Abstract

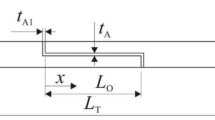

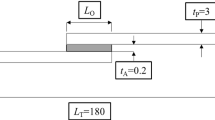

Adhesive bonding has become a promising joining technique, by satisfying the needs of diverse industrial fields. Several joint configurations are available for the designer, and the most common and exhaustively studied are single-lap, double-lap and scarf joints (Petrie in Handbook of adhesives and sealants. McGraw-Hill, New York, 2000; Moreira and Campilho in Eng Struct 101:99–110, 2015). Stepped-lap joints consist of a finite number of steps in the bonded region, and they are characterized by having stress concentrations at the end of each step rather than only at the bonded length edges, which leads to a higher load transfer through the interior part of the overlap compared to lap joints and, consequently, to a higher performance. The present work experimentally and numerically evaluates the static tensile strength of stepped-lap joints bonded with three adhesives, Araldite® AV138 (brittle), Araldite® 2015 (moderately ductile) and Sikaforce® 7752 (ductile), considering different overlap lengths (LO). A finite element analysis was undertaken to compare through-thickness normal (σy) and shear (τxy) stresses in the adhesive layer between joint configurations. Additionally, a cohesive zone model (CZM) analysis was considered to study the failure modes and the CZM damage variable during failure and to evaluate the CZM technique’s accuracy. It was possible to conclude that the recommended adhesive depends on the joint geometry, since strong and brittle adhesives are better for small LO, while for higher LO ductile adhesives with less strength can give better results. The CZM technique was accurate in the strength prediction, although with slight under-predictions for highly ductile adhesives.

Similar content being viewed by others

References

Petrie EM (2000) Handbook of adhesives and sealants. McGraw-Hill, New York

Moreira RDF, Campilho RDSG (2015) Strength improvement of adhesively-bonded scarf repairs in aluminium structures with external reinforcements. Eng Struct 101:99–110. https://doi.org/10.1016/j.engstruct.2015.07.001

Adams RD (2005) Adhesive bonding: science, technology and applications. Woodhead Publishing Limited, Cambridge

Öz Ö, Özer H (2017) An experimental investigation on the failure loads of the mono and bi-adhesive joints. J Adhes Sci Technol 31(19–20):2251–2270. https://doi.org/10.1080/01694243.2016.1264661

Charbonnet P, Clad A, Fant-Jaeckels H, Thirion JL (2000) Weld bonding: a very well adapted joining technique to decrease the weight of steel structures. La Revue de Métallurgie April:543–551

Murakami S, Sekiguchi Y, Sato C, Yokoi E, Furusawa T (2016) Strength of cylindrical butt joints bonded with epoxy adhesives under combined static or high-rate loading. Int J Adhes Adhes 67:86–93. https://doi.org/10.1016/j.ijadhadh.2015.12.030

Fernandes TAB, Campilho RDSG, Banea MD, da Silva LFM (2015) Adhesive selection for single lap bonded joints: experimentation and advanced techniques for strength prediction. J Adhesion 91(10–11):841–862. https://doi.org/10.1080/00218464.2014.994703

Zhao B, Lu Z-H, Lu Y-N (2014) Two-dimensional analytical solution of elastic stresses for balanced single-lap joints—Variational method. Int J Adhes Adhes 49:115–126. https://doi.org/10.1016/j.ijadhadh.2013.12.026

Fessel G, Broughton JG, Fellows NA, Durodola JF, Hutchinson AR (2007) Evaluation of different lap-shear joint geometries for automotive applications. Int J Adhes Adhes 27(7):574–583. https://doi.org/10.1016/j.ijadhadh.2006.09.016

Akpinar S (2014) The strength of the adhesively bonded step-lap joints for different step numbers. Compos Part B 67:170–178. https://doi.org/10.1016/j.compositesb.2014.06.023

