Abstract

Cadmium telluride (CdTe) thin films of different thicknesses deposited onto titanium dioxide (TiO2) nanoparticle layer by spray pyrolysis deposition (SPD) are demonstrated as major photo-active semiconductor in photo-electrochemical solar cell configuration using iodide/triiodide (I−/I3−) redox couple as a hole transport layer. The CdTe–TiO2 heterogeneous films were characterized by X-ray photoelectron spectroscopy which identified doublet split of Cd 3d and Ti 2p which confirms CdTe and TiO2. Optical absorbance and transmittance of CdTe and TiO2 films which were examined by UV–Vis spectroscopy confirm that the optical bandgap of CdTe is 1.5 eV with a dominant photo-absorption in the spectral window of 350–800 nm, while TiO2 showed a bandgap of 3.1 eV and is optically transparent in the visible spectral window. The present work examined photo-anodes comprising 1, 3, 5, and 10 SPD cycles of CdTe coated on TiO2 nanoparticle layer. The solar cell with 5 SPD cycles of CdTe resulting in 0.4% efficiency. Results can be articulated to the CdTe deposited by 5 SPD cycles provided an optimum surface coverage in the bulk of TiO2, while the higher SPD cycles leads to agglomeration which blocks the porosity of the heterogeneous films.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Third generation energy-harvesting technology comprises all thin-film-based solar cells in addition to the excitonic photovoltaic devices which include dye and quantum-dot-sensitized solar cells [1,2,3]. Dye- and quantum-dot-based photovoltaic devices are important category in electrochemical solar cell technology due to their high performance and lower cost [4, 5]. Various dyes and quantum dots exhibiting optical absorption at different energy ranges were explored to develop electrochemical solar cell technology with different electrolytes [6, 7]. Various technical challenges including adsorption and stability of dyes onto electron acceptors, volatile, and corrosive nature of electrolytes are a few major hurdles in the progress roadmap of photo-electrochemical solar cell technology [8, 9]. Quantum dots of CdTe, CdS, and CdSe are being used as major photo-absorbing candidates in excitonic solar cells with wide bandgap semiconductors as electron acceptors such as TiO2 and ZnO [10,11,12].

CdTe has been realized as one of the potential energy-harvesting material candidate in thin-film solar cells due to its optimum bandgap energy and other attractive opto-electronic properties [13, 14]. CdTe is widely used as a major photo-active candidate (bandgap of 1.5 eV) along with CdS as a window layer (bandgap of 2.5 eV) in heterojunction thin-film solar cells [15]. It has been predicted that CdTe-based thin-film photovoltaic technology will enable better energy payback time compared to other thin-film-based solar cells [16]. It is an essential requirement to make energy-harvesting technology more viable and affordable by employing suitable low-cost materials. While the other electrochemical solar cells experience major problems in terms of stability and photo-absorption, CdTe thin film can be considered as a highly stable which can be used to harvest photons in the visible spectral energy window. Various material processing techniques including close space sublimation, chemical bath deposition, and metal organic chemical vapor deposition are effectively utilized to deposit CdTe thin films for solar cell applications [17,18,19,20]. CdTe solar cell module with 16.5% efficiency (η) with an active area of 1 cm2 and 10.5% in an area of 1400 cm2 was reported by Green et al. [21, 22]. Accelerated tests on CdTe-based thin-film solar cells under harsh environments, including high temperature and illumination, were performed and the materials have shown promising stability and lifetime except for few issues addressed by Corwine et al. [23, 24]. CdTe thin-film solar cells employ Cu as a back contact and it has been observed that Cu diffusion through the grain boundaries of CdTe is one of the major issue affecting its performance and stability to an extent [25]. Various deposition methods have been employed to coat CdTe thin films for energy-harvesting applications [17, 19]. Specifically, quantum-confined CdTe was coated on TiO2 by successive ionic layer adsorption and reaction and reasonable photovoltaic performance values were reported [10]. CdTe has been explored as a co-sensitizer along with traditional organic dyes on TiO2 and the solar cells have shown promising photovoltaic performance [26]. SPD is a versatile material processing technique, widely used in photovoltaic research to coat various functional materials including transparent conductor oxide and electron acceptor such as TiO2 [27]. It has been realized that SPD can be a potential technique for both thin- and thick-film production for energy-related applications [28]. SPD offers wide choices in choosing precursors and deposition temperature for desired material deposition [29].

