Abstract

Hollandite-type K1.88Ga1.88Sn6.12O16 and K1.58Ga1.58Ti6.42O16 powders obtained by the solid-state reaction method were examined by DRIFT spectroscopy to evaluate their NO adsorption properties. Two key findings were deduced from the refined structure information and evaluation of NO adsorption on a hollandite surface: first, the presence of oxygen in carrier gas contributed significantly to NO adsorption; second, the occupation probability and atomic coordinate of alkaline-metal at the end of the one-dimensional tunnel structure influenced the adsorption volume per unit cell.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hollandite-type compounds have hitherto studied as the one-dimensional fast ionic conductor [1–3], as the nuclear waste immobilizers [4, 5] and as NO x reduction catalysts [6, 7]. It is thought that these properties contribute significantly to the crystal structure. Figure 1 shows the crystal structure of hollandite-type compound. The general chemical formula for hollandite compounds can be described as A x M y N8-yO16 (x ≤ 2, y ≤ 2), where “A” usually consists of alkali or alkaline earth ions, “M”, of di or trivalent cations, and “N”, of tetravalent cations. And, the hollandite-type structure has a tetragonal symmetry and contains one-dimensional tunnels extended along a unique axis with a lattice period of about 0.3 nm. The framework of a hollandite structure consists of double chains of metal–oxygen octahedra edge-shared with adjacent ones.

The potassium ions in the tunnels are well known to contribute to the one-dimensional fast ionic conductivity of Ti-type hollandites such as K1.6Al1.6Ti6.4O16 and K1.6Mg0.8Ti7.2O16 [1–3]. The correlations between physical properties and the crystal structure can be studied in hollandite structures by substituting the “N” element in A x M y N8-yO16 by Sn or by Ti.

The NO x selective catalytic reduction properties of K2Ga2Sn6O16 and K1.6Ga1.6Ti6.4O16 have been evaluated using hydrocarbons as a reductant source in the presence of NO, C3H6 and O2 [6, 7]. The NO x conversion rates of K2Ga2Sn6O16 and K1.6Ga1.6Ti6.4O16 are estimated to be 40 and 10 %, respectively, at 350 °C. The active site of nitrogen oxide adsorption can be determined by studying the crystal structure in detail by single crystal X-ray diffraction and evaluating the adsorption form by infrared spectroscopy. Fujimoto et al. [8, 9] previously studied the single crystal growth and structure refinement of K1.88Ga1.88Sn6.12O16, K1.98Fe1.98Sn6.02O16 [10], and K1.59Ga1.59Ti6.41O16 [11] using the flux slow-cooling method. In the present study we prepared K x Ga x Sn8-xO16 (KGSO, x ~ 2) and K y Ga y Ti8-yO16 (KGTO, y ~ 1.6) powders and observed their NO adsorption properties to elucidate the NO adsorption mechanism on hollandite surfaces.

Experimental

Preparation of KGSO and KGTO powders

KGSO and KGTO powders were prepared by the conventional solid-state reaction method. The starting materials were K2CO3, Ga2O3, SnO2, and TiO2 powders of 99.99 % purity. The KGSO powder was prepared by weighing out K2CO3, Ga2O3, and SnO2 powders in a molar ratio of 1.05:1:3. The KGTO powder was prepared by weighing out K2CO3, Ga2O3, and TiO2 powders in a molar ratio of 1.68:1.6:6.4. The mixtures were calcined at 950 °C for 1 h, ground, and sintered at either 1,350 °C for 24 h (KGSO) or 1,250 °C for 15 h (KGTO). The powders thus obtained were identified by the powder X-ray diffraction method using a Rigaku miniflex system with CuKα radiation (λ = 0.15405 nm). The chemical compositions were analyzed by ICP emission spectrometry (SHIMADZU ICPS-7510). In the chemical analysis, the single crystal aggregate was dissolved in concentrated HCl in a pressure vessel heated to about 100 °C.

Study of NO adsorption on hollandite surfaces

The NO adsorption behavior on the KGSO and KGTO powders was evaluated by diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS). The combination of a selector and environmental chamber (Specac Ltd.) served as the diffuse reflectance apparatus. An environmental chamber consisting of a mounted furnace and ZnSe window was placed in the FT-IR spectrometer (FTS-45RD, BioRad Jpn. Co. Ltd.). KGSO and KGTO powders were preheated at 700 °C for 30 min with a gas mixture of N2 (>99.9 %) and O2 (>99.9 %) flowed through at a rate of 50 mL min−1, to remove the adsorbate on the hollandite surfaces. After preheating at 700 °C, the background spectra were taken at 700, 600, 500, 400, 300, 200, 100 °C, and room temperature. The mixing ratio of N2/O2 was also switched from 100/0 to 80/20 to examine the correlation between the extent of NO adsorption and the amount of oxygen in the gas mixture. The pretreated powder was exposed to an NO (8,087 ppm) stream balanced with Ar (flow rate of 50 mL min−1) at ambient temperature for 10 min. After the NO gas supply was stopped, the inside of the furnace was purged of the N2/O2 gas mixture for 10 min until the NO species in the gas phase became undetectable in the infrared spectrum. The powder exposed to the gas mixture was then heated stepwise to 100, 200, 300, 400, 500, 600, and 700 °C, to calculate the NO adsorption condition at each temperature by subtracting the background spectrum. Infrared spectra were recorded by accumulating 256 scans at a spectral resolution of 2 cm−1.

