Abstract

Background and objective

Factor VIII (FVIII) is indicated for the prevention or treatment of bleeding in patients with hemophilia A. FVIII product stability under high and fluctuating temperatures is important, particularly for patients who reside in, or travel to, regions with high ambient temperatures, as they may remove their product from the refrigerator and return it, unused, multiple times. We evaluated the effect of variable temperature storage conditions, including up to 40 °C, on the stability of the recombinant FVIII product, turoctocog alfa.

Methods

Turoctocog alfa dry powder stability was assessed when moved between storage conditions of 5 °C (ambient humidity) and 40 °C (75% relative humidity) multiple times over a 2-month period, followed by long-term storage at 40 °C for 3 months and 5 °C for 1 month. Three product strengths (250, 1500, and 3000 IU), including the lowest and highest doses, were evaluated. Stability assessments included potency, purity, oxidized forms, high molecular weight protein (HMWP), and water content.

Results

Overall, the three doses of turoctocog alfa tested remained stable under varying temperature conditions, without any potency or purity impairment, nor were any major increases in oxidized forms, HMWP, or water content observed. All results were within shelf-life specification limits.

Conclusion

The results demonstrated that turoctocog alfa can be subjected to variable storage conditions, including cycling between 5 °C and ≤ 40 °C, and subsequent storage for 3 months up to 40 °C, without loss of stability. This suggests that turoctocog alfa may offer greater product storage flexibility for patients in everyday practice, with a potential reduction in wastage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Patient survey results indicate it is important that factor VIII products are stable at various temperatures. |

Stability of the recombinant factor VIII, turoctocog alfa, was assessed after cycling between 5 °C and ≤ 40 °C, and after 3 months at ≤ 40 °C (conditions simulating those experienced in everyday life). |

For all doses tested, stability parameters such as potency and purity were not impaired. |

1 Introduction

Factor VIII (FVIII) is indicated to treat bleeding episodes or prevent bleeding in patients with hemophilia A [1]. It is usually administered at home by the patient or their caregiver, enabling direct access to therapy. This results in greater freedom for the patient and facilitates early treatment, which has been shown to improve clinical outcomes [1, 2].

The stability of FVIII products under varying temperature conditions has been reported as an important element of patient satisfaction, as it allows patients more freedom in their daily lives, particularly with regard to sports and traveling to countries with high daytime temperatures [3, 4]. As such, an important aspect of any FVIII replacement product is its storage flexibility [3]. A survey of patients with hemophilia and/or their caregivers revealed that 47.4% had discarded unused product and, in 26.6% of cases, this was due to storage problems [5]. As many patients and/or their caregivers experience financial difficulties related to the cost of clotting factor products [6], any reduction in product waste is desirable.

Published studies on the stability of FVIII products at very high temperatures are scarce [7, 8] and, to our knowledge, only one has investigated product stability in response to multiple sequences of temperature cycling; that study demonstrated the stability of octocog alpha when cycled three times through room temperature and refrigerated storage [9]. Temperature cycling is an important parameter to assess, as it simulates a situation in which the product is removed from the refrigerator and then returned, unused, multiple times—a normal activity for many patients. For example, patients who carry their FVIII product with them when conducting daily activities or participating in physical activity may not experience a bleed for some time, which can result in the product being subjected to varying temperature conditions. Additionally, when patients are traveling, the FVIII product may be exposed to unpredictable changes in temperature and humidity, especially if traveling to a hot country and moving between air-conditioned environments. Furthermore, a disruption of the cold chain during product distribution could occur in some regions, resulting in temperature cycling between refrigerated storage and ambient conditions [10, 11].

Turoctocog alfa (NovoEight®, Novo Nordisk, Bagsværd, Denmark) is a recombinant FVIII product for the prophylaxis and treatment of bleeding, and for coverage during surgery in patients with hemophilia A [12,13,14]. Turoctocog alfa is supplied as dry powder in single-dose vials of 250, 500, 1000, 1500, 2000, and 3000 IU. The dry powder can be stored at ≤ 40 °C for up to 3 months and the reconstituted product at ≤ 40 °C for up to 4 h [15, 16].