The present work demonstrates the possibility of establishing photo-electrochemical solar cell technology based on all SPD-based photo-anodes comprising CdTe thin-film-coated TiO2 nanoparticle layer and I−/I3− redox couple as a hole transport layer. Photo-electrochemical solar cells employing the heterogeneous CdTe–TiO2 heterogeneous photo-anodes and I−/I3− electrolyte as a hole transporting layer were fabricated and characterized for 1, 3, 5, and 10 SPD cycles of CdTe to examine the effect of CdTe layer thickness on performance. Results show the possibility of establishing all SPD-based nanostructured photo-anodes (both electron acceptor and photo-active semiconductor) for photo-electrochemical solar cell technology.

Experimental

Both TiO2 and CdTe films reported in the present work were prepared by SPD technique (KM-150, SPD Laboratory Inc from Japan). For the TiO2 deposition, colloidal solution of TiO2 was prepared by mixing 5 mL of acetic acid and 50 mL of titanium iso-propoxide with 40 mL isopropyl alcohol. All these chemicals were used as purchased from Sigma-Aldrich without any further modifications. This solution was used as a precursor for SPD-coating process directly onto fluorine doped tin oxide (FTO)-coated glass substrates at 110 °C. The SPD-coated TiO2 films were annealed at 450 °C for 1 h. For the deposition of CdTe on TiO2, 0.25 mM of cadmium nitrate tetrahydrate and 0.25 mM of tellurium dioxide were used as precursors. The SPD process for CdTe was carried out at 100 °C. Photo-electrochemical solar cells were fabricated using the CdTe-coated TiO2 on FTO as photo-anodes, I−/I3− electrolyte as a hole transporting layer and Pt thin-film-coated glass substrates as counter electrode.

X-ray photoelectron spectroscopy was used to confirm the SPD-processed CdTe and TiO2 using Kratos Analytical unit. Raman spectroscopy was carried out on TiO2 and CdTe samples using Witec Alpha confocal Raman-300 AR spectrometer with an excitation wavelength of 532 nm. Surface morphology of the TiO2- and CdTe-coated TiO2 films was studied by scanning electron microscope (SEM) using JEOL JSM-6490-LA. Perkin Elmer Lambda-750 was used to study the optical absorbance and transmittance characteristics of the SPD-processed TiO2 and CdTe films. Newport Oriel Class-A solar simulator was used to study the current density–voltage (J–V) measurements under AM 1.5 illumination using a Keithley 2400 digital source meter.

Results and discussion

Figure 1a shows XPS survey scan obtained on the heterogeneous CdTe–TiO2 film used as a photo-anode in the solar cells. The wide survey spectrum confirmed cadmium, tellurium, and oxygen at 404.3, 575, and 531.3 eV, respectively. Carbon was spotted at 284.3 eV as an impurity present in the film. The characteristic peak corresponding to titanium (Ti 2p) did not show up in the survey spectrum due to the thickness of CdTe layer on TiO2 porous film. The particular sample used for XPS studies utilized 5 cycles of CdTe on TiO2 which covered the surface completely, and due to the limitation of XPS, the Ti 2p state was not found in the heterogeneous CdTe–TiO2 sample. High-resolution XPS scan was performed on the sample to examine the constituent elements in the heterogeneous film and Fig. 1b shows doublet split of Cd 3d state. Cd 3d5/2 and 3d3/2 states were observed at 404.9 and 411.6 eV, respectively. Figure 1c shows Te 3d5/2 and 3d3/2 at 575.9 and 586.3 eV, respectively. The major characteristic peaks corresponding to Cd 3d and Te 3d states assure the SPD-processed CdTe thin film. As shown in the survey spectrum obtained from the CdTe-coated TiO2 sample, the Ti 2p was not noticed due to the presence of CdTe on TiO2. Thus, we performed XPS on pure TiO2 with no CdTe layer on it to confirm the presence of Ti 2p, as shown in Fig. 1d. Ti 2p3/2 and Ti 2p1/2 states were observed at the binding energy values of 459.3 and 465.1 eV, respectively. The inset shows the high-resolution XPS scan obtained from the CdTe-coated TiO2 film in the same binding energy range showing no Ti 2p feature which further assures proper surface coverage of CdTe film on TiO2. Figure 1e shows that O 1s high-resolution spectrum exhibiting two peaks at binding energy values of 530.5 and 532.5 eV represent oxygen with metal oxide and metal carbonate, respectively. These two peaks were further de-convoluted using two Gaussian peak fit which assures that the respective binding energy values correspond to the oxygens coordinate with metal and carbonate in the SPD-processed heterogeneous CdTe–TiO2 film.