Adams RD, Comyn J, Wake WC (1997) Structural adhesive joints in engineering, 2nd edn. Chapman & Hall, London

Xiaoquan C, Baig Y, Renwei H, Yujian G, Jikui Z (2013) Study of tensile failure mechanisms in scarf repaired CFRP laminates. Int J Adhes Adhes 41:177–185. https://doi.org/10.1016/j.ijadhadh.2012.10.015

Volkersen O (1938) Die nietkraftoerteilung in zubeanspruchten nietverbindungen konstanten loschonquerschnitten. Luftfahrtforschung 15:41–47

Goland M, Reissner E (1944) The stresses in cemented joints. J Appl Mech 66:A17–A27

Mehidi A, Kaddouri K, Belhouari M, Amiri A, Bachir Bouiadjra B (2015) Three-dimensional finite element analysis of a crack normal to and terminating at a bi-material interface. J Braz Soc Mech Sci Eng 37(6):1785–1792. https://doi.org/10.1007/s40430-014-0264-6

Sarrado C, Turon A, Costa J, Renart J (2016) On the validity of linear elastic fracture mechanics methods to measure the fracture toughness of adhesive joints. Int J Solids Struct 81:110–116. https://doi.org/10.1016/j.ijsolstr.2015.11.016

Barenblatt GI (1959) The formation of equilibrium cracks during brittle fracture. General ideas and hypothesis. Axisymmetrical cracks. J Appl Math Mech 23:622–636

Barenblatt GI (1962) The mathematical theory of equilibrium cracks in brittle fracture. Adv Appl Mech 7:55–129. https://doi.org/10.1016/S0065-2156(08)70121-2

Dugdale DS (1960) Yielding of steel sheets containing slits. J Mech Phys Solids 8(2):100–104. https://doi.org/10.1016/0022-5096(60)90013-2

Feraren P, Jensen HM (2004) Cohesive zone modelling of interface fracture near flaws in adhesive joints. Eng Fract Mech 71(15):2125–2142. https://doi.org/10.1016/j.engfracmech.2003.12.003

Campilho RDSG, Banea MD, Pinto AMG, da Silva LFM, de Jesus AMP (2011) Strength prediction of single- and double-lap joints by standard and extended finite element modelling. Int J Adhes Adhes 31(5):363–372. https://doi.org/10.1016/j.ijadhadh.2010.09.008

Malekan M (2016) Finite element simulation of gaseous detonation-driven fracture in thin aluminum tube using cohesive element. J Braz Soc Mech Sci Eng 38(3):989–997. https://doi.org/10.1007/s40430-014-0270-8

Campilho RDSG, Banea MD, Neto JABP, da Silva LFM (2013) Modelling adhesive joints with cohesive zone models: effect of the cohesive law shape of the adhesive layer. Int J Adhes Adhes 44:48–56. https://doi.org/10.1016/j.ijadhadh.2013.02.006

Liu G, Zhou D, Ma J, Han Z (2016) Numerical investigation of mixed-mode crack growth in ductile material using elastic–plastic XFEM. J Braz Soc Mech Sci Eng 38(6):1689–1699. https://doi.org/10.1007/s40430-016-0557-z

Mubashar A, Ashcroft IA, Crocombe AD (2014) Modelling damage and failure in adhesive joints using a combined XFEM-cohesive element methodology. J Adhesion 90(8):682–697. https://doi.org/10.1080/00218464.2013.826580

Sancaktar E, Karmarkar U (2014) Mechanical behavior of interlocking multi-stepped double scarf adhesive joints including void and disbond effects. Int J Adhes Adhes 53:44–56. https://doi.org/10.1016/j.ijadhadh.2014.01.012

Hart-Smith LJ (1973) Adhesive-bonded scarf and stepped-lap joints. NASA Langley Report CR 112237. Douglas Aircraft Co