The aim of this study was to assess the stability of turoctocog alfa dry powder when moved between storage conditions of 5 °C and 40 °C multiple times over a 2-month period, followed by long-term storage at 40 °C for 3 months and then at 5 °C for 1 month.

2 Methods

2.1 Recombinant Factor VIII Product and Sample Preparation

This study used commercially available turoctocog alfa dry powder batches representing the lowest, middle, and highest strengths of the drug product (250, 1500, and 3000 IU).

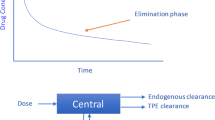

2.2 Study Design

The stability of turoctocog alfa dry powder batches under varying storage conditions was investigated over the full 30-month shelf-life period [15, 16], with sampling throughout the study period (see below for further details) (Fig. 1). All drug products were initially stored at 5 °C for 24 months to enable testing toward the end of the product’s shelf-life. Turoctocog alfa test samples were then cycled ten times between 5 °C with ambient humidity (AH) and 40 °C with 75% relative humidity (RH) over a period of 2 months. One cycle was equal to 96 h at 5 °C and 72 ± 2 h at 40 °C. After 10 temperature cycles, test samples were stored at 40 °C/75% RH for 3 months and then at 5 °C/AH for 1 month (the 1-month period at 5 °C allowed the full 30-month shelf-life to be reached). Reference samples were stored at 5 °C, whereas test samples underwent temperature cycling and were then stored at 40 °C/75% RH for 3 months and at 5 °C/AH for 1 month, alongside the test samples. For the test samples, purity, high molecular weight proteins (HMWPs), and oxidized forms were assessed after each temperature cycle, once a month during storage at 40 °C (3 months), and at study end (after 1 month at 5 °C). Potency and water content were assessed after temperature cycles 1, 3, 5, 7, 9, and 10, once a month during storage at 40 °C, and at study end (after 1 month at 5 °C). Reference samples were assessed at day 31 (equivalent to cycle 5) and day 66 (equivalent to cycle 10), once a month during storage at 40 °C (3 months), and at study end (after 1 month at 5 °C).

Study design. The stability of turoctocog alfa dry product was assessed following temperature cycling (ten times between 5 °C and 40 °C), and after storage at 40 °C for 3 months and 5 °C for 1 month. *One cycle is equal to 96 h at 5 °C and 72 ± 2 h at 40 °C. AH ambient humidity, RH relative humidity

2.3 Assay Methods

The study was performed according to current International Conference for Harmonisation bracketing design guidelines [17]. The parameters assessed include those from the drug product specification that are susceptible to change during storage and/or those likely to influence product quality. The results from all assays were compared with turoctocog alfa 250-, 1500-, and 3000-IU reference samples and evaluated against predetermined specification limits, calculated using appropriate statistical methods [17]. The specific limits for each assay are noted within the appropriate following sections.

2.3.1 Potency

Potency was investigated using the chromogenic kit Coamatic® FVIII (Chromogenix, Instrumentation Laboratory, Bedford, MA, USA) on the ACL® Elite Pro analyzer (Instrumentation Laboratory) in accordance with European Pharmacopoeia Assay of human coagulation FVIII using a product-specific standard as calibrator. Turoctocog alfa product samples and the product-specific calibrator were reconstituted in 4.3 ml 0.9% sodium chloride before undergoing three dilution steps: (1) predilution to approximately 11 IU/ml using the Coamatic® FVIII kit buffer solution; (2) dilution to approximately 1 IU/ml using FVIII-deficient plasma; (3) dilution to approximately 0.005 IU/ml using the Coamatic® FVIII kit buffer solution. Blank samples were prepared by dilution of 20-µl FVIII-deficient plasma with 4000-µl buffer solution.

Turoctocog alfa product samples, calibrator, and blank samples were analyzed in triplicate on the ACL® Elite Pro analyzer. Absorbance readings for product and reference samples and calibrator were used to calculate the potency (FVIII:C) using a slope-ratio analysis. The acceptance criteria for the potency of the three turoctocog alfa samples were defined as follows: 200–313 IU/vial for the 250-IU dose; 1200–1875 IU/vial for the 1500-IU dose; 2400–3750 IU/vial for the 3000-IU dose.