Figure 2 shows Raman spectra obtained from the a TiO2 and b CdTe samples processed by SPD method. Four Raman active modes were observed at 157, 400, and 520 cm− 1 for TiO2, corresponding to bandgap and other modes, respectively. These four Raman active modes shown in Fig. 2a represent anatase nanocrystalline TiO2. The longitudinal optical (LO) mode and the second and third orders were observed at 166, 333, and 460 cm− 1, respectively. These Raman modes suggest that it can be either cubic or hexagonal phase of polycrystalline CdTe as both exhibit the LO modes at the same frequencies.

Figure 3 shows SEM images showing a cross-sectional view obtained from the CdTe-coated TiO2 sample. The film thickness is estimated to be around ~ 15 µm as shown in the cross-sectional view. Surface morphologies of the SPD-coated pure TiO2- and CdTe-covered TiO2 samples were examined to understand the physical nature of the resultant heterogeneous film. Figure 3b shows surface morphology of the TiO2 film obtained at 10,000 × showing a highly porous nature in the bulk as can be viewed clearly through the clusters formed during the growth. The TiO2 film comprises particles of different sizes and agglomerates to form clusters and the clusters are of the order of microns in size. Furthermore, the morphology of the TiO2 film asserts randomly distributed TiO2 particles formed the loosely packed clusters which are observed to be well connected to each other that can be considered as an essential requirement for an electron acceptor in nanoparticle based solar cells. Figure 3c, d shows surface morphology of CdTe-coated TiO2 film obtained at 10,000 × and 20,000 ×, respectively. Since the TiO2 film itself was observed as a porous nanoparticle network, CdTe deposition on porous TiO2 simply covered the surface and resulted in the mesoporous heterogeneous CdTe–TiO2 photo-anode. Mesoporosity of CdTe-coated TiO2 can be confirmed through the surface morphology images, as shown in Fig. 3b–d. This can be viewed as randomly distributed mesoscopic clusters of SPD-processed CdTe/TiO2 heterogeneous film. Furthermore, the mesoscopic clusters of CdTe/TiO2 are, in general, expected to provide an efficient charge transport pathway for photo-generated electrons from CdTe to TiO2 to reach FTO electrode by diffusion-based transport process. The mesoporous nature of CdTe-coated TiO2 is a highly preferred morphology for photo-electrochemical solar cells due to an advantage in forming large surface area electrochemical junction between TiO2/CdTe and I−/I3− electrolyte. The mesoporous morphology observed in the SEM images asserts that I−/I3− electrolyte ions can diffuse into the bulk of CdTe covered TiO2 to make hole transport process. In the SPD process, initially, TiO2 layer was deposited onto FTO substrate and annealed at 450 °C for 4 h in atmospheric condition. The cross-sectional and surface morphologies of the CdTe-coated TiO2 demonstrate that the bottom TiO2 layer was porous in nature through which the CdTe diffused into the bulk and get coated on the surface to form the heterogeneous photo-electrode stack comprising TiO2/CdTe.

SEM images show a cross-sectional view of heterogeneous CdTe–TiO2 film on FTO coated glass substrate, b surface morphology of the TiO2 with no CdTe layer on the surface c and d surface morphologies of CdTe-coated TiO2 at the magnifications of × 10,000 and × 20,000 exhibit the resulting porous surface