Results and discussion

KGSO powder and its NO adsorption property

Figure 2 shows the powder X-ray diffraction pattern of KGSO powder after sintering at 1,350 °C for 24 h. The powder obtained showed a single phase of hollandite. The chemical composition of the KGSO powder was calculated to be K1.88Ga1.88Sn6.12O16 by ICP emission spectrometry and corresponded to the result for a single crystal.

Figures 3 and 4 show the DRIFT spectra in gas flows of N2/O2 at ratios of 100/0 and 80/20, respectively. The absorption bands of 1,800–1,950 cm−1 are attributable to the NO species in the gaseous phase. The NO adsorption on the KGSO surface was unobservable from the infrared spectra in Fig. 2, as all of the absorption bands were close to negligible for the N2/O2 = 100/0 gas flow, except for the NO species in the gaseous phase. When the carrier gas used included 20 % oxygen, absorption bands were observed around 1,400 and 1,750 cm−1 up to a temperature of 600 °C, as shown in Fig. 4. These results indicated that the NO adsorption on the hollandite compound surface required oxygen gas and manifested a pattern consistent with chemisorption.

KGTO powder and its NO adsorption property

Figure 5 shows the powder X-ray diffraction pattern of the KGTO powder after sintering at 1,250 °C for 15 h. The crystal structure of the sintered compound showed a single phase of hollandite. The chemical composition of the KGTO powder was calculated to be K1.58Ga1.58Ti6.42O16 by ICP emission spectrometry and corresponded to the result for a single crystal.

Figures 6 and 7 show DRIFT spectra in gas flow of N2/O2 at ratios of 100/0 and 80/20, respectively. In the former gas flow, at the gas composition ratio N2/O2 = 100/0, all of the absorption bands were close to negligible except for the NO species in the gaseous phase (see Fig. 6). When carrier gas included 20 % oxygen, absorption bands were observed around 1,400 and 1,750 cm−1 up to the temperature of 500 °C, as shown in Fig. 7.

NO adsorption mechanism on the hollandite compound surfaces

Figure 8 shows DRIFT spectra observed just after the NO gas supply was stopped and the inside of the furnace was purged of the N2/O2 gas mixture. The absorbance intensity of NO adsorption clearly differed between the KGSO and KGTO surfaces when the N2/O2 gas mixture was 80/20.

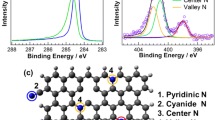

Figure 9 shows the IR spectra of KNO3 determined by the Nujol mull method [13] and the DRIFT spectrum of KNO3 powder at room temperature. Nujol mull method is measured by grinding up the solid material, mixing it with liquid paraffin and nipping between NaCl or KBr plates. From these absorption bands defined as 1,763 and 1,368 cm−1, it is thought that the NO adsorption form on hollandite surface is attributable to KNO3.

DRIFT spectrum of KNO3 powder and the IR spectra of KNO3 by the Nujol mull method [13]

Our group previously reported the structure refinement results for KGSO and KGTO single crystals [8, 9, 11]. From those results, we can conclude the following here:

-

1.

The alkaline-metal site in hollandite-type KGSO and KGTO has the two atomic coordinates reported by Michiue [12], that is, a K1-site set in a special position located at the center of the bottleneck and a K2-site slightly shifted along the c-axis from the bottleneck center (one vacancy in the hollandite-tunnel makes two K2-sites, to stabilize the crystal structure) as shown in Fig. 10.

-

2.

The atomic coordinate of the potassium ion located nearest the surface in hollandite-type compound was assumed to be the K2-site, for the above reason. Under this scheme, the distance between the center of K2-site and surface was calculated to be 0.785 nm for KGTO and 0.766 nm for KGSO.

-

3.

From the chemical formulas for KGSO and KGTO, the occupation probabilities for potassium ions at the K2-sites were assumed to be 75 % (KGTO) and 90 % (KGSO).

Furthermore, from the crystallite size and the NO adsorption amount using temperature programmed desorption measurement of KGSO powder obtained by the solid-state reaction, the number of adsorbed NO molecules on hollandite surface was almost the same as the number of alkali ions at the end of the one-dimensional tunnel [14].