2.3.2 Purity

The purity of reconstituted turoctocog alfa product samples was assessed using reverse-phase high-performance liquid chromatography (RP-HPLC). Analysis was performed on an HPLC system equipped with processing software and a 4.0 × 250-mm, C4 5-μM, 300 Å column (Novo Nordisk Pharmatech A/S, Køge, Denmark). The column temperature was set at 40 °C, with a detection wavelength of 215 nm. A gradient of 35–100% eluent B (0.09% trifluoracetic acid [TFA] in 80% acetonitrile in purified water) and 65–0% eluent A (0.1% TFA in purified water) was applied over a duration of 40 min at a flow rate of 1 ml/min. The composition of 100% eluent B was then maintained for 5 min before the composition was changed back to the initial conditions over 1 min and the column was then equilibrated for 14 min, resulting in a total run time of 60 min. The purity of the turoctocog alfa product was calculated as the sum of area percentages of the following components on the resulting chromatograms: turoctocog alfa light chain; turoctocog alfa single chain; and three heavy chain (HC) components (nontruncated form, one with the C-terminal at amino acid 740 [HC_740], and one with the C-terminal at amino acid 720 [HC_720]). The acceptance criterion was ≥ 89.4% purity.

2.3.3 Oxidized Forms

Oxidized forms within the reconstituted turoctocog alfa product were assessed using RP-HPLC. The RP-HPLC system, column, HPLC parameters (column temperature, detection wavelength, mobile phase eluents), and elution gradients used to assess oxidized forms were the same as those used to assess product purity. Oxidized forms were calculated as the percentage area on the resulting chromatograms. The acceptance criterion was ≤ 6.8% oxidized forms.

2.3.4 High Molecular Weight Proteins

Turoctocog alfa samples were analyzed by size exclusion-HPLC (SE-HPLC) to determine the presence of protein aggregates. Prior to SE-HPLC analysis, product samples were reconstituted in either 1.0 (250-IU samples) or 4.3 ml (1500- and 3000-IU samples) 0.9% sodium chloride solution. SE-HPLC measurements were performed using an HPLC system equipped with a BioSep SEC S3000 7.8 × 300-mm, 5-μm, 290 Å column (Phenomenex, Torrance, CA, USA) or a Shodex PROTEIN KW-803, 8 × 300-mm column (Shodex) or equivalent. Elution was employed at a flow rate of 0.4 ml/min, using a column temperature of 30 °C and excitation and emission detection wavelengths of 285 and 335 nm, respectively. The eluent buffer consisted of 10 mM TRIS, 10 mM CaCl2, 300 mM sodium chloride, and 5% 2-propanol pH 7.0; the injection volume of turoctocog alfa was 100 µl, independent of protein concentration. The running times were ≥ 70 and ≥ 80 min for the turoctocog alfa product reconstituted in 4.3- and 1.0-ml 0.9% sodium chloride, respectively. HMWP content was determined by calculating the area percentage of the HMWP peak on the resulting chromatogram. The acceptance criterion was ≤ 3.9% HMWP.

2.3.5 Water Content

The water content of turoctocog alfa dry product samples prior to reconstitution was evaluated by near-infrared (NIR) spectroscopy using an FT-NIR Spectrometer (MPA, Bruker, Billerica, MA, USA) equipped with an integrating sphere (or equivalent). Turoctocog alfa samples were scanned in the frequency ranges of 7502.1–6098.1 and 5450.1–4597.7 nm at a resolution of 8 cm−1, and an average of 32 scans was recorded for each spectrum. The spectrometer was equipped with OPUS software (Bruker) (or equivalent), and data were analyzed using a partial least squares fit method. Turoctocog alfa samples were analyzed without any pretreatment; however, NIR spectra data were pretreated using vector normalization and a first derivative to enhance spectral information and correct interferences from the analyzed material that might otherwise induce baseline drift and changes in maximum absorbance [18]. Karl-Fischer coulometry was used as the reference method for determining the calibration function and to analyze samples in cases where NIR spectroscopy results were not accepted (for example, because of persistent outliers) [19]. The acceptance criterion for water content was ≤ 1.7%.