CdTe and TiO2 samples were deposited by SPD onto bare glass substrates to study their optical properties using UV–Vis spectroscopy. Figure 4a shows digital photographs of the CdTe thin-film samples processed by SPD showing 1, 3, 5, and 10 cycles of deposition to examine the effect of thickness on photovoltaic performance of resulting photo-electrochemical solar cells. The images show variation in contrast due to the increasing thickness starting from 1 to 10 cycles having samples processed at 3 and 5 cycles in the middle range. While the contrast is exceptionally clear between 1 and 3 cycles, the higher number of cycles saturated the film color. All four CdTe films on glass substrates are observed to be highly smooth and continuous for naked eye, as can be seen in Fig. 4a. The films are observed to be pinhole free and highly uniform. These four films were subjected to UV–Vis spectroscopic studies to examine their optical properties. Figure 4b shows optical absorbance spectra of CdTe thin film of 1, 3, 5, and 10 cycles in a wavelength range of 350–800 nm. It is observed that optical absorbance of the films increased systematically with increasing thickness, as depicted in Fig. 4b. The characteristic feature of absorbance spectra for all four samples was similar but differed in magnitude due to the variation in thickness. Particularly, the 10 SPD cycles yield maximum possible absorbance among all four samples explicitly articulate the effect of thickness on the ability of trapping more photons. Figure 4c shows transmittance of the same four CdTe samples which further confirms the effect of sample thickness on transmittance. The variation in transmittance due to the difference in CdTe thickness is in good agreement with the absorbance spectra, as illustrated in Fig. 4b. The CdTe sample of 1 SPD cycle showed maximum transmittance compared to other samples as expected. Figure 4d shows a comparative plot showing optical transmittance of CdTe and TiO2 films. The inset in Fig. 4d shows calculated optical bandgap values for both CdTe and TiO2 using Tauc plot technique, (αhν)1/2 vs. incident energy, showing 1.5 and 3.1 eV, respectively. It is important to note that TiO2 as a wide bandgap (3.1 eV) material does not interact with photons in the visible solar spectrum, while CdTe interact with visible energy photons as a narrow gap (1.5 eV) material. In this study, TiO2 is used as an electron acceptor, while CdTe is considered as a major photo-active semiconductor. The optical absorbance, transmittance characteristics along with the optical bandgap values of both layers assert the SPD-processed heterogeneous CdTe–TiO2 and can be a good choice for photo-electrochemical solar cell application. Semiconductors with optical bandgap close to 1.5 eV, such as CdTe, exhibit dominant photo-absorption in the visible spectral range. The present study shows absorption around 300 nm which could be due to the diffusion of TiO2 which has optimum bandgap for high-energy photo-absorption. Moreover, morphology of the heterogeneous TiO2–CdTe film is randomly distributed nanoparticle network which may facilitate optical diffusion through which light scattering can be enhanced to efficient absorption.

a Photographs of SPD-processed CdTe thin films, b optical absorbance of CdTe thin films of 1, 3, 5, and 10 cycles showing thickness dependent variation in absorbance, and c corresponding transmittance spectra. d Comparative transmittance spectra of CdTe and TiO2 with an inset showing calculated optical bandgap for both materials

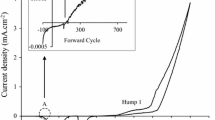

Figure 5 a–d shows J–V characteristics of the four sets of photo-electrochemical solar cells employed heterogeneous CdTe–TiO2 photo-anodes in which thickness of CdTe layer on the surface of TiO2 was varied by varying the number of SPD cycles. Table 1 lists JSC, VOC, FF, and η values of solar cells extracted from four different measurements performed to examine the consistency in their performance. Table 2 summarizes mean values and their standard deviations from four measurements showing JSC, VOC, FF, and η values of all four cells for 1, 3, 5, and 10 SPD cycles of CdTe extracted from the data set, as shown in Fig. 5a–d. The key parametric values reported in the present study indicate that some of the values are much better than previously reported, but some are not [4, 6, 24]. However, the present study explores the possibility of fabricating the complete photo-anode (TiO2–CdTe) by SPD method and the results showed the feasibility to achieve the solar cells with decent performance metrics. The cells used 1, 3, 5, and 10 SPD cycles of CdTe showed an average η values (obtained from four cells) of 0.12, 0.08, 0.15, and 0.04%, respectively. While JSC of the cells highly depends on number of SPD cycles, which determines thickness of CdTe, VOC in this cell design represents the energy difference between the quasi-fermi level of CdTe and the redox potential of electrolyte. It is expected that cells using 10 cycles of CdTe can yield higher JSC value compared to other cells only due to the increase in thickness of CdTe. Increasing thickness offers photons better chance to be trapped in the layer in which they can generate more photons which result in improved current in the cell. Results show that 1 SPD cycle of CdTe yields JSC of 613 mA cm− 2 in an average of four cells, while the average JSC value obtained from 10 SPD cycles of CdTe is 829 mA cm− 2. It is elucidated that by varying the CdTe coating from 1 SPD cycle to 10 cycles, 35% variation can be obtained in JSC values of the cell in an average. Particularly, 5 cycles of CdTe in the cell showed η of 0.4% with JSC, VOC, and FF values 686 mA cm− 2, 176 mV, and 33.2%, respectively. This is one of the relatively higher values obtained from four cells using 5 SPD cycles of CdTe on TiO2. It shows that there is an optimum CdTe thickness on the surface of TiO2 through which efficient photo-absorption, exciton generation, and charge injection can be achieved to get improved photovoltaic performance.