Bendemra H, Compston P, Crothers PJ (2015) Optimisation study of tapered scarf and stepped-lap joints in composite repair patches. Compos Struct 130:1–8. https://doi.org/10.1016/j.compstruct.2015.04.016

ASTM-E8M-04 (2004) Standard test methods for tension testing of metallic materials [Metric]. ASTM International, West Conshohocken

Faneco T, Campilho R, Silva F, Lopes R (2017) Strength and fracture characterization of a novel polyurethane adhesive for the automotive industry. J Test Eval 45(2):398–407. https://doi.org/10.1520/JTE20150335

Leitão ACC, Campilho RDSG, Moura DC (2016) Shear characterization of adhesive layers by advanced optical techniques. Exp Mech 56:493–506. https://doi.org/10.1007/s11340-015-0111-4

Nunes SLS, Campilho RDSG, da Silva FJG, de Sousa CCRG, Fernandes TAB, Banea MD, da Silva LFM (2016) Comparative failure assessment of single and double-lap joints with varying adhesive systems. J Adhesion 92:610–634. https://doi.org/10.1080/00218464.2015.1103227

Pandey PC, Narasimhan S (2001) Three-dimensional nonlinear analysis of adhesively bonded lap joints considering viscoplasticity in adhesives. Comput Struct 79(7):769–783. https://doi.org/10.1016/S0045-7949(00)00160-7

Khoramishad H, Crocombe AD, Katnam KB, Ashcroft IA (2010) Predicting fatigue damage in adhesively bonded joints using a cohesive zone model. Int J Fatigue 32(7):1146–1158. https://doi.org/10.1016/j.ijfatigue.2009.12.013

Rocha RJB, Campilho RDSG (2017) Evaluation of different modelling conditions in the cohesive zone analysis of single-lap bonded joints. J Adhesion:in press. https://doi.org/10.1080/00218464.2017.1307107

Campilho RDSG, Fernandes TAB (2015) Comparative evaluation of single-lap joints bonded with different adhesives by cohesive zone modelling. Procedia Eng 114:102–109. https://doi.org/10.1016/j.proeng.2015.08.047

Luo H, Yan Y, Zhang T, Liang Z (2016) Progressive failure and experimental study of adhesively bonded composite single-lap joints subjected to axial tensile loads. J Adhes Sci Technol 30(8):894–914. https://doi.org/10.1080/01694243.2015.1131806

Ribeiro TEA, Campilho RDSG, da Silva LFM, Goglio L (2016) Damage analysis of composite—aluminium adhesively-bonded single-lap joints. Compos Struct 136:25–33. https://doi.org/10.1016/j.compstruct.2015.09.054

Sane AU, Padole PM, Manjunatha CM, Uddanwadiker RV, Jhunjhunwala P (2018) Mixed mode cohesive zone modelling and analysis of adhesively bonded composite T-joint under pull-out load. J Braz Soc Mech Sci Eng 40(3):167. https://doi.org/10.1007/s40430-018-1056-1

Dimitri R, Trullo M, De Lorenzis L, Zavarise G (2015) Coupled cohesive zone models for mixed-mode fracture: a comparative study. Eng Fract Mech 148:145–179. https://doi.org/10.1016/j.engfracmech.2015.09.029

Davis M, Bond D (1999) Principles and practices of adhesive bonded structural joints and repairs. Int J Adhes Adhes 19(2–3):91–105. https://doi.org/10.1016/S0143-7496(98)00026-8

Abaqus® (2013) Documentation of the software Abaqus®. Dassault Systèmes, Vélizy-Villacoublay

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Technical Editor: Paulo de Tarso Rocha de Mendonça, Ph.D.

Rights and permissions

About this article

Cite this article

Silva, J.O.S., Campilho, R.D.S.G. & Rocha, R.J.B. Crack growth analysis of adhesively-bonded stepped joints in aluminium structures. J Braz. Soc. Mech. Sci. Eng. 40, 540 (2018). https://doi.org/10.1007/s40430-018-1466-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1466-0