3 Results

3.1 Potency

The potency of turoctocog alfa test samples was not affected during 10 cycles of temperature changes between 5 °C AH and 40 °C/75% RH (Fig. 2a). Similarly, there were no changes in the potency following subsequent storage at 40 °C/75% RH for 3 months and 5 °C AH for 1 month (Fig. 2b). Potency results for test samples were comparable to those of reference samples, and all results were within shelf-life specifications.

Potency of turoctocog alfa. Potency of product strengths 250, 1500, and 3000 IU assessed during a 10 temperature cycles between 5 °C/AH and 40 °C/75% RH*; b storage at 40 °C for 3 months, followed by storage at 5 °C for 1 month†. *During temperature cycling, turoctocog alfa test samples were evaluated for potency at seven time points (0, 3, 17, 31, 45, 59, and 66 days), whereas reference samples were assessed at three time points (0, 31, and 66 days). †Month 0 is the end of the temperature-cycling stage; months 1–3 show storage at 40 °C; month 4 shows storage at 5 °C. AH ambient humidity, ref reference sample, RH relative humidity

3.2 Purity

Repeated temperature cycling resulted in a slight reduction in product purity compared with the reference samples. The purity of the 250-IU sample had greater variability than the 1500- and 3000-IU products; this is because the total amount of turoctocog alfa per vial in the 250-IU sample was very low (Fig. 3a). Purity decreased slightly in all product strengths throughout subsequent storage at 40°/75% RH for 3 months. During the final month of storage at 5 °C, no further decreases in purity were observed for the turoctocog alfa 1500- and 3000-IU products. There was an additional reduction in purity in the turoctocog alfa 250-IU sample (Fig. 3b), which had lower purity levels than the corresponding reference sample, whereas the purity for all 1500- and 3000-IU test samples was similar to that of the reference samples. All purity levels were maintained within shelf-life specification limits.

Purity of turoctocog alfa. Purity of product strengths 250, 1500, and 3000 IU assessed during a 10 temperature cycles between 5 °C/AH and 40 °C/75% RH*; b storage at 40 °C for 3 months followed by storage at 5 °C for 1 month†. *During temperature cycling, turoctocog alfa test samples were evaluated for purity at all 11 time points (0, 3, 10, 17, 24, 31, 38, 45, 52, 59, and 66 days), whereas reference samples were assessed at three time points (0, 31, and 66 days). †Month 0 is the end of the temperature-cycling stage; months 1–3 show storage at 40 °C; month 4 shows storage at 5 °C. AH ambient humidity, ref reference sample, RH relative humidity

3.3 Oxidized Forms

There was a slight increase in oxidized forms during temperature cycling for all strengths of turoctocog alfa tested (Fig. 4a). This increase continued for all strengths during subsequent storage at 40 °C/75% RH for 3 months, although no further change was observed after the final month of storage at 5 °C for 1 month for the 250- and 1500-IU samples, whereas the level of oxidized forms decreased slightly for the turoctocog alfa 3000-IU sample (Fig. 4b). All results were maintained within shelf-life specification limits.

Oxidized forms. Turoctocog alfa product strengths 250, 1500, and 3000 IU assessed during a 10 temperature cycles between 5 °C/AH and 40 °C/75% RH*; b storage at 40 °C for 3 months followed by storage at 5 °C for 1 month†. *During temperature cycling, turoctocog alfa test samples were evaluated for oxidized forms at all 11 time points (0, 3, 10, 17, 24, 31, 38, 45, 52, 59, and 66 days), whereas reference samples were assessed at three time points (0, 31, and 66 days). †Month 0 is the end of the temperature-cycling stage; months 1–3 show storage at 40 °C; month 4 shows storage at 5 °C. AH ambient humidity, ref reference sample, RH relative humidity

3.4 High Molecular Weight Protein

HMWP levels in the turoctocog alfa test samples varied following multiple temperature changes. There was a slight overall increase for the 250- and 1500-IU samples, although the variation in HMWP levels was greatest for the 250-IU samples (Fig. 5a). There was also a slight increase in HMWP levels during subsequent storage at 40 °C (3 months) and 5 °C (1 month) (Fig. 5b). However, at all times and for all strengths, results obtained for the test samples were within shelf-life specifications and comparable with those from reference samples.