From a combination of previously reported data and these results, it is thought that NO gases are adsorbed as KNO3 at the end of the one-dimensional tunnel by mediating oxygen gases in carrier gas. And, it is thought that the difference in adsorption intensity as shown in Fig. 9 depends on the occupation probability of the K2-site and distance and the distance between the K2-site and surface. In order to confirm these speculations, it is necessary to observe DRIFT spectrum using various crystal planes of single crystal and simulate adsorption behavior by molecular dynamics method and so on.

Conclusion

Hollandite-type K1.88Ga1.88Sn6.12O16 and K1.58Ga1.58Ti6.42O16 powders were prepared by the conventional solid-state reaction method to study the correlativity of the nitrogen oxide adsorption mechanism on the hollandite surface and the crystal structure information. The NO adsorption was observed by diffuse reflectance infrared Fourier transformed spectroscopy (DRIFTS). Absorption bands attributed to KNO3 were observed as 1,763 and 1,368 cm−1. NO adsorption on the KGSO and KGTO surfaces was observed up to temperatures of 600 and 500 °C, respectively. From structure refinement data and the NO adsorption property on the hollandite surface, we deduced that the presence of oxygen in the carrier gas contributed significantly to the NO adsorption, and that the occupation probability and atomic coordinate of the alkaline-metal at the end of the one-dimensional tunnel influenced the adsorption volume per unit cell.

References

Yoshikado, S., Ohachi, T., Taniguchi, I., Onoda, Y., Watanabe, M., Fujiki, Y.: Frequency-independent ionic conductivity of hollandite type compounds. Solid State Ion. 9(10), 1305–1309 (1983)

Yoshikado, S., Ohachi, T., Taniguchi, I., Onoda, Y., Watanabe, M., Fujiki, Y.: AC ionic conductivity of hollandite type compounds from 100 Hz to 37.0 GHz. Solid State Ion. 7(4), 335–344 (1982)

Yoshikado, S., Taniguchi, I., Watanabe, M., Onoda, Y., Fujiki, Y.: Frequency dependence of ionic conductivity in one-dimensional ionic conductors K1.6Mg0.8Ti7.2O16 and K1.6Al1.6Ti6.4O16. Solid State Ion. 79, 34–39 (1995)

Ringwood, A.E., Kesson, S.E., Ware, N.G., Hibberson, W., Major, A.: Immobilisation of high level nuclear reactor wastes in SYNROC. Nature 278, 219–223 (1979)

Mitamura, H., Matsumoto, S., Stewart, M.W.A., Tsuboi, T., Hashimoto, M., Vance, E.R., Hart, K.P., Togashi, Y., Kanazawa, H., Ball, C.J., White, T.J.: α-decay damage effects in curium-doped titanate ceramic containing sodium-free high-level nuclear waste. J. Am. Ceram. Soc. 77(9), 2255–2264 (1994)

Watanabe, M., Mori, T., Yamauchi, S., Yamamura, H.: Catalytic property of the hollandite-type 1-D ion-conductors: selective reduction of NO x . Solid State Ion. 79, 376–381 (1995)

Mori, T., Yamauchi, S., Yamamura, H., Watanabe, M.: New hollandite catalysts for selective reduction of nitrogen monoxide with propene. Appl. Cat. A Gen. 129, L1–L7 (1995)

Fujimoto, K., Ito, S., Watanabe, M.: Crystal growth and refinement of K1.88Ga1.88Sn6.12O16 hollandite-type compound. Solid State Ion. 177, 1901–1904 (2006)

Fujimoto, K.: Private communication (in preparation)

Fujimoto, K., Takamori, K., Yamaguchi, K., Ito, S.: Single crystal growth and structure refinement of hollandite-type K1.98Fe1.98Sn6.02O16 (To be submitted)

Fujimoto, K., Yamakawa, C., Ito, S.: Crystal growth and structure refinement of hollandite-type K1.59Ga1.59Ti6.41O16. Solid State Ion. 184, 74–77 (2011)

Michiue, Y.: Superstructure of hollandite K x Mg(8+x)/3Sb(16−x)/3O16 (x ≈ 1.76). J. Solid State Chem. 180(6), 1840–1845 (2007)

Spectral Database for Organic Compounds:http://sdbs.riodb.aist.go.jp/sdbs/cgi-bin/direct_frame_disp.cgi?sdbsno=40130

Fujimoto, K., Suzuki, J., Harada, M., Awatsu, S., Mori, T., Watanabe, M.: Preparation of hollandite-type K x Ga x Sn8-xO16 thin film and NO adsorption behavior. Solid State Ion. 152–153, 769–775 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under license to BioMed Central Ltd. Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Fujimoto, K., Yamakawa, C., Yamaguchi, Y. et al. Correlativity of the nitrogen oxide adsorption mechanism and crystal structure in hollandite-type compounds. Mater Renew Sustain Energy 3, 19 (2014). https://doi.org/10.1007/s40243-013-0019-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-013-0019-9