/10.1016/j.compositesb.2016.10.043

Croom B, Wang WM, Li J, Li X (2016) Unveiling 3D deformations in polymer composites by coupled micro X-ray computed tomography and volumetric digital image correlation. Exp Mech 56:999–1016. https://doi.org/10.1007/s11340-016-0140-7

Vitorino LS, Oréfice RL (2017) Layer-by-layer technique employed to construct multitask interfaces in polymer composites. Polímeros 27:330–338. https://doi.org/10.1590/0104-1428.15616

Paganin D, Mayo SC, Gureyev TE, Miller PR, Wilkins SW (2002) Simultaneous phase and amplitude extraction from a single defocused image of a homogeneous object. J Microsc 206:33–40. https://doi.org/10.1046/j.1365-2818.2002.01010.x

Miqueles EX, Helou ES (2016) Fast backprojection operator for synchrotron tomographic data. In: Russo G, Capasso V, Nicosia G, Romano V (eds) Progress in industrial mathematics at ECMI 2014. ECMI 2014. Mathematics in industry, vol 22. Springer, Cham. https://doi.org/10.1007/978-3-319-23413-7_32

Patterson BM, Cordes NL, Henderson K, Williams JJ, Stannard T, Singh SS, Ovejero AR, Xiao X, Robinson M, Chawla N (2016) In situ X-ray synchrotron tomographic imaging during the compression of hyper-elastic polymeric materials. JOM 51:171–187. https://doi.org/10.1007/s10853-015-9355-8

Rao G, Amirkhanov A, Salaberger D, Heinzl C, Kastner J (2017) Damage characterization in SFRP using X-ray computed tomography after application of incremental an interrupted in situ quasi static tensile loading. In: 7th conference on industrial computed tomography. Leuven (Belgium)

Garcea SC, Wang Y, Withers PJ (2018) X-ray computed tomography of polymer composites. Compos Sci Technol 156:304–319. https://doi.org/10.1016/j.compscitech.2017.10.023

Greenhalgh ES (2009) Failure analysis and fractography of polymer composites, 1st edn. Woodhead Publishing, Sawston

Ma P-C, Liu J-W, Gao S-L, Mäder E (2013) Development of functional glass fibres with nanocomposite coating: a comparative study. Compos Part A 44:16–22. https://doi.org/10.1016/j.compositesa.2012.08.027

Fu J, Zhang M, Liu L, Xiao L, Li M, Ao Y (2019) Layer-by-layer electrostatic self-assembly silica/graphene oxide onto carbon fiber surface for enhance interfacial strength of epoxy composites. Mater Lett 236:69–72. https://doi.org/10.1016/j.matlet.2018.10.077

Gao B, Zhang R, He M, Sun L, Wang C, Liu L, Zhao L, Cui H, Cao A (2016) Effect of a multiscale reinforcement by carbon fiber surface treatment with graphene oxide/carbon nanotubes on the mechanical properties of reinforced carbon/carbon composites. Compos Part A 90:433–440. https://doi.org/10.1016/j.compositesa.2016.08.012

Acknowledgements

The authors acknowledge funding from FAPEMIG (Grant No. APQ-02786-14), National Council for Scientific and Technological Development (CNPq) and the National Council for the Improvement of Higher Education (CAPES).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Oliveira, A.F., Isaac, A.C., Vitorino, L.S. et al. Development and application of a miniaturized tensile testing device for in situ synchrotron microtomography experiments. J Braz. Soc. Mech. Sci. Eng. 42, 94 (2020). https://doi.org/10.1007/s40430-019-2163-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-2163-3