HMWP content. Turoctocog alfa product strengths 250, 1500, and 3000 IU assessed during a 10 temperature cycles between 5 °C/AH and 40 °C/75% RH*; b storage at 40 °C for 3 months followed by storage at 5 °C for 1 month†. *During temperature cycling, turoctocog alfa test samples were evaluated for HMWP at all 11 time points (0, 3, 10, 17, 24, 31, 38, 45, 52, 59, and 66 days), whereas reference samples were assessed at three time points (0, 31, and 66 days). †Month 0 is the end of the temperature-cycling stage; months 1–3 show storage at 40 °C; month 4 shows storage at 5 °C. AH ambient humidity, HMWP high molecular weight protein, ref reference sample, RH relative humidity

3.5 Water Content

At study start, the turoctocog alfa dry powdered products had low water content (data not shown). Small increases in water content were observed during the temperature-cycling phase and subsequent storage at 40 °C/75% RH for 3 months for all product strengths. The water content for each of the three turoctocog alfa doses prior to the first temperature cycle, at the end of the tenth temperature cycle, and at the end of 3 months’ storage at 40 °C were 0.5%, 0.7%, and 1.3% (250 IU); 0.4%, 0.7%, and 1.3% (1500 IU); and 0.3%, 0.6%, and 1.0% (3000 IU), respectively. There were no further changes in water content for the 250- and 3000-IU samples during storage at 5 °C for 1 month; however, water content decreased slightly to 1.1% for the intermediate strength sample (1500 IU). Water content levels were comparable between reference and test samples, and all results remained within shelf-life specification limits.

4 Discussion

This study examined the stability of turoctocog alfa in response to repeated temperature changes, after subsequent storage at 40 °C/75% RH for 3 months and at 5 °C for 1 month following an extended storage period of 24 months at 5 °C. The temperature-cycling phase of this study replicates a situation common to many patients where their product is removed and then returned, unused, to a refrigerator multiple times. While many FVIII products are stable at ambient temperatures up to 30 °C for a limited time [15, 16, 20,21,22], for patients living in and/or traveling to a region where daytime temperatures can exceed 30 °C, their product may be exposed to fluctuating temperature conditions, particularly as patients may want to store their product in a refrigerator or transport it in a cooler after exposure to higher room temperatures.

Our study showed that turoctocog alfa remained stable when subjected to temperature cycling (10 cycles between 5 °C and 40 °C) over a 2-month period. There were no unexpected changes, and the results remained within shelf-life specification limits, for the parameters of potency, purity, HMWP, oxidized forms, and water content across the range of turoctocog alfa strengths tested (250, 1500, and 3000 IU). The consistency in purity and potency of turoctocog alfa during this period of temperature cycling is important for patients for whom storage flexibility is key. Furthermore, all stability parameters remained within shelf-life specification limits after the temperature cycles and subsequent storage at 40 °C/75% RH for 3 months. It is worth mentioning that, during this study, the stability of the drug products was assessed toward the end of the product’s shelf-life, when the product may be most susceptible to degradation.

Turoctocog alfa has a robust and reliable manufacturing process, resulting in a product with high purity and homogeneity [23, 24]. This purification process may be important for the observed stability of turoctocog alfa when stored at high temperatures and variable conditions. Increased understanding of patient/caregiver perspectives and preferences in terms of hemophilia treatment is leading to a growing awareness that factors such as product storage, portability, and usage are directly related to successful disease management [3]. Indeed, a wide range of temperature storage conditions has been cited as one of the biggest drivers of product choice among adult patients and a significant factor in patient satisfaction [4]. Furthermore, flexible factor storage conditions may reduce wastage caused by improper storage [3]. Although many patients desire factor products with flexible storage conditions, many are unaware that some products already offer such benefits [4]. It is therefore important that hemophilia physicians and nurses provide education in this area.