Figure 6 shows energy band diagram of the solar cell employing FTO, Pt as contact layers, TiO2 as an electron acceptor, electrolyte as a hole transport layer, and CdTe as a major photo-active semiconductor. Optical bandgap values for FTO and TiO2 are 3.6 and 3.1 eV, respectively. These two wide bandgap materials do not absorb photons in the visible spectral range and the incident light can pass through to reach CdTe coated on TiO2. Photo-excitation in CdTe creates electrons and holes in the conduction and valence bands, respectively. Photo-generated electrons from the conduction band of the CdTe are further injected into the conduction band of the TiO2 and transported to FTO by diffusion process. The free holes from the valence band of CdTe are transported to electrolyte. In the cell operation, exciton generation occurs at CdTe layer coated on TiO2. In general, electronic quality of CdTe, TiO2, and the interface formed by these two materials are considered to be major factors that determine electron transport. We believe that interfacial recombination loss at the heterogeneous CdTe–TiO2 films dominated which adversely affected the key photovoltaic parameters under illumination condition. We believe that the present work is an initial attempt to develop photo-electrochemical solar cell technology based on all SPD-processed photo-anodes. Further improvisation in terms of performance is possible by improving the opto-electronic properties of CdTe and interfacial quality of heterogeneous CdTe–TiO2 photo-anodes in the solar cell.

Conclusion

Heterogeneous CdTe–TiO2 films were prepared by SPD processing and demonstrated their applications in solar energy harvesting. The SPD-processed CdTe exhibits an optical bandgap of 1.5 eV with a dominant photo-absorption in the spectral window of 350–800 nm. The presented results lead to the possibility of establishing all SPD-based material-processing scheme for photo-electrochemical solar cells.

References

Green, M., Martin, A.: Third generation photovoltaics: ultra-high conversion efficiency at low cost. Prog. Photovolt. Res. Appl. 9, 123–135 (2001)

Brown, G.F., Wu, J.: Third generation photovoltaics. Laser Photon. Rev. 3, 394–405 (2009)

Conibeer, G.: Third-generation photovoltaics. Mater. Today 10, 42–50 (2007)

Gong, J., Liang, J., Sumathy, K.: Review on dye-sensitized solar cells (DSSCs): fundamental concepts and novel materials. Renew. Sust. Eenerg. Rev. 16, 5848–5860 (2012)

Sogabe, T., Shen, Q., Yamaguchi, K.: Recent progress on quantum dot solar cells: a review. J. Photon. Energy 6, 040901–040930 (2016)

Choi, H., Nahm, C., Kim, J., Kim, C., Kang, S., Hwang, T., Park, B.: Toward highly efficient quantum-dot-and dye-sensitized solar cells. Curr. Appl. Phys. 13, S2–S13 (2013)

Carey, G.H., Abdelhady, A.L., Ning, Z., Thon, S.M., Bakr, O.M., Sargent, E.H.: Colloidal quantum dot solar cells. Chem. Rev. 115, 12732–12763 (2015)

Sauvage, F.: A review on current status of stability and knowledge on liquid electrolyte-based dye-sensitized solar cells. Adv. Chem. 2014, 1–23 (2014)

Mozaffari, S., Nateghi, M.R., Zarandi, M.B.: An overview of the challenges in the commercialization of dye sensitized solar cells. Renew. Sust. Eenerg. Rew. 71, 675–686 (2017)

Bang, J.H., Kamat, P.V.: Quantum dot sensitized solar cells. A tale of two semiconductor nanocrystals: CdSe and CdTe. ACS Nano 3, 1467–1476 (2009)

Kamat, P.V.: Quantum dot solar cells. Semiconductor nanocrystals as light harvesters. J. Phys. Chem. C 112, 18737–18753 (2008)

