Abstract

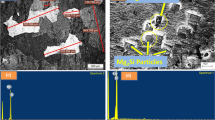

Tensile properties, microstructural evolution and fracture toughness of Al 2014 alloy subjected to cryorolling followed by warm rolling (CR + WR) have been investigated in the present study. The solution-treated (ST) Al 2014 alloy is cryorolled followed by warm rolling process at different temperatures (110, 170 and 210 °C). The mechanical properties and microstructural features of deformed and undeformed Al 2014 alloys were characterised by optical microscopy, transmission electron microscopy (TEM) and scanning electron microscopy (SEM). The CR + WR samples at 170 °C showed an improved hardness (179 HV), tensile (UTS 499 MPa, YS 457 MPa) and fracture toughness (KQ = 37.49 MPa \(\sqrt {\text{m}}\), Kee = 37.39 MPa \(\sqrt {\text{m}}\) and J integral = 33.25 kJ/mm2) with respect to ST alloy as measured from the tensile and fracture toughness test. The improved mechanical properties of CR + WR alloy are attributed to grain boundary strengthening, combined recovery and recrystallisation, precipitation hardening and dynamic ageing effect during the deformation. The precipitation of metastable spherical phase Al2Cu was responsible for the improved tensile and fracture properties of fine-grained Al 2014 alloy observed in the present work.

Similar content being viewed by others

References

E.A. Starke Jr., J.T. Staley, Prog. Aerospace Sci. 32, 131 (1996)

D.B. Miracle, S.L. Donaldson, S.D. Henry, C. Moosbrugger, G.J. Anton, B.R. Sanders, N. Hrivnak, ASM Handbook (ASM International, Metals Park, 2001), pp. 107–119

A. Joshi, K.K. Yogesha, R. Jayaganthan, Mater. Charact. 127, 253 (2017)

S. Cheng, Y.H. Zhao, Y.T. Zhu, E. Ma, Acta Mater. 55, 5822 (2007)

N. Kumar, S. Goel, R. Jayaganthan, H.G. Brokmeier, Mater. Charact. 124, 229 (2017)

K.K. Yogesha, N. Kumar, A. Joshi, R. Jayaganthan, S.K. Nath, Metallogr. Microstruct. Anal. 3, 251 (2016)

K.K. Yogesha, A. Joshi, R. Jayaganthan, J. Mater. Eng. Perform. 26, 2826 (2017)

A. Joshi, N. Kumar, K.K. Yogesha, R. Jayaganthan, S.K. Nath, J. Mater. Eng. Perform. 25, 3031 (2016)

Y. Estrin, A. Vinogradov, Acta Mater. 61, 782 (2013)

J. Jiang, Y. Ding, F. Zuo, A. Shan, Scr. Mater. 60, 905 (2009)

S. Goel, R. Jayaganthan, I.V. Singh, D. Srivastava, G.K. Dey, N. Saibaba, Acta Metall. Sin. (Engl. Lett.) 28, 837 (2015)

R. Verma, A. Srinivasan, R. Jayaganthan, S.K. Nath, S. Goel, Mater. Sci. Eng. A 704, 412 (2017)

Y. Iwahashi, J.T. Wang, Z. Horita, M. Nemoto, T.G. Langdon, Scr. Mater. 35, 143 (1996)

K.K. Yogesha, A. Joshi, N. Kumar, R. Jayaganthan, Mater. Manuf. Process. 32, 1336 (2017)

A. Dhal, S.K. Panigrahi, M.S. Shunmugam, J Alloys Compd. 726, 1205 (2017)

A. Joshi, K.K. Yogesha, N. Kumar, R. Jayaganthan, Metallogr. Microstruct. Anal. 5(6), 1 (2016)

Y.M. Wang, E. Ma, Acta Mater. 52, 1699 (2004)

S.K. Panigrahi, D. Devanand, R. Jayaganthan, Trans. Ind. Inst. Met. 61, 159 (2008)

S.K. Panigrahi, R. Jayaganthan, Metall. Mater. Trans. A 41, 2675 (2010)

S.K. Panigrahi, R. Jayaganthan, Mater. Sci. Forum 584, 734 (2008)

P.N. Rao, B. Viswanadh, R. Jayaganthan, Mater. Sci. Eng. A 606, 1 (2014)

P.N. Rao, A. Kaurwar, D. Singh, R. Jayaganthan, Proc. Eng. 75, 123 (2014)

R. Jayaganthan, Mater. Des. 39, 226 (2012)

D. Singh, P.N. Rao, R. Jayaganthan, Mater. Des. 50, 646 (2013)

A. Dhal, S.K. Panigrahi, M.S. Shunmugam, J. Alloys Compd. 649, 229 (2015)

A. Dhal, S.K. Panigrahi, M.S. Shunmugam, Mater. Sci. Eng. A 645, 383 (2015)

U.G. Kang, J.C. Lee, S.W. Jeong, W.J. Nam, J. Mater. Sci. 45, 4739 (2010)

A.S.M. Handbook, Aluminum and Aluminum Alloys (ASM International, Metals Park, 1993), p. 117

A. Hohenwarter, R. Pippan, Scr. Mater. 64, 982 (2011)

A. Hohenwarter, R. Pippan, Mater. Sci. Eng., A 527, 2649 (2010)

A. Hohenwarter, R. Pippan, Mater. Sci. Eng. A 540, 89 (2012)

ASTM, E. “399-05” Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials (2005)

L.P. Pook, Linear Elastic Fracture Mechanics for Engineers: Theory and Applications (WIT Press, Southampton, 2000)

M.O. Lai, Eng. Fract. Mech. 27, 121 (1987)

B. Li, X. Wang, H. Chen, J. Hu, C. Huang, G. Gou, J. Alloys Compd. 678, 160 (2016)

G.E. Dieter, Mechanical Metallurgy, 3rd edn. (McGraw-Hill, Boston, 1986)

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Pathak, M.K., Joshi, A., Mer, K.K.S. et al. Mechanical Properties and Microstructural Evolution of Bulk UFG Al 2014 Alloy Processed Through Cryorolling and Warm Rolling. Acta Metall. Sin. (Engl. Lett.) 32, 845–856 (2019). https://doi.org/10.1007/s40195-018-0849-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-0849-7