A limitation of our study is that, while a range of drug strengths were assessed, only one batch number per drug strength was used in each assay. However, there was no significant impairment of any stability parameter evaluated for any of the three doses tested. Although not a limitation to this study and FVIII product alone, it should be noted that, because of insufficient space to write notes on individual turoctocog alfa product labels or packaging, it is difficult to track when a vial is moved in and out of the refrigerator. Therefore, the results of this study provide more reassurance about the storage flexibility of turoctocog alfa than an indication of the exact number of times turoctocog alfa can be cycled between these temperatures.

5 Conclusions

From these results, we conclude that turoctocog alfa can be subjected to variations in storage conditions, including cycling between temperatures of 5 °C and ≤ 40 °C (simulating removal and replacement into a refrigerator) over a 2-month period and subsequent storage for an additional 3 months up to 40 °C without loss of stability. These findings should reassure healthcare providers and patients/caregivers that turoctocog alfa can be stored under flexible conditions in everyday practice, which should also lead to a potential reduction in wastage and increased patient satisfaction.

References

Srivastava A, Brewer AK, Mauser-Bunschoten EP, et al. Guidelines for the management of hemophilia. Haemophilia. 2013;19(1):e1–47.

Bolton-Maggs PH, Pasi KJ. Haemophilias A and B. Lancet. 2003;361(9371):1801–9.

DiBenedetti DB, Coles TM, Sharma T, Pericleous L, Kulkarni R. Assessing patients’ and caregivers’ perspectives on stability of factor VIII products for haemophilia A: a web-based study in the United States and Canada. Haemophilia. 2014;20(4):e296–303.

Tischer B, Marino R, Napolitano M. Patient preferences in the treatment of hemophilia A: impact of storage conditions on product choice. Patient Prefer Adherence. 2018;12:431–41.

Novais T, Duclos A, Varin R, Lopez I, Chamouard V. Treatment-related knowledge and skills of patients with haemophilia and their informal caregivers. Int J Clin Pharm. 2016;38(1):61–9.

Saxena K. Barriers and perceived limitations to early treatment of hemophilia. J Blood Med. 2013;4:49–56.

Parti R, Ardosa J, Yang L, Mankarious S. In vitro stability of recombinant human factor VIII (Recombinate). Haemophilia. 2000;6(5):513–22.

Parti R, Schoppmann A, Lee H, Yang L. Stability of lyophilized and reconstituted plasma/albumin-free recombinant human factor VIII (ADVATE rAHF-PFM). Haemophilia. 2005;11(5):492–6.

Parti R, Lee H, Yang L et al. Stability of plasma/albumin free full-length human factor FVIII (ADVATE rAHF-PFM) after temperature cycling between refrigerated and room temperature. Presented at the XXVIIth International Congress of the World Federation of Hemophilia. 21–25 May 2006. Vancouver, Canada. Haemophilia. 2006;12(Suppl 2):1–154.

Bardin C, Astier A, Vulto A, et al. Guidelines for the practical stability studies of anticancer drugs: a European consensus conference. Ann Pharm Fr. 2011;69(4):221–31.

Larena Fernandez I, Vara Callau M, Pena Blasco G, Atance Melendo E, Gay Gasanz B, Perez-Aramendia MJ. [Vaccine cold chain interruption in a primary care center and economic evaluation]. Enferm Clin. 2017;27(1):44–8. Interrupcion de la cadena de frio vacunal en un centro de atencion primaria y su valoracion economica.

Kulkarni R, Karim FA, Glamocanin S, et al. Results from a large multinational clinical trial (guardian3) using prophylactic treatment with turoctocog alfa in paediatric patients with severe haemophilia A: safety, efficacy and pharmacokinetics. Haemophilia. 2013;19(5):698–705.

Santagostino E, Lentz SR, Misgav M, et al. Safety and efficacy of turoctocog alfa (NovoEight(R)) during surgery in patients with haemophilia A: results from the multinational guardian clinical trials. Haemophilia. 2015;21(1):34–40.