Semonin, O.E., Luther, J.M., Choi, S., Chen, H.-Y., Gao, J., Nozik, A.J., Beard, M.C.: Peak external photocurrent quantum efficiency exceeding 100% via MEG in a quantum dot solar cell. Science 334, 1530–1533 (2011)

Green, M.A.: Thin-film solar cells: review of materials, technologies and commercial status. J Mater. Sci-Mater. Electron. 18, 15–19 (2007)

Gloeckler, M., Sankin, I., Zhao, Z.: CdTe solar cells at the threshold to 20% efficiency. IEEE J. Photovolt 3, 1389–1393 (2013)

Kumar, S.G., Koteswara Rao, K.S.R.: Physics and chemistry of CdTe/CdS thin film heterojunction photovoltaic devices: fundamental and critical aspects. Energy Environ. Sci. 7, 45–102 (2014)

Bloss, W.H., Pfisterer, F., Schubert, M., Walter, T.: Thin-film solar cells. Prog. Photovolt. Res. Appl. 3, 3–24 (1995)

Romeo, N., Bosio, A., Menossi, D., Romeo, A., Aramini, M.: Last progress in CdTe/CdS thin film solar cell fabrication process. Energy Procedia 57, 65–72 (2014)

Başol, B.M., McCandless, B.: Brief review of cadmium telluride-based photovoltaic technologies. J. Photon. Energy 040996, 1–11 (2014)

Diso, D.G., Bichi, T.S., Hotoro, M.A.Y., Faragai, I.A., Musa, A.O.: Growth techniques used to develop CDS/CDTE thin film solar cells: a review. Bayero J. Pure Appl. Sci. 8, 58–67 (2015)

Durose, K., Edwards, P.R., Halliday, D.P.: Materials aspects of CdTe/CdS solar cells. J. Cryst. Growth 197, 733–742 (1999)

Green, M.A., et al.: Solar cell efficiency tables (version 22). Prog. Photovolt. 11(5), 347–352 (2003)

Green, M.A., Emery, K., Hishikawa, Y., Warta, W.: Solar cell efficiency tables (version 36). Prog. Photovolt. Res. Appl. 18, 346–352 (2010)

Corwine, C.R., Pudov, A.O., Gloeckler, M., Demtsu, S.H., Sites, J.R.: Copper inclusion and migration from the back contact in CdTe solar cells. Sol. Energy Mater. Sol. Cells 82, 481–489 (2004)

Bätzner, D.L., Romeo, A., Zogg, H., Wendt, R., Tiwari, A.N.: Development of efficient and stable back contacts on CdTe/CdS solar cells. Thin Solid Films 387, 151–154 (2001)

Chou, H.C., Rohatgi, A., Jokerst, N.M., Thomas, E.W., Kamra, S.: Copper migration in CdTe heterojunction solar cells. J. Electron. Mater. 25, 1093–1098 (1996)

Bhattacharya, S., Datta, J.: CdTe nanoparticles decorated titania for dye sensitized solar cell: a novel co-sensitizer approach towards highly efficient energy conversion. New J. Chem. 41(16), 8663–8672 (2017)

Aouaj, M.A., Diaz, R., Belayachi, A., Rueda, F., Abd-Lefdil, M.: Comparative study of ITO and FTO thin films grown by spray pyrolysis. Mater. Res. Bull. 44, 1458–1461 (2009)

Haridas, K., Gangaja, B., Srikrishnarka, P., Unni, G.E., Nair, A.S., Nair, S.V., Santhanagopalan, D.: Spray pyrolysis-deposited nanoengineered TiO2 thick films for ultra-high areal and volumetric capacity lithium ion battery applications. J. Power Sources 345, 50–58 (2017)

Perednis, D., Gauckler, L.J.: Thin film deposition using spray pyrolysis. J. Electroceram. 14, 103–111 (2005)

Acknowledgements

The authors would like to thank the Department of Science and Technology for financial support through Solar Energy Research Initiative program. Mr. Sarath and Sajin’s help in XPS and SEM studies on materials and is appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Vijayaraghavan, S.N., Ashok, A., Gopakumar, G. et al. All spray pyrolysis-coated CdTe–TiO2 heterogeneous films for photo-electrochemical solar cells. Mater Renew Sustain Energy 7, 12 (2018). https://doi.org/10.1007/s40243-018-0120-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-018-0120-1