Abstract

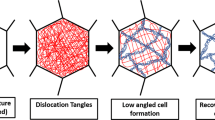

The mechanical properties and microstructural evolution of aluminium–lithium (Al–Li) 8090 alloy subjected to room temperature rolling (RTR) followed by annealing were investigated in the present work. Tensile, hardness test and three-point bend tests were performed to identify the mechanical properties, while optical microscopy, scanning electron microscopy and transmission electron microscopy were used for correlating mechanical properties with microstructural features. Results showed that the tensile strength and hardness increase firstly and then decrease with elevating annealing temperature when the holding time is kept for 1 h that is attributed to the strengthening of grain boundary, solid solution strengthening and precipitation strengthening. An increment in ultimate tensile strength from 265 to 359 MPa (approx. 35% increase) and yield strength from 186 to 234 MPa (approx. 25% increase) was observed substantiating the formation of ultrafine-grained microstructure at room temperature. On annealing in the 100–350 °C temperature range with 50 °C interval, the mechanical properties such as tensile strength and yield strength increase significantly up to 150 °C (UTS-522 MPa and YS-398 MPa); however, there is gradual decrease in the tensile and yield strength observed beyond these temperatures and these values (UTS-124 MPa and YS-109 MPa) become least on annealing at 350 °C. It is observed that a 19% increase in the apparent fracture toughness (KQ) occurred for RTR Al–Li (8090) alloy as compared to solution-treated Al–Li 8090 alloy in three-point bend test.

Similar content being viewed by others

References

R.Z. Valiev, A.V. Korznikov, R.R. Mulyukov, Structure and properties of ultrafine-grained materials produced by severe plastic deformation. Mater. Sci. Eng. A 168(2), 141–148 (1993)

P. Xue, B.L. Xiao, Z.Y. Ma, High tensile ductility via enhanced strain hardening in ultrafine-grained Cu. Mater. Sci. Eng. A 532, 106–110 (2012)

T. Sakai, H. Miura, Mechanisms of ultrafine grain formation in severe plastic deformation. Mater. Sci. Form. 638, 98–103 (2010)

R.Z. Valiev, T.G. Langdon, Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater Sci. 51(7), 881–981 (2006)

M.K. Pathak, A. Joshi, K.K.S. Mer, Evaluating tensile properties and fracture toughness of Al 2014 alloy processed by different rolling methods. Mater. Res. Express 6(10), 105012 (2019)

R. Kapil, A. Joshi, R. Jayaganthan, S. Gairola, R. Verma, Improvement of fracture toughness of ultra fine grained Al–Li 8090 alloy processed through multi axial forging. Mater. Res. Express 6(8), 085064 (2019)

T. Shanmugasundaram, B.S. Murty, V.S. Sarma, Development of ultrafine grained high strength Al–Cu alloy by cryorolling. Scr. Mater. 54(12), 2013–2017 (2006)

K.K. Yogesha, N. Kumar, A. Joshi, R. Jayaganthan, S.K. Nath, A Comparative study on tensile and fracture behavior of Al–Mg alloy processed through cryorolling and cryo groove rolling. Metallogr. Microstruct. Anal. 5(3), 251–263 (2016)

S. Gairola, A. Joshi, B. Gangil, P. Rawat, R. Verma, Correlation of tensile properties and fracture toughness with microstructural features for Al–Li 8090 alloy processed by cryorolling and post-rolled annealing. Trans. Indian Inst. Met. 72, 1743–1755 (2019)

S.K. Panigrahi, R. Jayaganthan, Effect of rolling temperature on microstructure and mechanical properties of 6063 Al alloy. Mater. Sci. Eng. A 492(1–2), 300–305 (2008)

M.K. Pathak, A. Joshi, K.K.S. Mer, R. Jayaganthan, Mechanical properties and microstructural evolution of bulk UFG Al 2014 alloy processed through cryorolling and warm rolling. Acta Metall. Sin. (Engl. Lett.) 32(7), 845–856 (2019). https://doi.org/10.1007/s40195-018-0849-7

A. Joshi, N. Kumar, K.K. Yogesha, R. Jayaganthan, S.K. Nath, Mechanical properties and microstructural evolution in Al 2014 alloy processed through multidirectional cryoforging. J. Mater. Eng. Perform. 25(7), 3031 (2016)

S.K. Panigrahi, R. Jayaganthan, Effect of ageing on microstructure and mechanical properties of bulk, cryorolled, and room temperature rolled Al 7075 alloy. J. Alloys Compd. 509(40), 9609–9616 (2011)

K.K. Yogesha, A. Joshi, N. Kumar, R. Jayaganthan, Effect of cryo groove rolling followed by warm rolling (CGW) on the mechanical properties of 5052 Al alloy. Mater. Manuf. Process. 32(12), 1336–1344 (2017)

A. Joshi, K.K. Yogesha, R. Jayaganthan, Influence of cryorolling and followed by annealing on high cycle fatigue behavior of ultrafine grained Al 2014 alloy. Mater. Charact. 127, 253–271 (2017)

S.K. Panigrahi, R. Jayaganthan, A comparative study on mechanical properties of Al 7075 alloy processed by rolling at cryogenic temperature and room temperature. Mater. Sci. Form. 584, 734–740 (2008)

A. Dhal, S.K. Panigrahi, M.S. Shunmugam, Influence of annealing on stain hardening behaviour and fracture properties of a cryorolled Al 2014 alloy. Mater. Sci. Eng. A 645, 383–392 (2015)

K.K. Yogesha, A. Joshi, R. Jayaganthan, Fatigue behavior of ultrafine-grained 5052 Al alloy processed through different rolling methods. J. Mater. Eng. Perform. 26(6), 2826–2836 (2017)

K.K. Yogesha, A. Joshi, A. Raja, R. Jayaganthan, High-cycle fatigue behaviour of ultrafine grained 5052 Al alloy processed through cryo-forging, in Materials Processing Fundamentals 2019 (Springer, Cham, 2019), pp. 153–161

A. Hohenwarter, R. Pippan, Fracture toughness evaluation of ultrafine-grained nickel. Scr. Mater. 64(10), 982–985 (2011)

D.B. Miracle, S.L. Donaldson, S.D. Henry, C. Moosbrugger, G.J. Anton, B.R. Sanders, N. Hrivnak, C. Terman, J. Kinson, K. Muldoon, W.W. Scott Jr, in ASM Handbook, vol 21 (ASM International, Materials Park, OH, 2001), pp. 107–119

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Panthri, S., Joshi, A. & Pathak, M.K. Effect of Room Temperature Rolling Followed by Annealing on Tensile and Fracture Behaviour of Bulk Ultrafine-Grained Al–Li 8090 Alloy. Metallogr. Microstruct. Anal. 8, 581–590 (2019). https://doi.org/10.1007/s13632-019-00570-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-019-00570-z