Lentz SR, Misgav M, Ozelo M, et al. Results from a large multinational clinical trial (guardian1) using prophylactic treatment with turoctocog alfa in adolescent and adult patients with severe haemophilia A: safety and efficacy. Haemophilia. 2013;19(5):691–7.

Novo Nordisk A/S. NovoEight Summary of Product Characteristics. http://www.ema.europa.eu/docs/en_GB/document_library/EPAR_-_Product_Information/human/002719/WC500157553.pdf. Accessed August 23, 2018.

Novo Nordisk A/S. NovoEight Highlights of Prescribing Information. https://www.novo-pi.com/novoeight.pdf. Accessed August 10, 2018.

International Conference for Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use. ICH Harmonised Tripartite Guideline: Quality of Biotechnological Products: Stability Testing of Biotechnological/Biological Products Q5C. Current Step 4 version. https://database.ich.org/sites/default/files/Q5C_Guideline.pdf. Accessed June 4, 2018.

Eldin AB, Shalaby AA. Comparison of FT-NIR transmission and HPLC to assay montelukast in its pharmaceutical tablets. Am J Anal Chem. 2011;2(8):885–91.

European Pharmacopoeia. Technical Guide for the Elaboration of Monographs. https://www.edqm.eu/sites/default/files/technical_guide_for_the_elaboration_of_monographs_7th_edition_2015.pdf. Accessed July 27, 2018.

Octapharma AB. NUWIQ Prescribing Information, United States. https://www.fda.gov/downloads/BiologicsBloodVaccines/BloodBloodProducts/ApprovedProducts/LicensedProductsBLAs/FractionatedPlasmaProducts/UCM461328.pdf. Accessed September 18, 2018.

Baxter Healthcare Corporation. Advate Prescribing Information, United States https://www.fda.gov/downloads/BloodBloodProducts/ucm059095.pdf. Accessed September 18, 2018.

Bayer HealthCare Manufacturing S.r.l. Kogenate Summary of Product Characteristics, European Medicines agency. http://www.ema.europa.eu/ema/index.jsp?curl=pages/medicines/human/medicines/000275/human_med_000879.jsp&mid=WC0b01ac058001d124. Accessed September 18, 2018.

Ahmadian H, Hansen EB, Faber JH, et al. Molecular design and downstream processing of turoctocog alfa (NovoEight), a B-domain truncated factor VIII molecule. Blood Coagul Fibrinolysis. 2016;27(5):568–75.

Baunsgaard D, Nielsen AD, Nielsen PF, et al. A comparative analysis of heterogeneity in commercially available recombinant factor VIII products. Haemophilia. 2018.

Acknowledgements

Both authors contributed to the analysis and/or interpretation of data, critical writing, or revising the intellectual content and final approval of the version to be published. The authors wish to thank Patrycia Wojtyniak Dahl and Sigrun Debes Johansen for design and execution of the study. Julie Smith and Emily Bruce (Parexel) provided drafts and editorial assistance to the authors during the preparation of this manuscript, supported by funding from Novo Nordisk A/S. Novo Nordisk’s policy on data sharing may be found at https://www.novonordisk-trials.com/how-access-clinical-trial-datasets.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This study was supported by funding from Novo Nordisk A/S.

Conflict of interest

Mariasanta Napolitano has received consulting fees or honorarium from Novo Nordisk, Bayer HealthCare, and Bio FVIIx; has received speaker fees from Novo Nordisk, Kedrion, Octapharma, Shire, and Bayer HealthCare; and has provided expert testimony for Kedrion, Shire, and Bayer HealthCare. Anne Mette Nøhr is a full-time employee of Novo Nordisk.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution-NonCommercial 4.0 International License (http://creativecommons.org/licenses/by-nc/4.0/), which permits any noncommercial use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Napolitano, M., Nøhr, A.M. The Effect of Fluctuating Temperature on the Stability of Turoctocog Alfa for Hemophilia A. Drugs R D 19, 381–390 (2019). https://doi.org/10.1007/s40268-019-00290-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40268-019-00290-3